Patents

Literature

45results about How to "Thickening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

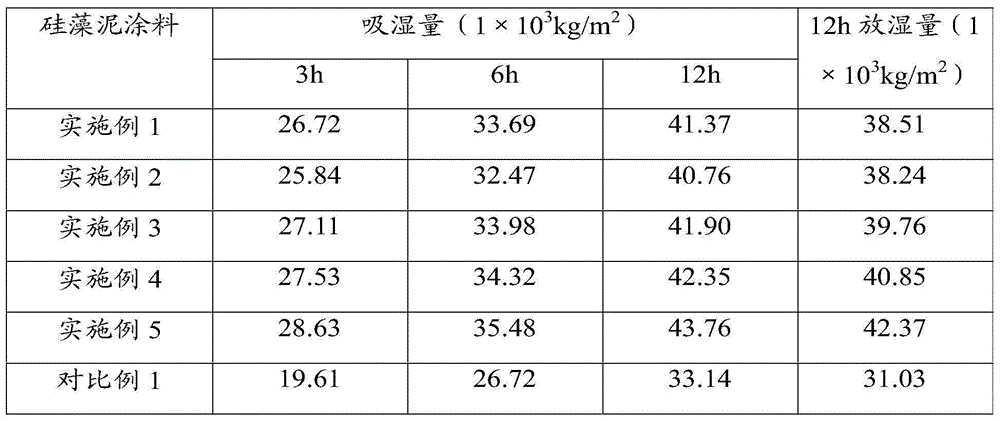

Diatom ooze coating and preparation method thereof

InactiveCN105176216AGuaranteed StrengthReduce contentAntifouling/underwater paintsPaints with biocidesEmulsionUltimate tensile strength

The invention provides a diatom ooze coating, belonging to the technical field of decoration coatings. Components of the diatom ooze coating mainly comprise synthesized emulsion, a dispersant, kieselguhr, a filler, a silver ion antibacterial agent, an additive and water and the like. The aperture of the selected kieselguhr is 280-580 meshes, and a micropore structure of the kieselguhr can be kept, and actions of humidifying and absorbing and dissolving formaldehyde can be achieved. The content of emulsion is reduced, and the strength of the coating after a wall is coated is ensured, and powder falling is avoided, and kieselguhr particles are not fully wrapped due to a formed membrane thus the micropores are not blocked, so that the functionality is not affected. The silver ion antibacterial agent is added into the coating, so the growth and propagation of microorganisms are effectively inhibited. The diatom ooze coating is obtained in a manner of charging materials in batches and stirring. Before the emulsion is added, under stirring, a thickener and a pH regulator are added, and the thickener can be fully dissolved by a shearing action, and an advanced dissolving step for the thickener is reduced.

Owner:BEIJING DAIJIN DIATOMITE NEWLY BUILDING MATERIAL

Composite adhesive specially for heat insulating polystyrene outer-wall board

InactiveCN1403522AImprove adhesionImprove aging resistanceHydrocarbon polymer adhesivesPolymer scienceAdhesive

The composite adhesive is prepared with styrene and acrylic acid copolymer emulsion, which is inorganic silica gel and organosilicon modified and has low vitrification point and high adhesion, as main adhesive component and through adding quartzite, asbestos and other reinforcing material and some assistants. The composite adhesive has high adhesion effect, high adhesion strength, good antiaging performance, high hardness and high water resistance.

Owner:上海丰慧节能环保科技有限公司

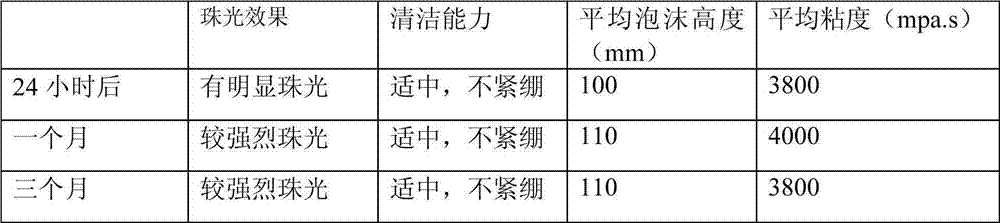

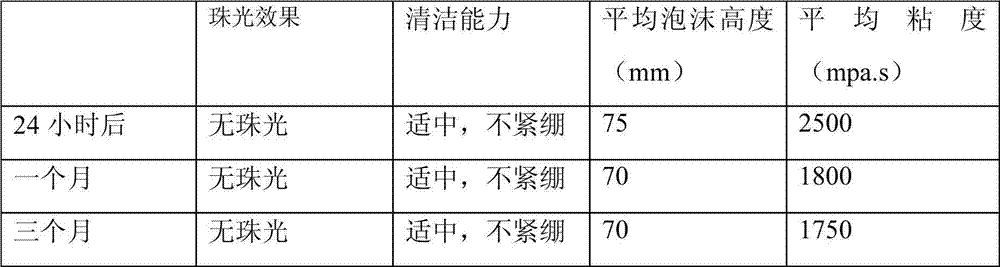

Pearly-lustre type foamingly clean facial wash and preparation method thereof

ActiveCN102920616ALess irritatingGood foaming performanceCosmetic preparationsToilet preparationsBetaineIrritation

The invention provides a pearly-lustre type foamingly clean facial wash and a preparation method thereof. The pearly-lustre type foamingly clean facial wash comprises the following raw materials of 10-30 percent of sodium cocoyl isethionate, 1-8 percent of stearic acid, 1-10 percent of glycine betaine ampholytic surfactant, 0.5-10 percent of alkyl glycoside non-ionic surface active agent, 0.2-1.5 percent of hydroxyethyl cellulose, 1-10 percent of polyhydric alcohols, 1-8 percent of crylic acid (ester) copolymer, 0.1-2 percent of sodium chloride and 0.1-5 percent of grease-enriching agent. The pearly-lustre type foamingly clean facial wash has the advantages of mild property without irritation, stable performance and good pearly-lustre effect.

Owner:TIANJIN YU MEI JING GRP

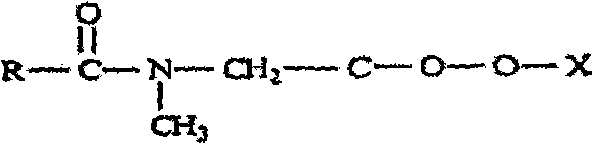

Conductive adhesive for screen printing, joined body of inorganic material, and method for producing same

ActiveUS20150282330A1Improve conductivityImprove productivityPrinted circuit assemblingNon-macromolecular adhesive additivesAdhesiveMetal colloids

The present invention relates to a conductive adhesive for screen printing containing metal colloid particles (A) containing metal nanoparticles (A1) and a protective colloid (A2) containing an organic compound having a carboxyl group and a polymer dispersant having a carboxyl group, a viscosity modifier (B) having an amide bond and / or a urea bond, and a dispersion solvent (C).

Owner:MITSUBOSHI BELTING LTD

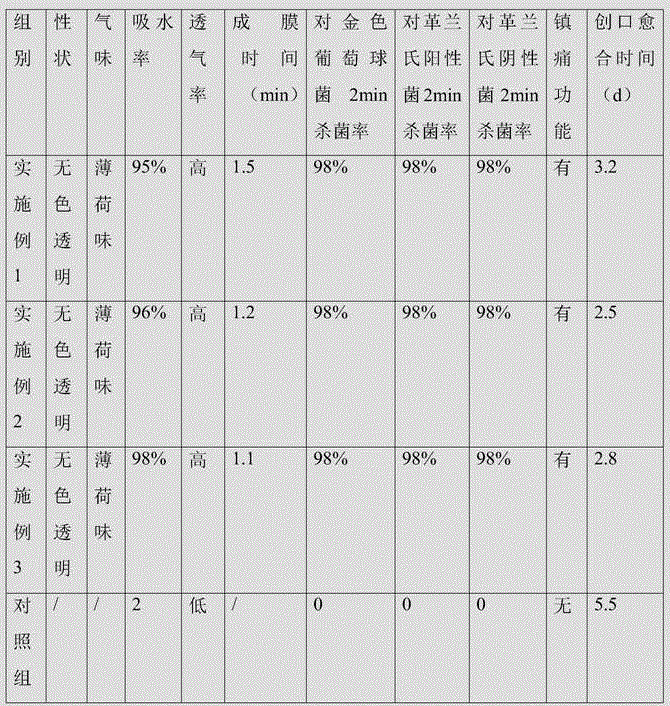

Multifunctional liquid dressing and preparation method thereof

InactiveCN106139239AGood for growth and angiogenesisPromote wound healingSurgical adhesivesBandagesCarrageenanChemistry

The invention relates to the field of medicinal dressings and in particular relates to a multifunctional liquid dressing and a preparation method thereof. The multifunctional liquid dressing comprises the following components in parts by mass: 2-8 parts of polyvinyl butyral, 0.5-0.8 part of sodium alginate-polyvinylpyrrolidone, 0.2-0.6 part of nano-silver-chitosan, 0.1-0.4 part of sodium carboxymethylcellulose, 0.1-0.4 part of carrageenan, 0.1-0.4 part of menthol and 91-97 parts of absolute ethyl alcohol. The multifunctional liquid dressing disclosed by the invention is waterproof, breathable and visible in wound, can prevent infection and contributes to wound healing.

Owner:怡越医疗(广东)有限公司

Energy-saving brick prepared on basis of building waste and preparation method thereof

InactiveCN108264333AImprove stabilityImprove compactnessCeramic materials productionClaywaresFiberTO-18

The invention discloses an energy-saving brick prepared on the basis of building waste. The energy-saving brick is prepared from the following raw materials in parts by weight: 32 to 36 parts of modified building waste, 24 to 28 parts of modified flay ash, 14 to 18 parts of coal gangue, 12 to 14 parts of lithium bentonite, 8 to 12 parts of cotton fiber, 6 to 10 parts of wood fiber, 8 to 12 parts of glass beads, 8 to 12 parts of crushed crude pearlite, 4 to 6 parts of water reducers, 3 to 5 parts of anti-foaming agents, 3 to 5 parts of cement and 1 to 3 parts of filling materials. The inventionaims at providing the energy-saving brick prepared on the basis of building waste. The energy-saving brick has the advantages that the building waste is sufficiently utilized; meanwhile, the properties such as the intensity, the sound isolation and heat isolation performance and the like of the brick can be improved; high use value and good application prospects are realized.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

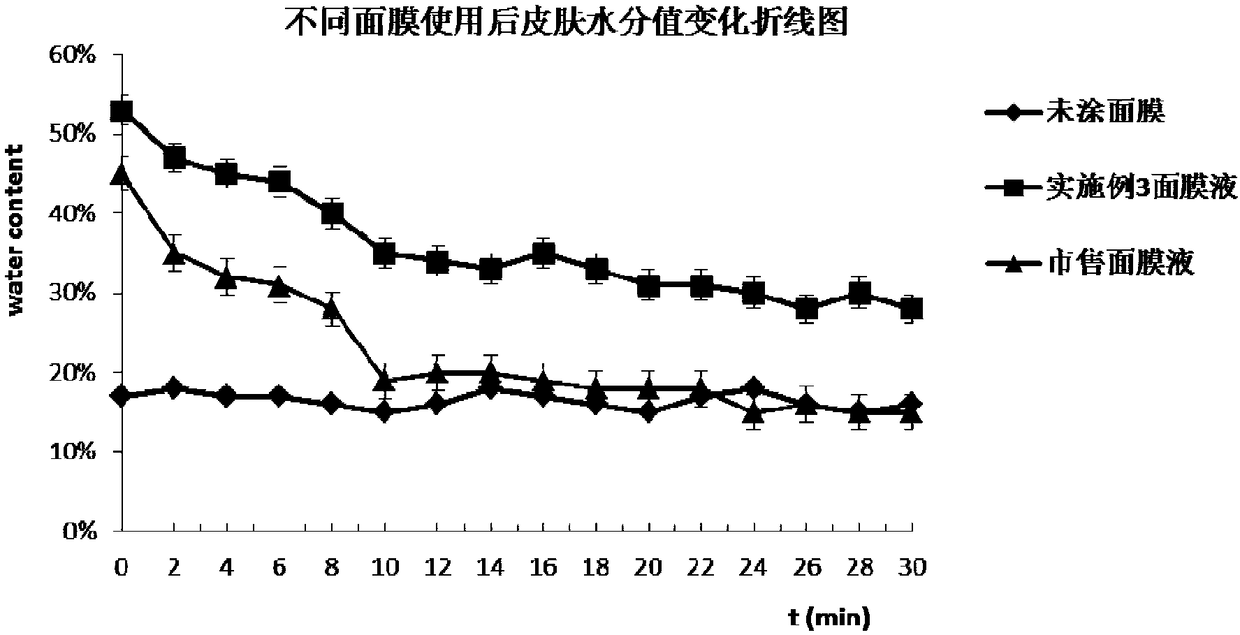

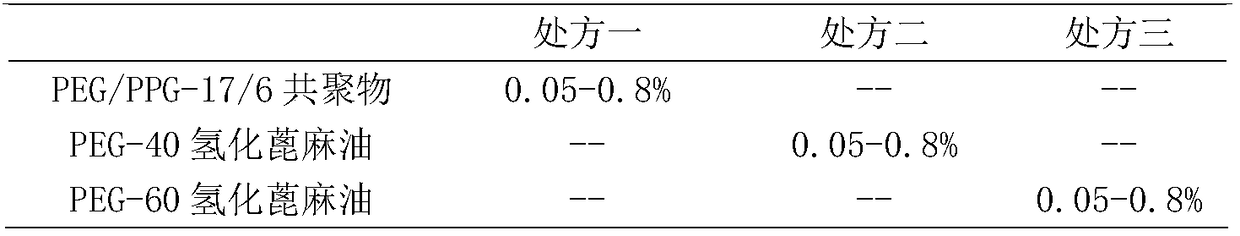

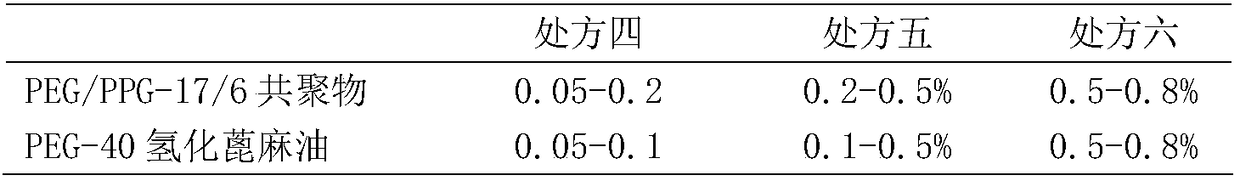

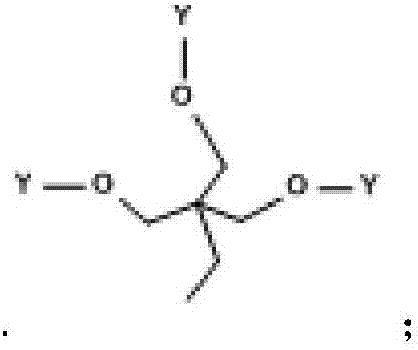

Moisturizing and whitening mask solution and preparation method thereof

InactiveCN108524395AIncrease stimulationThickening effectCosmetic preparationsToilet preparationsFine lineDipotassium Glycyrrhizinate

The invention discloses a moisturizing and whitening mask solution and a preparation method thereof. The mask solution comprises, by mass, 2-6 parts of glycerin, 0.1-0.5 part of SANGELOSE-60L, 0.1-0.5part of PEG-14M, 0.05-0.2 part of sodium hyaluronate, 0.5-2 parts of AA2G, 0.5-3 parts of fish collagen, 0.2-0.5 part of PEG / PPG-17 / 6 copolymer, 3-8 parts of 1,3-butanediol, 0.1-0.5 part of phenoxyethanol, 0.1-0.5 part of PEG-40 hydrogenated castor oil, 0.1-0.5 part of methylparaben, 0.1-0.5 part of dipotassium glycyrrhizinate, 5-10 parts of sodium citrate buffer solution, 0-1 part of plant extraction solution and the balance deionized water, wherein the sum of weight parts of the components is 100. SANGELOSE-60L serves as an efficient thickener, and the thickening effect of the thickener isbasically not influenced by the pH value and the ion strength. After the mask solution is used, a soft and comfortable protective film can be formed on skin, so that a good moisturizing effect is achieved, and the skin is nourished. The mask solution is refreshing in texture, easy to absorb and capable of smoothing fine lines, the effect of deep moisturizing is achieved, dull-looking skin is prevented by inhibiting formation of melanin and reducing existing melanin, and the whitening effect is more stable and durable.

Owner:SHENYANG PHARMA UNIVERSITY

Flax-like skin-core composite fiber and preparation method thereof

ActiveCN103993383AGood coloring effectAdd depthFilament/thread formingConjugated synthetic polymer artificial filamentsCompanion animalSkin core

The invention relates to a flax-like skin-core composite fiber and a preparation method thereof. The flax-like skin-core composite fiber comprises a skin layer and a core layer, wherein the skin layer is made of PET with a nucleating agent, and the core layer is made of a PET-PP blend. Since the extrusion swell behaviors of the skin layer material and the core layer material of the skin-core composite fiber are different, a skin-core composite spinning process is employed to prepare the surface-cracked flax-like skin-core composite fiber, and the flax-like skin-core composite fiber has hand feeling of flax and a deep dyeing effect.

Owner:JIANGSU DELI CHEM FIBER CO LTD

Method for preparing modified special wax for rheological additive of solvent-based coating

A method for preparing modified special wax for a rheological additive of a solvent-based coating belongs to the technical field of coating additives, and is characterized by comprising the following steps: adding 10-40 parts of polyethylene wax with the viscosity-average molecular weight of 1,000-1,500 and 10-40 parts of polyethylene wax with the viscosity-average molecular weight of 700-900, obtained through pyrolysis of high density polyethylene, into a compounding kettle, raising the temperature to 130-180 DEG C, performing uniform stirring, adding 5-30 parts of paraffin, and performing uniform stirring; after raising the temperature of a reaction kettle to 120-160 DEG C, and transferring the mixed liquid into the reaction kettle; and putting an oxidizing agent into the mixed liquid, keeping the temperature in the reaction kettle at 120-160 DEG C, and performing continual stirring till the acid value is 10-30 to obtain modified special oxidized polyethylene wax. The physical and chemical properties of the oxidized polyethylene wax are within the index range, and as the rheological additive of the coating, the prepared modified special wax has excellent rheological properties and good matting property and storage stability, causes no influence on the color and the clarity of the coating, and has strong scratch resistance.

Owner:淄博市临淄齐泉工贸有限公司

Low-volatility environment-friendly building interior concrete interface treating agent and preparation method thereof

Owner:MEICHAO GROUP

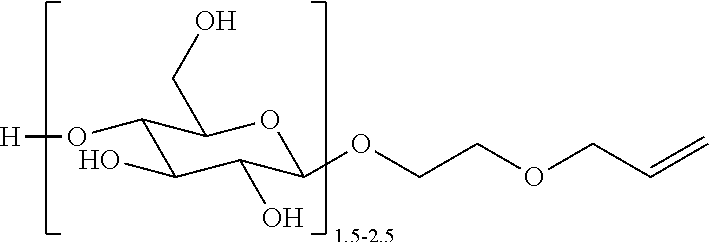

Polyorganosiloxane gels having glycoside groups

ActiveUS20160311980A1Good compatibilityImprove compatibilityCosmetic preparationsToilet preparationsGlycosideGlycerol

Organopolysiloxane gel compositions containing an organopolysiloxane gel produced by hydrosilylation of an unsaturated silicone resin and a compound containing glycoside residues and a hydrosilylatable group with at least one Si—H-functional organopolysiloxane can form creamy, storage-stable gels which are capable of containing large amounts of polar or hydrophilic substances such as water and glycerol while remaining monophasic. The compositions are especially useful in providing cosmetic compositions with a silky skinfeel.

Owner:WACKER CHEM GMBH

Low-VOC (Volatile Organic Compound) environment-friendly concrete interface treating agent and preparation method thereof

