Patents

Literature

34results about How to "Avoid manual installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fire automatic alarming system based on LORA wireless communication and method thereof

InactiveCN107833428AReduce usageRealize fire alarmTransmission systemsFire alarmsControl systemControl signal

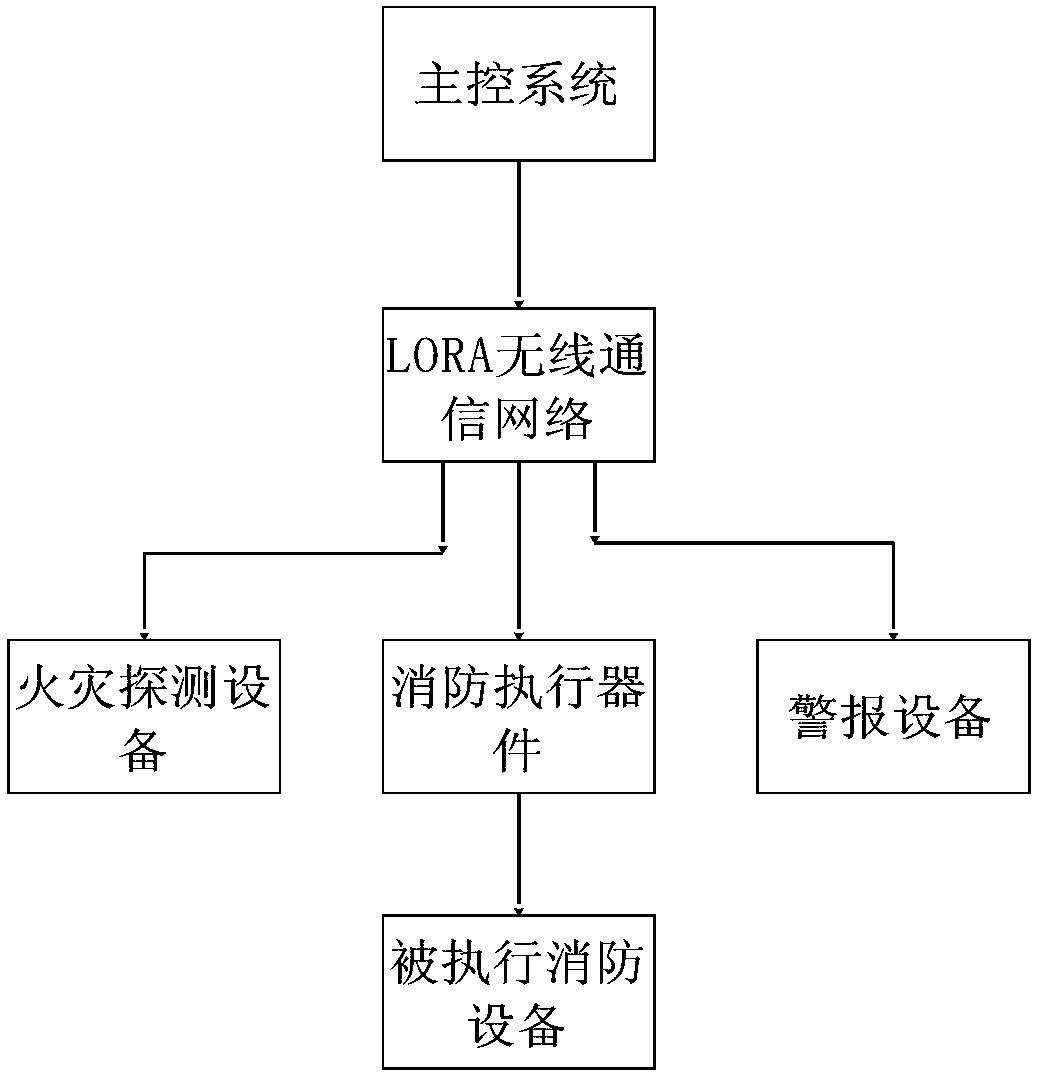

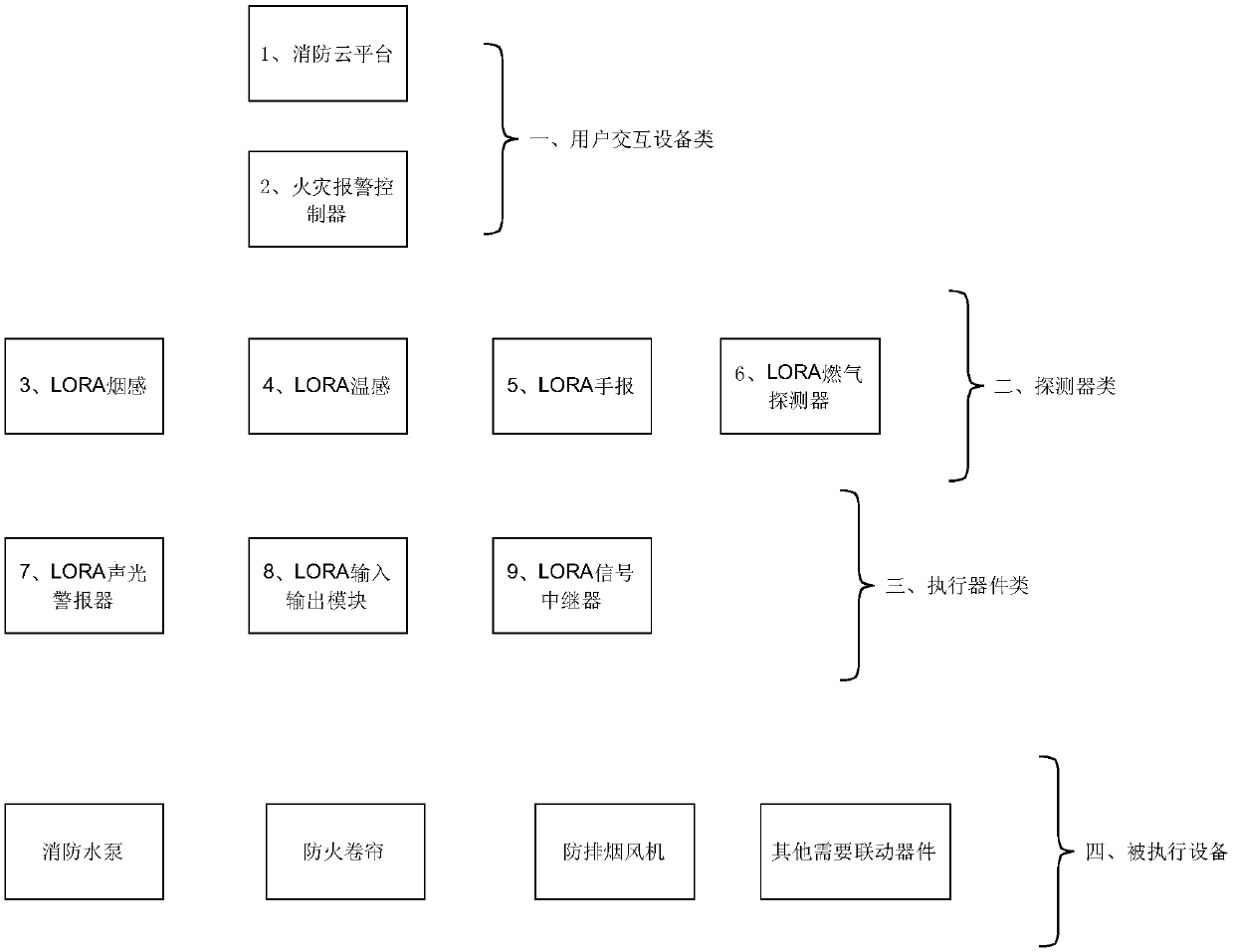

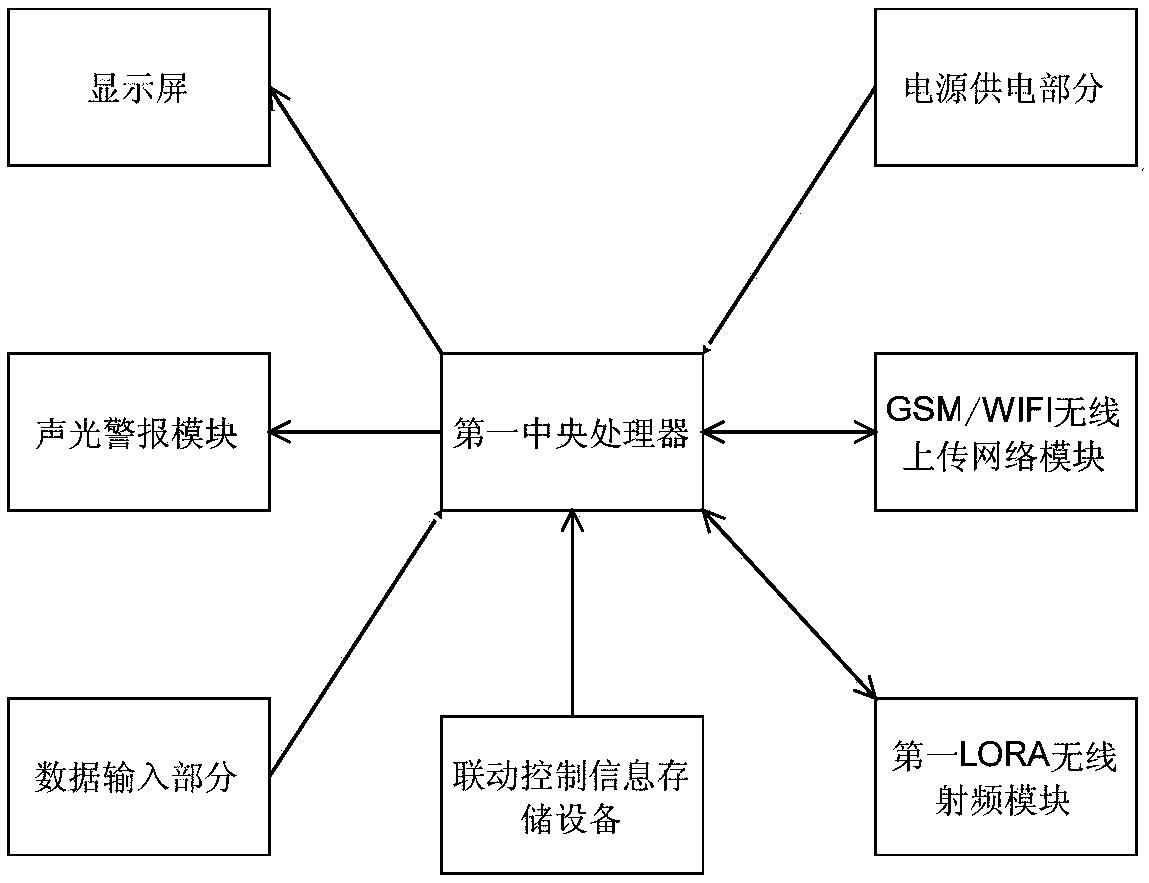

The invention discloses a fire automatic alarming system based on LORA wireless communication and a method thereof. The system comprises a master control system, fire detecting equipment, alarm equipment, a firefighting executing device and an LORA wireless communication network. The fire detecting equipment is used for monitoring a fire signal and transmits a fire signal to the master control system. After the master control system receives the fire signal, the master control system transmits an alarm signal to the alarm equipment, and simultaneously the master control system transmits a firefighting control signal to the firefighting executing device. After the alarm equipment receives the alarm signal, the alarm equipment notifies a user of a fire alarm condition in a manner of transmitting a high-strength sound-and-light alarm signal. The firefighting executing device makes field executed firefighting equipment perform fire extinguishing according to the firefighting control signal. According to the fire automatic alarm system and the method thereof, LORA wireless communication technology is utilized, thereby truly realizing an alarming and firefighting linkage function of an existing wired firefighting automatic alarm system, and preventing defects of complicated wiring, many difficulties in manual mounting and complicated maintenance in a wired fire automatic alarm system.

Owner:SHANDONG BEIRENHUIZHI ENERGY DEV

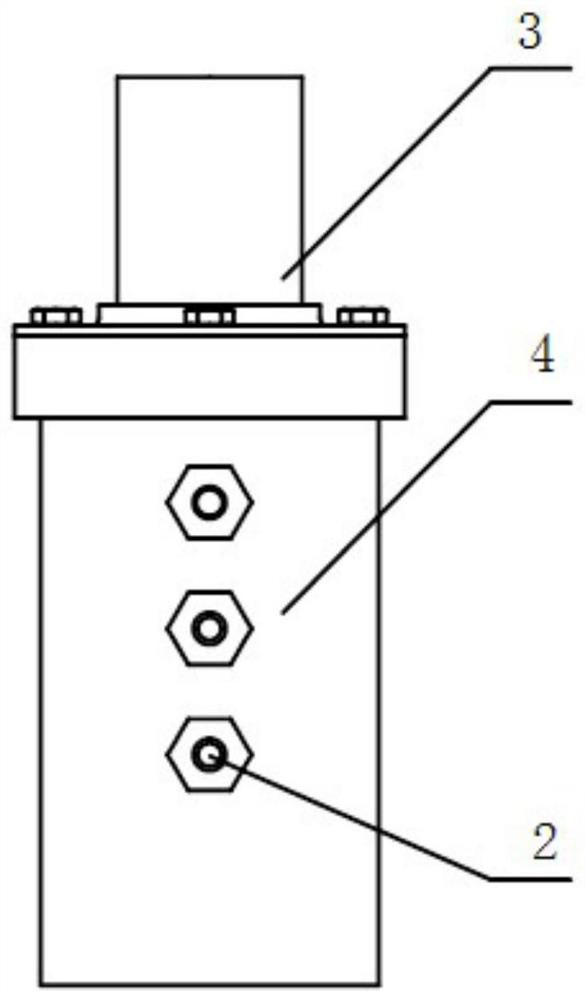

