Composite adhesive specially for heat insulating polystyrene outer-wall board

A technology of external thermal insulation of external walls and polystyrene, applied in the direction of inorganic adhesives, hydrocarbon copolymer adhesives, adhesives, etc., can solve problems such as high cost, shortened service life of adhesives, and aging of adhesives , to achieve the effect of increasing the hardness, improving the bonding performance, and increasing the strength of the adhesive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 1. Preparation of 30% silica sol

[0062] Dilute water glass to prepare 15% NaSiO 3The aqueous solution is pressurized to pass through the cation exchange resin, the pH value is controlled below 5.5, and then passed through the anion exchange resin to adjust the pH value between 8-10, and the NaSiO 3 The aqueous solution is heated to 80°C, filtered and evaporated, and when the density is 1.18-1.20 as measured by a density meter, a 30% white silica sol can be obtained.

[0063] 2. Preparation of Silicone Modified Styrene-Acrylic Polymer Emulsion

[0064] (1) Prepare raw materials with the following weights:

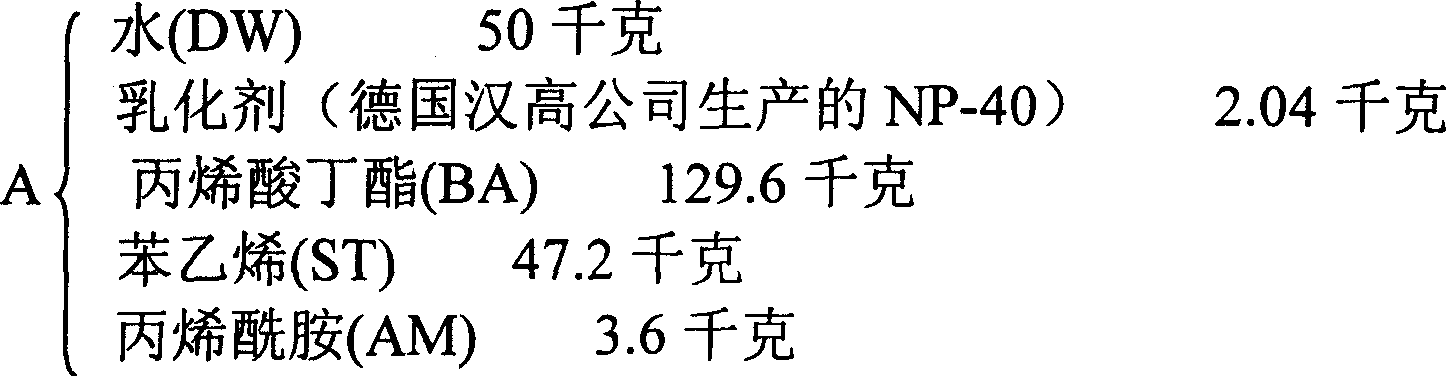

[0065] 1. Pre-emulsion

[0066]

[0067]

[0068] Second, the kettle material

[0069]

[0070] Three, the initial initiator

[0071]

[0072] 4. Dropping the initiator

[0073]

[0074] 5. Post-elimination of oxidants

[0075]

[0076] 6. Post-elimination reducing agent

[0077]

Embodiment 2

[0098] 1. Preparation of 30% silica sol

[0099] Concrete preparation method is with embodiment 1.

[0100] 2. Preparation of Silicone Modified Styrene-Acrylic Polymer Emulsion

[0101] (1) Prepare raw materials with the following weights:

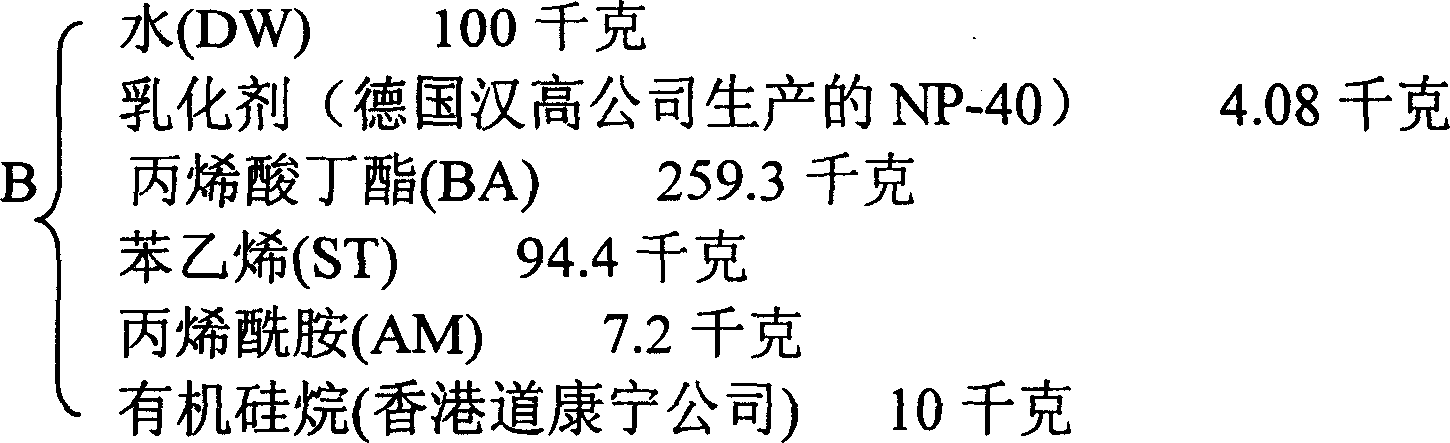

[0102] 1. Pre-emulsion

[0103]

[0104]

[0105] Second, the kettle material

[0106]

[0107] Three, the initial initiator

[0108]

[0109] 4. Dropping the initiator

[0110]

[0111] 5. Post-elimination of oxidants

[0112]

[0113] 6. Post-elimination reducing agent

[0114]

[0115] 7. Ammonium hydroxide (NH 4 OH) about 4S PH=7.5-8.0

[0116] (2) Specific production process

[0117] Concrete production technology is with embodiment 1.

[0118] (3) Preparation of binder

[0119] Weigh according to the following parts by weight:

[0120]

[0121]

[0122] After stirring the above-mentioned component A for half an hour, add component B sequentially under the stirring state, and after dispersing for...

Embodiment 3

[0125] 1. Preparation of 30% silica sol

[0126] Concrete preparation method is with embodiment 1.

[0127] 2. Preparation of Silicone Modified Styrene-Acrylic Polymer Emulsion

[0128] (1) Prepare raw materials with the following weights:

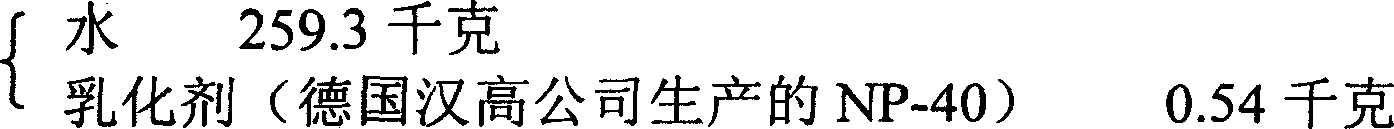

[0129] 1. Pre-emulsion

[0130]

[0131]

[0132] Second, the kettle material

[0133]

[0134] Three, the initial initiator

[0135]

[0136] 4. Dropping the initiator

[0137]

[0138] 5. Post-elimination of oxidants

[0139]

[0140] 6. Post-elimination reducing agent

[0141]

[0142] 7. Ammonium hydroxide (NH 4 OH) about 4S PH=7.5-8.0

[0143] (2) Concrete production process Concrete production process is the same as embodiment 1.

[0144] (3) Preparation of binder

[0145] Weigh according to the following parts by weight:

[0146]

[0147]

[0148] After stirring the above-mentioned component A for half an hour, add component B sequentially under the stirring state, and after dispersing for 20 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com