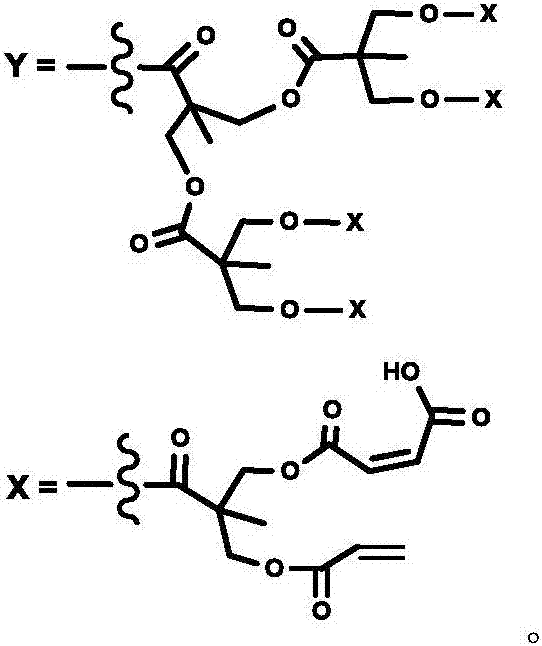

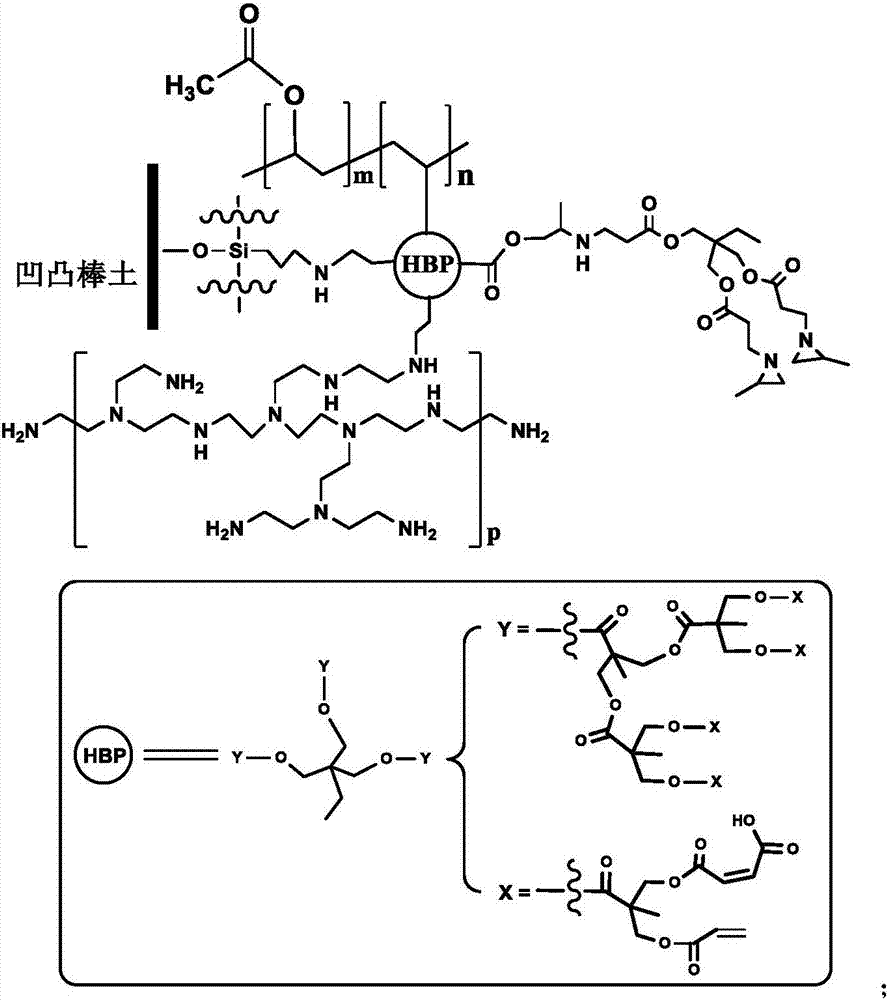

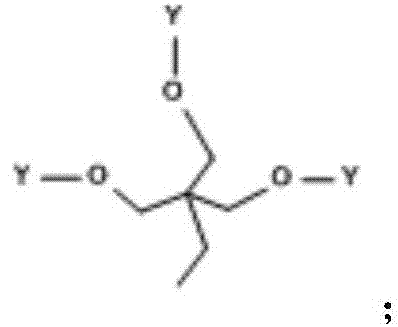

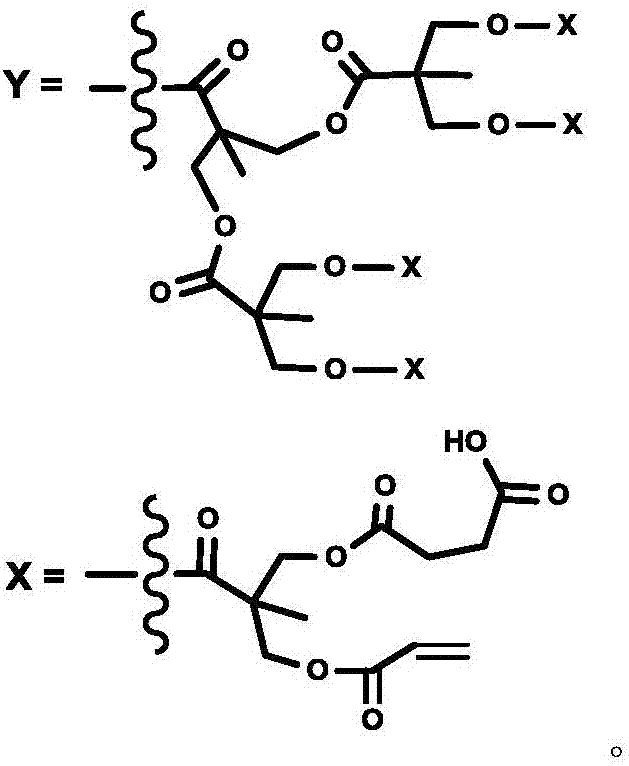

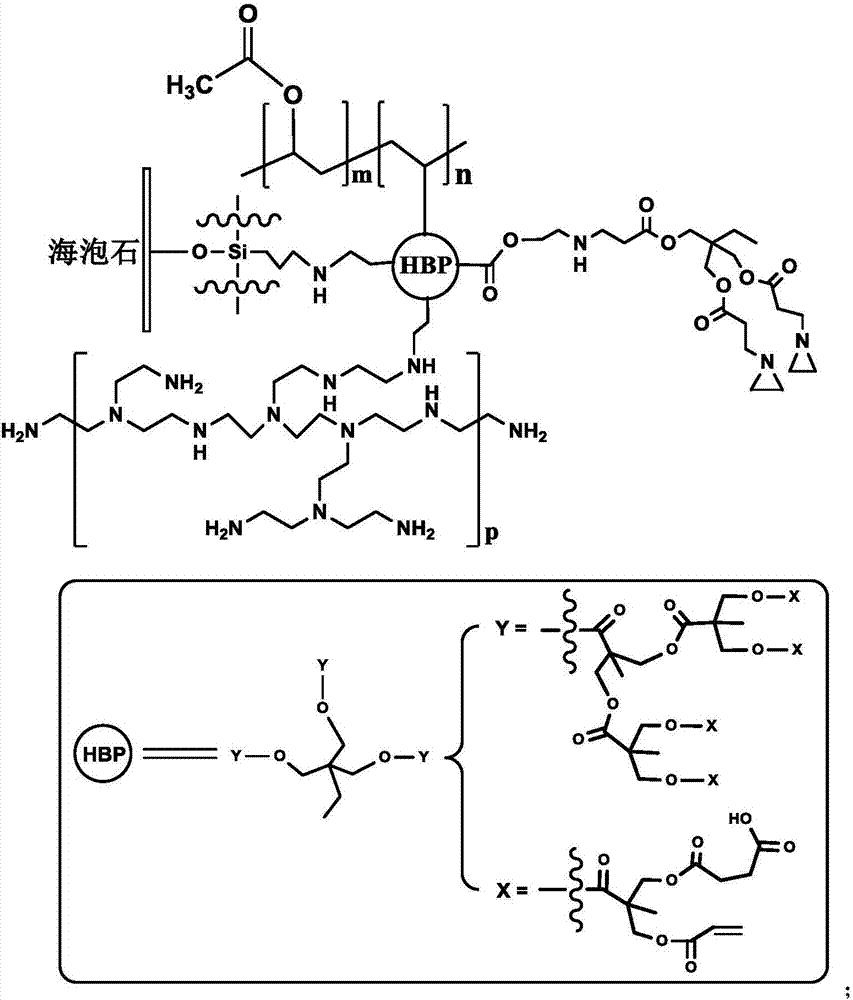

The invention provides a low-VOC (Volatile Organic Compound) environment-friendly concrete interface treating agent. The low-VOC environmental-friendly concrete interface treating agent is prepared by cross-linking reaction of sepiolite with grafted end vinyl and carboxylhyperbranched polyester, vinyl acetate-vinyl copolymer emulsion, polyethyleneimine and trimethylolpropane-tri(3-aziridinyl propionate). The low-VOC environmental-friendly concrete interface treating agent provided by the invention has the advantages that the VOC is lower, the viscosity is good, and the problems of high volatilization and environmental pollution in the traditional interface treating agent are effectively solved.

Owner:MEICHAO GROUP

Disinfecting and sterilizing medical ultrasonic coupling agent with moisturizing and skin-moistening effects and preparation method of disinfecting and sterilizing medical ultrasonic coupling agent

InactiveCN104721845AFast actingGood biocompatibilityOrganic active ingredientsAntisepticsPolyhexamethylene guanidineCompatibilization

The invention relates to a disinfecting and sterilizing medical ultrasonic coupling agent with moisturizing and skin-moistening effects and a preparation method of the disinfecting and sterilizing medical ultrasonic coupling agent. The coupling agent comprises the following raw materials in percentage by weight: 0.1%-0.5% of polyhexamethylene guanidine, 1%-4% of cationic chitosan, 1%-8% of a cationic polymer, 0.4%-1.5% of allantoin polyaluminum chloride, 0.1%-0.5% of water-soluble vitamin E, 5%-20% of glycerin and the balance of distilled water. The preparation technology comprises the following steps: measuring distilled water and glycerin, stirring and mixing evenly, heating to 100 DEG C; when cooling water to 60-70 DEG C, adding polyhexamethylene guanidine, cationic chitosan, cationic polymer, allantoin polyaluminum chloride and water-soluble vitamin E under agitation; and further slowly stirring for 30-60 minutes, standing for 24 hours, filling and packaging. The medical ultrasonic coupling agent prepared by the method has the advantages of fast disinfecting and sterilizing effects, no corrosion on an ultrasonic probe, few bubbles (clear image), excellent biocompatibility and high lubricating property, and has moisturizing and skin-moistening efficacies; meanwhile, the preparation technology is simple and environmentally friendly; large-scale production is easy to realize; and the cost is low.

Owner:HUBEI UNIV

Preparation method of stain-resistant high-hardness real stone paint

PendingCN110591532AImprove hardness and wear resistanceImprove impact resistancePolyurea/polyurethane coatingsEpoxy resin coatingsEmulsionHardness

The invention relates to the technical field of real stone coatings, in particular to a preparation method of a stain-resistant high-hardness real stone paint. The preparation method comprises a primer, a finish paint and a finish-coat paint, wherein the finish-coat paint comprises the following components in parts by mass: 10-20 parts of polyurethane emulsion, 0.6-2.4 parts of a hardening scratch-resistant agent, 10-12 parts of fumed silica, 0.15-0.3 part of an amide defoaming agent, 0.07-0.15 part of a preservative and 0.16-0.32 part of a nano additive. The finish paint comprises the following components in parts by mass: 10-20 parts of styrene-acrylic emulsion, 8-16 parts of polyurethane modified epoxy resin, 40-60 parts of fine aggregates, 2-4 parts of a thickening agent and 1.2-1.8 parts of a toughening agent. According to the preparation method, the hardening agent is added into the finish-coat paint, so that the coating layer of the finish-coat paint is reinforced, the hardnessand the wear resistance of the coating layer are improved, the hardness is improved along with the increase of the addition amount, the impact resistance of the coating can be improved, the adhesion force and the transparency of the coating layer of the coating are not influenced by the hardening agent, volume shrinkage of the coating layer during curing can be relieved by addition of the hardening agent, and the adhesion force between the coating layer and a substrate is improved; and therefore, the hardness of the real stone paint is improved.

