Automatic rope turning device

An automatic thread turning and thread turning technology, which is applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems of yarn waste and large deviation of yarn length, etc., and achieve the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

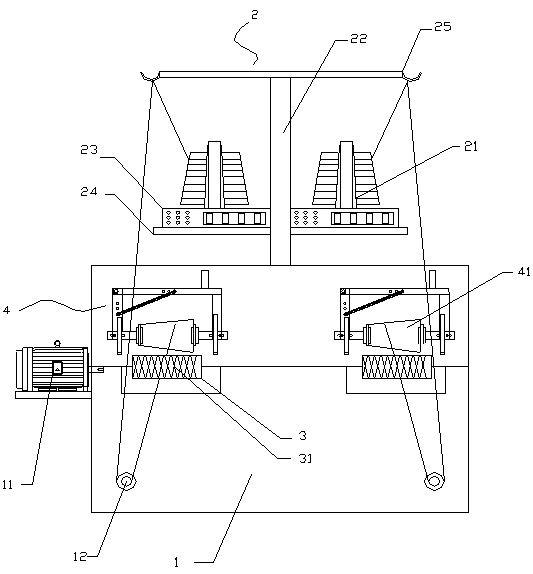

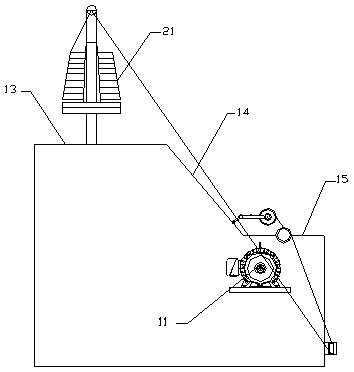

[0024] Such as Figure 1 to Figure 3 A kind of automatic rope turning device shown, comprises

[0025] A workbench 1, a drive motor 11 is installed in the workbench 1, a rotary encoder is arranged on the drive motor 11; a reversing roller 12 is installed on a vertical side of the workbench 1; the workbench 1 There is a guide roller installation groove on the top.

[0026] A lead frame 2, the lead frame 2 is installed on the upper surface of the workbench 1, and a first yarn tube 21 is arranged on the lead frame 2.

[0027] A wire roller 3, the wire roller 3 is arranged in the wire roller installation groove, the wire roller 3 is driven by the driving motor 11; the wire roller 3 is provided with a spiral wire groove 31.

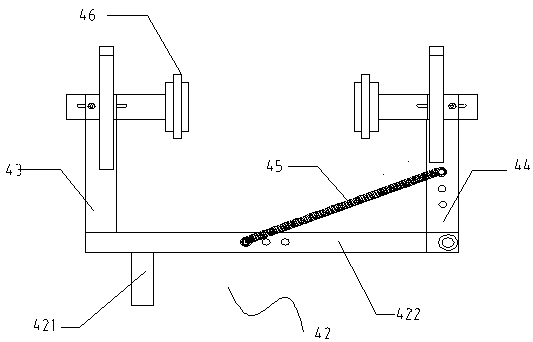

[0028] A thread turning frame 4, said thread turni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com