Supercritical carbon dioxide oil-in-oil emulsion thickener and its preparation method and application

A carbon dioxide and oil-in-oil technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high cost, unfavorable storage, transportation and environmental protection, and high dosage, and achieve the effect of low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

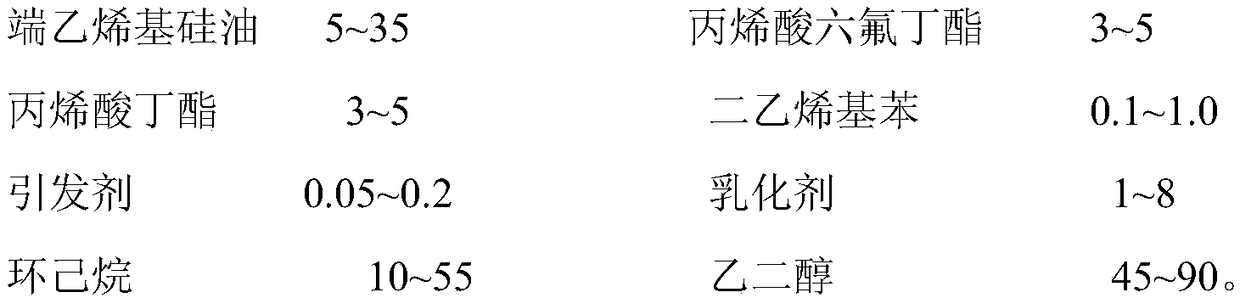

[0037] The method of supercritical carbon dioxide oil-in-oil emulsion thickener of the present invention, adopts the raw material of following weight portion proportioning and carries out as follows:

[0038] a. Take 5 grams of terminal vinyl silicone oil, 5 grams of hexafluorobutyl acrylate, 3 grams of butyl acrylate, 1.0 grams of divinylbenzene, 0.05 grams of azobisisobutyronitrile, 8 grams of fatty acid ester GMS, and 10 grams of cyclohexane gram, 58.5 grams of ethylene glycol, are placed in container, high-speed shearing 25 minutes, get pre-emulsion;

[0039] b. Add the remaining ethylene glycol 31.5 grams and the pre-emulsion of step a 6% amount in a dry three-necked flask provided with a stirrer, a condenser and a dropping funnel, heat up to 50° C. under stirring, and keep warm for 40 minutes;

[0040] c. Add the remaining amount of pre-emulsion dropwise and react for 25 hours;

[0041] d. Cool to room temperature to obtain the product.

Embodiment 2

[0043] The method of supercritical carbon dioxide oil-in-oil emulsion thickener of the present invention, adopts the raw material of following weight portion proportioning and carries out as follows:

[0044] a. Take 35 grams of terminal vinyl silicone oil, 3 grams of hexafluorobutyl acrylate, 5 grams of butyl acrylate, 0.1 grams of divinylbenzene, 0.2 grams of azobisisobutyronitrile, 1 gram of fatty acid ester GMS, and 55 grams of cyclohexane gram, ethylene glycol 67.5 grams, be placed in container, high-speed shearing 35 minutes, get pre-emulsion;

[0045] b. Add the remaining ethylene glycol 22.5 grams and the pre-emulsion of step a step 4% in the dry there-necked flask provided with agitator, condenser and dropping funnel, heat up to 80°C under stirring, and keep warm for 25 minutes;

[0046] c. Add the remaining amount of pre-emulsion dropwise and react for 5 hours;

[0047] d. Cool to room temperature to obtain the product.

[0048] Example: 3:

[0049] The method of ...

Embodiment 4

[0055] The method of supercritical carbon dioxide oil-in-oil emulsion thickener of the present invention, adopts the raw material of following weight portion proportioning and carries out as follows:

[0056]a. Take 35 grams of terminal vinyl silicone oil, 3 grams of hexafluorobutyl acrylate, 5 grams of butyl acrylate, 0.1 grams of divinylbenzene, 0.2 grams of azobisisobutyronitrile, 1 gram of fatty acid ester GMS, and 55 grams of cyclohexane gram, ethylene glycol 33.75 grams, be placed in container, high-speed shearing 35 minutes, get pre-emulsion;

[0057] b. Add remaining 11.25 grams of ethylene glycol and 4% pre-emulsion in step a to a dry three-necked flask equipped with agitator, condenser and dropping funnel, heat up to 80°C under stirring, and keep warm for 25 minutes;

[0058] c. Add the remaining amount of pre-emulsion solution dropwise and react for 5 hours;

[0059] d. Cool to room temperature to obtain the product.

[0060] Embodiment: 5:

[0061] The method of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com