A voice coil wire bending fixture and bending method

A voice coil and wire technology, applied in the field of loudspeaker production jigs, can solve problems such as difficulty in unifying the sound performance of finished products, difficulty in achieving a unified line shape, and lack of production jigs, etc., to reduce the brain drain rate, single action, and frequency response curve consistent and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

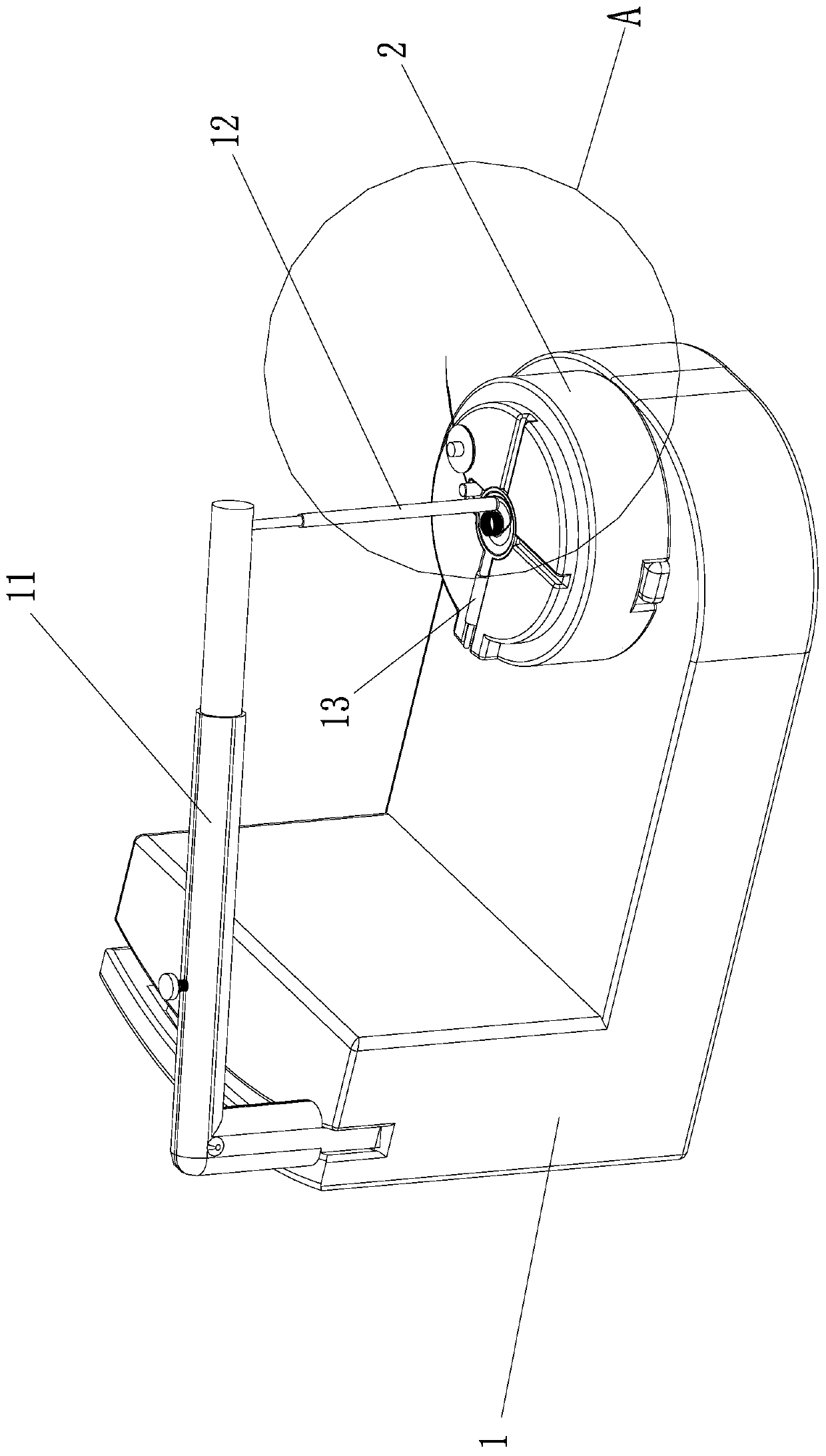

[0038] according to figure 1 , figure 2 , image 3 As shown, the voice coil wire bending jig in this embodiment includes a platform 1 and a wire bending base 2 .

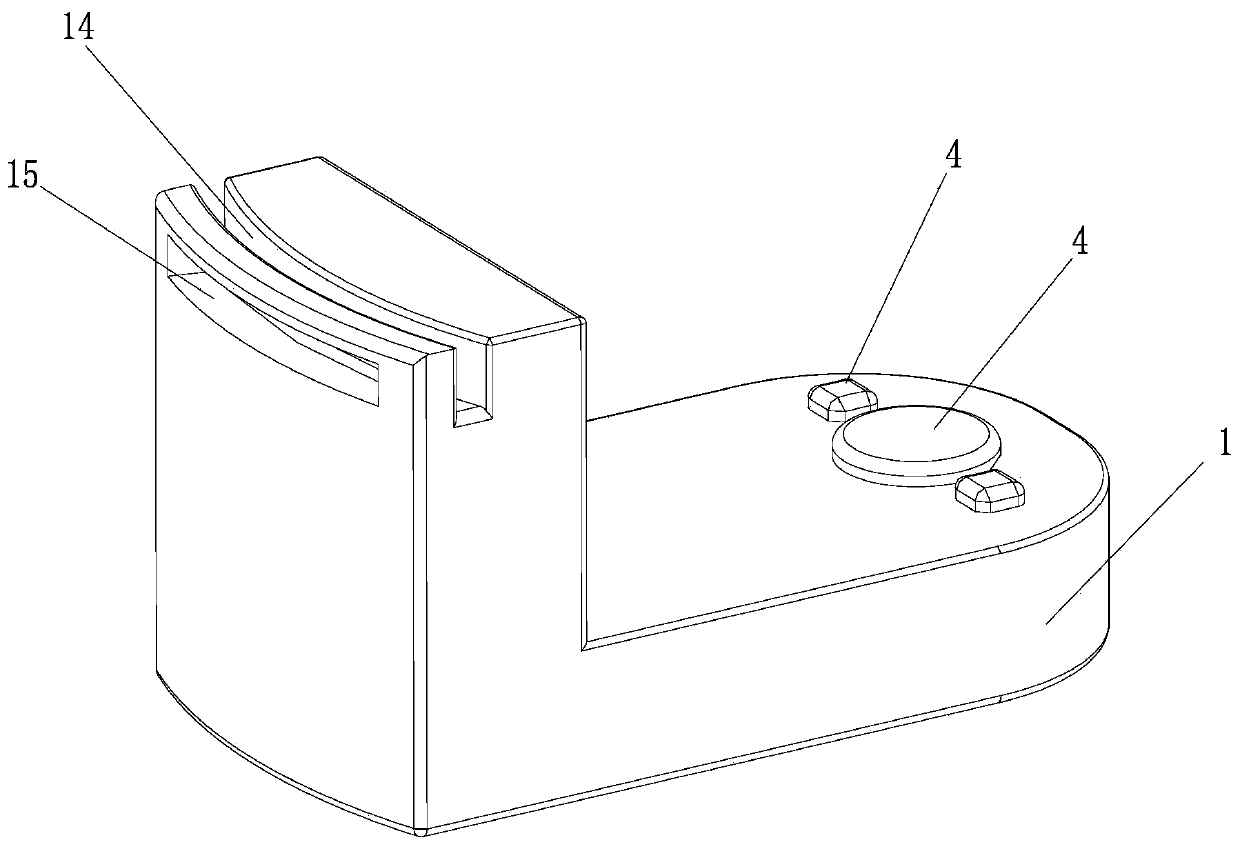

[0039] Such as Figure 4 As shown, a limiting groove 3 is provided at the bottom of the bending line base 2 , and a limiting protrusion 4 for being embedded in the limiting groove 3 is provided at the front of the platform 1 . The bending line base 2 is detachably placed on the front part of the bearing platform 1. Under the limited cooperation of the limiting groove 3 and the limiting protrusion 4, the bending line base 2 cannot rotate freely relative to the bearing platform 1, which is necessary for the subsequent bending line. Provide a unified space coordinate system and a relatively fixed bending line environment.

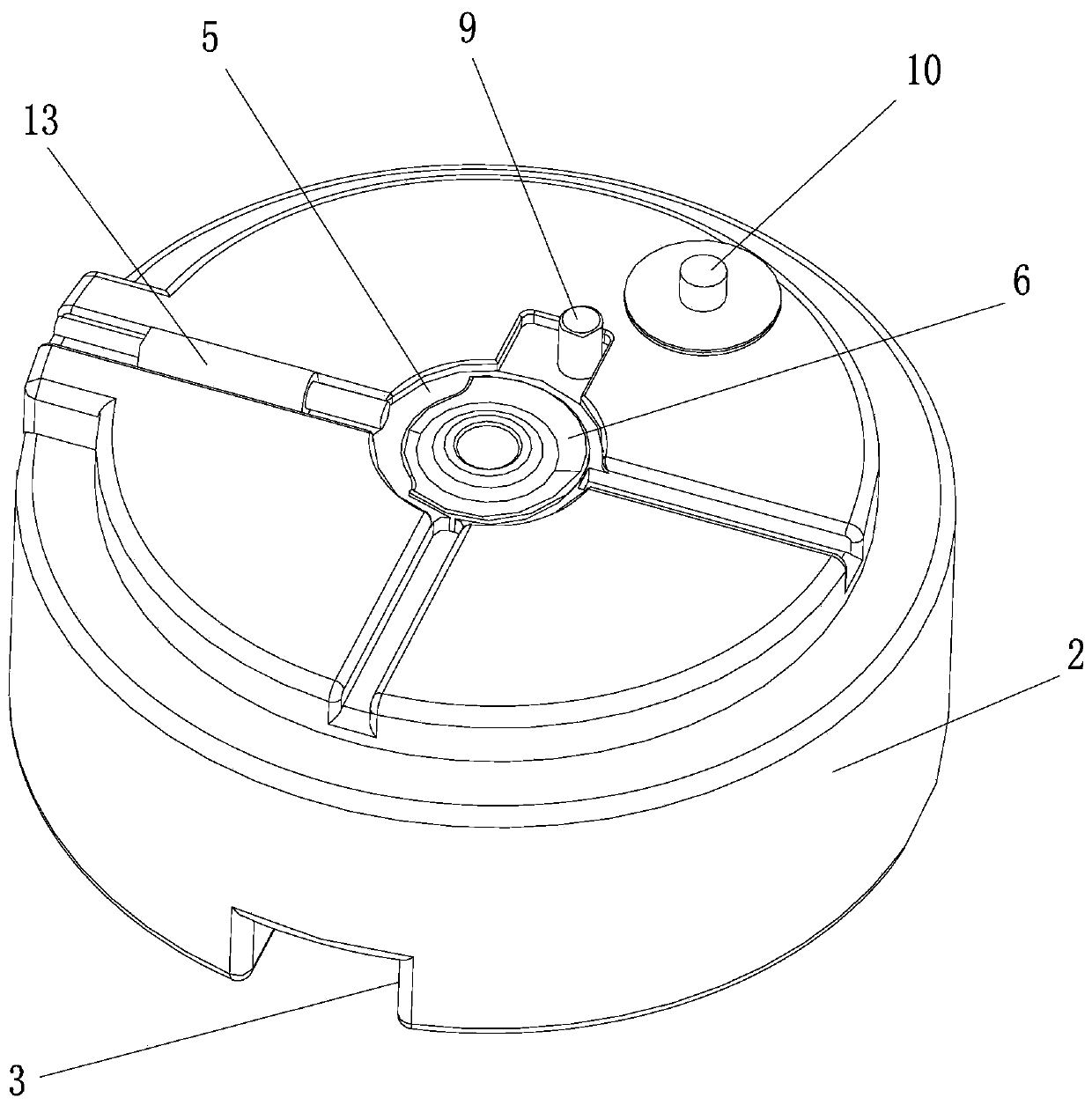

[0040] Such as Figure 6 As shown, the diaphragm is composed of a diaphragm 7 and a copper ring 8 connected to the edge of the diaphragm 7 . A diaphragm placement area 5 is formed in a depres...

Embodiment 2

[0046] In order to unify the connection between the voice coil and the diaphragm and improve production efficiency, this embodiment is an improvement on the basis of Embodiment 1, as Figure 8 and Figure 9 As shown, it also includes a top cover 16 for pressing onto the bending wire base 2. On the inner cover surface of the top cover 16, there is an annular protrusion opposite to the center of the diaphragm tray 6 and used for connecting the voice coil 99. The top cover 16 is provided with a group of light-transmitting holes 18 around the circumference of the annular flange. A connecting groove 19 for connecting with the upper rotating shaft of the glue machine is formed in an upward depression on the bottom surface of the bending line base 2 .

[0047] When connecting the voice coil 99, the wire bending base 2 is first moved to the glue machine, and connected to the rotating shaft in the middle of the glue machine table through the connecting groove 19, and the wire bending ...

Embodiment 3

[0049] This embodiment provides a method for bending the voice coil wire 98 through the voice coil wire bending jig in the above embodiment, such as Figure 5 shown, including the following steps:

[0050] i. Place the diaphragm in the diaphragm tray 6 and glue the voice coil 99 to the center of the diaphragm. In this step, the diaphragm can be further pushed up and limited by the spring thimble mechanism 13 .

[0051] ii. Adjust the second winding post 12 to the preset position relative to the diaphragm. The adjustment in this step includes adjusting the position of the swing arm 11 in the groove-shaped raceway, as well as the height position of the second winding post 12 adjust.

[0052] iii. Bending the voice coil wire 98 around the second winding post 12 and the first winding post 9 in order to conform to the pre-wire design.

[0053] iv. The free end of the voice coil wire 98 is compressed and limited by the wire crimping block 10, and the bent voice coil wire 98 is bon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com