Treating method and system for tungsten smelting waste gas

A treatment method and exhaust gas technology, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of large alkali consumption, high cost, high energy consumption, etc., and achieve the effect of efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Using Nessler's reagent spectrophotometry (HJ535-2009) to determine the concentration of ammonia before tungsten smelting waste gas treatment is 200mg / m 3 , Using ion chromatography (HJ549-2009) to determine the concentration of hydrogen sulfide before tungsten smelting waste gas treatment is 10mg / m 3 .

[0042] This embodiment provides a method for treating waste gas from tungsten smelting, including:

[0043] S1. The waste gas from tungsten smelting is subjected to a heat exchange and cooling treatment, and the temperature of the heat exchange outlet water is controlled to be ≤45°C to obtain a condensed ammonia and waste gas.

[0044] S2. The primary condensed ammonia and waste gas obtained from S1 are sprayed with tap water circulation to obtain sulfur-containing ammonia and waste gas. When the free ammonia (NH 3 When the concentration of) reaches 50g / L, add hydrogen peroxide gradually and take samples for testing. When S 2- When the concentration is 0g / L, stop adding hydrog...

Embodiment 2

[0051] Using Nessler's reagent spectrophotometry (HJ535-2009) to determine the concentration of ammonia before exhaust gas treatment is 200mg / m 3 , Using ion chromatography (HJ549-2009) to determine the concentration of hydrogen sulfide before exhaust gas treatment is 10mg / m 3 .

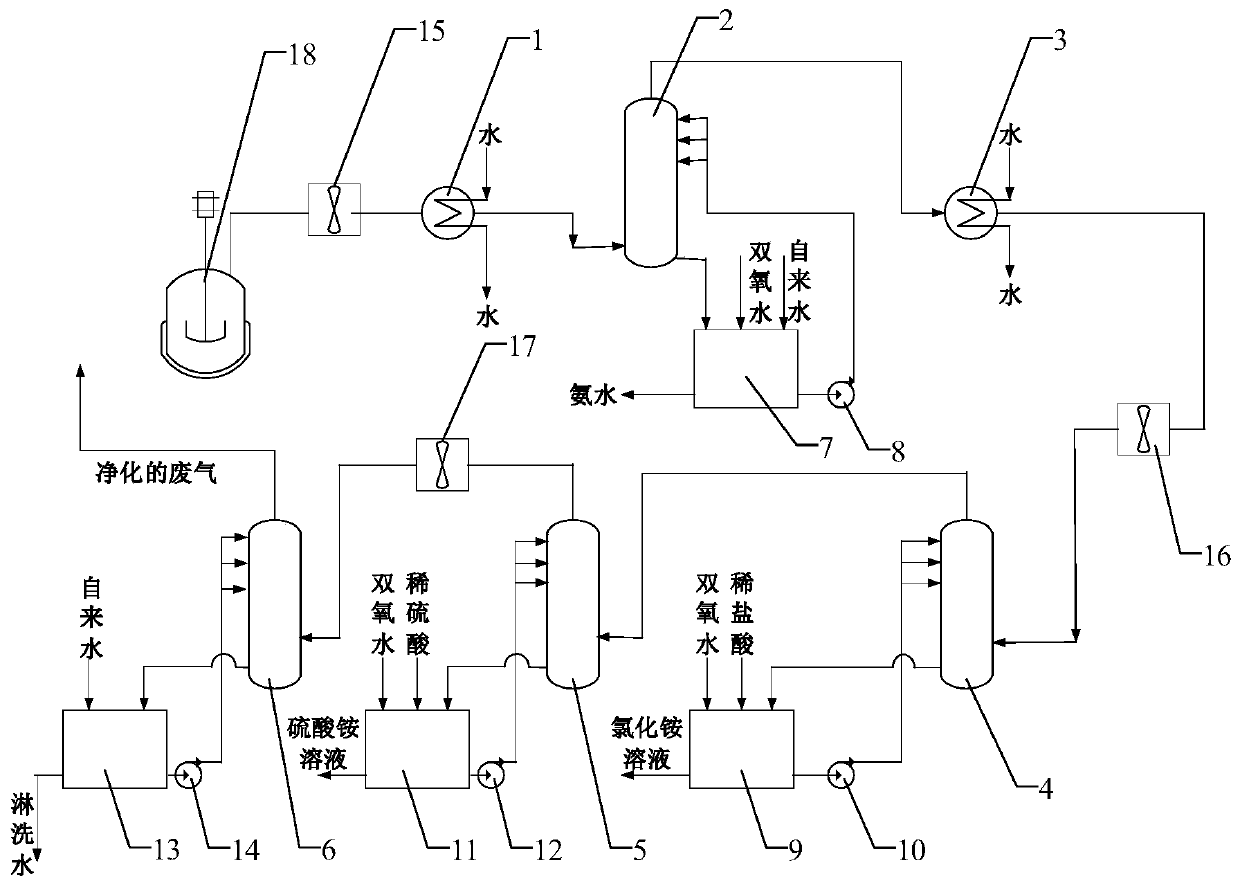

[0052] This embodiment provides a tungsten smelting waste gas treatment system, which includes a first heat exchanger 1, a first leaching tower 2, a second heat exchanger 3, and a The second leaching tower 4, the third leaching tower 5, and the fourth leaching tower 6, the first fan 15 is connected to the gas inlet of the first heat exchanger 1, and the second fan 16 is connected to the second heat exchanger 3 and the Between the two leaching towers 4, the third fan 17 is connected between the third leaching tower 5 and the fourth leaching tower 6. Among them, the leaching tower is equipped with an elution tank and a leaching pump, the first leaching tower 2 is equipped with an eluting tank 7 and a leac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com