Multifunctional liquid dressing and preparation method thereof

A liquid dressing and multi-functional technology, applied in the field of medical accessories, can solve the problems of easy water ingress at the wound dressing, affecting the recovery effect, aggravating the condition, etc. The effect of wound infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

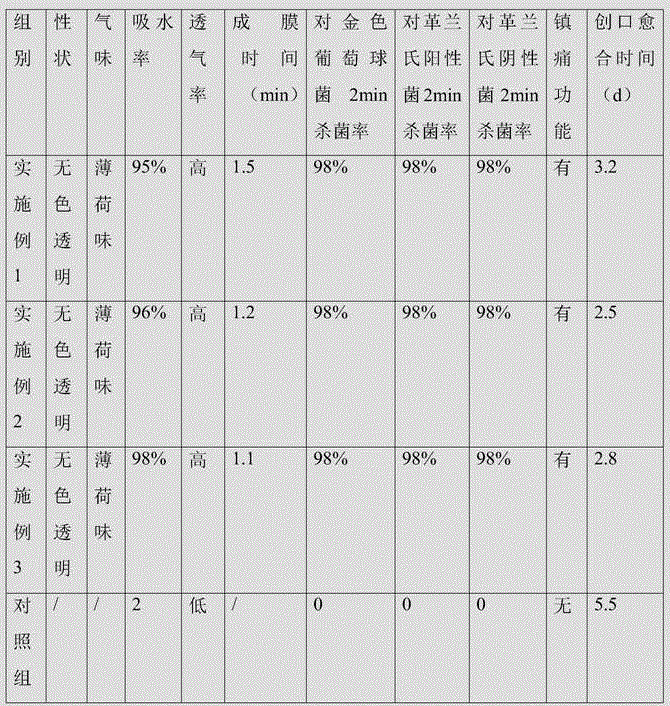

Examples

Embodiment 1

[0023] The multifunctional liquid dressing, in parts by mass, consists of 2-8 parts of polyvinyl butyral, 0.5-0.8 parts of sodium alginate-polyvinylpyrrolidone, 0.2-0.6 parts of nano-silver-chitosan, carboxymethyl 0.1-0.4 parts of sodium cellulose, 0.1-0.4 parts of carrageenan, 0.1-0.4 parts of menthol and 91-97 parts of absolute ethanol.

[0024] In this embodiment, the mass ratio of sodium alginate to polyvinylpyrrolidone in the sodium alginate-polyvinylpyrrolidone is 1:3.

[0025] In this embodiment, the model of the polyvinyl butyral has a viscosity of 260CP, and the specification of the polyvinylpyrrolidone is K22.

[0026] In the present embodiment, in parts by mass, the components are 4 parts of polyvinyl butyral, 0.5 part of sodium alginate-polyvinylpyrrolidone, 0.4 part of nano-silver-chitosan, 0.1 part of sodium carboxymethyl cellulose, 0.1 part of carrageenan, 0.1 part of menthol and 94.8 parts of absolute ethanol.

[0027] The preparation method of multifunctiona...

Embodiment 2

[0034] The multifunctional liquid dressing, in parts by mass, consists of 2-8 parts of polyvinyl butyral, 0.5-0.8 parts of sodium alginate-polyvinylpyrrolidone, 0.2-0.6 parts of nano-silver-chitosan, carboxymethyl 0.1-0.4 parts of sodium cellulose, 0.1-0.4 parts of carrageenan, 0.1-0.4 parts of menthol and 91-97 parts of absolute ethanol.

[0035] In this embodiment, the mass ratio of sodium alginate to polyvinylpyrrolidone in the sodium alginate-polyvinylpyrrolidone is 1:3.

[0036] In this embodiment, the model of the polyvinyl butyral has a viscosity of 270CP, and the specification of the polyvinylpyrrolidone is K24.

[0037] In this example, by mass parts, the components are 6 parts of polyvinyl butyral, 0.6 part of sodium alginate-polyvinylpyrrolidone, 0.5 part of nano-silver-chitosan, 0.1 part of sodium carboxymethylcellulose, 0.1 part of carrageenan, 0.1 part of menthol and 92.6 parts of absolute ethanol.

[0038] The preparation method of multifunctional liquid dress...

Embodiment 3

[0045] The multifunctional liquid dressing, in parts by mass, consists of 2-8 parts of polyvinyl butyral, 0.5-0.8 parts of sodium alginate-polyvinylpyrrolidone, 0.2-0.6 parts of nano-silver-chitosan, carboxymethyl 0.1-0.4 parts of sodium cellulose, 0.1-0.4 parts of carrageenan, 0.1-0.4 parts of menthol and 91-97 parts of absolute ethanol.

[0046] In this embodiment, the mass ratio of sodium alginate to polyvinylpyrrolidone in the sodium alginate-polyvinylpyrrolidone is 1:3.

[0047] In this embodiment, the model of the polyvinyl butyral has a viscosity of 280CP, and the specification of the polyvinylpyrrolidone is K25.

[0048] In this example, by mass parts, the components are 6 parts of polyvinyl butyral, 0.6 part of sodium alginate-polyvinylpyrrolidone, 0.5 part of nano-silver-chitosan, 0.1 part of sodium carboxymethylcellulose, 0.1 part of carrageenan, 0.1 part of menthol and 92.6 parts of absolute ethanol.

[0049] The preparation method of multifunctional liquid dress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com