Multifunctional large-area flatbed printing machine

A flatbed printer, printer technology, applied in printing and other directions, can solve the problems of increasing motor power loss, lag, reducing printing speed and printing accuracy, etc., to achieve the effect of high radial concentricity, accurate transmission, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

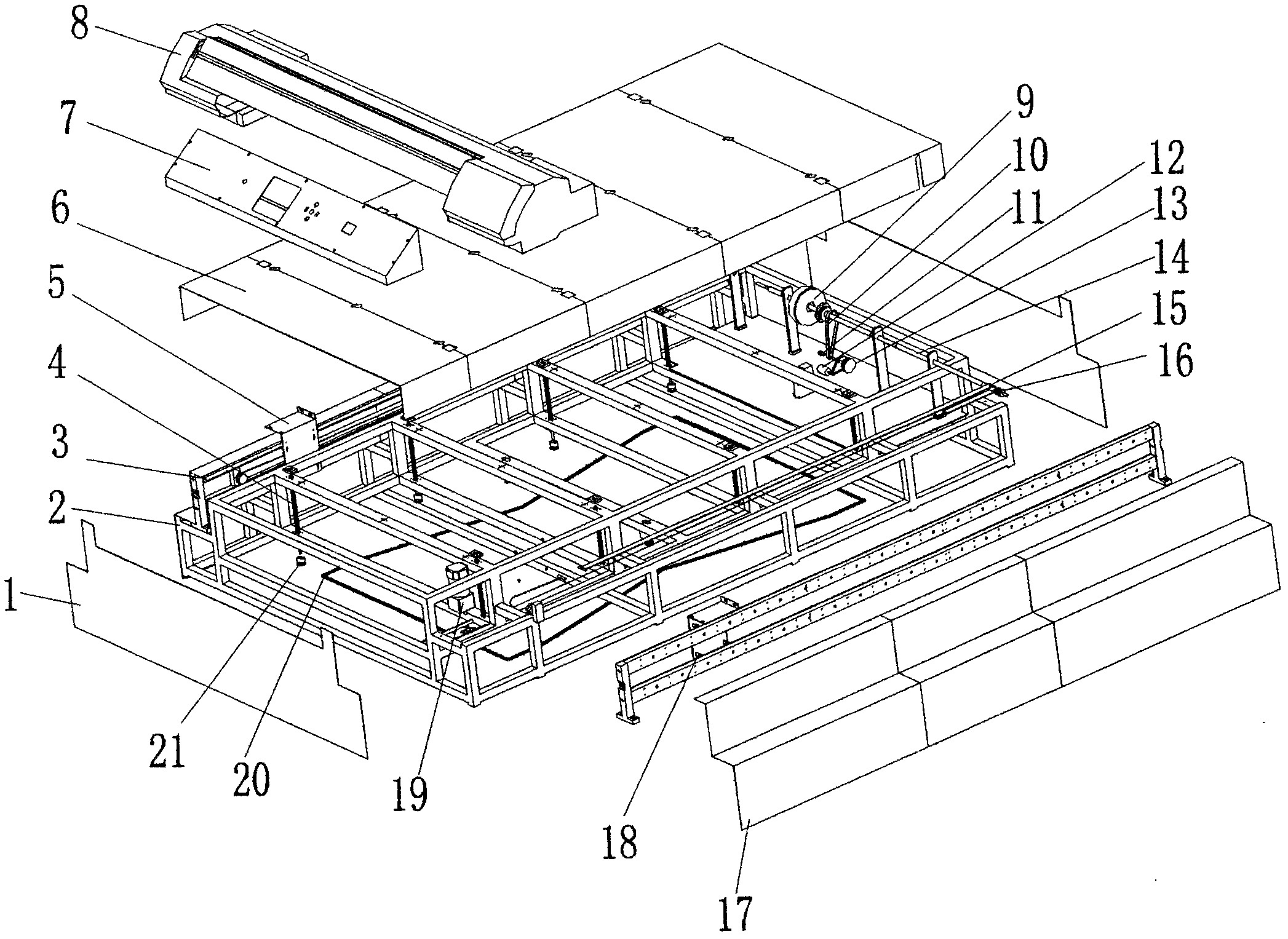

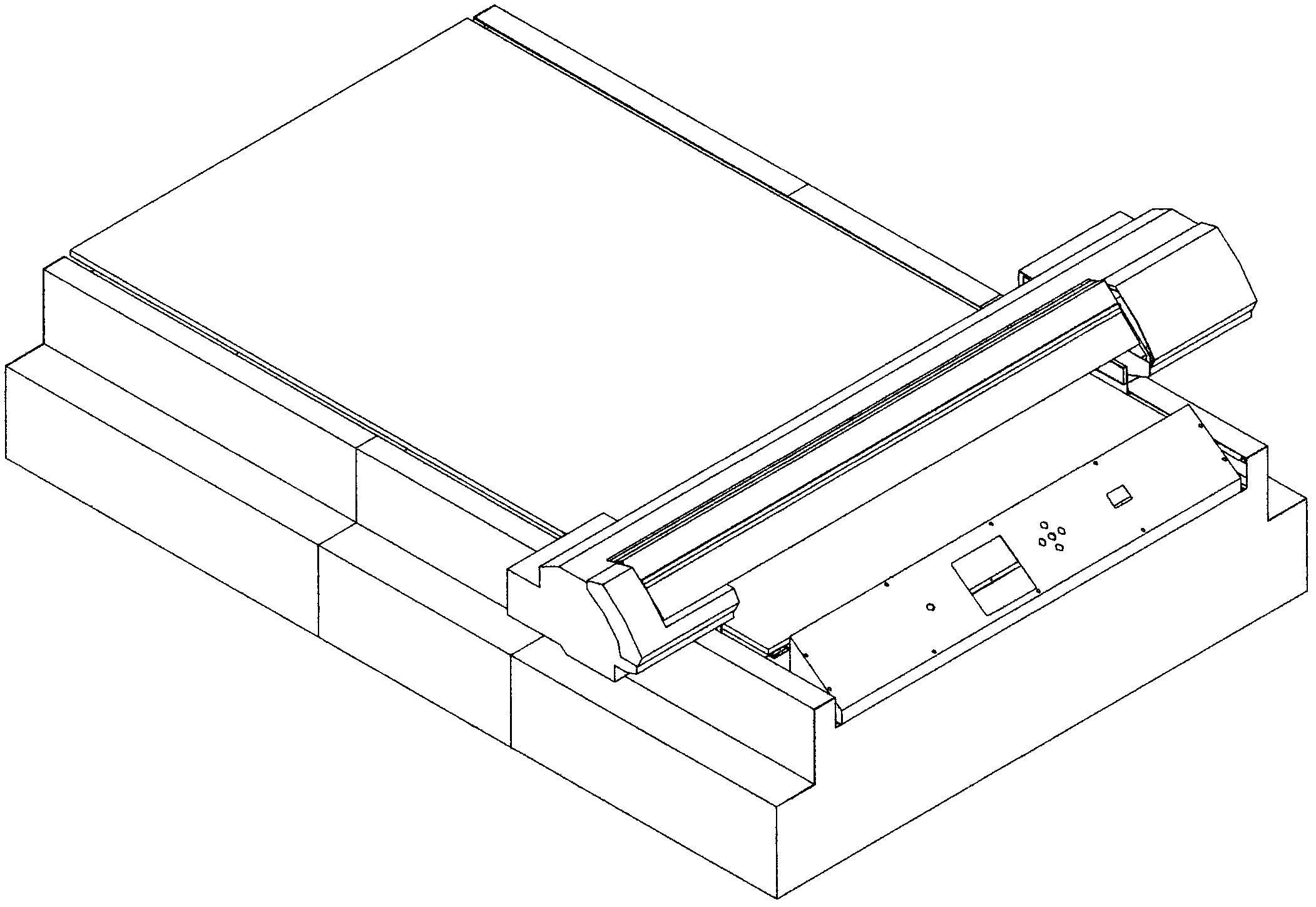

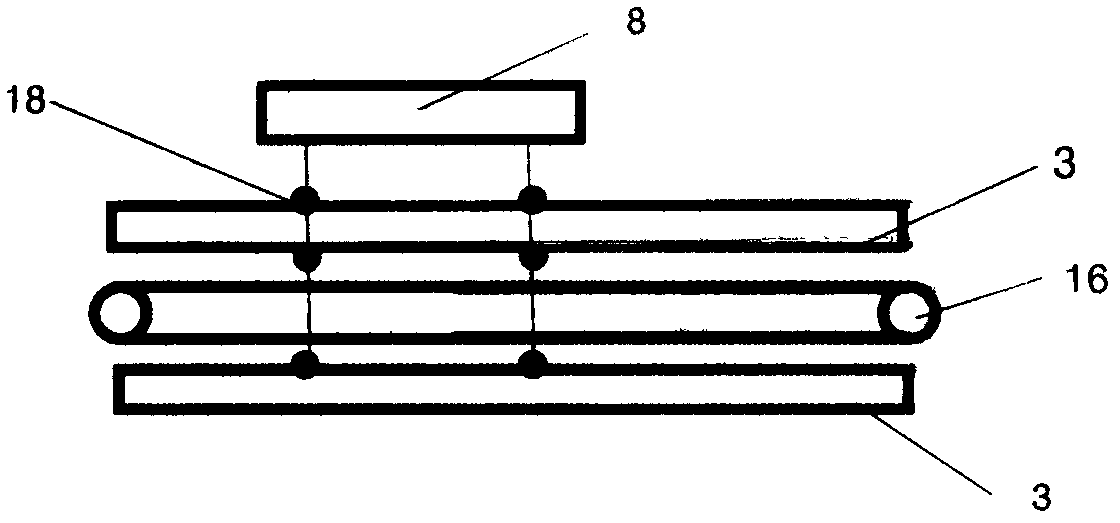

[0015] Such as figure 1 The present invention consists of a front plate 1, a base 2, a guide rail 3, a screw mandrel 4, a frame fixing plate 5, a printer flat plate 6, a key board 7, a printer head 8, a clutch 9, a belt 10, A synchronous wheel 11, a motor 12, B synchronous wheel 13, power transmission shaft 14, printer head transmission belt 15, C synchronous wheel 16, side plate 17, bearing 18, lift motor 19, chain 20, sprocket wheel 21, small transmission shaft 22 and D synchronous wheel 23 form. Such as Figure 3-5 , the motor is energized to run, and the belt 10 drives the B synchronous wheel to rotate 13. When the synchronous wheel 13 drives the A synchronous wheel 11 to rotate through the small transmission shaft, the A synchronous wheel 11 drives the left half of the clutch 9 to run through the belt 10. When pressing When printing is switched on and off, the clutch 9 is engaged, and the left half of the rotating clutch 9 drives the right half of the clutch 9 to rotate,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap