Full-automatic sleeve pipe rolling machine

A coiling machine, fully automatic technology, applied in the direction of metal chains, etc., can solve the problems of low production efficiency, scratch damage, mixed waste products, etc., and achieve the effect of improving labor productivity, avoiding peach-shaped end faces, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention is described in further detail;

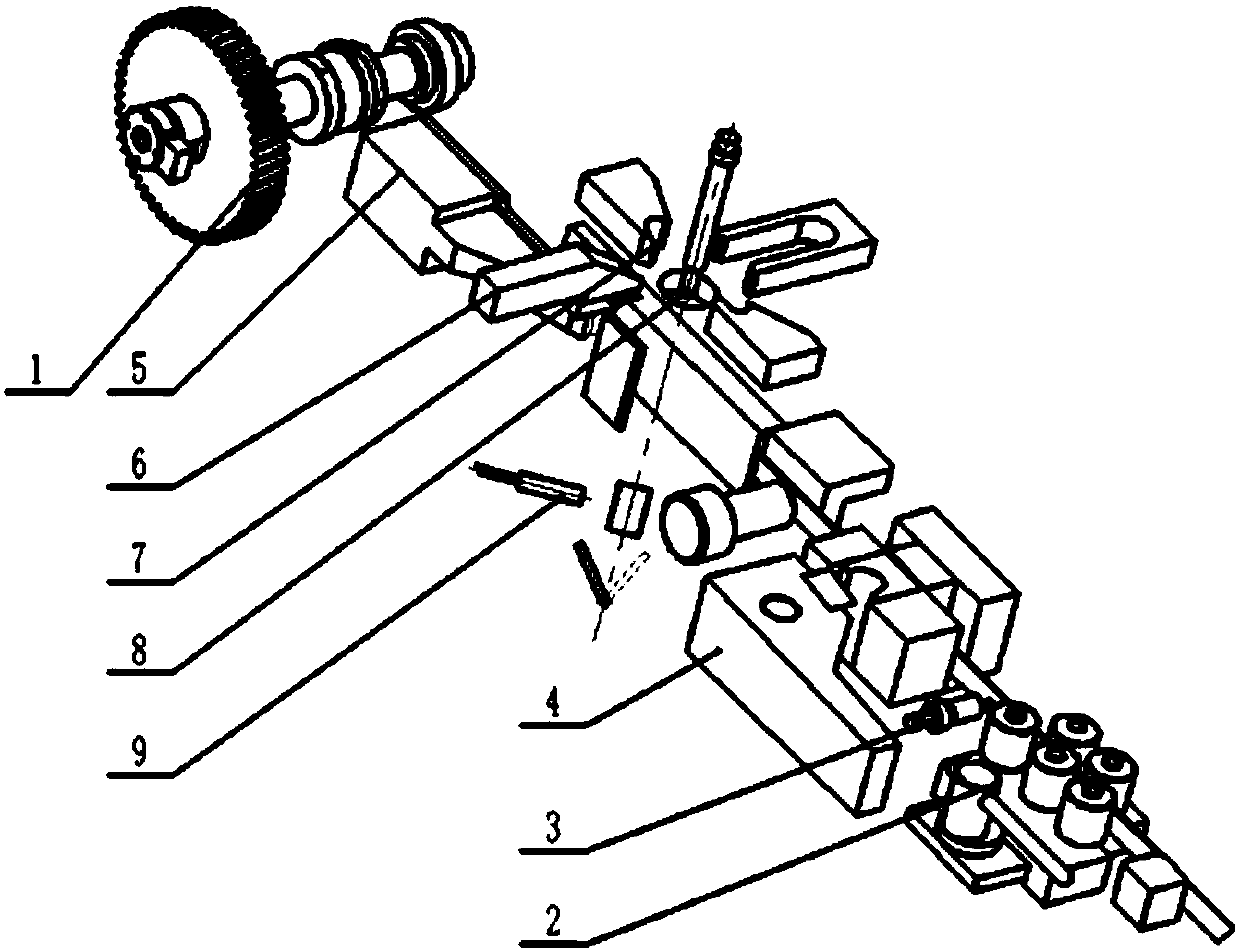

[0035] figure 1 , a structural schematic diagram of the present invention, such as figure 1 A fully automatic sleeve coiling machine is shown, including a driving device 1, a strip steel straightening device 2, a strip steel punching device 3, an active feeding device 4, a strip steel pre-bending cutting device 5, a semi-finished product conveying device 6, a rounding Device 7, round device 8 and finished product detection device 9;

