A dieless spinning method for non-axisymmetric thin-walled shell parts

A non-axisymmetric, dieless spinning technology is applied in the field of non-axisymmetric thin-walled shell parts in the field of dieless spinning, which can solve the problems of high processing cost, low processing quality of parts, and high processing cost of parts. Achieve the effect of reducing processing costs, small batches of products, and ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

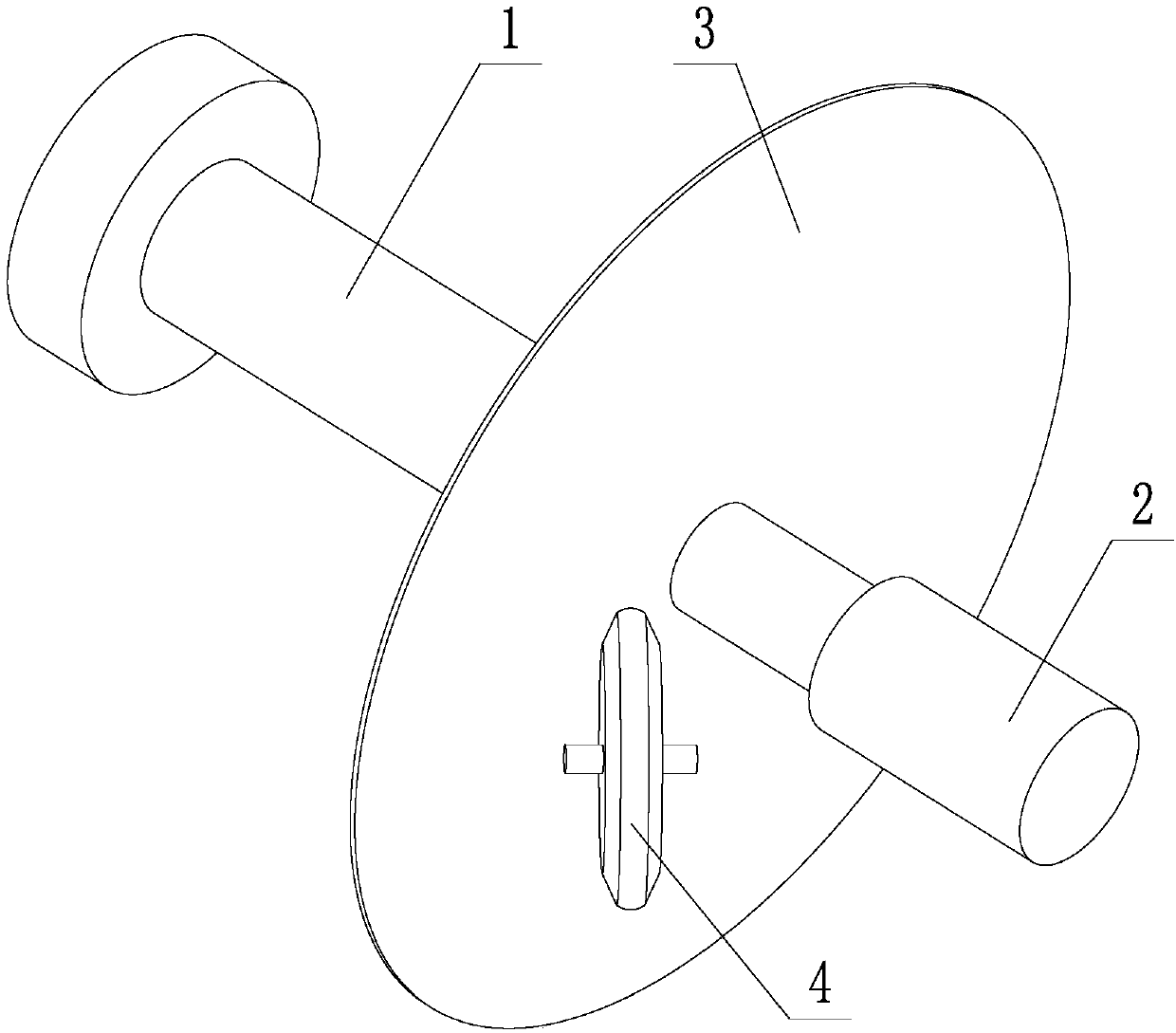

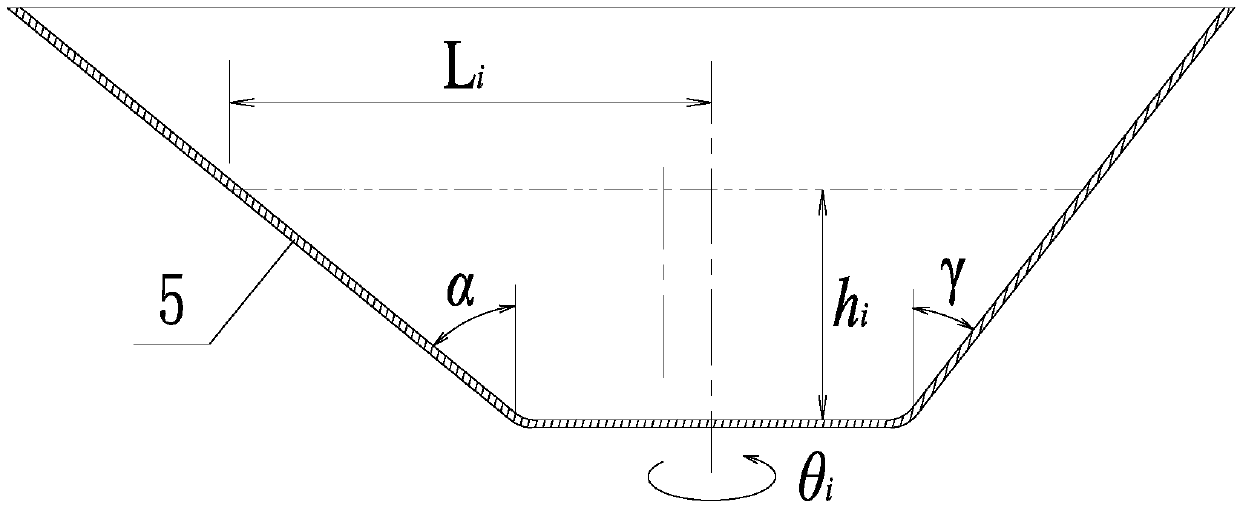

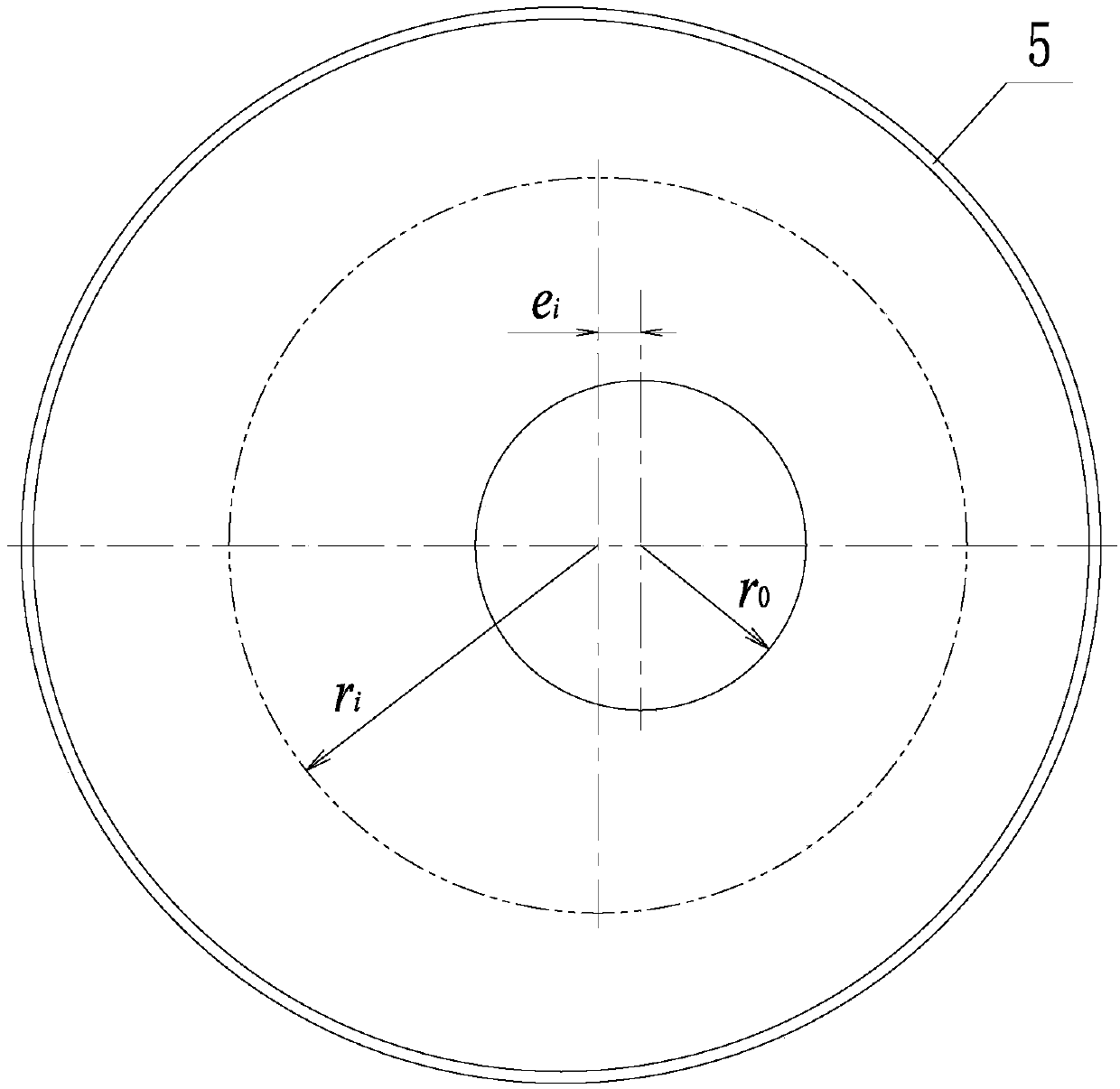

[0021] In this embodiment, the model of the CNC spinning machine is PS-CNCSXY-5, the CNC spinning machine has a built-in Siemens CNC system, and the rotating speed of the main shaft 1 is set to 60r / min; The plate thickness of slab 3 is 1.2mm, and the material of circular slab 3 is 6061-O state aluminum alloy; Figure 2~4 As shown, the final form of the forming part 5 is a non-axisymmetric frustum shell, the initial cross-sectional radius of the frustum of the forming part 5 is 25 mm, the axial depth of the frustum of the forming part 5 is 50 mm, and the frustum of the forming part 5 The left half cone angle is 45°, and the right half cone angle of the frustum of the formed part 5 is 30°.

[0022] A method for dieless spinning forming of non-axisymmetric thin-walled shell parts, comprising the following steps:

[0023] Step 1: Select...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com