Tool and method for installing robot trolley suspension spring

A technology for robots and trolleys, which is applied to manufacturing tools, hand-held tools, etc., can solve the problems of difficulty in installing the suspension springs of robot trolleys, and achieve the effect of saving manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

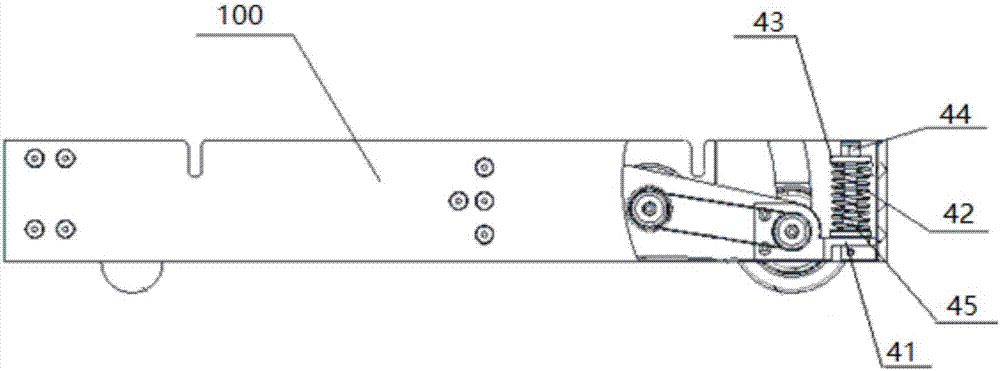

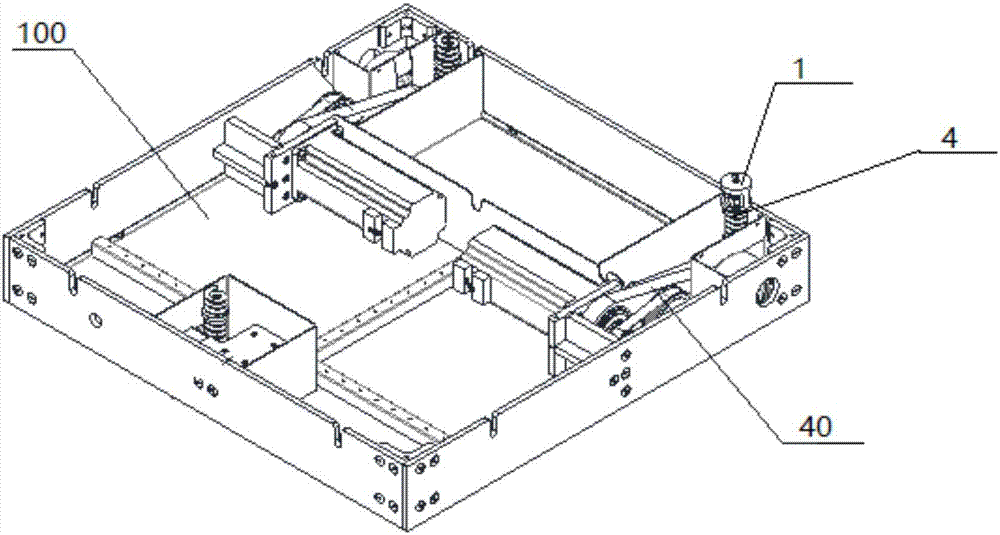

[0071] refer to Figure 4a , the spring support 41 is erected with a spring pull bar 45, the suspension spring 42 is set on the spring pull rod 45, the spring cover 43 is placed on the top of the suspension spring 42, the spring cover 43 is provided with a hole, the hole is aligned with the spring pull bar 45, and the spring pull bar 45 can be placed in the hole middle activity. A fastening nut 44 is placed above the spring cover 43 .

