Microswitch with forced separating mechanism

A separation mechanism, micro switch technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of permanent deformation of the moving contact piece, switch elastic attenuation, switch application restrictions, etc., to achieve thickening of the material thickness of the moving contact piece, Effect of preventing material deformation and ensuring electrical safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

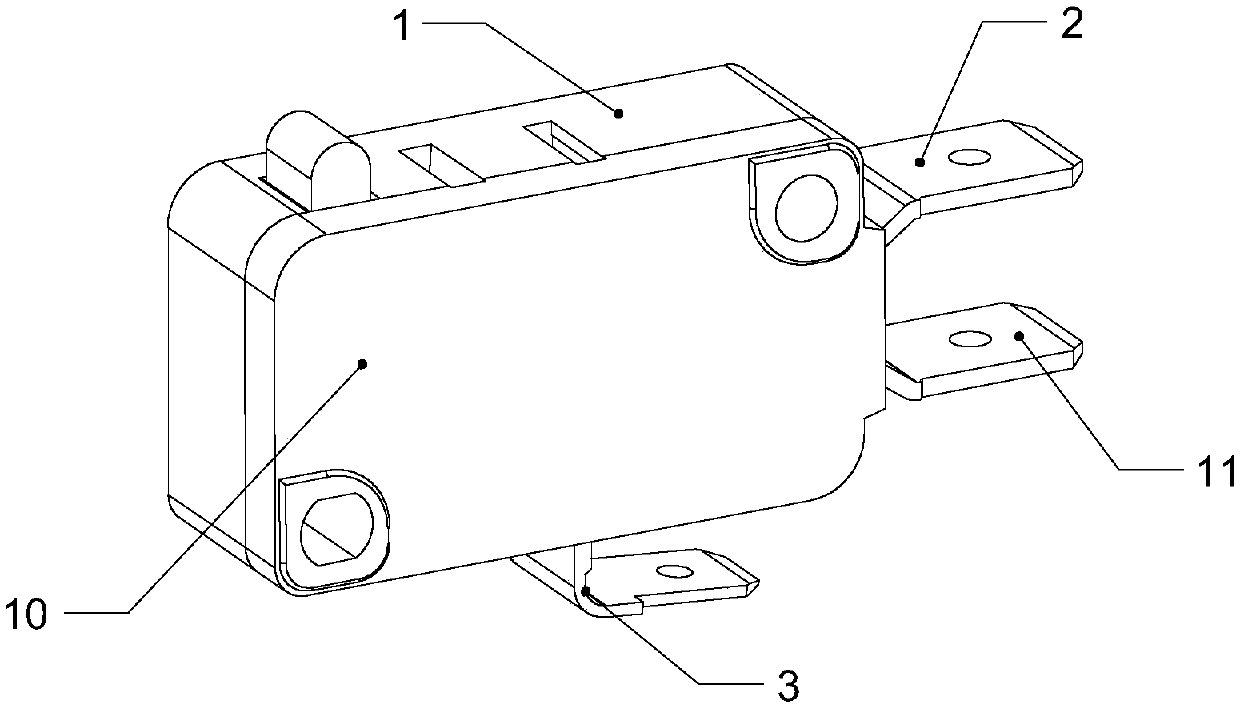

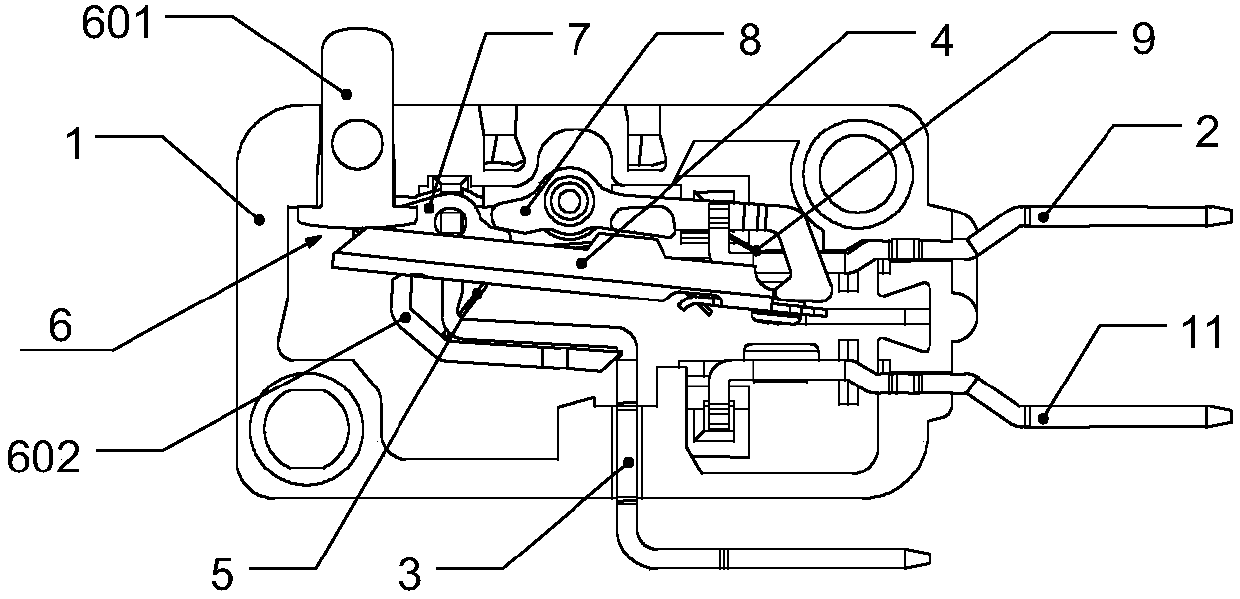

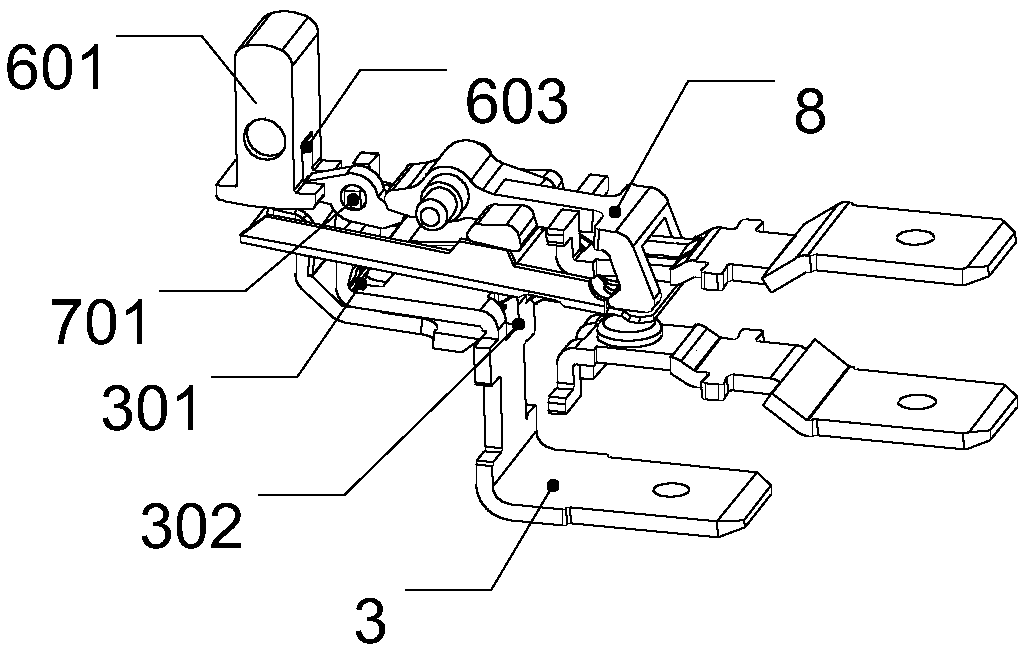

[0075] like figure 1 and figure 2 As shown, a micro switch with a forced separation mechanism of the present invention includes a housing 1 and a cover plate 10 adapted to the housing 1, and the housing is provided with a normally closed connector 2, a common connector 3, The normally open connector 11, the movable contact piece 4, the elastic member 5, the trigger assembly 6 and the forced separation mechanism for forcibly separating the moving and static contacts of the multi-stage transmission. One end of the normally open connector 11 , the normally closed connector 2 and the common connector 3 is located inside the housing 1 , and one end extends out of the housing 1 . The movable contact piece 4 is electrically connected with the public connector 3, and has a movable contact that can communicate with the static contact of the normally closed connector 2; The elastic member 5 and the trigger assembly 6. The elastic member 5 is a reed. One end of the reed abuts against...

Embodiment 2

[0084] like Figure 9 and Figure 10 As shown, the structure of embodiment 2 is the same as that of embodiment 1, the difference is that the elastic member 5 of the present invention is a reed that forms an integral structure with the movable contact 4, and one end of the reed is fixed to the movable contact 4 The upper end and the other end are freely cantilevered, and the free cantilever end of the reed abuts against the first notch 301 of the public connector 3 . like Figure 11 and Figure 12 As shown, the moving contact piece 4 includes a moving contact piece base 401 and a contact structure 402 located on the moving contact piece base 401 as a moving contact. The movable contact piece base 401 is a sheet structure with a hollowed-out area in the middle. The hollowed-out area on the side of the sheet structure close to the contact structure 402 is fixedly connected with one end of the reed, and the hollowed-out area near the free cantilever end of the reed is connected...

Embodiment 3

[0087] like Figure 13 and Figure 14 As shown, the structure of embodiment 3 is the same as that of embodiment 1, the difference is that the elastic member 5 is a tension spring, one end of the tension spring is hooked on the moving contact piece 4, and the other end is hooked on the first support member 602 superior. The movable contact piece 4 and the first supporting member 602 can respectively have connection notches matching with the extension springs. The moving contact piece 4 includes a moving contact piece base 401 and a contact structure 402 on the moving contact piece base 401 serving as a moving contact; and there is no need to add flanges and gaskets.

[0088] Working process: same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com