A vehicle-mounted integrated scrapped ammunition de-energy resource disposal system

A disposal system and resource-based technology, which is applied in the field of vehicle-mounted integrated scrap ammunition de-energy resource disposal system, can solve the problems of increasing investment cost and processing cost, not being able to completely eliminate hidden dangers, increasing the complexity of the processing system, etc., and achieving reduction The process of evaporative concentration and spray granulation achieves continuity and high efficiency and reduces the effect of danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

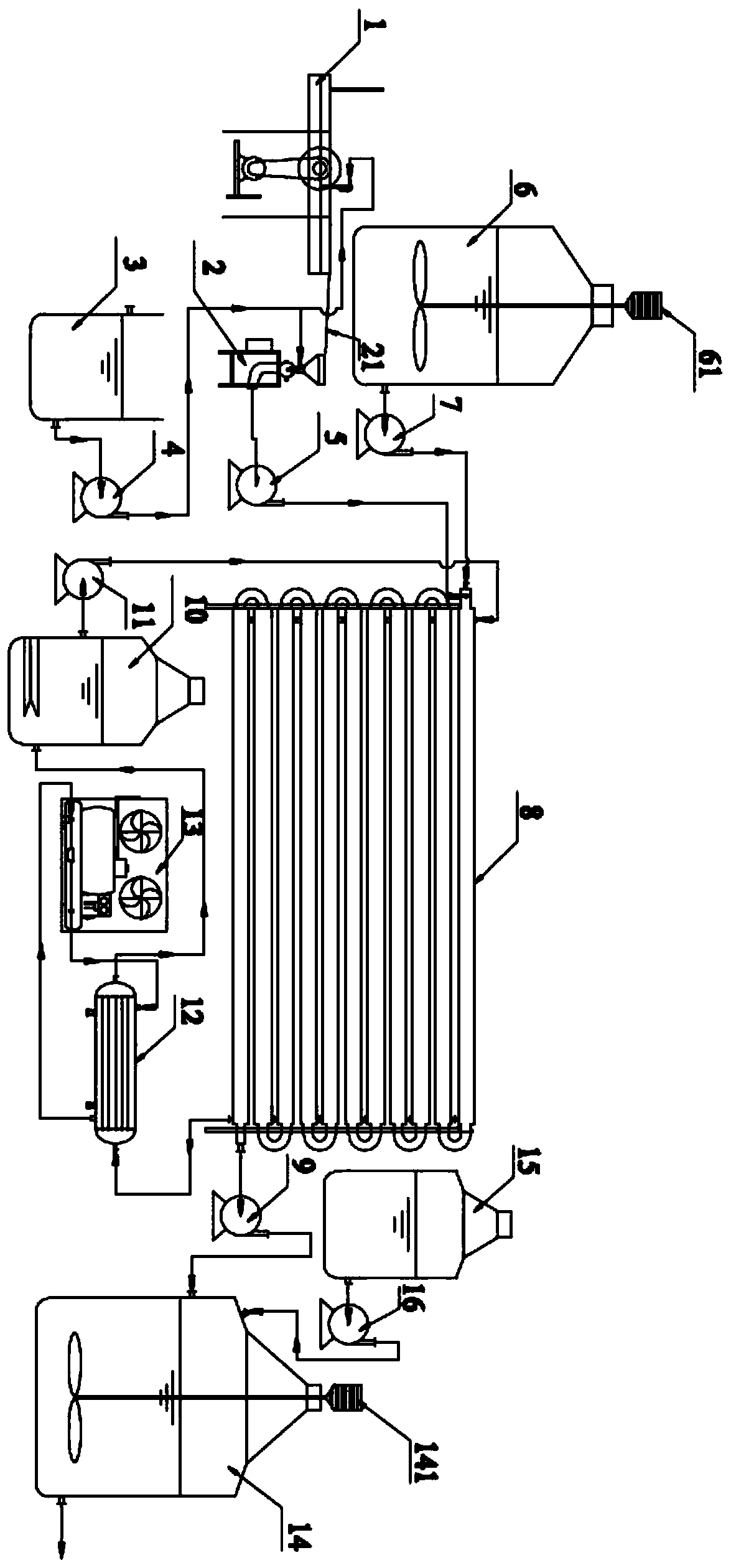

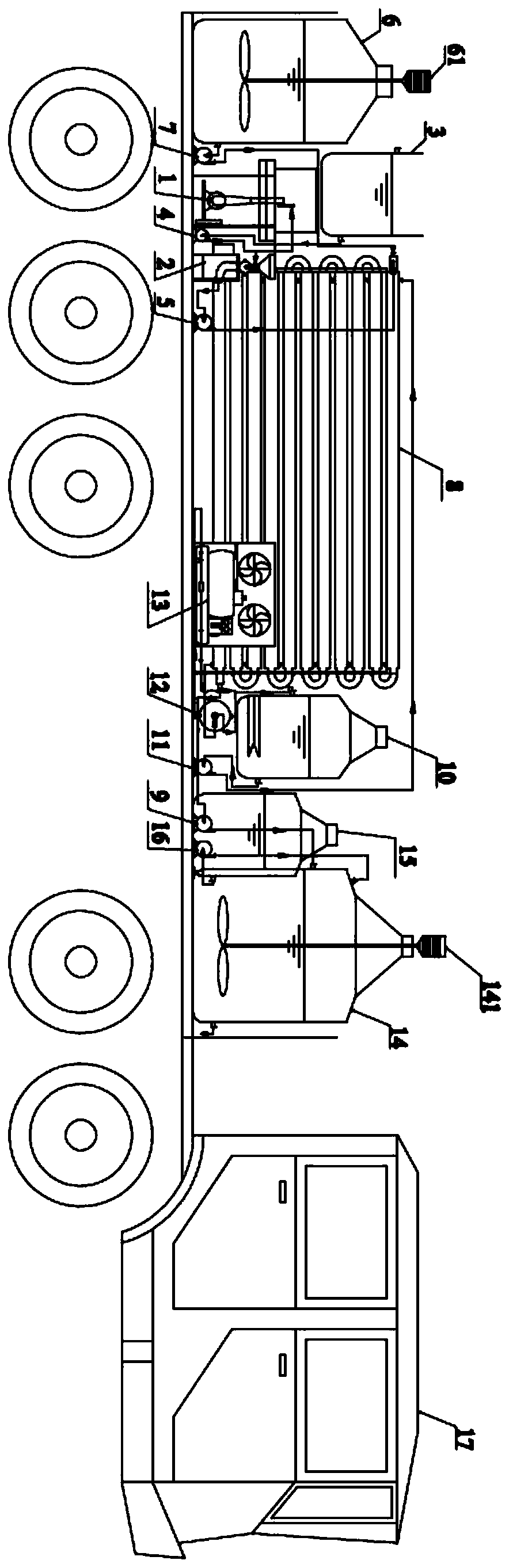

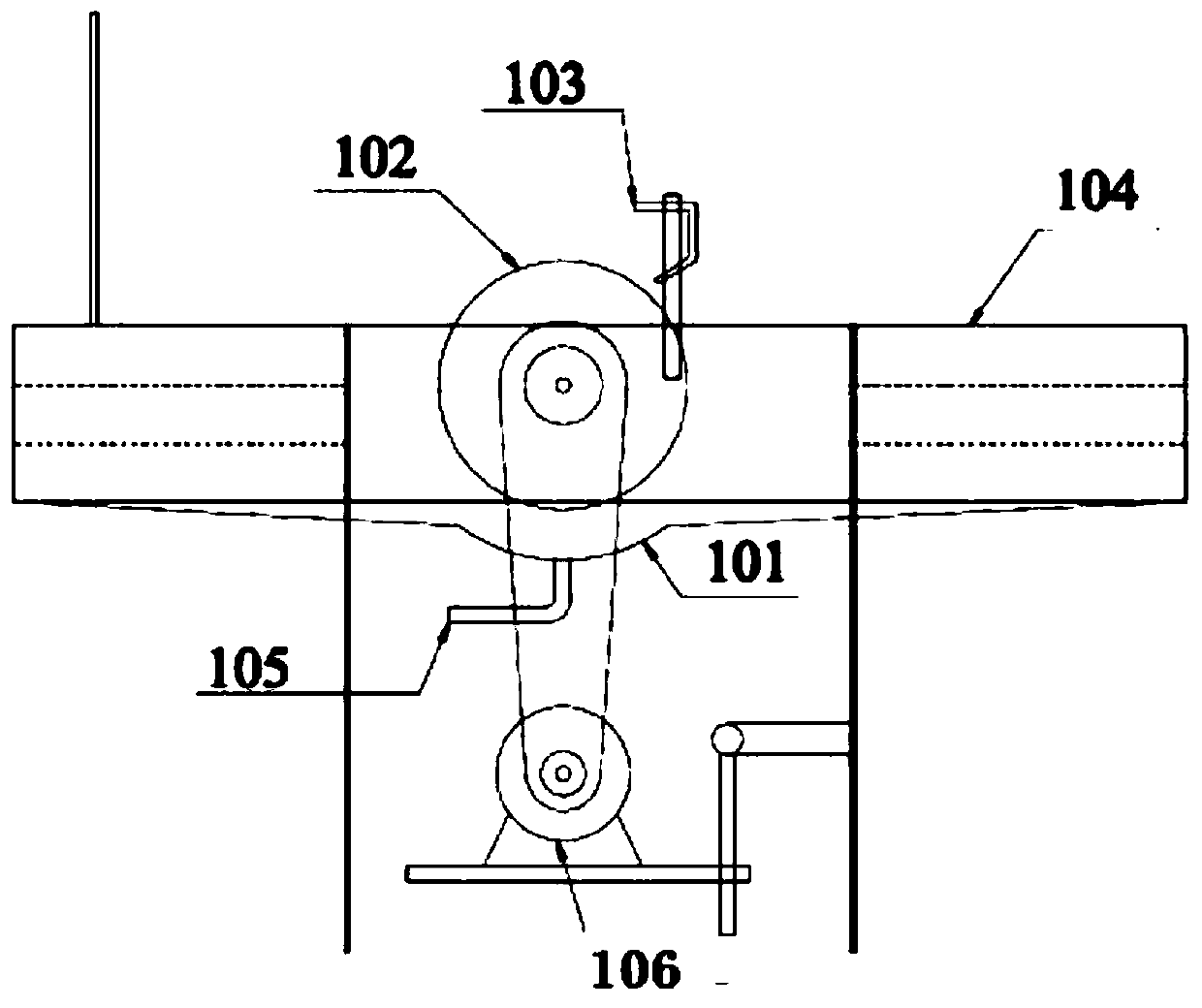

[0037] like figure 1 and figure 2As shown, a vehicle-mounted integrated scrapped ammunition deenergy resource disposal system includes a scrapped ammunition processing system installed on a military heavy truck 17. The scrapped ammunition processing system includes a cutting machine 1, and the discharge port of the cutting machine 1 passes through a conveyor belt 21 and The pulverizer 2 feed port 201 is connected, the pulverizer 2 discharge port 205 is connected with the first feed port of the casing type alkali hydrolysis reactor 8 through the scrapped ammunition feed pump 5, and the casing type alkali hydrolysis reactor 8 enters the second The feed port is connected with the lye tank 6 discharge port through the lye feed pump 7, the casing type alkali hydrolysis reactor 8 discharge port is connected with the first feed port of the stirring adjustmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com