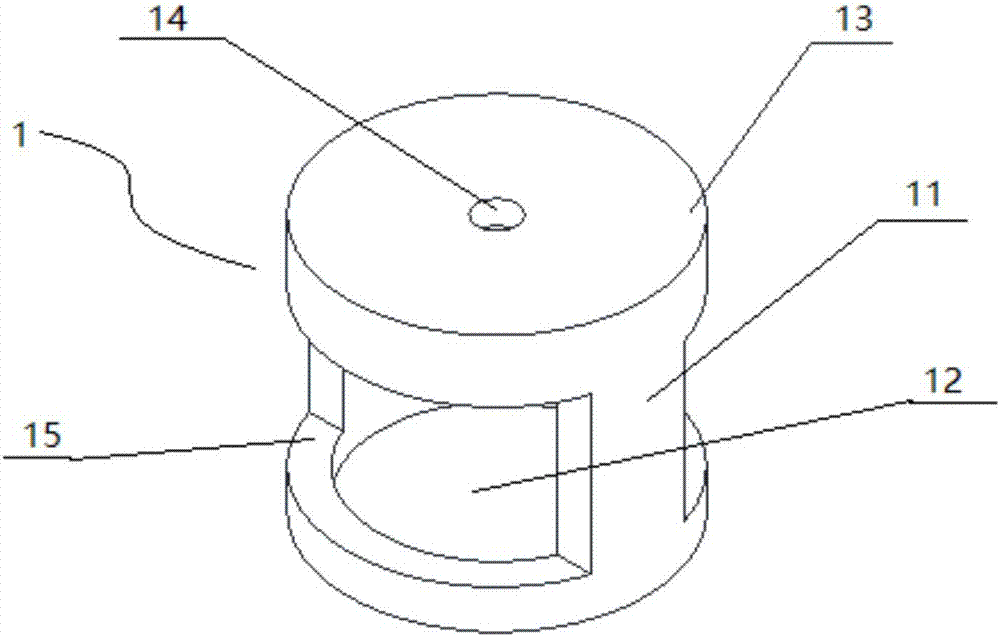

[0072] Put the cylindrical body 1 over the fastening nut 44 and the suspension spring 42, place the auxiliary nut 3 on the upper end surface of the cylindrical body 1, and align the second hole of the auxiliary nut 3 with the first hole 14 of the cylindrical body 1 to assist fastening The rod body of the member 2 passes through the second through hole, the first through hole 14 and the fastening nut 44 in turn, and extends into the inner channel. In the lower half of the rod body, external threads are provided on at least the outer surface pa...

Embodiment 2

[0078] In this embodiment, the rod body of the auxiliary fastener 2 is passed through the first through hole 14, and then the auxiliary nut 3 is sleeved on the rod body of the auxiliary fastener 2 from the outside of the cylindrical body 1, and the auxiliary nut 3 is inserted through the engaging thread. Screw to the vicinity of the cylindrical body 1 or contact with the cylindrical body 1.

[0079] The fastening nut 44 is sleeved onto the rod body from the inner channel of the cylindrical body 1 .

[0080] Referring to Embodiment 1, the fastening structure at the end of the rod body of the auxiliary fastener 2 is connected to the spring pull rod 45 to fix the auxiliary fastener 2 . In this embodiment, the fastening structure may also be:

[0081] The end of the rod body and the top of the spring rod, one is provided with a polygonal, elliptical, bow-shaped (including semicircular) protrusion, and the other is correspondingly provided with a recessed groove of the correspondi...

Embodiment 3

[0087] Referring to Embodiment 1, the fastening structure at the end of the rod body of the auxiliary fastener 2 is connected to the spring pull rod 45 to fix the auxiliary fastener 2 . In this embodiment, the fastening structure may also be:

[0088] The end of the rod body and the top of the spring pull rod, one is provided with a protrusion, the other is provided with a groove, and the wall of the groove is provided with a rivet insertion opening, the protrusion is inserted into the groove, and the rivet is inserted through the rivet insertion opening to displace the protrusion. The part is fixed, so that the auxiliary fastener 2 is fixed.

[0089] After fixing the auxiliary fastener 2, use a tool (such as a wrench) or manually rotate the auxiliary nut 3, the thread on the inner surface of the second perforation of the auxiliary nut 3 engages with the thread on the outer surface of the rod, and under the action of the engaging thread, the auxiliary nut 3 is pressed down Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com