Production method of direct scraping and penetrating adhesive mortar for concrete surface

A technology of concrete surface and production method, applied in the field of building materials, can solve the problems of high requirement of mortar ratio, difficulty, peeling and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

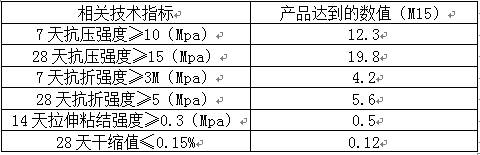

Examples

Embodiment 1

[0061] The production method of direct-scraping and penetrating adhesive mortar for concrete surface layer comprises the following raw materials in parts by weight: 58 parts of limestone machine-made sand, 30 parts of pure portland cement, 2 parts of composite coupling agent, and 10 parts of fly ash. 0.3 part of dispersed latex powder, 0.1 part of methyl cellulose ether, 0.02 part of potato starch ether, 0.01 part of polypropylene anti-cracking fiber, 0.05 part of melamine-based water reducer, and 0.1 part of osmotic crystallization masterbatch;

[0062] The production method of direct-scraping and penetrating adhesive mortar for concrete surface layer comprises the following steps:

[0063] First, the limestone machine-made sand is used as the aggregate, and the cement is used as the cementitious material. The fineness modulus of the sand aggregate is between 1.5 and 1.8. Dispersed latex powder, cellulose ether, starch ether, crack-resistant fiber, melamine-based water reduce...

Embodiment 2

[0065] The production method of direct-scraping and penetrating adhesive mortar for concrete surface layer comprises the following raw materials in parts by weight: 62 parts of limestone machine-made sand, 28 parts of pure Portland cement, 3 parts of composite coupling agent, and 7 parts of fly ash, which can be 0.4 part of dispersed latex powder, 0.2 part of hydroxyethyl cellulose ether, 0.03 part of corn starch ether, 0.02 part of polyacrylonitrile crack-resistant fiber, 0.1 part of melamine-based water reducer, and 0.2 part of osmotic crystallization masterbatch.

[0066] The production method of direct-scraping and penetrating adhesive mortar for concrete surface layer comprises the following steps:

[0067] First, the limestone machine-made sand is used as the aggregate, and the cement is used as the cementitious material. The fineness modulus of the sand aggregate is between 1.5 and 1.8. Dispersed latex powder, cellulose ether, starch ether, crack-resistant fiber, melami...

Embodiment 3

[0069] The production method of direct-scraping and penetrating adhesive mortar for concrete surface layer comprises the following raw materials in parts by weight: 65 parts of limestone machine-made sand, 22 parts of pure Portland cement, 4 parts of composite coupling agent, and 9 parts of fly ash. 0.5 part of dispersed latex powder, 0.3 part of hydroxypropyl methylcellulose ether, 0.04 part of starch ether, 0.03 part of polyester anti-cracking fiber, 0.15 part of melamine-based water reducer, and 0.3 part of osmotic crystallization masterbatch.

[0070] The production method of direct-scraping and penetrating adhesive mortar for concrete surface layer comprises the following steps:

[0071] First, the limestone machine-made sand is used as the aggregate, and the cement is used as the cementitious material. The fineness modulus of the sand aggregate is between 1.5 and 1.8. Dispersed latex powder, cellulose ether, starch ether, crack-resistant fiber, melamine-based water reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com