Owner:Jiangsu Jiunuo Architectural Materials Technology Co Ltd

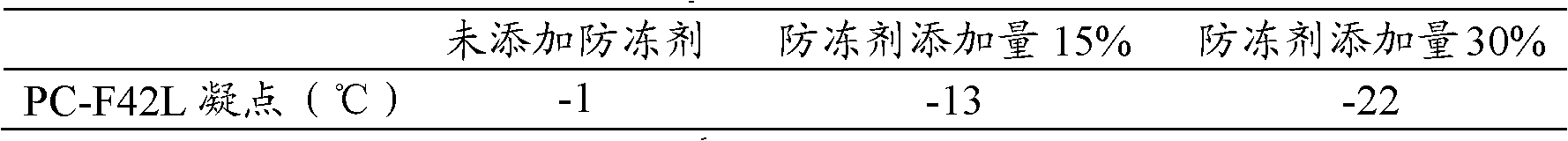

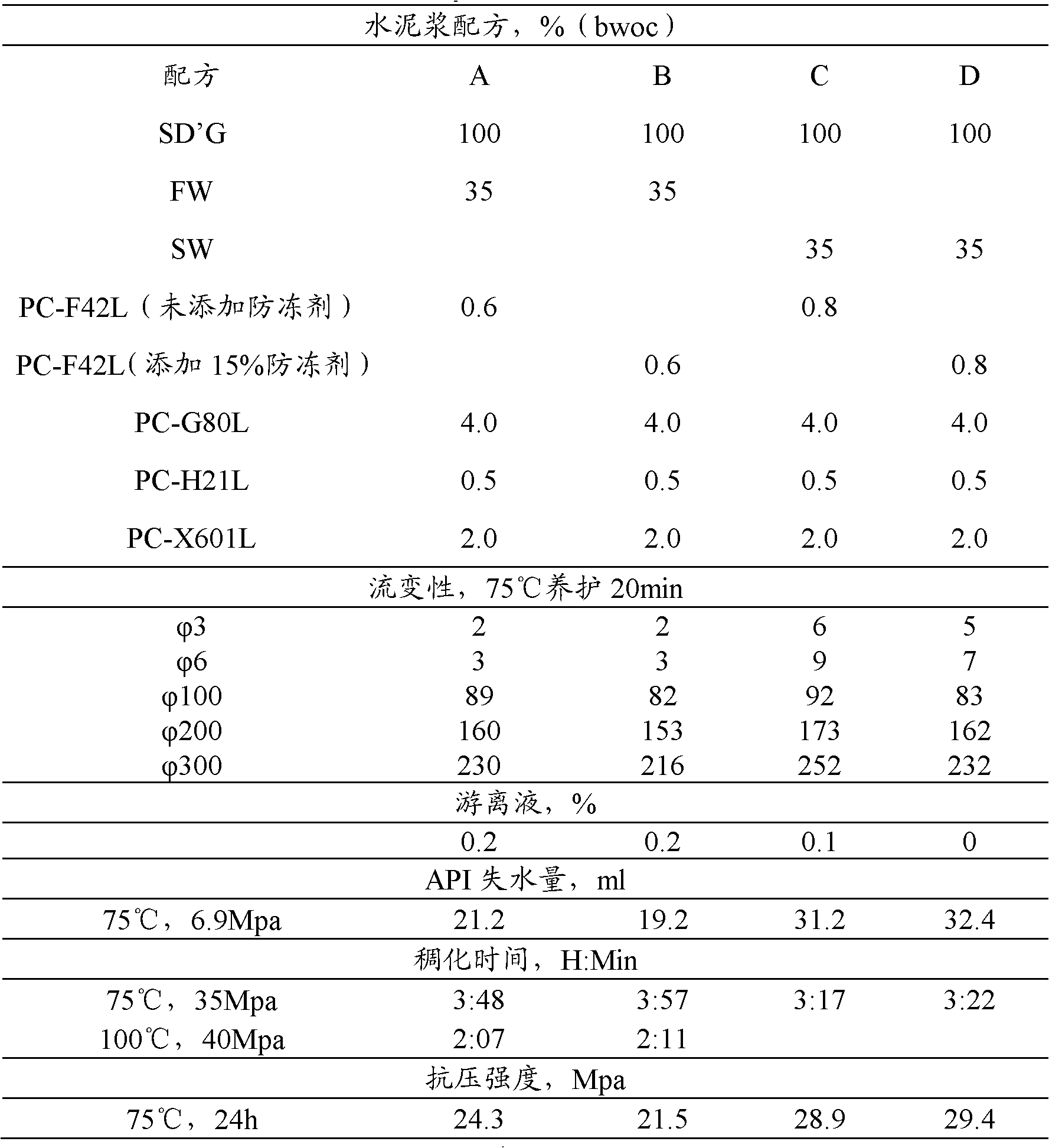

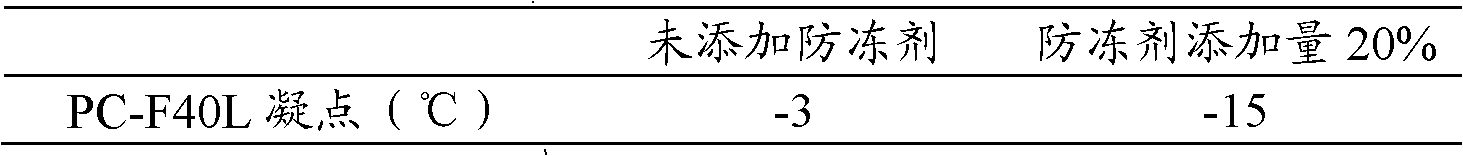

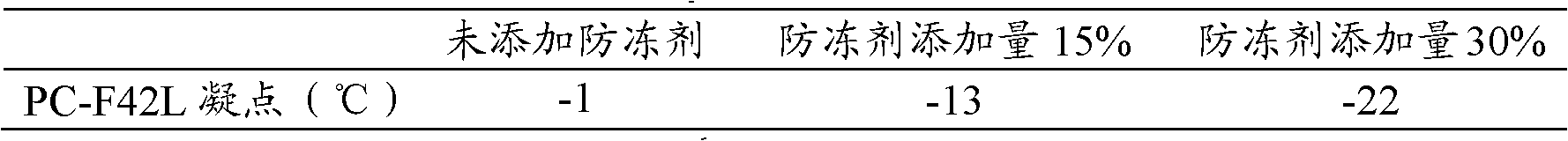

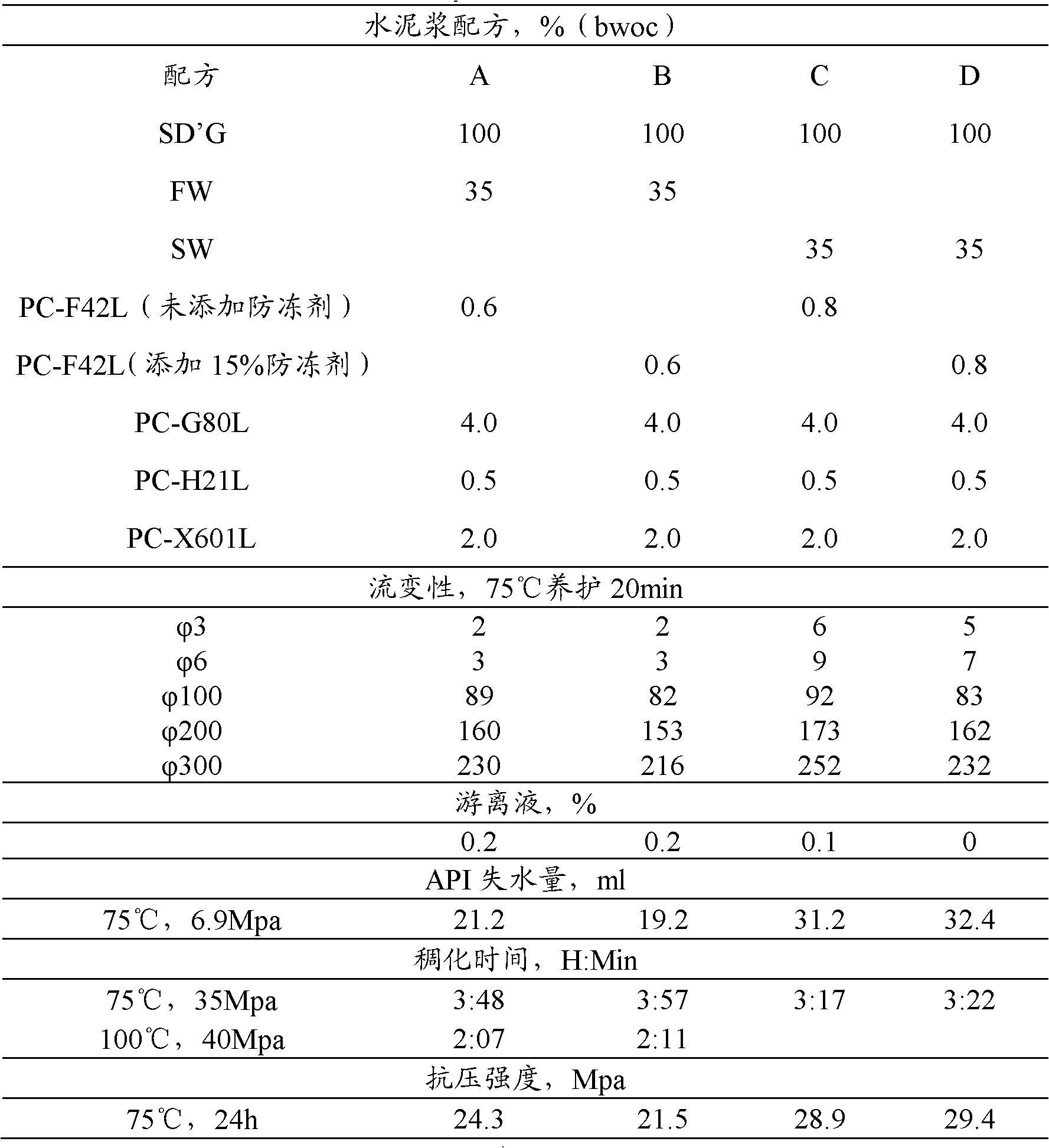

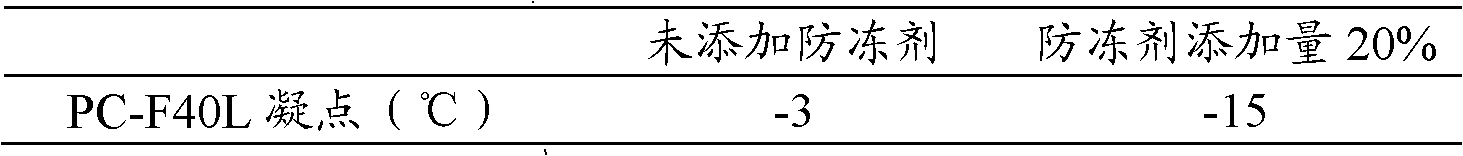

Anti-freezing agent and application of anti-freezing agent to cement additive water aqua for well cementation in oil field

ActiveCN102618233AAvoid corrosionExcellent physical and chemical compatibilityDrilling compositionOil fieldAntifreeze

The invention relates to application of an anti-freezing agent to cement additive water aqua for well cementation in an oil field. The anti-freezing agent comprises a) 20 to 80 weight parts of ethanol, b) 10 to 50 weight parts of glycol, 5 to 30 weight parts of sodium nitrite aqueous solution with solid content of 15 percent and / or d) 5 to 30 weight parts of sodium thiocyanate aqueous solution with solid content of 15 percent. The anti-freezing agent can effectively reduce the freezing point of the cement additive water aqua in the well cementation process, is effective within the wide range of pH value, and has high physical and chemical compatibility; and the anti-freezing agent improves the rheological property of a well cementation cement slurry system to a certain degree, does not influence important performance such as compressive strength, thickening time and the like and has the advantages of environment friendliness and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +1

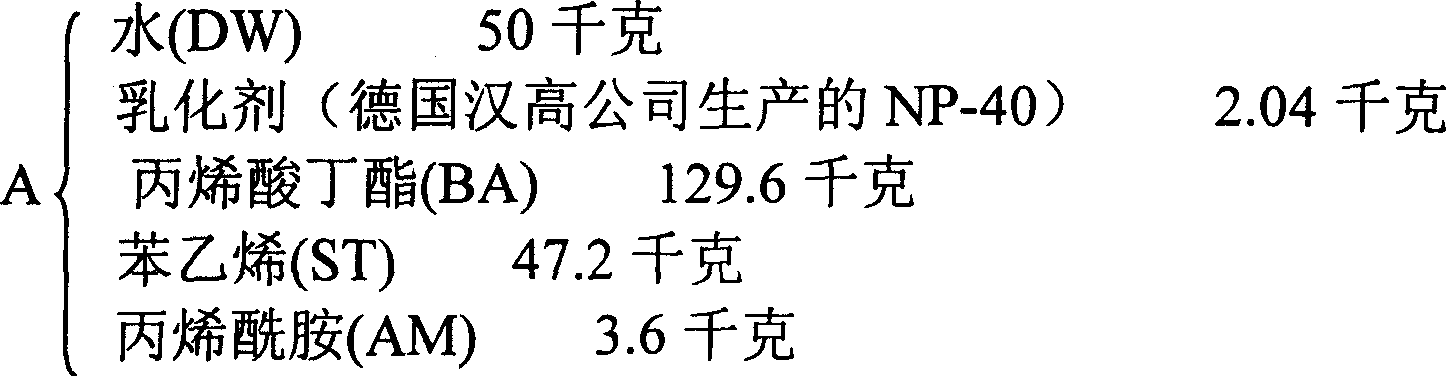

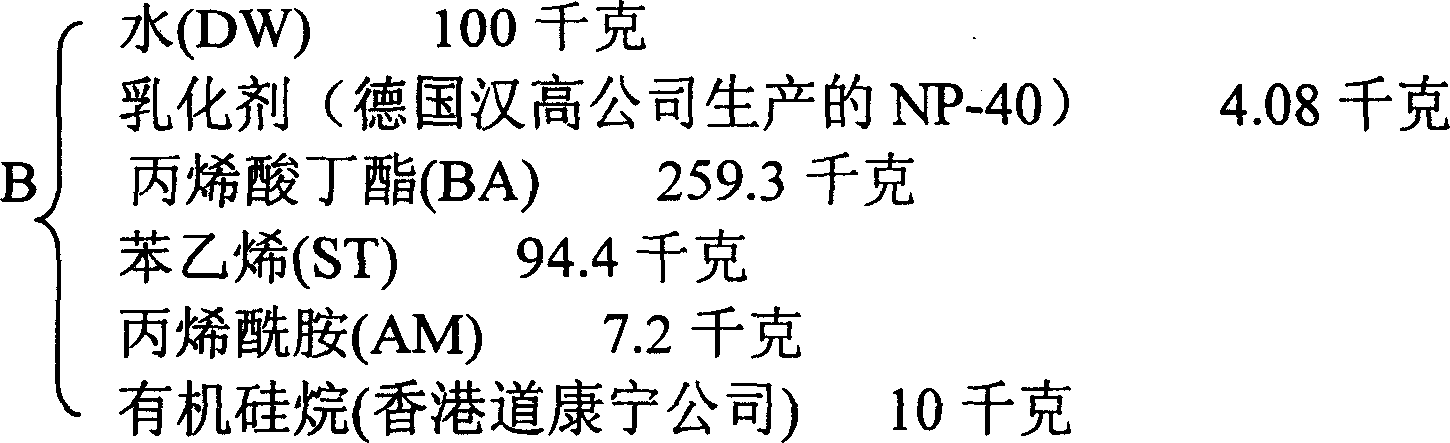

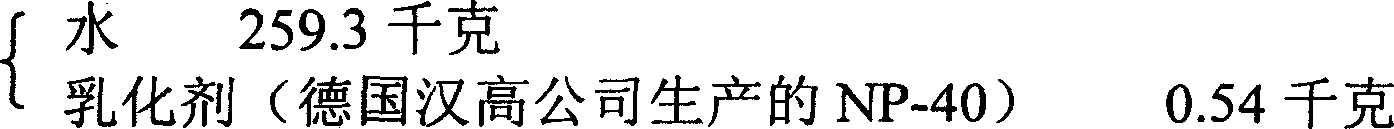

Composite adhesive specially for heat insulating polystyrene outer-wall board

InactiveCN1249187CImprove adhesionImprove aging resistanceInorganic adhesivesHydrocarbon polymer adhesivesPolymer scienceAdhesive

The composite adhesive is prepared with styrene and acrylic acid copolymer emulsion, which is inorganic silica gel and organosilicon modified and has low vitrification point and high adhesion, as main adhesive component and through adding quartzite, asbestos and other reinforcing material and some assistants. The composite adhesive has high adhesion effect, high adhesion strength, good antiaging performance, high hardness and high water resistance.