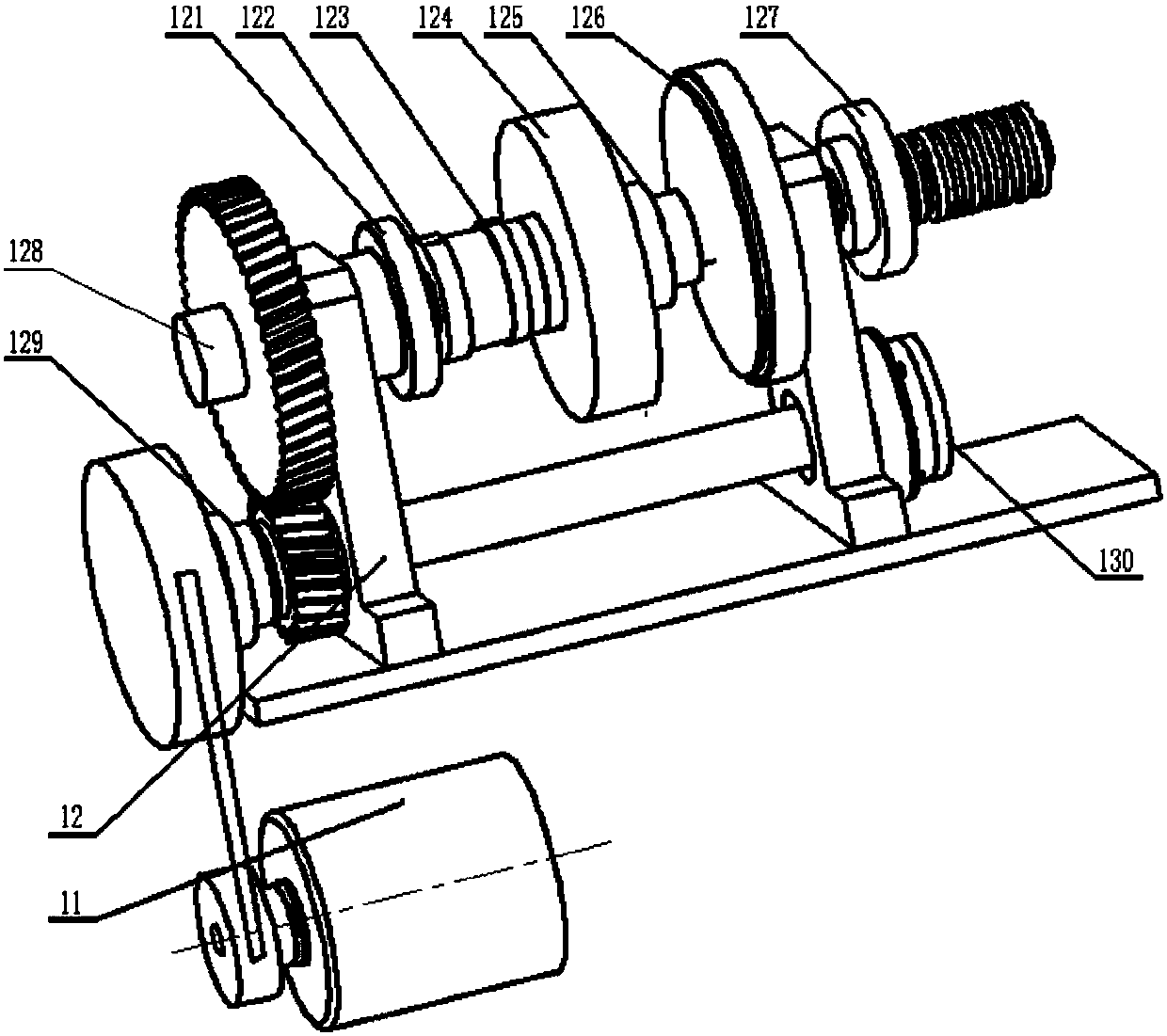

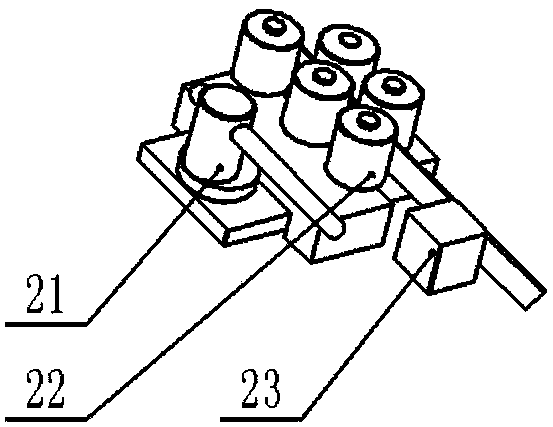

[0036] The strip is straightened by the strip straightening device 2, and enters the active feeding device 4, the driving device 1 drives the camshaft 12 to rotate, the active feeding device 4 moves, and its action conveys a predetermined length of strip steel Enter the strip steel pre-bending cutting device 5; the strip steel pre-bending cutting device 5 moves, and the two ends of the pre-bending strip steel become a semi-finished pro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap