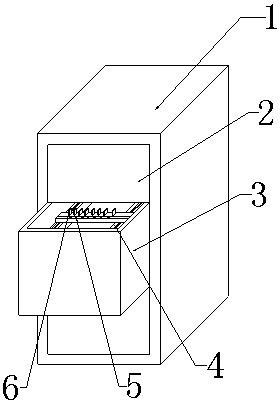

Integrated tester for LED driving power supply

A technology of LED drive and comprehensive tester, which is applied in the direction of power supply testing, etc., can solve problems such as poor stability of LED drive power supply and joints, insufficient safety of LED drive power supply tester, and influence on test results, so as to improve stability and improve Good stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

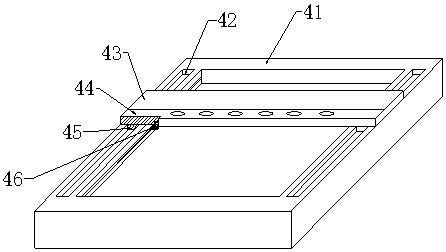

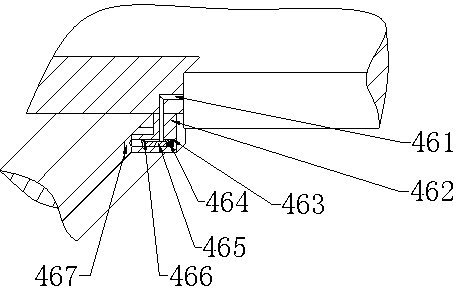

[0029] The specific embodiment: when the staff uses the present invention to test the LED drive power supply, the test box 3 is pulled out, and the display light on the mobile board 2 44 is checked. If the display light is not bright, then the LED drive power supply connection test is carried out, and the staff Push the splint 63 by hand to move the splint 63, and the movement of the splint 63 drives the moving block 62 to move inside the cavity 61, so that the spring 3 64 produces elastic deformation. When the distance between the splints 63 is appropriate, the staff will drive the LED power supply Placed between the splints 63, and release the splint 63, the splint 63 is closely attached to the LED drive power under the elastic force of the spring 3 64 to restore the deformation, thereby fixing the LED drive power, this design improves the stability of the LED drive power .

[0030] Then the staff holds the wiring of the LED drive power supply, connects the connector to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com