Owner:上海丰慧节能环保科技有限公司

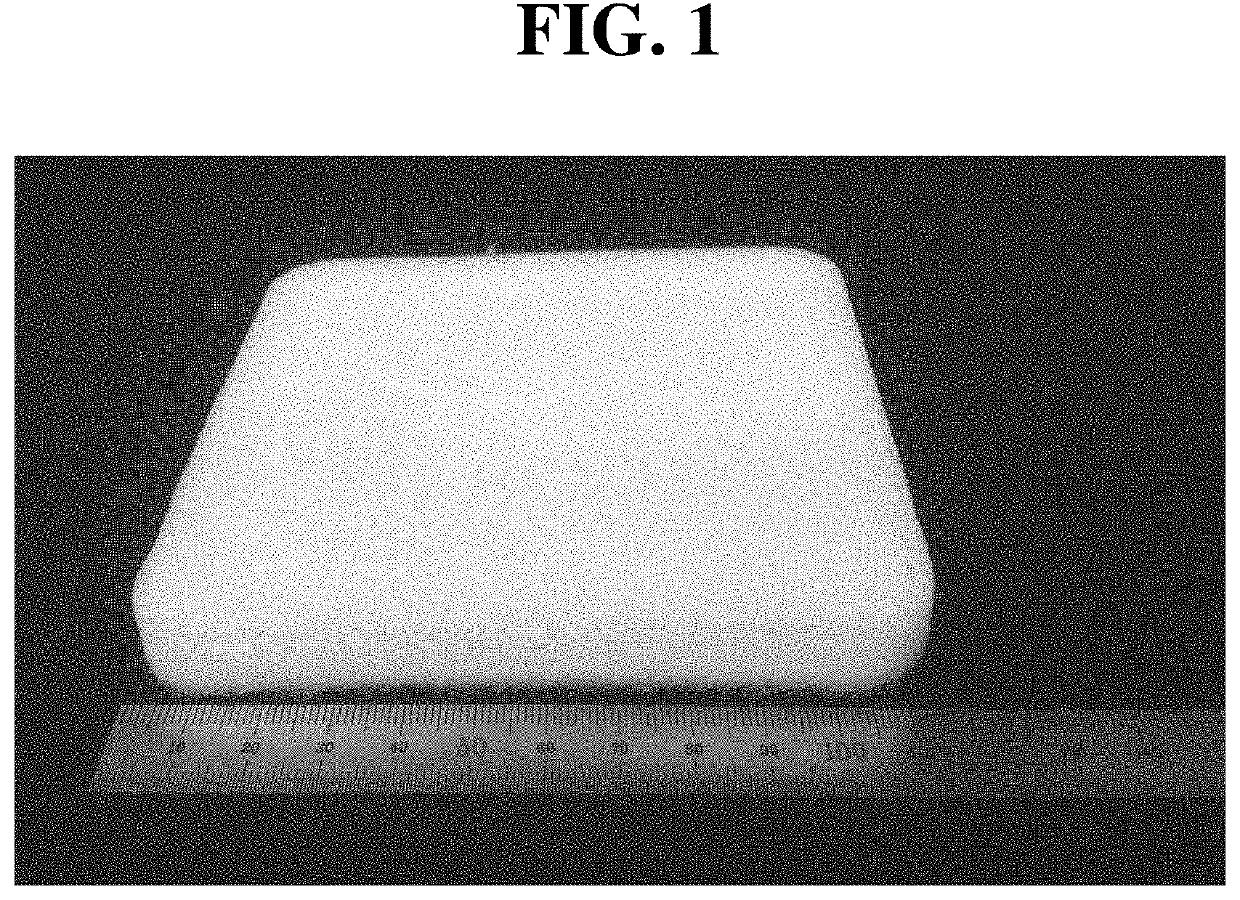

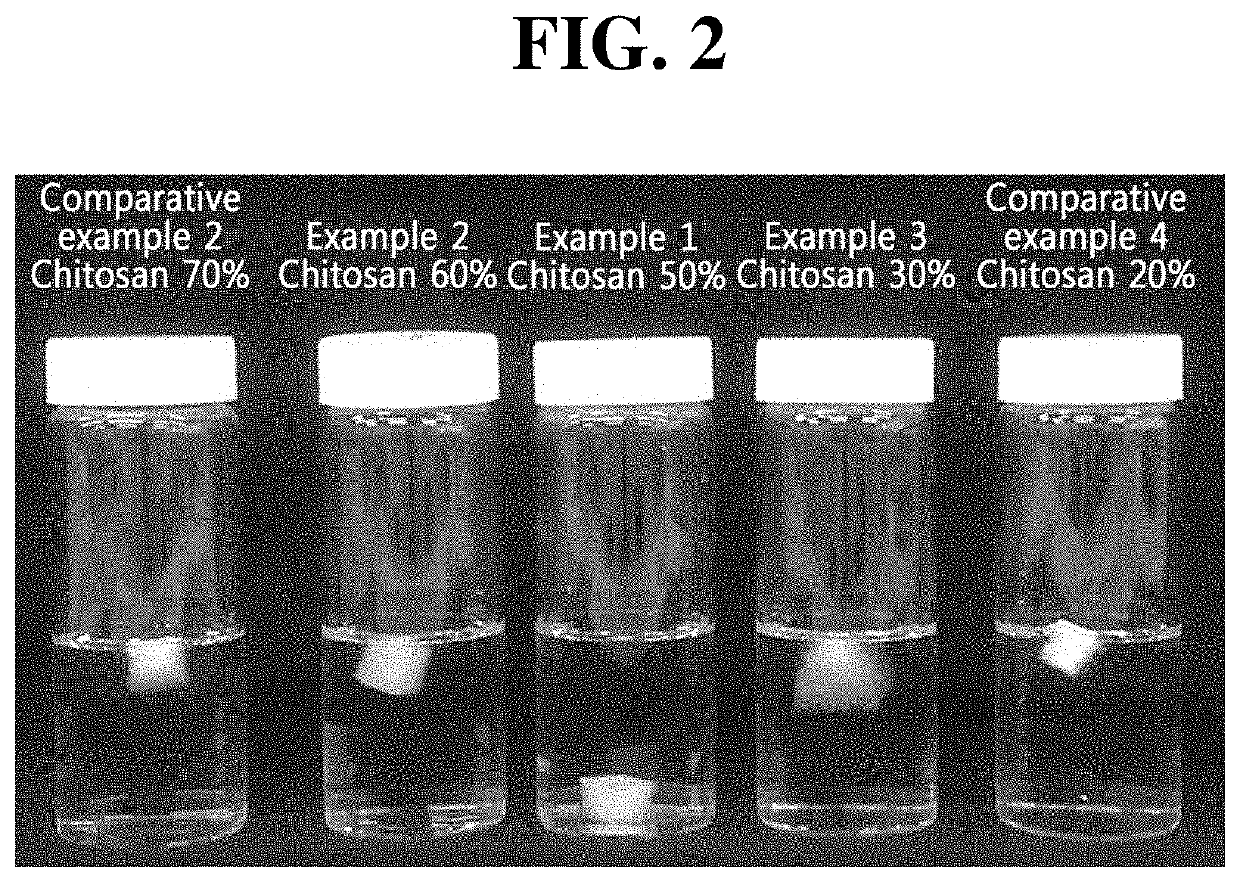

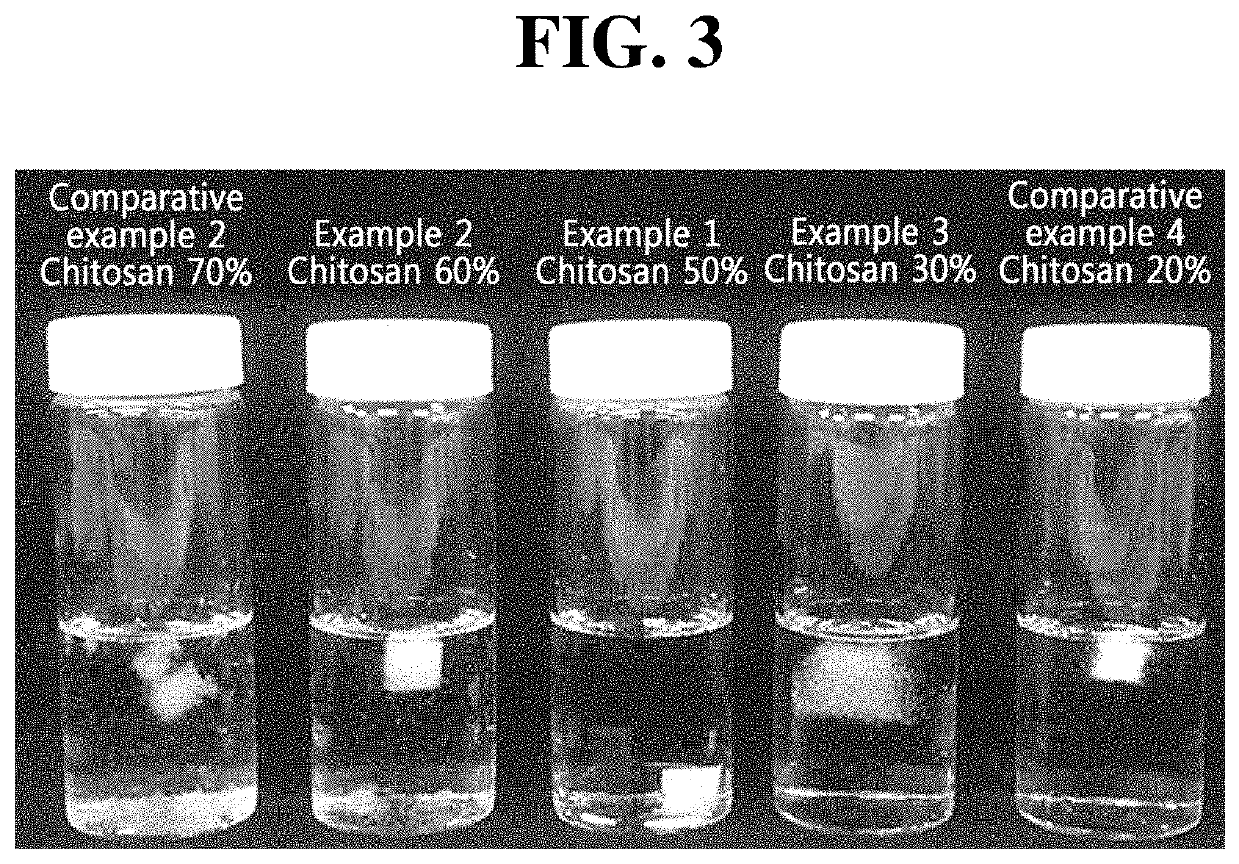

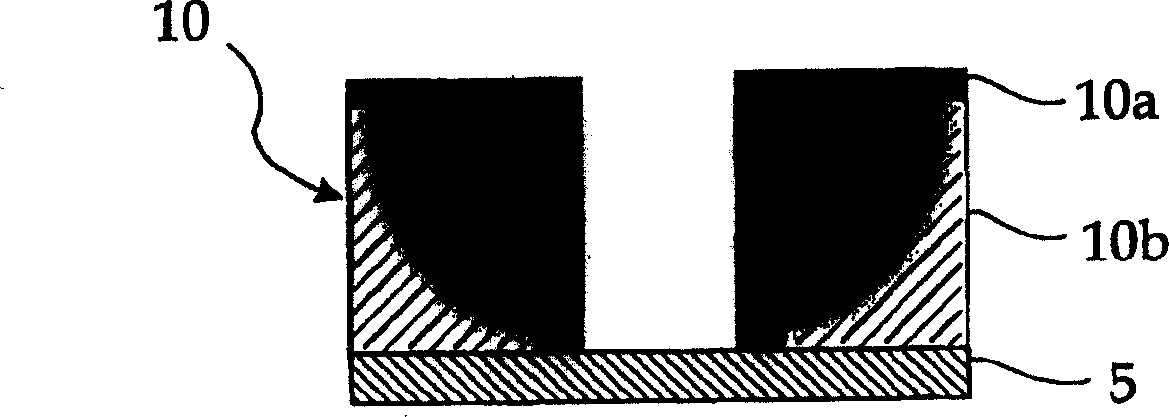

Porous structure and method for manufacturing same

PendingUS20200139001A1Improved shape stabilityReduce solubilitySurgical adhesivesNon-adhesive dressingsCarboxymethyl celluloseCellulose

Disclosed is a porous structure including water-soluble chitosan; and a carboxymethyl cellulose-based compound, wherein a weight ratio of the water-soluble chitosan and the carboxymethyl cellulose-based compound is from 65:35 to 25:75, and a process for preparing the same.

Owner:KOREA INST OF IND TECH

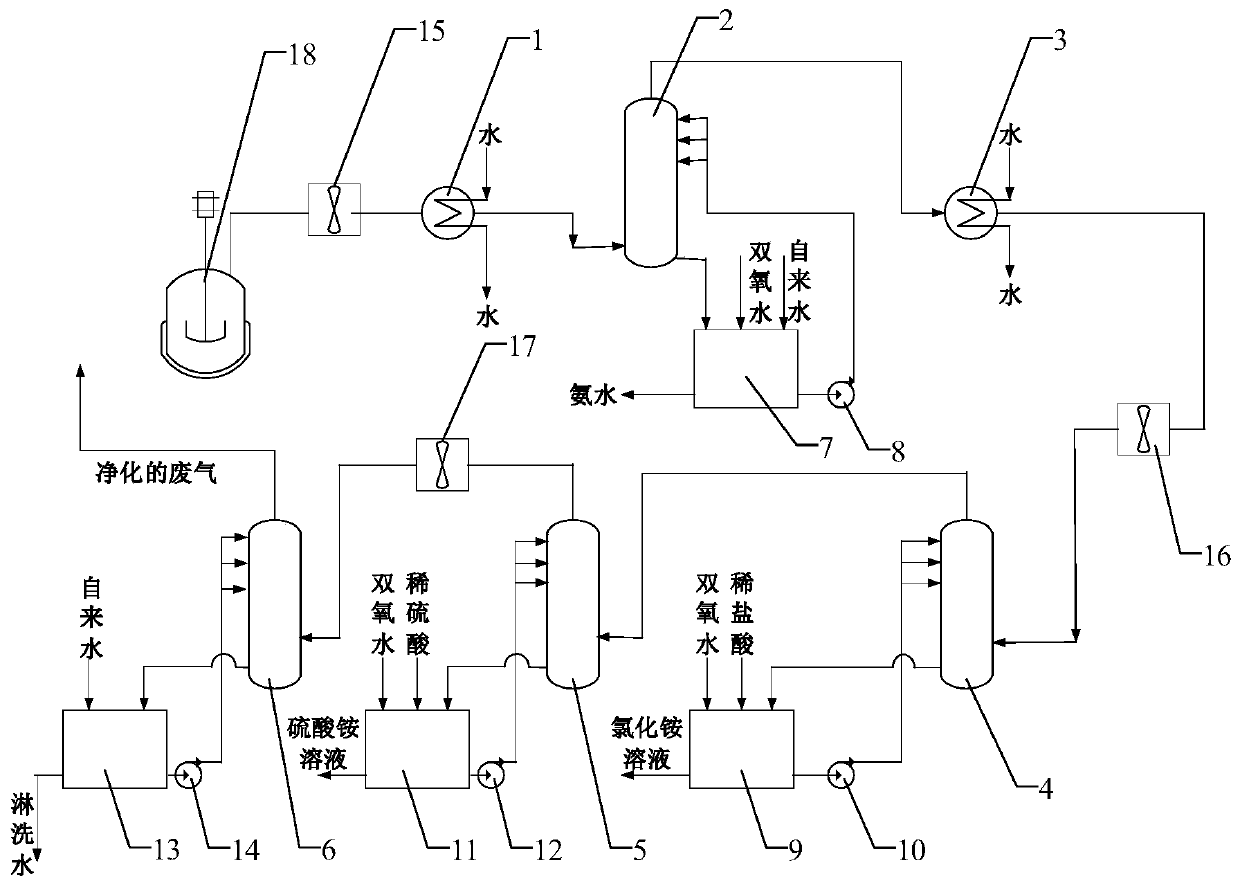

Treating method and system for tungsten smelting waste gas

ActiveCN110170222AThickening effectLow cost productionGas treatmentDispersed particle separationSulfateChloride

The invention provides a treating method for tungsten smelting waste gas. The method comprises the step that tungsten smelting waste gas is subjected to first-time heat exchange cooling treatment, tapwater circular spraying, second-time heat exchange cooling treatment, diluted hydrochloric acid circular spraying and diluted sulphuric acid circular spraying separately to obtain purified waste gas.The invention further provides a treating system for tungsten smelting waste gas. According to the method and system, condensed and cooled ammonia hydroxide and waste gas are subjected to tap water circular spraying at the same time, efficient recycling of ammonia can be completed with no alkali addition and air stripping, multi-stage spraying and absorption are performed, the ammonia and sulfurremoval effect is good, meanwhile, ammonia hydroxide, ammonia chloride, ammonia sulfate and other products with the high value can be obtained, and solutions for spraying can all be recycled; on one hand, the concentration of the obtained product can be increased; on the other hand, consumption of reagents is reduced, energy consumption is low, the cost is low, and tungsten smelting waste gas is efficiently absorbed and utilized.

Owner:JIANGXI UNIV OF SCI & TECH

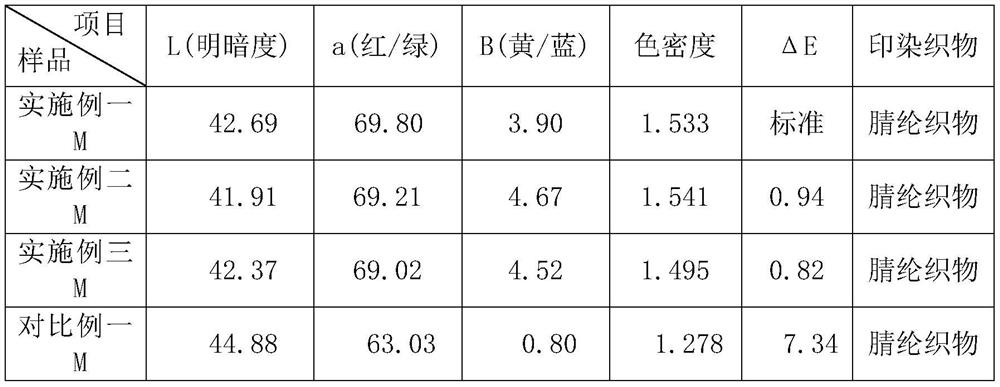

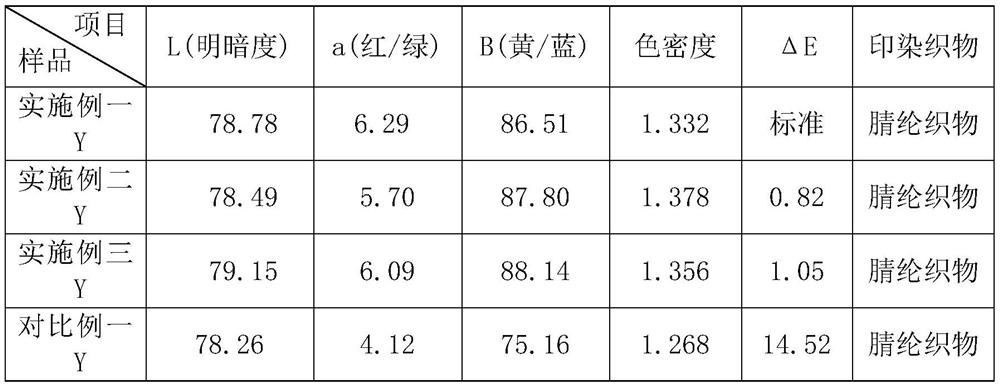

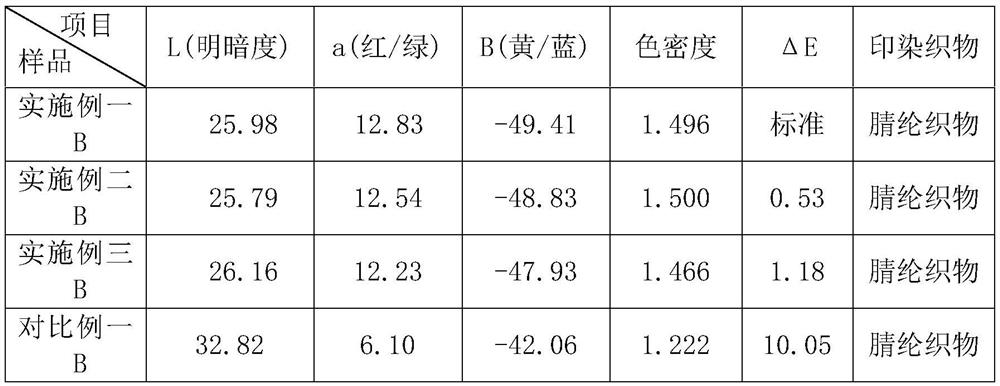

Printing preprocessing sizing agent and preparation method thereof, and jet ink printing technology for acrylic fibre fabric

The invention discloses a printing preprocessing sizing agent and a preparation method thereof, and a jet ink printing technology for an acrylic fibre fabric. The printing preprocessing sizing agent comprises the following raw materials in parts by weight of 1-5 parts of a cation thickener, 3-12 parts of a solubilizer, 2-4 parts of a pH buffer agent, 0-4 parts of electrolyte, 0-2 parts of a thickening agent and 0.2-2 parts of a retarding agent. The preprocessing sizing agent is used for preprocessing for jet ink printing of cationic dye ink for the acrylic fibre fabric, and further patterns obtained by jet ink printing are clear in outline, bright in color, good in color fastness and simple in dying steps.

Owner:深圳市墨库图文技术有限公司

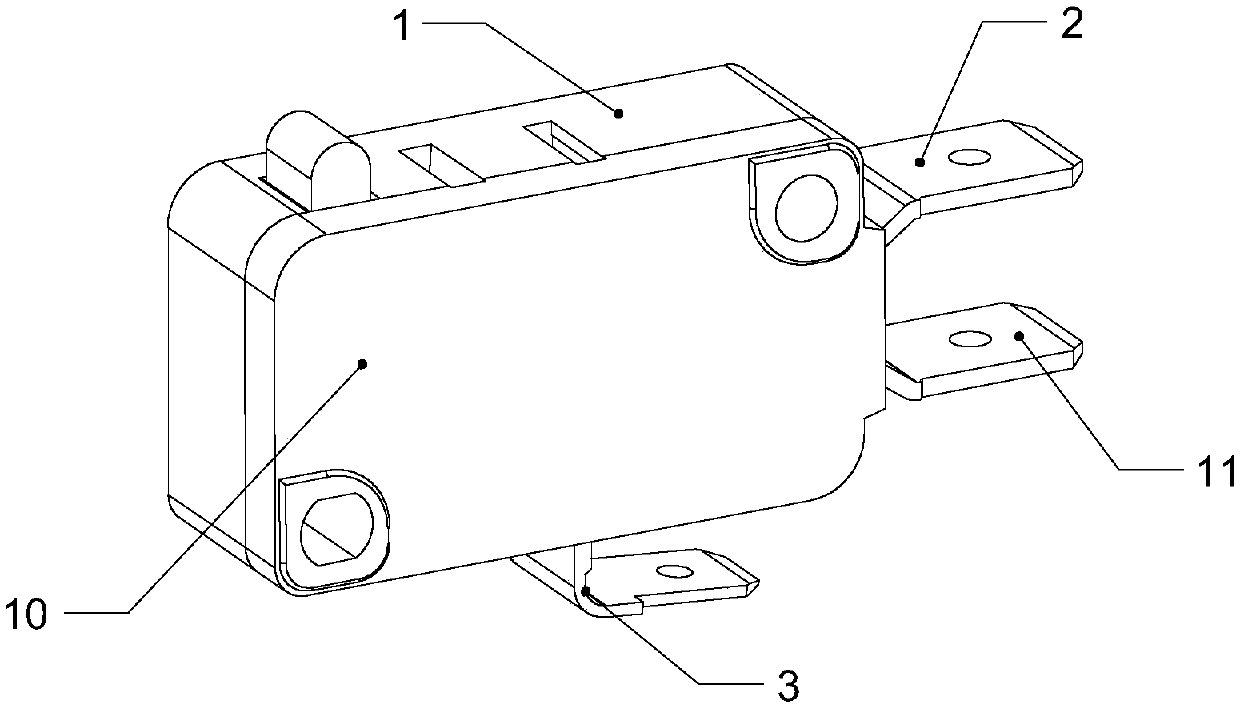

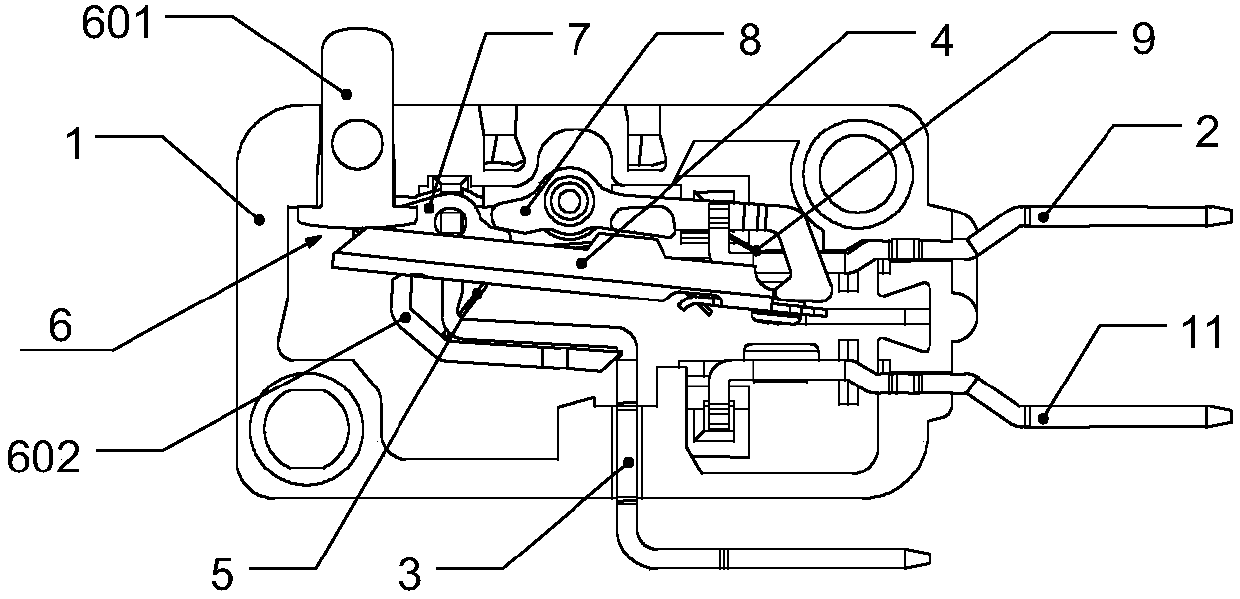

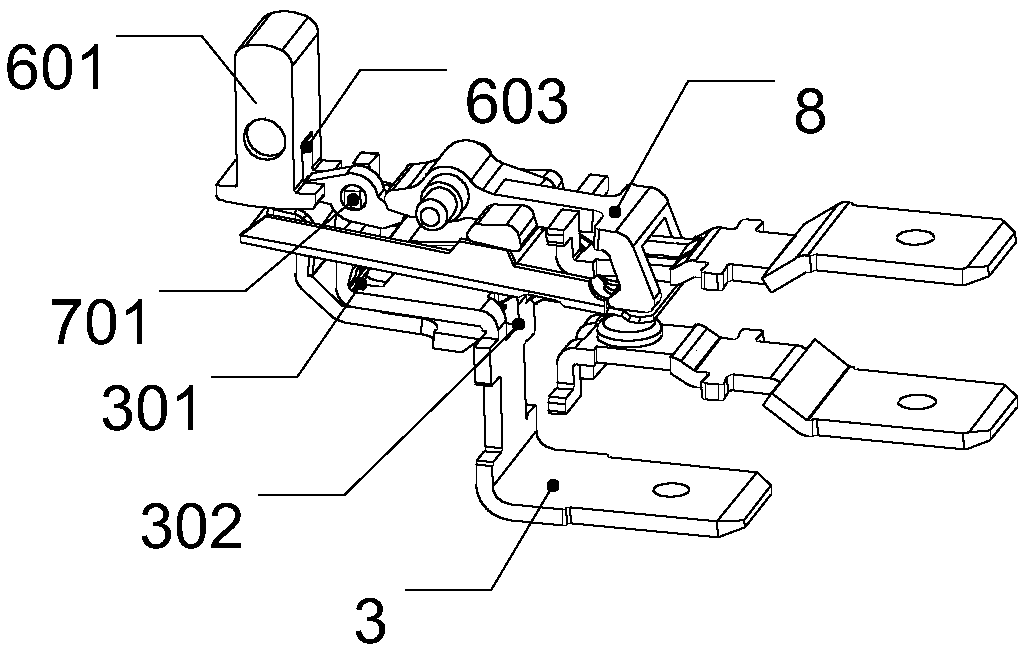

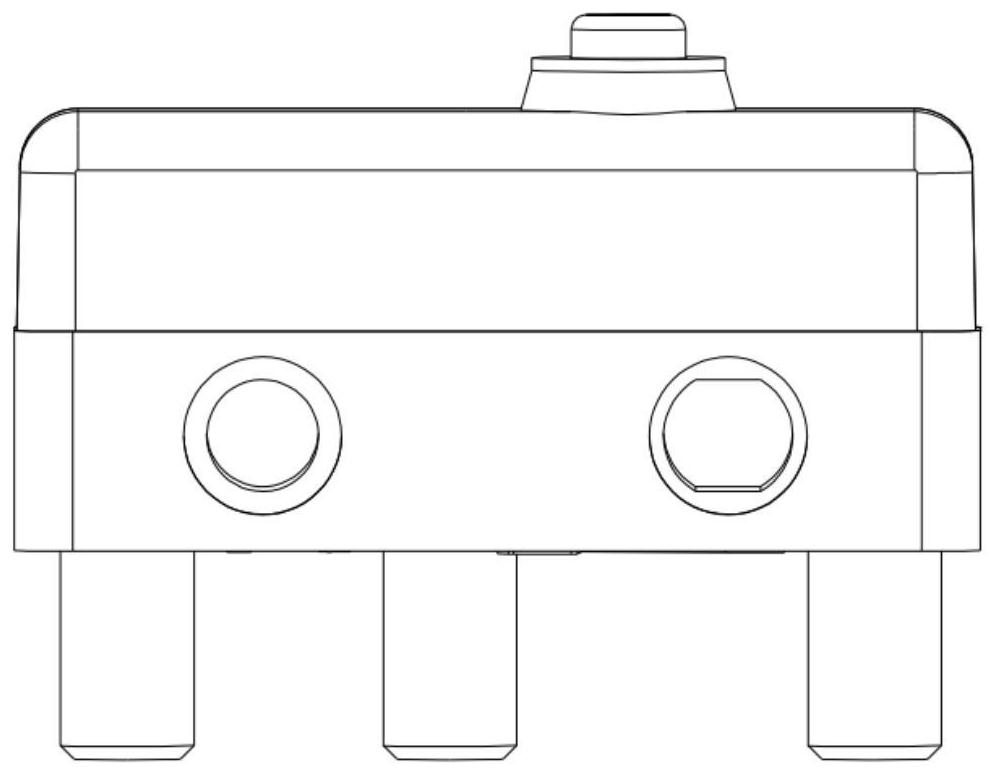

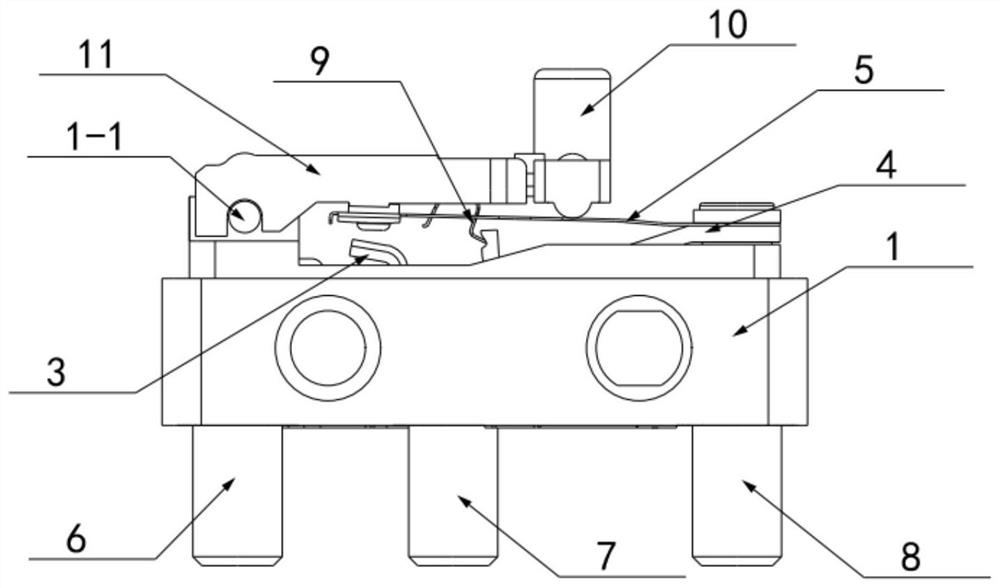

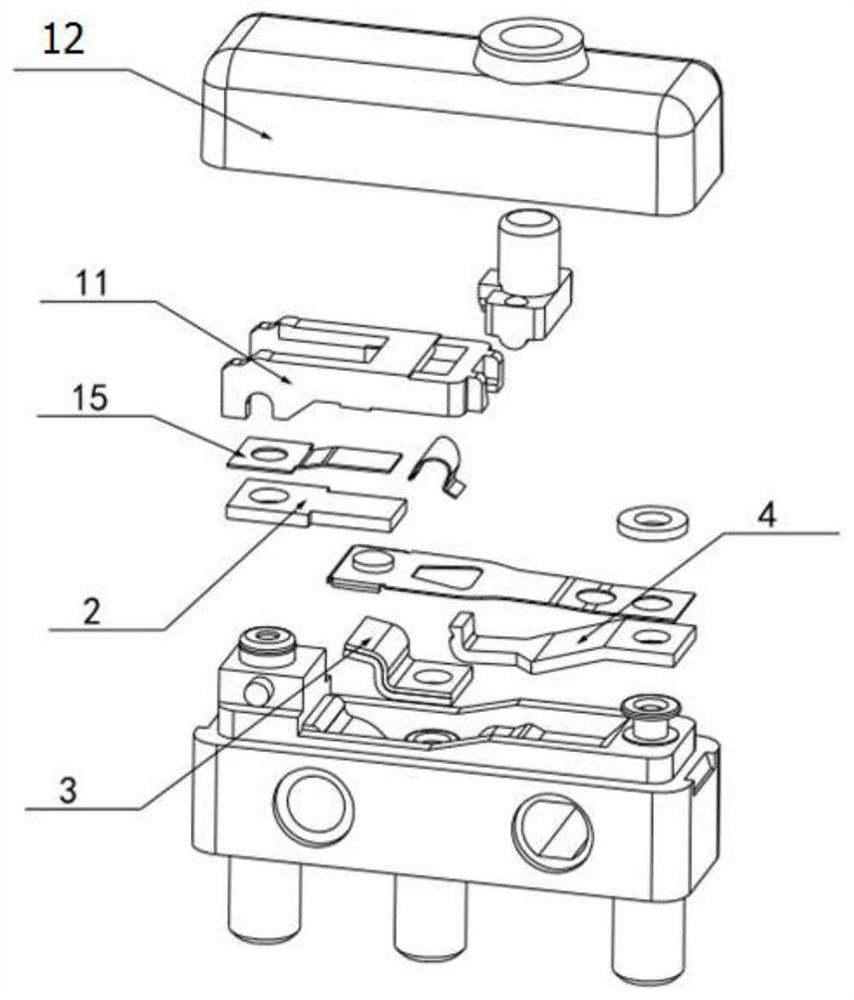

Microswitch with forced separating mechanism

The invention discloses a microswitch with a forced separating mechanism, and the microswitch comprises a housing. The interior of the housing is provided with a normally-closed connector assembly anda common connector assembly and also comprises an elastic assembly which is electrically connected with the common connector assembly and can be electrically connected with the normally-closed connector assembly. The elastic assembly is linked with a triggering assembly, and can swing around a supporting part of the common connector assembly under the action of the triggering assembly. The interior of the housing is also provided with the multi-stage transmission forced separating mechanism, and the forced separating mechanism can make contact with the elastic assembly under the action of thetriggering assembly, and can separate the elastic assembly with the normally-closed connector assembly in a forced manner. The microswitch is provided with the forced separating mechanism. When the microswitch has an abnormality and the contact of a static contact of the normally-closed connector assembly with a moving contact on the common connector assembly is not normally cut off, the forced separating part will separate the moving and static contacts in a forced manner, so as to guarantee the electrical safety.

Owner:ZHANGZHOU JUANMEI ELECTRIC TECH CO LTD

Fiber modified thermosetting rubber

The invention discloses fiber modified thermosetting rubber. The formula of the fiber modified thermosetting rubber is that 20 to 30 parts of vinyl phenyl silicon resin, 11 to 15 parts of melamine formaldehyde resin, 8 to 11 parts of methyl silicon hydroxy terminated silicone resin, 30 to 50 parts of solvents, 3 to 5 parts of chain transfer agents, 1 to 3 parts of catalysts, 2 to 4 parts of initiators, 12 to 18 parts of graphene fibers, 18 to 26 parts of ethanediamine, 3 to 5 parts of dispersants and 2 to 4 parts of thickeners. The invention further provides specific implementation materials and implementation manners. The fiber modified thermosetting rubber is simple in method, mild in process conditions, low in production cost, high in material structure stability, not destroyed by high temperature and improved stably in temperature resistance and toughness.

Owner:俞潮军

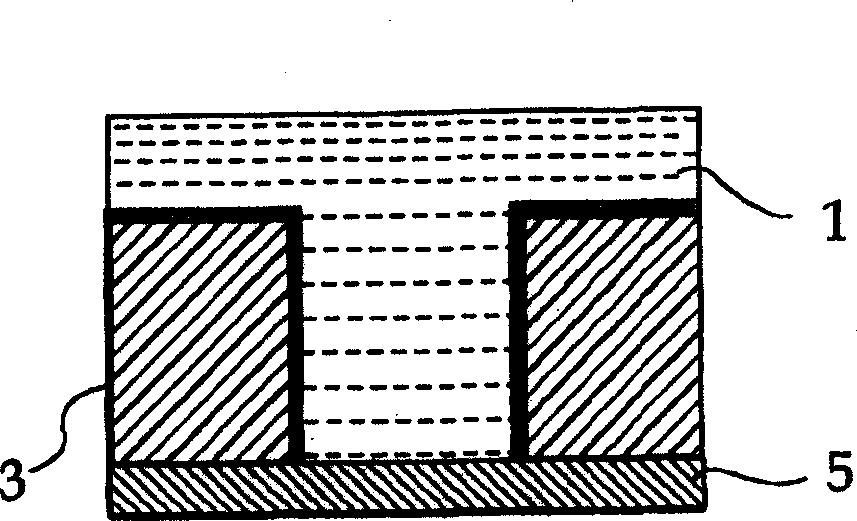

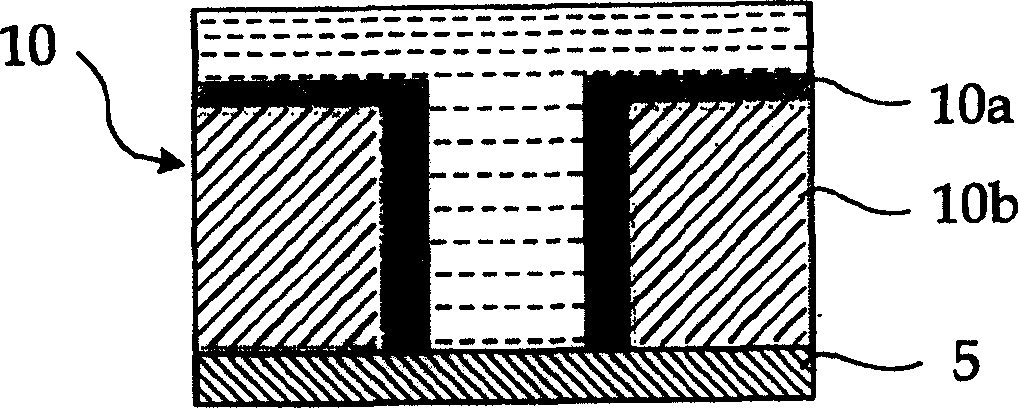

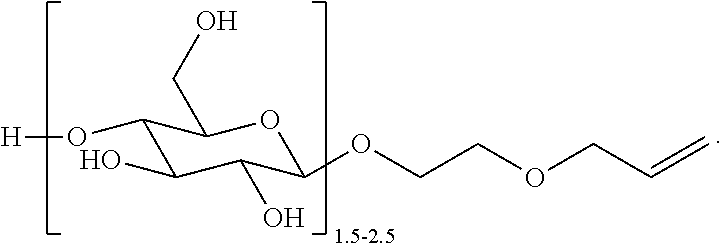

Producing technology for non-rusting agent pattern and thickening material thereof and semiconductor device producing technology

InactiveCN1637602AThickening effectiveUniform thickeningConstruction of head windingsRadiation applicationsResistDevice material

The present invention provides a resist pattern thickening material capable of thickening a resist pattern and forming fine space patterns beyond the exposure limit of exposure used during patterning. The resist pattern thickening material includes a resin and a phase transfer catalyst. The present invention also provides a process for forming a resist pattern and a process for manufacturing a semiconductor device, in which the resist pattern thickening material of the present invention is suitably utilized.

Owner:FUJITSU LTD

A kind of preparation method of high light absorbing rate solar absorbing material

ActiveCN106684197BFully dispersedStable bonding reactionFinal product manufacturePhotovoltaic energy generationWater bathsNitrogen gas

The invention relates to a method for preparing a high absorbency solar energy absorbing material. The method comprises the steps of firstly, mixing silicate, tungsten oxide, titanium source, an auxiliary agent and a solvent for reflux reaction; then adding a stabilizing liquid and carrying out ultrasonic reaction; afterwards, introducing nitrogen gas for aeration reaction to obtain a silica-based absorbing material; and finally, adding silicone resin, and obtaining a high absorbency solar energy absorbing material through water bath micro-boiling reaction and high temperature and high pressure reaction. Compared with the prior art, the method of the invention expands the solar spectrum utilization range of the material by adopting the silica-based absorbing material doped with tungsten and titanium elements, and also obtains a good bonding effect, ensures the stability of the material and improves the content of silica in the material by using the organic silicone resin for high temperature bonding. In addition, the preparation method is simple, the process conditions are mild, the reproducibility is good, the production cost is low, and the industrial production requirement can be satisfied.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Polyorganosiloxane gels having glycoside groups

ActiveUS10053543B2Good compatibilityImprove compatibilityCosmetic preparationsToilet preparationsGlycoside formationGlycerol

Organopolysiloxane gel compositions containing an organopolysiloxane gel produced by hydrosilylation of an unsaturated silicone resin and a compound containing glycoside residues and a hydrosilylatable group with at least one Si—H-functional organopolysiloxane can form creamy, storage-stable gels which are capable of containing large amounts of polar or hydrophilic substances such as water and glycerol while remaining monophasic. The compositions are especially useful in providing cosmetic compositions with a silky skinfeel.

