LED fluorescent lamp automatic detection and defective product excluding mechanism

An LED fluorescent lamp, automatic detection technology, applied in the direction of lamp testing, optical instrument testing, measuring devices, etc., can solve the problems of eye discomfort, low efficiency, unable to improve the efficiency of manufacturers, etc., to avoid eye discomfort and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

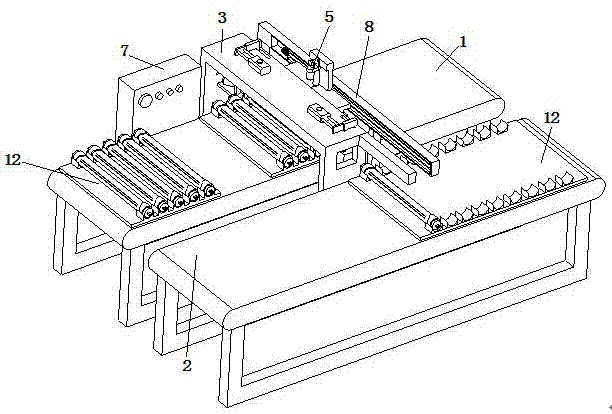

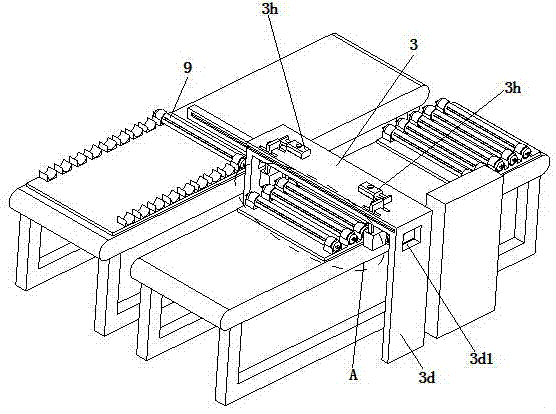

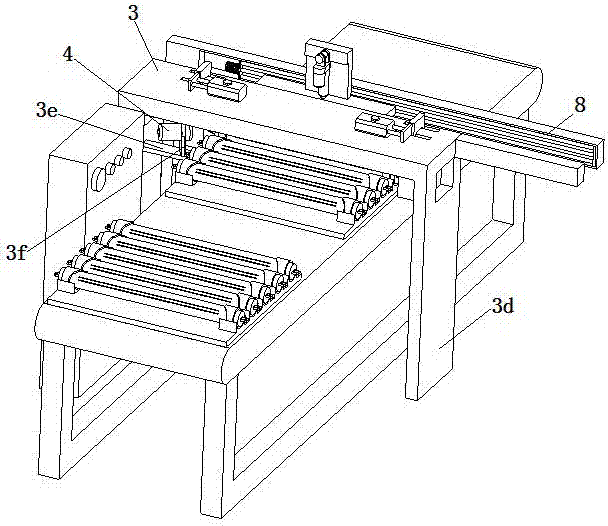

[0026] refer to Figure 1 to Figure 8 A mechanism for automatic detection of LED fluorescent lamps and removal of defective products is shown, including a first conveyor belt 1, a defective product conveyor belt 2, a detection component and an exclusion component 5, and the defective product conveyor belt 2 is located on the side of the first conveyor belt 1, The detection components include a rectangular mounting plate 3 and two energization detection blocks 3g, the rectangular mounting plate 3 is arranged above the first conveyor belt 1 and is located in the middle section of the first conveyor belt 1, and the two energization detection blocks 3g are respectively located on the rectangular mounting plate 3 Both ends of the bottom are horizontally slidably connected to the rectangular mounting plate 3. The top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com