Bias application for capacitive micromachined ultrasonic transducers

A technology of capacitive micromachines and ultrasonic transducers, which can be used in directions such as fluids that utilize vibrations, and can solve problems such as damaging bias source circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

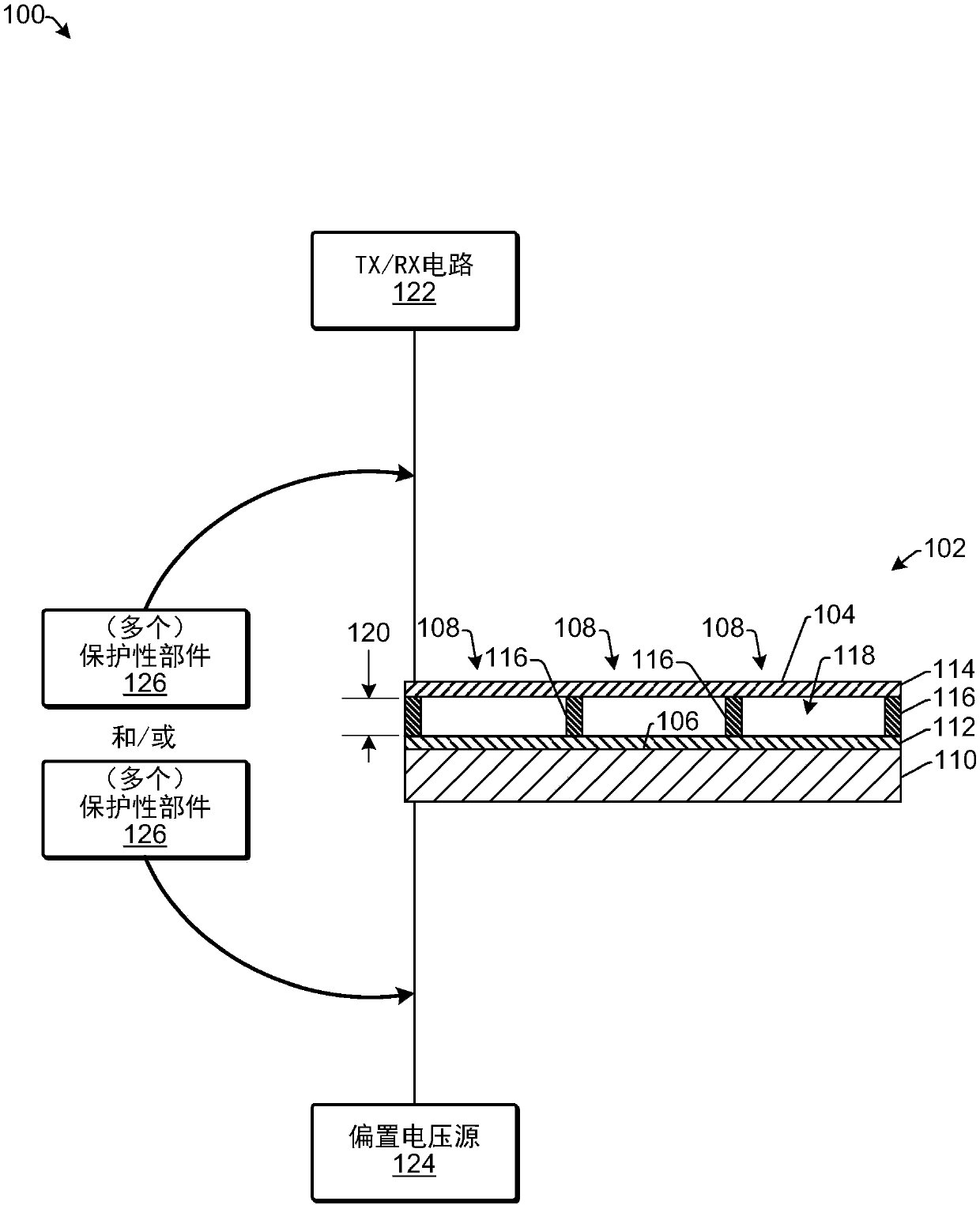

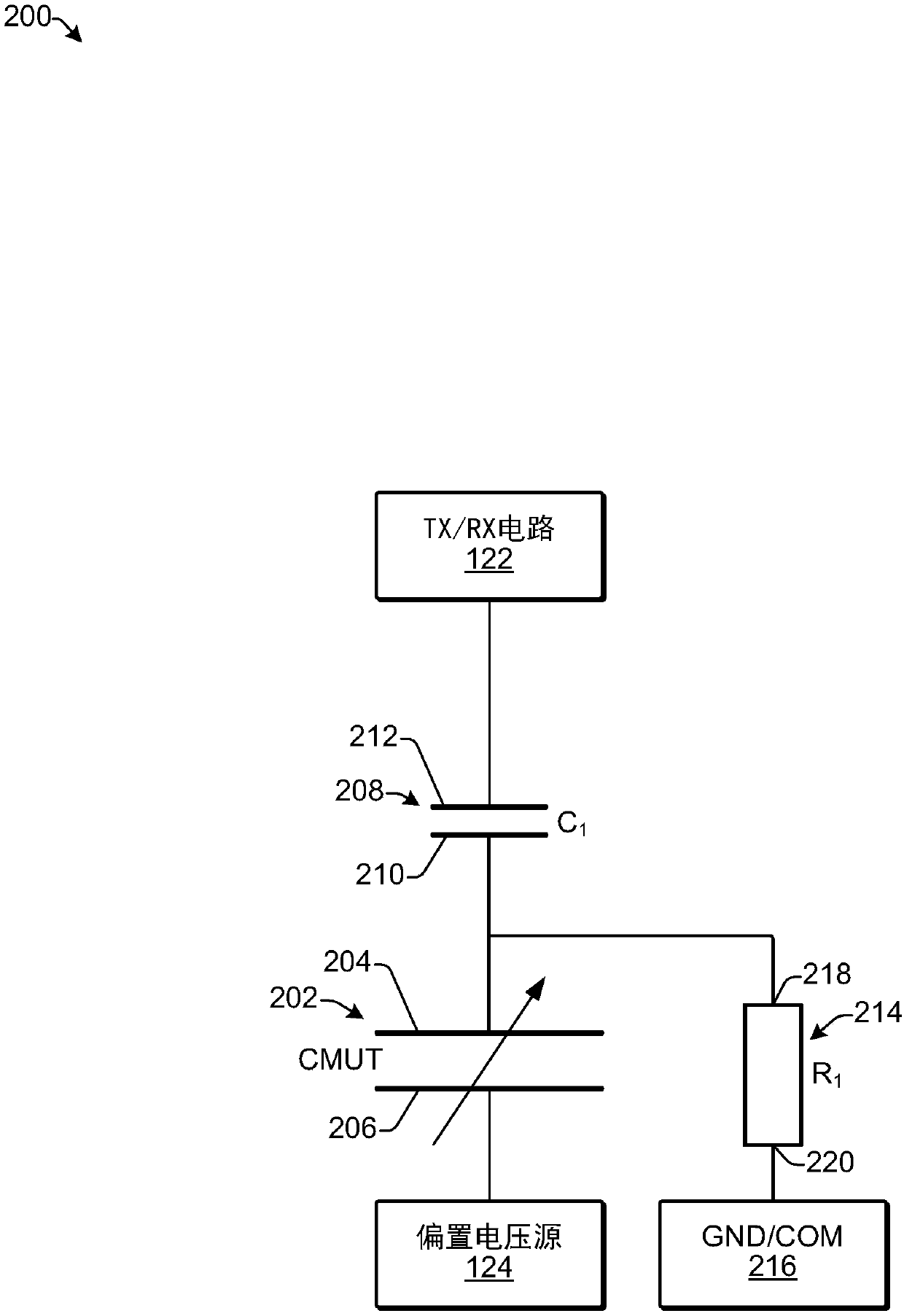

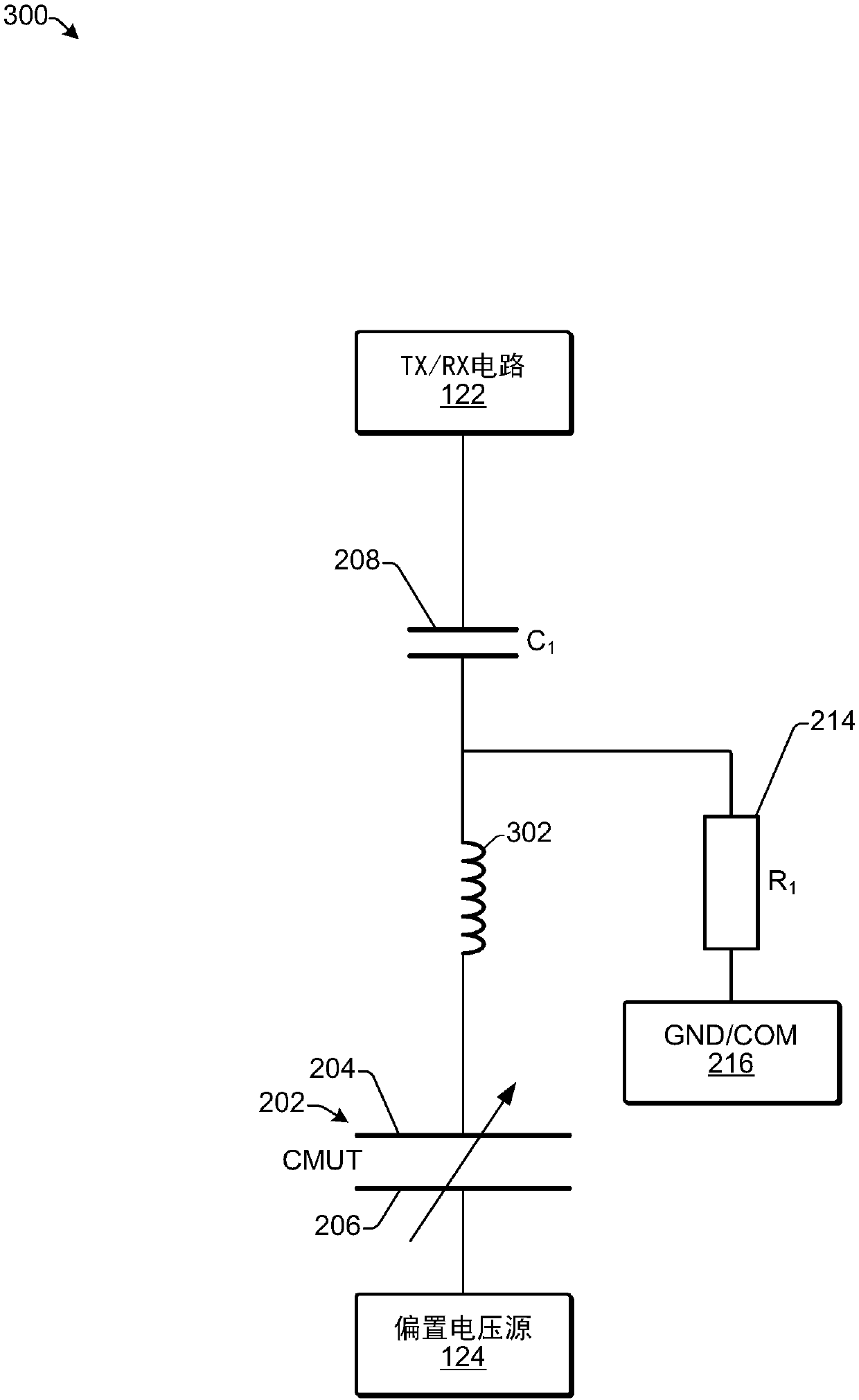

[0025] Some embodiments include techniques and arrangements for applying a bias voltage to a CMUT. Examples of CMUTs to which a bias voltage may be applied include: a CMUT element or subelement in a CMUT array, one or more CMUT cells in a CMUT system, and / or any other type of CMUT configuration. Herein the CMUT may comprise a first electrode opposite to a second electrode, wherein there is a transducing gap between the two electrodes. At least one of the electrodes is movable towards and away from the other for generating and / or receiving ultrasound energy. Transmit and / or receive (TX / RX) circuitry may be directly or indirectly electrically connected to one of the electrodes, and a bias voltage source may be directly or indirectly electrically connected to the other electrode (i.e., via or without any other electronic components).

[0026] In embodiments herein, one or more protective components may be included in the circuit between at least one of the electrodes and at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com