Thickener for surface active agent and detergent composition

A technology of surfactant and thickening agent, applied in the direction of surface active detergent composition, ampholyte/electrically neutral surface active compound, detergent composition, etc., to achieve the effect of excellent foam quality and excellent thickening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16 and comparative example 1~11

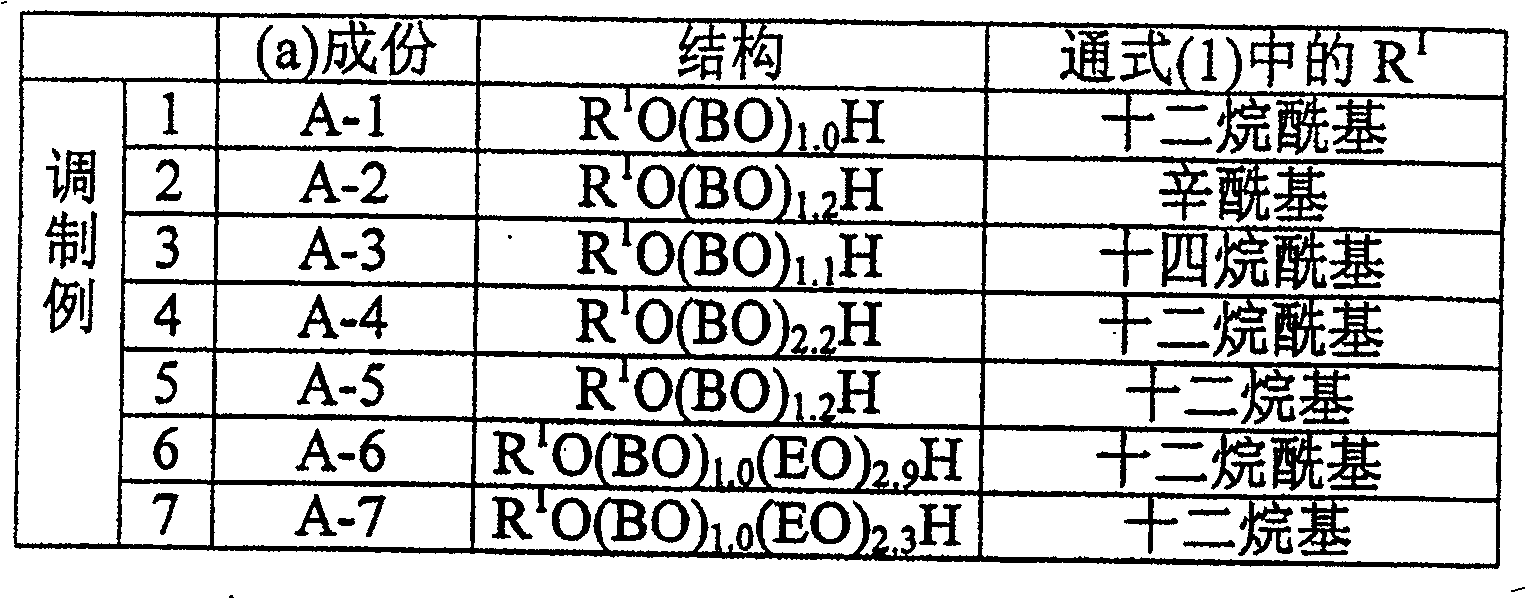

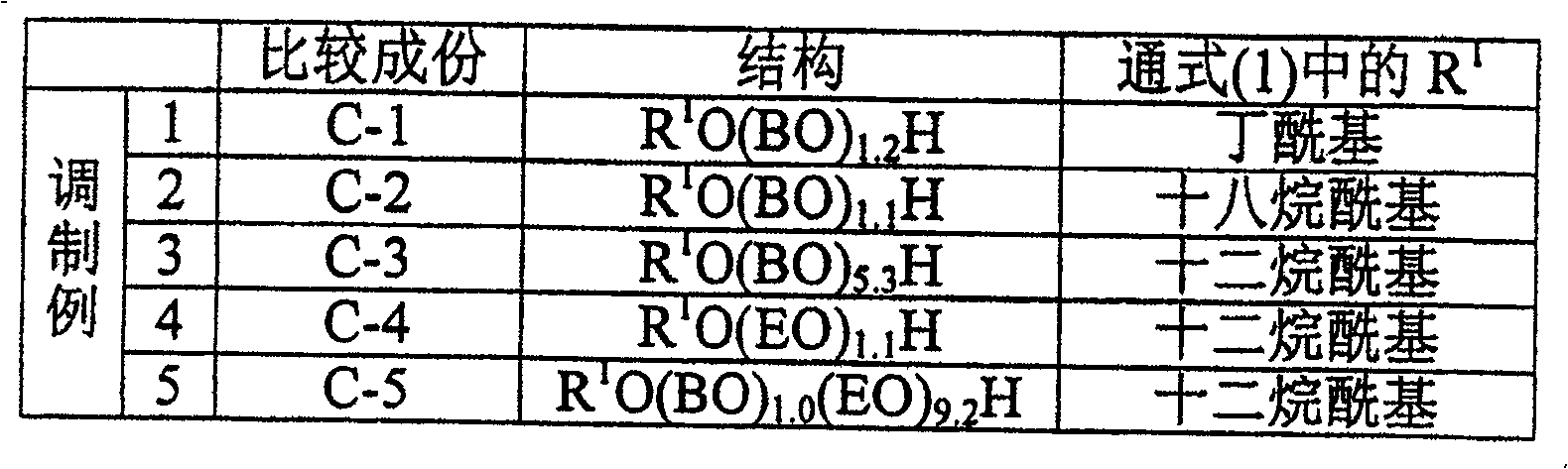

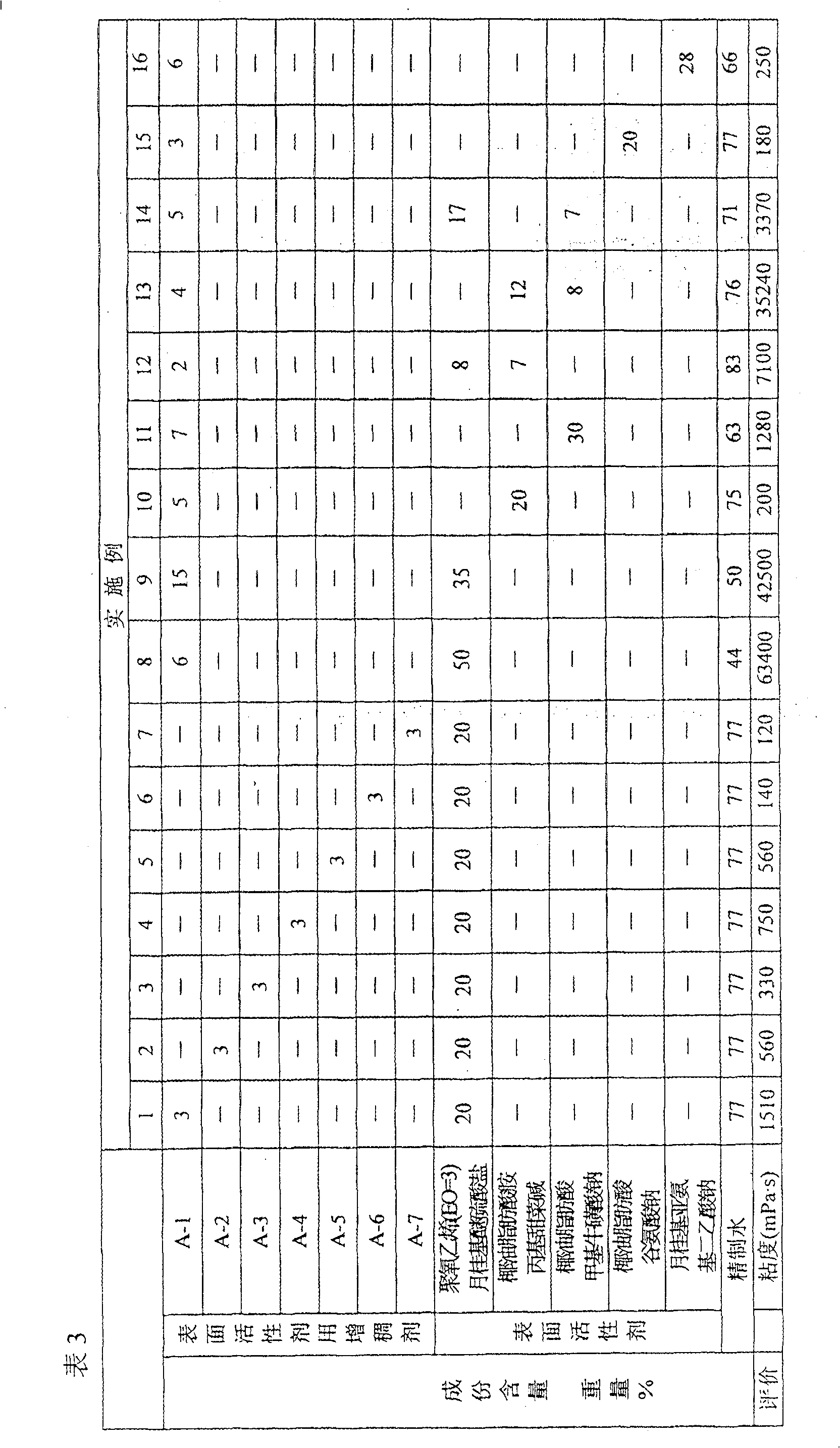

[0062] Mix the thickeners for surfactants (A-1~A-7 and C-1~C-5) shown in Tables 1 and 2 with various surfactants and water according to the ratios shown in Tables 3 and 4 , and the viscosity of the mixture was evaluated by the following method. The evaluation results are shown in Tables 3 and 4.

[0063] (1) Viscosity

[0064] The above-mentioned mixture was kept at 25° C., and the viscosity was measured with a B-type viscometer (manufactured by Tokyo Keiki Seisakusho Co., Ltd.) for a measurement time of 100 seconds.

[0065]

[0066]

[0067] From Table 3, it was confirmed that the thickeners for surfactants (A-1 to A-7) of Examples 1 to 16 had thickening effects on various active agents.

[0068] According to Table 4, it can be seen that in Comparative Example 6, due to the use of R 1 The comparative component C-1 with few carbon atoms in the acyl group has poor thickening effect; in comparative example 7, due to the use of R 1 The comparative component C-2 with ma...

Embodiment 17~32 and comparative example 12~20

[0070] The surfactant shown in Table 1 and 2 is mixed with thickener (a component), surfactant (b component) and water in the ratio shown in Table 5 and Table 6 to obtain a cleanser, use this cleanser, use The foam quality and usability were evaluated by the following methods. The evaluation results are shown in Table 5 and Table 6.

[0071] (2) foam quality

[0072] The foam quality after body cleansing with 5 g of the cleanser composition was evaluated by 10 experts each of men and women. When the bubble is fine and elastic, it is 2 points, when the bubble is slightly loose, it is 1 point, and when the bubble is loose and inelastic, it is 0 point. Based on the total points of 20 experts, it is evaluated by the following three-level method.

[0073] Good foam quality: ○ (a total of more than 30 points);

[0074] Poor bubble quality: △ (more than 20 points in total, less than 30 points);

[0075]Poor foam quality: × (the total points are less than 20 points).

[0076] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com