Owner:WACKER CHEM GMBH

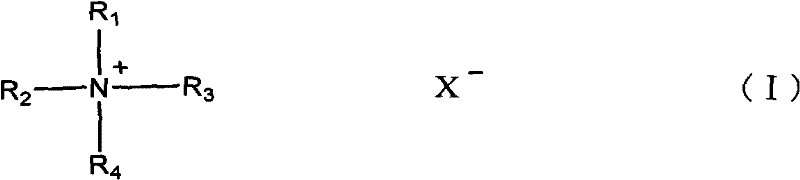

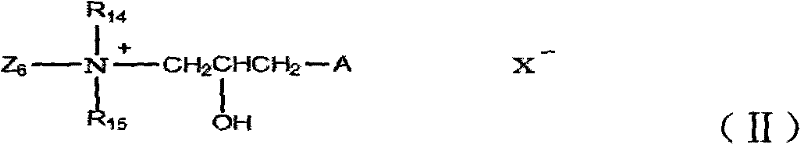

Transparent conditioning shampoo composition and preparation method thereof

ActiveCN101716128BThickening effectDoes not affect physical and chemical stabilityCosmetic preparationsHair cosmeticsSurface-active agentsAmmonium

The invention discloses a transparent conditioning shampoo composition, comprising the components in percent by weight: 5.0% to 50.0% of surface active agent, 0.1% to 7.0% of quaternary ammonium salt or amido amine and the balance of carrier with water, wherein the cationic quaternary ammonium salt or the amido amine of special structure is prepared into the shampoo composition for realizing the high unification of transparence and conditioning performance in a system; compared with the performance of the prior art and commercially available famous products, the major indexes of combing performance of dry hair and wet hair, the softness of the dry hair, luster and the like are obviously enhanced. In addition, the cationic quaternary ammonium salt or the amido amine of the special structure also has a certain thickness increase function; therefore, the use quantity of alkanolamide is reduced; and the bubble quantity, the bubbling speed and the rational stability of the shampoo composition are not influenced.

Owner:广东名臣日化有限公司

Micro switch with forced separation mechanism

ActiveCN107799346BEnsure electricity safetyImprove reset abilityElectric switchesClassical mechanicsEngineering

The invention discloses a micro switch with a forced separation mechanism. The micro switch comprises a normally closed static contact piece, a button and an elastic component and further comprises aforced separation piece, wherein one end of the forced separation piece is installed on a shell through a rotary shaft, the other end thereof props against the end surface of the elastic component, and the button and the forced separation piece are linked so as to force the normally closed static contact piece to separate from the elastic component. The micro switch is provided with the forced separation piece, so that when a movable contact and a static contact cannot separate from each other normally, the movable contact and the static contact are forced to separate so as to keep the electric appliance safe. The micro switch has a bright application prospect.

Owner:ZHANGZHOU JUANMEI ELECTRIC TECH CO LTD

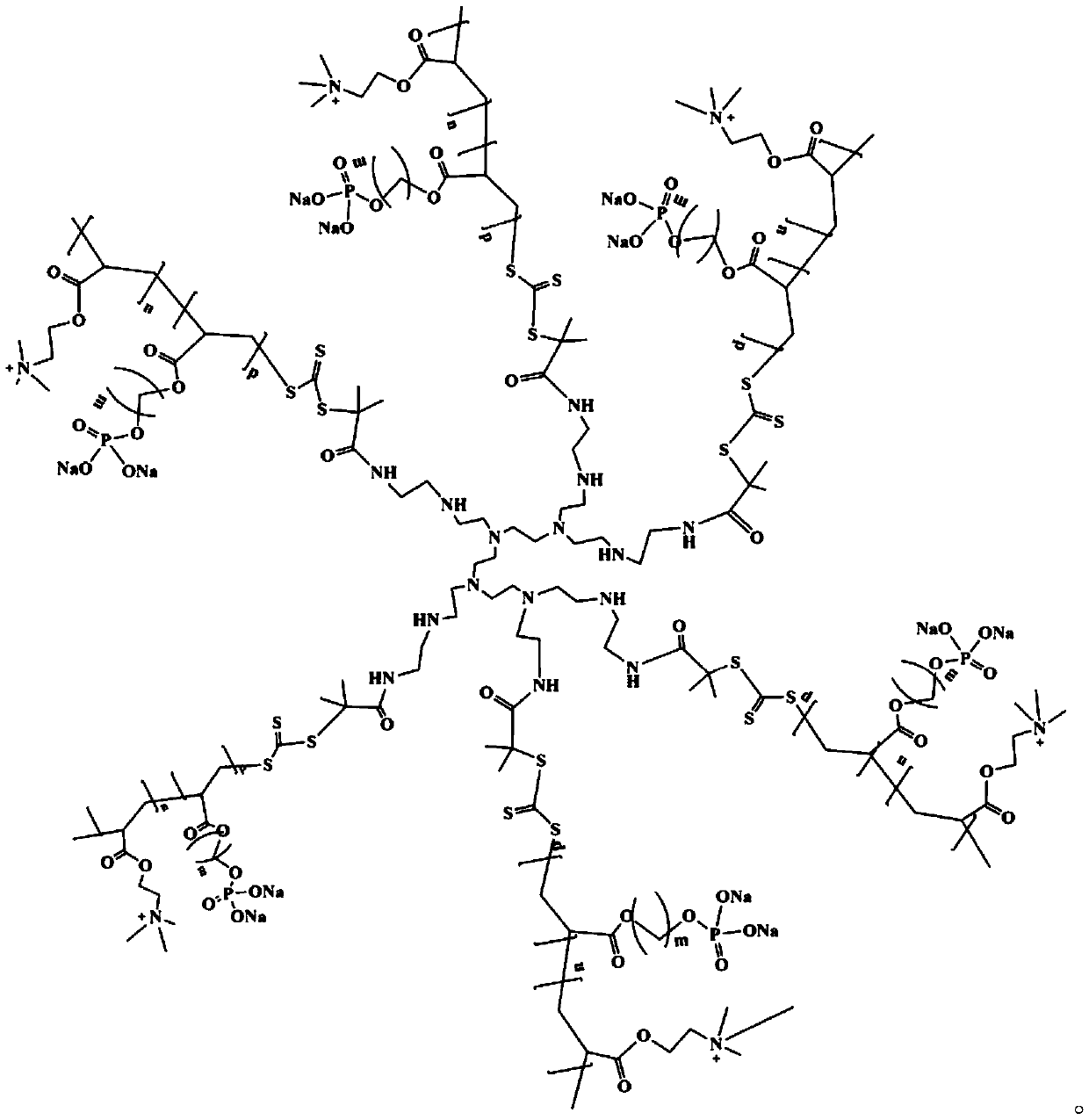

A kind of hyperbranched copolymer ceramic reinforcing agent and its preparation method and application

The invention relates to a novel hyper-branched copolymer ceramic enhancer, and a preparation method and an application of same. The hyper-branched copolymer ceramic enhancer is a hyper-branched polymer synthesized through a RAFT water solution polymerization process, wherein polyethylene imine serves as a center and an acryloyloxyalkoxyphosphate monomer and a cationic monomer copolymer serve as arms; the hyper-branched copolymer is 10000-50000 in average molecular weight and is less than 1.25 in molecular weight polydispersity coefficient. The hyper-branched copolymer ceramic enhancer has noinfluence on viscosity of ceramic green body slurry, has good enhancing effect and stable performance, and has wide application prospect.

Owner:广东智洁卫浴有限公司

A kind of silicone elastomer gel and its preparation method and application

ActiveCN112915046BExcellent silky feelingGood matteCosmetic preparationsToilet preparationsPlatinumPolymer science

The invention belongs to the technical field of silicone elastomers, and in particular relates to a silicone elastomer gel and its preparation method and application. The silicone elastomer gel of the present invention comprises the following components and their mass parts: 100-200 parts of hydrogen-containing silicone oil, 2-50 parts of vinyl MQ resin, 8-80 parts of vinyl-terminated silicone oil, platinum Catalyst 1ppm-30ppm, carrier fluid 400-1000 parts. The silicone elastomer gel provided by the invention can provide products with a long-lasting velvet-like smoothness, can bring matte and soft-focus effects to products, can reduce the stickiness of products, and provide products with a refreshing and non-greasy skin feel , can be used as a highly transparent system, has good waterproof performance, can not only play a thickening effect in anhydrous formula and water-in-oil formula, but also improve product stability.

Owner:广州市仲沅其新型材料有限公司

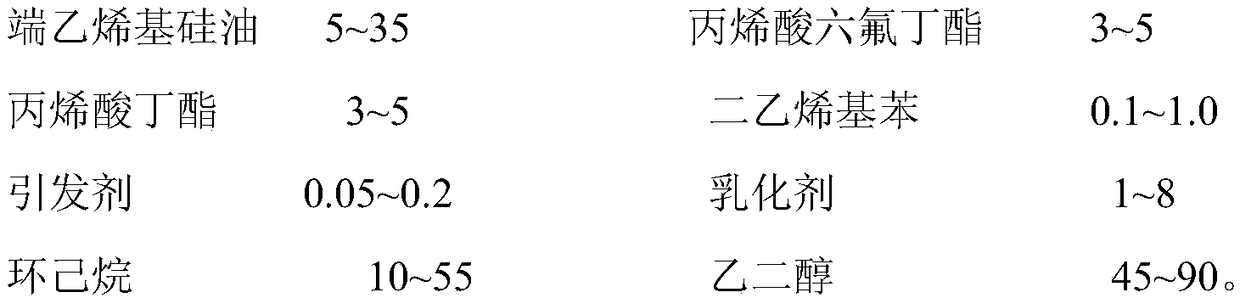

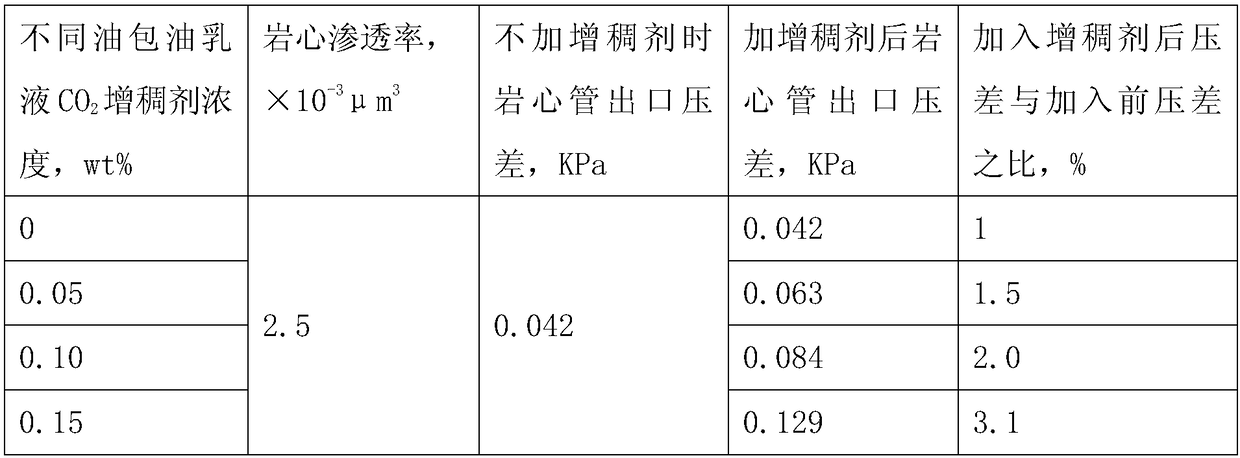

Supercritical carbon dioxide oil-in-oil emulsion thickener and its preparation method and application

The invention provides a supercritical carbon dioxide oil-in-oil emulsion thickener and a preparation method and application thereof. The preparation method is carried out according to the following steps: a. terminal vinyl silicone oil, hexafluorobutyl acrylate, butyl acrylate, diethylene Base benzene, initiator, emulsifier, cyclohexane, and 65-75% ethylene glycol are placed in a container, and sheared at high speed for 25-35 minutes to obtain a pre-emulsion; b. Add the remaining amount of ethylene glycol and the pre-emulsion of 4 to 6% of the amount of step a in the dry three-necked flask of the dropping funnel, heat up to 50 ° C to 80 ° C under stirring, and keep the temperature for 25 to 40 minutes; c. drip the remaining amount The pre-emulsion is reacted for 5h~25h; d. Cool to room temperature to obtain the product. It has the characteristics of rapid dissolution in SC-CO2, low cost and good thickening effect on SC-CO2.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anti-freezing agent and application of anti-freezing agent to cement additive water aqua for well cementation in oil field

ActiveCN102618233BThickening effectAvoid corrosionDrilling compositionSodium thiocyanateChemical compatibility

The invention relates to application of an anti-freezing agent to cement additive water aqua for well cementation in an oil field. The anti-freezing agent comprises a) 20 to 80 weight parts of ethanol, b) 10 to 50 weight parts of glycol, 5 to 30 weight parts of sodium nitrite aqueous solution with solid content of 15 percent and / or d) 5 to 30 weight parts of sodium thiocyanate aqueous solution with solid content of 15 percent. The anti-freezing agent can effectively reduce the freezing point of the cement additive water aqua in the well cementation process, is effective within the wide range of pH value, and has high physical and chemical compatibility; and the anti-freezing agent improves the rheological property of a well cementation cement slurry system to a certain degree, does not influence important performance such as compressive strength, thickening time and the like and has the advantages of environment friendliness and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com