A dynamic scheduling optimization method for flexible job shop insertion orders

A flexible operation and dynamic scheduling technology, which is applied to combustion engines, control/regulation systems, internal combustion piston engines, etc., can solve the problems of increased delays and lack of reasonableness, and achieve the effect of reducing delays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

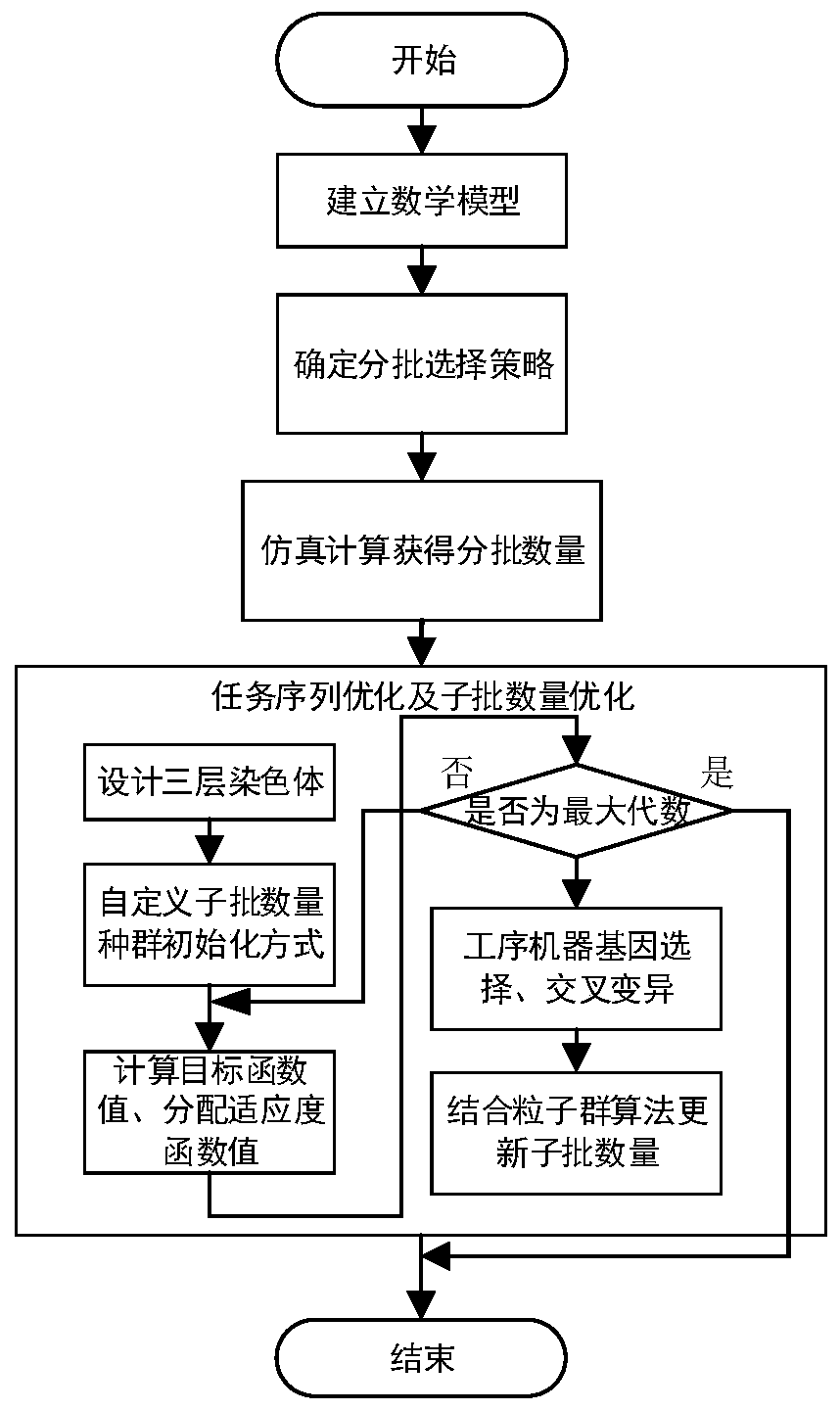

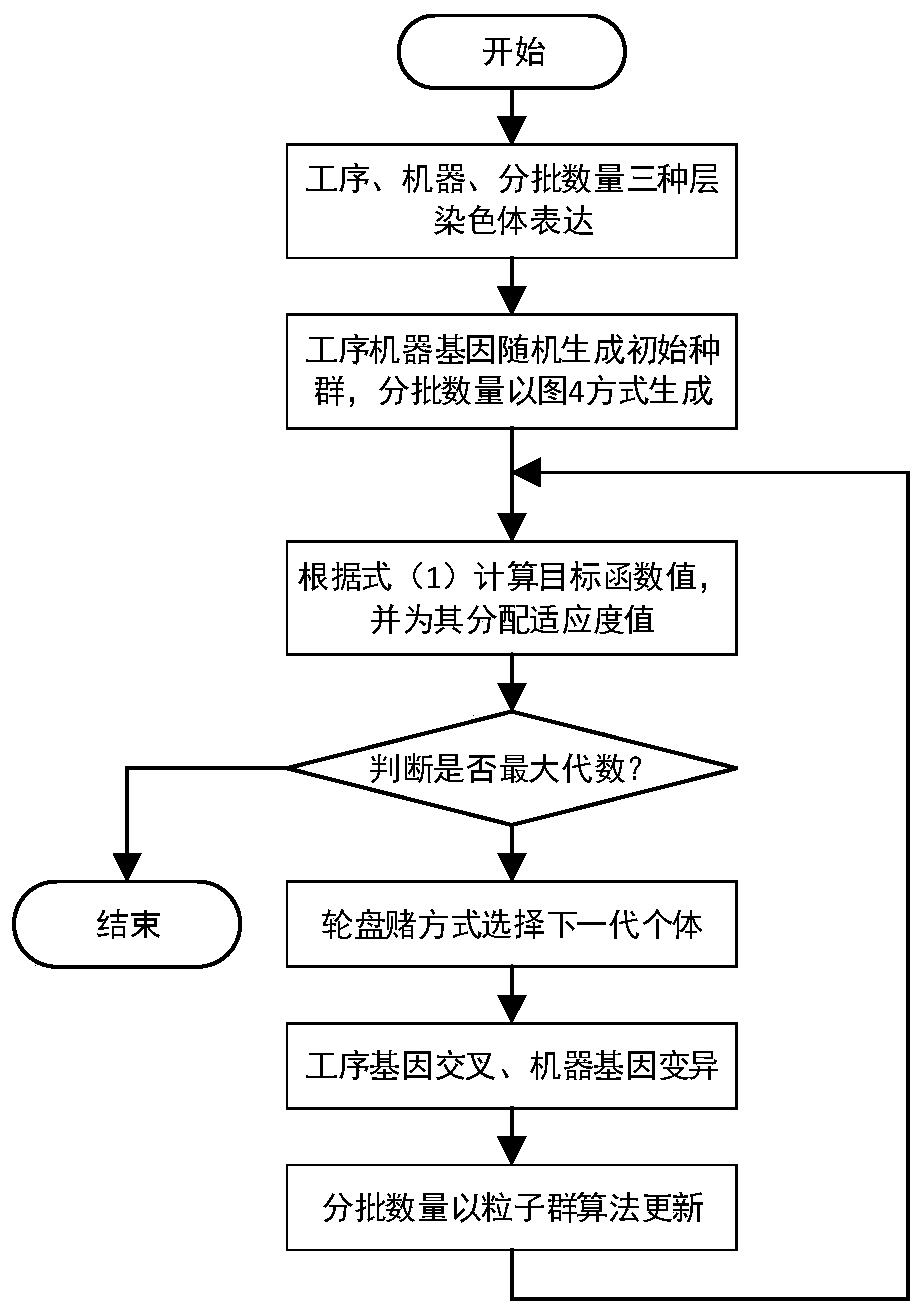

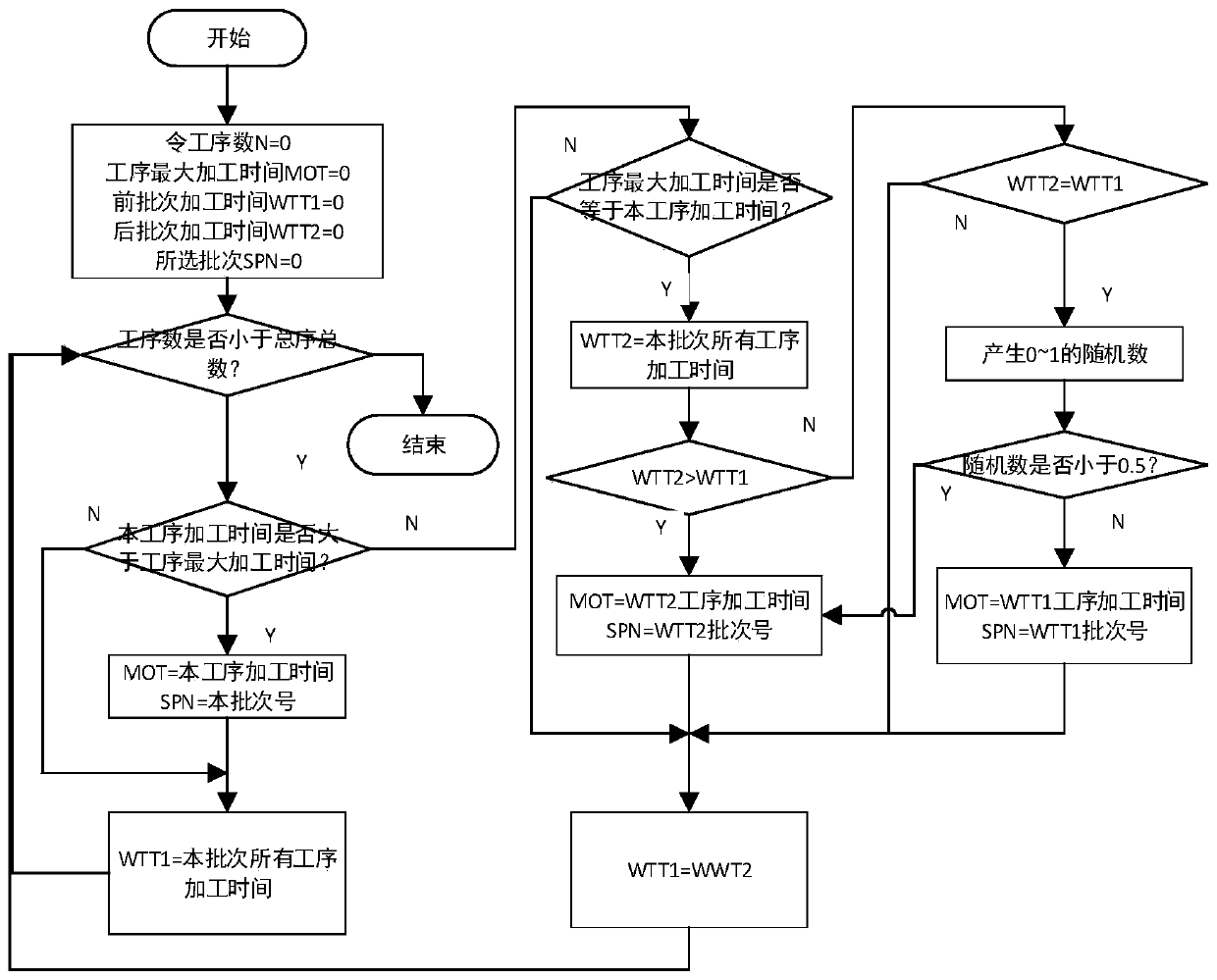

Method used

Image

Examples

Embodiment

[0065] Taking 10 batches of workpieces, 4 machine tools and 2 processes in an aerospace structural parts factory as an example, the feasibility and effectiveness of the above algorithm are verified. Table 2 shows a set of tasks with a batch size of 3. The date of order start processing is 2016 / 11 / 07. The delivery period of each batch is shown in Table 2. At the same time, in order to meet the actual production situation, this patent considers cutting tools and logistics transportation constraints.

[0066] Table 1 Implementation example process processing time

[0067]

[0068] specific operation

[0069] First of all, according to the example, the mathematical model of the example is established according to the formula (1)-(8)

[0070] The objective function is: minf=xf 1 +(1-x)f 2

[0071] f 1 =maxT i ,i=1,2,...,8

[0072]

[0073] constraint equation

[0074] When X ijk =X i(j-1)k' =1,k=k'

[0075] When X ijk =X i(j-1)k' =1,k≠k'

[0076] When X ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com