Absorption spectrum-based special printing color matching method

An absorption spectrum and spot color technology, which is applied in the field of printing spot color matching based on absorption spectrum, can solve the problems of inaccurate color matching ratio, large influence of subjective factors, and large material waste, so as to improve color matching accuracy, reduce waste, and reduce waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

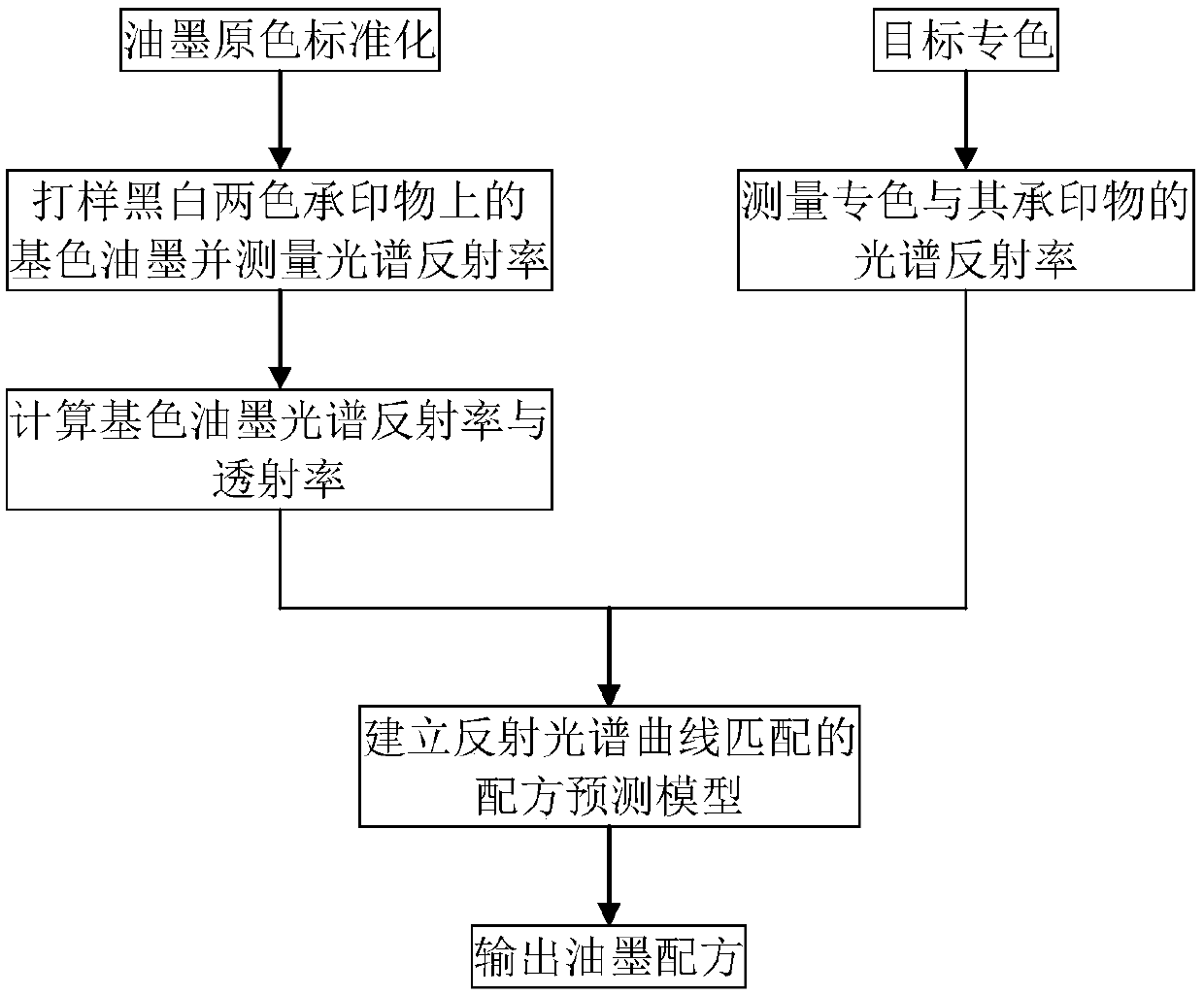

[0066] The invention provides a printing spot color matching method based on absorption spectrum, the process of which is as follows figure 1 As shown, follow the steps below to implement:

[0067] Step 1, select a white printing material as the printing substrate of the primary color ink for the standardization of the primary color ink;

[0068] Step 2, primary color ink standardization:

[0069] Standardization of primary color inks is to calibrate and convert primary color inks into primary color inks for formula calculation and color matching. The specific method of primary color ink standardization is:

[0070] Dilute the n kinds of primary color inks and diluents according to a certain ratio, print out the color sample ladder of different dilution rates of the primary color inks on the printing material selected in step 1, and measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com