A kind of hyperbranched copolymer ceramic reinforcing agent and its preparation method and application

A technology of hyperbranched copolymer and hyperbranched polymer, which is applied in the field of ceramic reinforcing agents, can solve the problems of large addition, wide molecular weight distribution of reinforcing agents, unstable performance, etc., and achieve increased green body strength, increased yield, and high performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

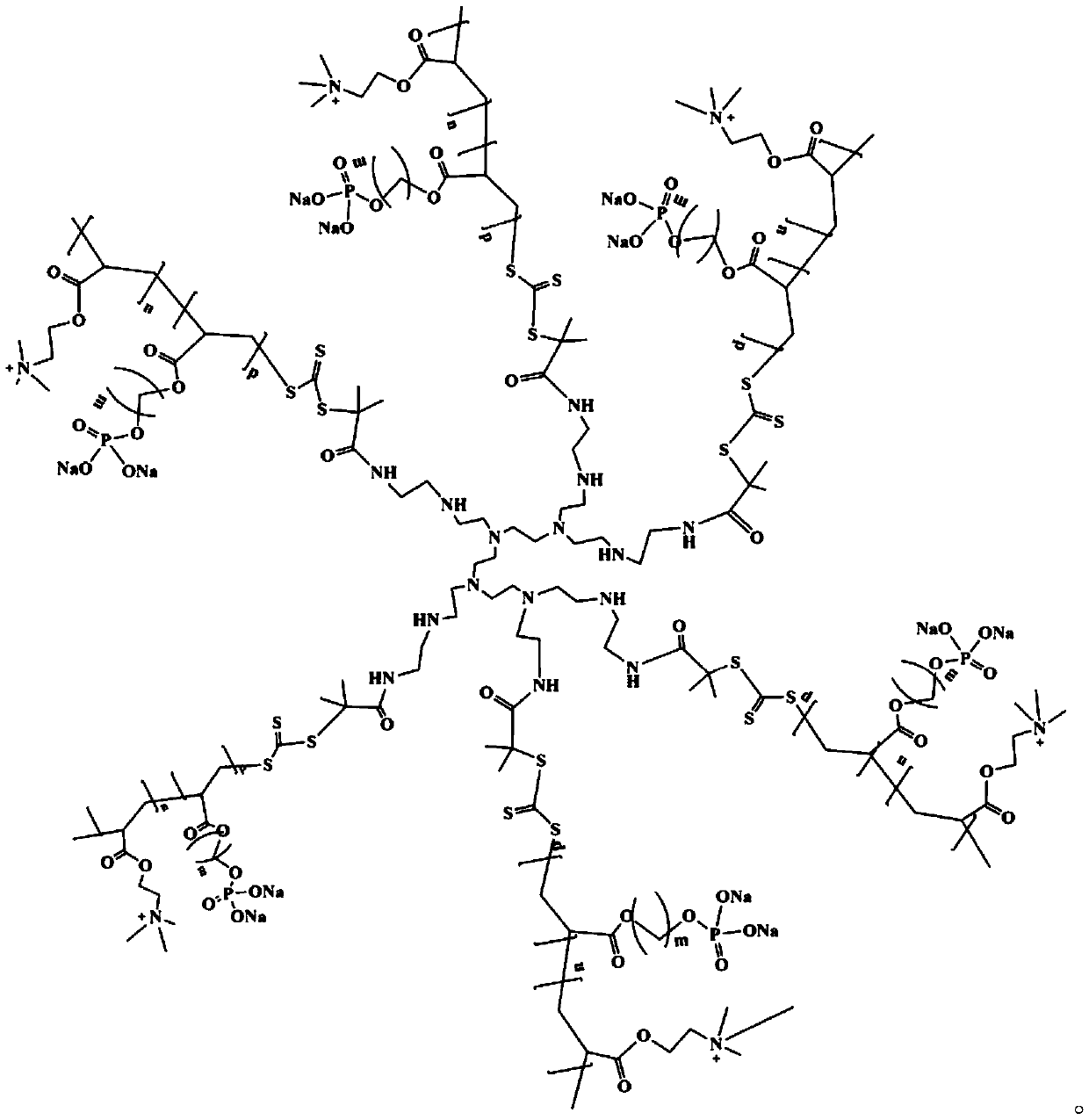

Image

Examples

Embodiment 1

[0022] A kind of hyperbranched copolymer ceramic reinforcing agent of the present invention, its RAFT preparation method is as follows:

[0023] (1) Synthesis of hyperbranched RAFT reagent: 5.6 parts of 2-(methyltrithiocarbonate)-2-methylpropionyl chloride are dissolved in 30 parts of acetone, which is referred to as solution I; 25 parts of hyperbranched poly Put ethyleneimine into the reactor, heat to 40°C under stirring, then add solution I dropwise, after 1h dropwise addition, continue to react at 40°C for 6h, add ammonia solution to precipitate, wash with acetone, and vacuum dry to obtain overspend Chemical RAFT reagents.

[0024] (2) RAFT polymerization: 26 parts of acryloyloxyethoxy sodium phosphate, 5 parts of acryloyloxyethyltrimethylammonium chloride, 3 parts of (1) hyperbranched RAFT reagent, 80 parts of water, 0.5 parts Add sodium phosphate and 0.5 parts of white cubes into the reactor, fully dissolve and mix evenly, then heat to 55°C, add 10 parts of 7.5% hydrogen...

Embodiment 2

[0027] A kind of hyperbranched copolymer ceramic reinforcing agent of the present invention, its RAFT preparation method is as follows:

[0028] (1) Synthesis of hyperbranched RAFT reagent: 6.2 parts of 2-(propyltrithiocarbonate)-2-methylpropionyl chloride are dissolved in 25 parts of butanone, which is referred to as solution I; 14 parts of hyperbranched Put polyethyleneimine into the reactor, heat to 55°C under stirring, then add solution I dropwise, after 0.5h dropwise addition, continue to react at 55°C for 5h, add ammonia solution to precipitate, wash with methyl ethyl ketone, and vacuum dry Afterwards, the hyperbranched RAFT reagent is obtained.

[0029] (2) RAFT polymerization: 24 parts of acryloyloxypropoxy sodium phosphate, 5.3 parts of acryloyloxyethyltrimethylammonium bromide, 2 parts of (1) hyperbranched RAFT reagent, 65 parts of water, 1.5 parts of Add sodium bisulfate into the reactor, fully dissolve and mix evenly, then heat to 65°C, add 9 parts of 6% ammonium ...

Embodiment 3

[0032] A kind of hyperbranched copolymer ceramic reinforcing agent of the present invention, its RAFT preparation method is as follows:

[0033] (1) Synthesis of hyperbranched RAFT reagent: 7 parts of 2-(propyltrithiocarbonate)-2-methylpropionyl chloride are dissolved in 37 parts of butyl acetate, which is referred to as solution I; 22 parts of hyperbranched Put polyethyleneimine into the reactor, heat it to 60°C under stirring, then add solution I dropwise, after 1h dropwise addition, continue to react at 60°C for 4.5h, add ammonia solution to precipitate, wash with butyl acetate, The hyperbranched RAFT reagent is obtained after vacuum drying.

[0034] (2) RAFT polymerization: 28 parts of sodium methacryloyloxybutoxy phosphate, 8 parts of methacryloyloxyethyltrimethylammonium chloride, 4 parts of hyperbranched RAFT reagent in (1), 80 parts of water 1.3 parts of ferrous sulfate were added to the reactor, fully dissolved and mixed evenly, then heated to 50°C, and 11 parts of 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com