Automobile glass foam strip and securing pin tool equipment

A technology of automotive glass and locating pins, which is applied in lamination devices, motor vehicles, transportation and packaging, etc. It can solve the problems that the proficiency of employees is greatly affected, mass production cannot keep up with the progress, and affect product quality, etc., and achieve consistency Good, ensure mass production, beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

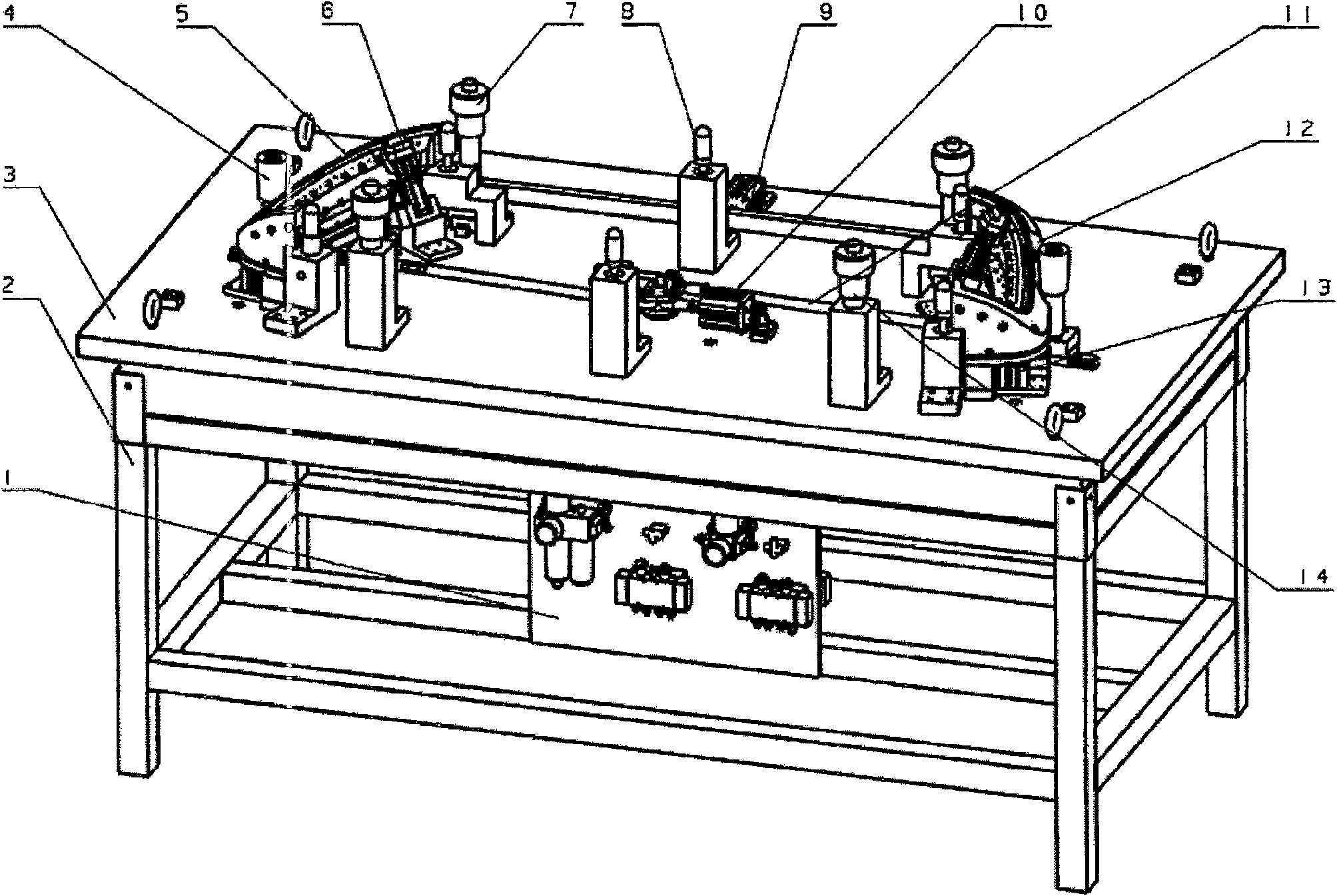

[0053] The automotive glass foam sticking strip and positioning pin tooling device of the present invention is composed of an underframe 2, a base plate 3, a bracket 5, a control system 1, a working system and a positioning mechanism, the base plate 3 is connected with the underframe 2 by bolts, and the bracket 5 And the positioning mechanism is installed on the bottom plate 3 with bolts, and the control system 1 is installed on the bottom of the chassis 2.

[0054] figure 1 It is a three-dimensional structure diagram of the present invention, the control system 1 is installed on the bottom of the chassis 2, the bottom plate 3 is installed on the upper part of the chassis 2, two left and right symmetrically placed brackets 5 are installed on the bottom plate 3, and two left and right centered backers are installed. 4 and two left and right symmetrical...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap