Anti-freezing agent and application of anti-freezing agent to cement additive water aqua for well cementation in oil field

A technology for cementing cement and antifreeze, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of abnormal thickening time of cement slurry, little research on antifreeze, change of compressive strength, etc. Excellent physical and chemical compatibility, environmental friendliness, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Mix each component by following weight parts to prepare antifreeze of the present invention:

[0029] a) ethanol: 35 parts by weight; b) ethylene glycol: 35 parts by weight; c) a solid content of 15% sodium nitrite aqueous solution: 15 parts by weight; d a solid content of 15% sodium thiocyanate aqueous solution: 15 weight performance evaluation

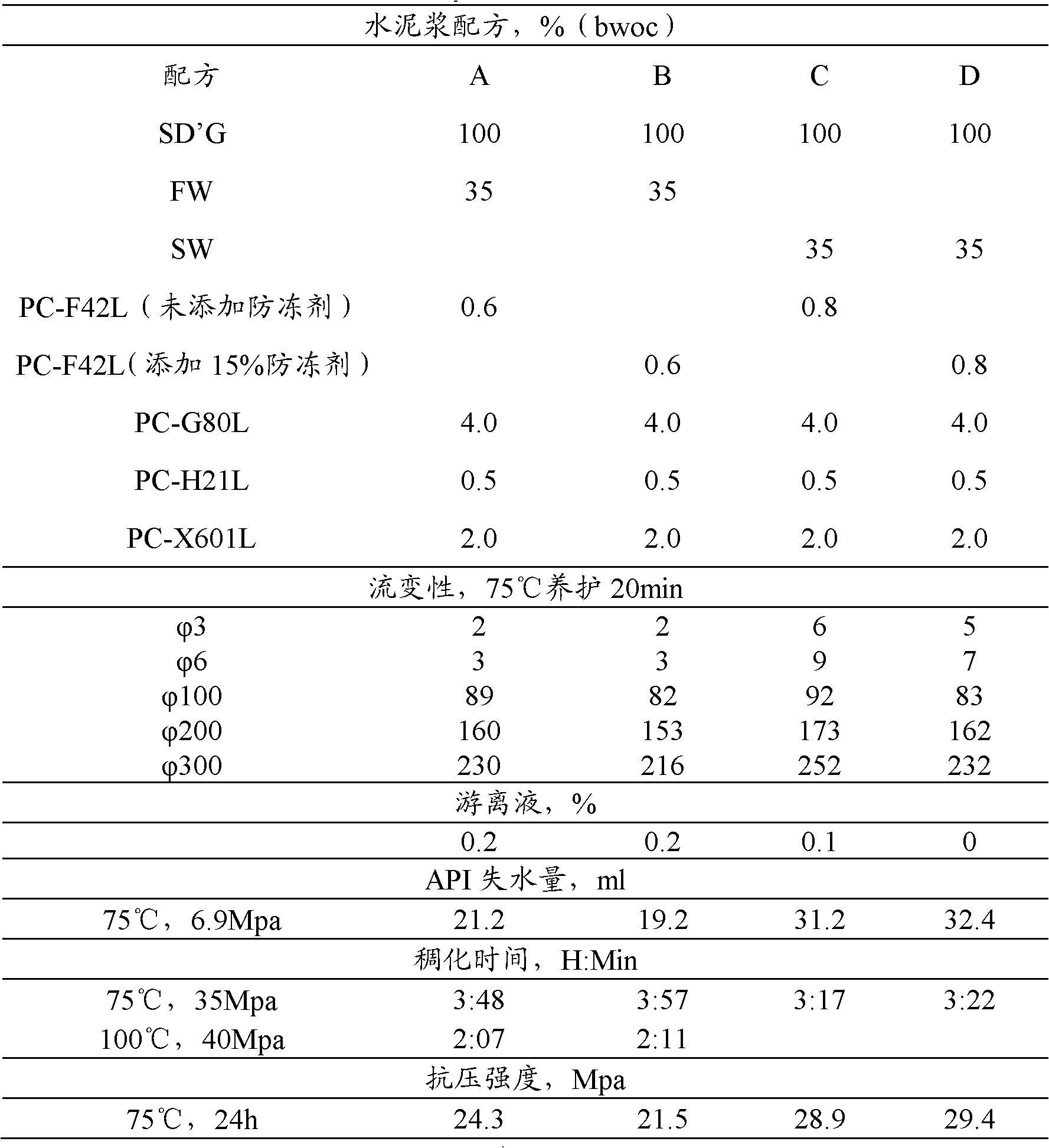

[0030] In the following, the antifreeze prepared in Example 1 was added to the cement admixture water product, and the performance of the antifreeze was evaluated. Cement slurries A, B, C and D were prepared according to the formulations in Table 2.

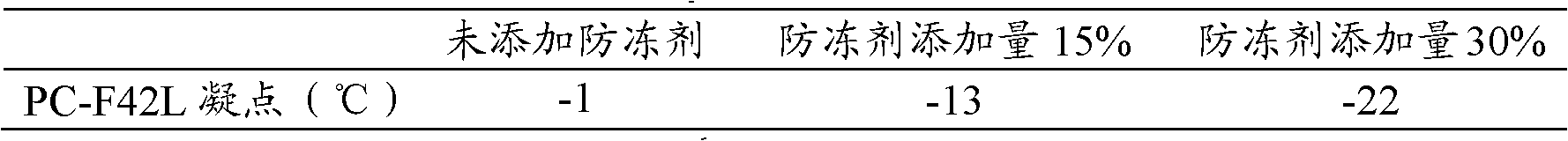

[0031] The main component of cementing cement admixture water agent product: polycarboxylate water reducer PC-F42L for oilfield well cementing (refer to the disclosure in Chinese Patent 201110071969.4), with a solid content of 23%. The amount of antifreeze added is 15% or 30% of the mass of the water solution as required. In Table 1 and Table 2, the freezing point of the water...

Embodiment 2

[0040] Mix each component by following weight parts to prepare antifreeze of the present invention:

[0041] a) ethanol: 60 parts by weight; b) ethylene glycol: 30 parts by weight; c) aqueous solution of sodium nitrite with a solid content of 15%: 10 parts by weight.

[0042] performance evaluation

[0043] In the following, the antifreeze prepared in Example 2 was added to the cement admixture water product to evaluate the performance of the antifreeze. Cement slurries A, B and C were prepared according to the formulations in Table 4.

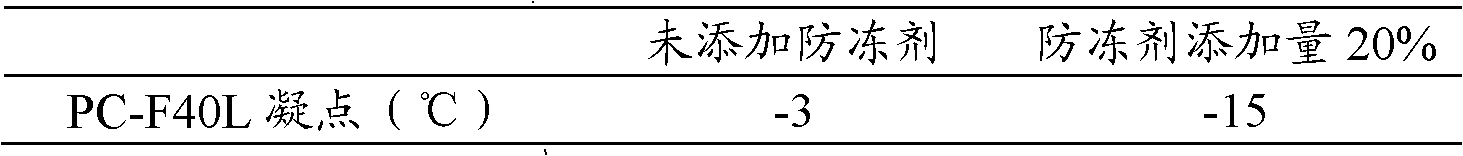

[0044] Cementing cement admixture water agent product main components: PC-F40L sulfonated aldehyde and ketone condensation polymer dispersant for oil field cementing, solid content 33%. The amount of antifreeze added, if necessary, is 20% of the mass of the water-based product. In Table 3 and Table 4, the freezing point of the water-based product and the performance of the cement slurry are shown respectively.

[0045] Table 3 The effect of ...

Embodiment 3

[0053] Mix each component by following weight parts to prepare antifreeze of the present invention:

[0054] a) ethanol: 60 parts by weight; b) ethylene glycol: 40 parts by weight

[0055] performance evaluation

[0056] In the following, the antifreeze prepared in Example 3 was added to the cement admixture water product to evaluate the performance of the antifreeze. Grouts A and B were prepared according to the formulations in Table 6.

[0057] Cementing cement admixture water agent product main components: anti-channeling enhancer PC-GS12L for oil field cementing, solid content 50%. The amount of antifreeze added, if necessary, is 35% of the mass of the water-based product. The freezing point of the water-based product and the properties of the cement slurry are shown in Table 5 and Table 6 below without adding antifreeze and after adding antifreeze, respectively.

[0058] Table 5 Effect of adding antifreeze on PC-GS12L freezing point

[0059]

[0060] It can be see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com