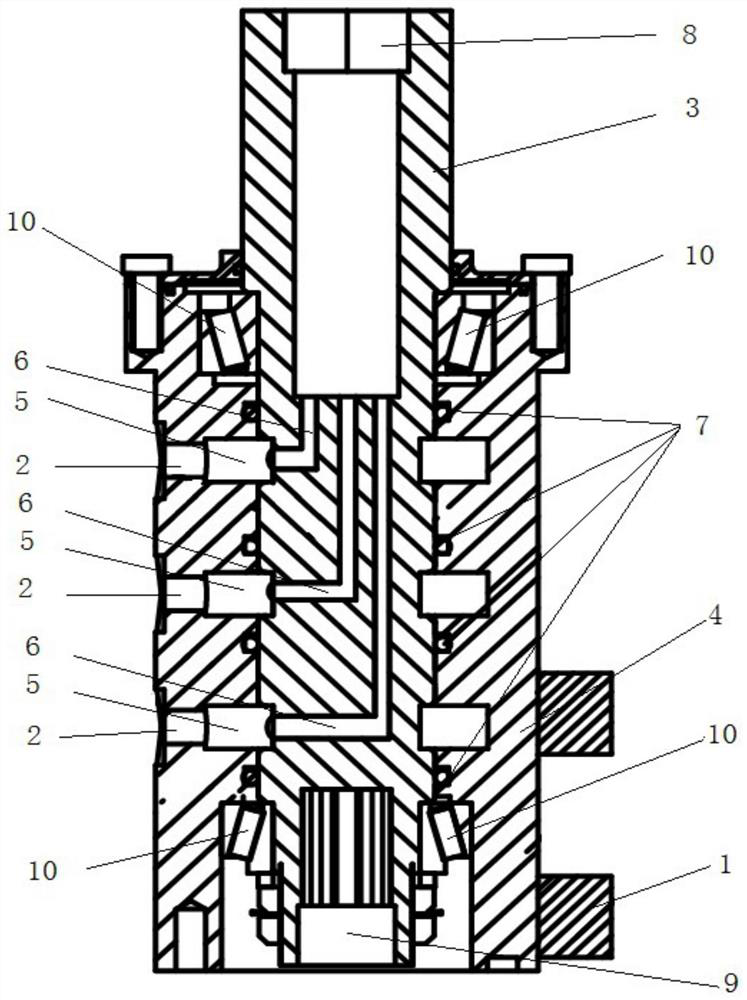

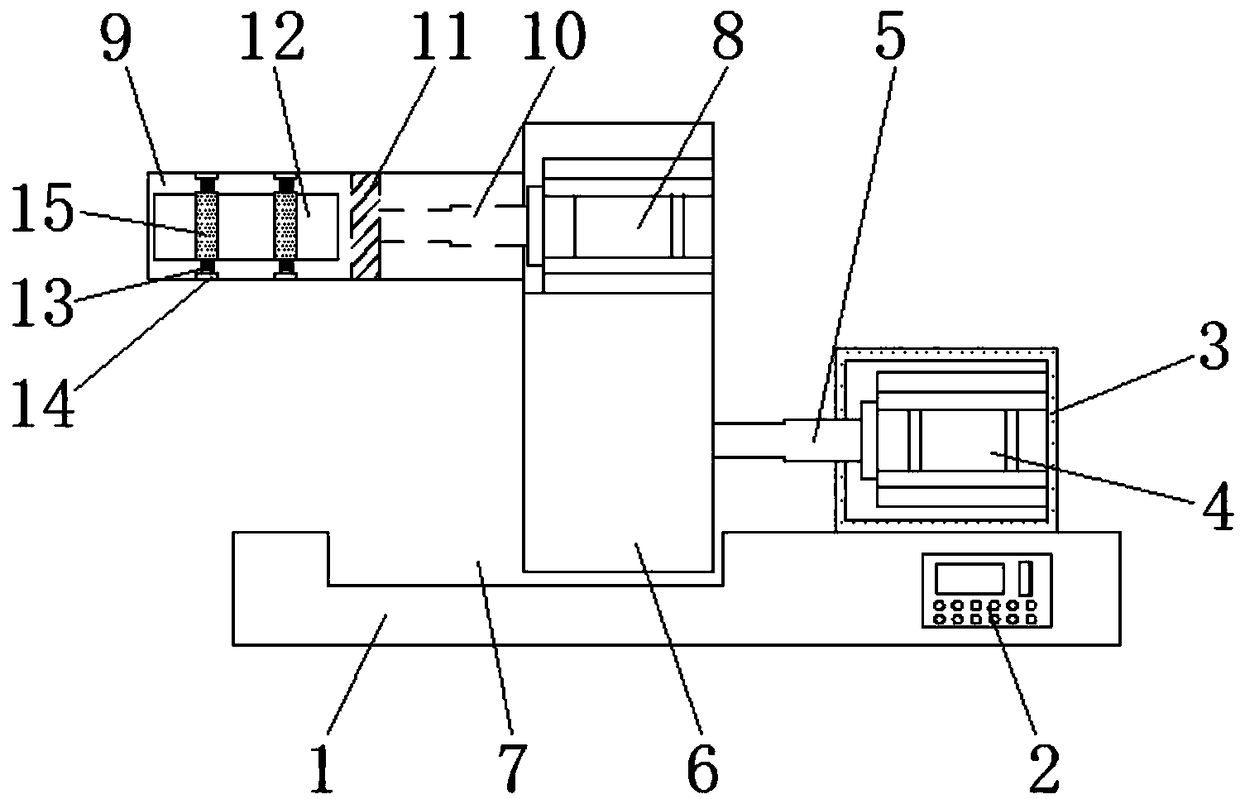

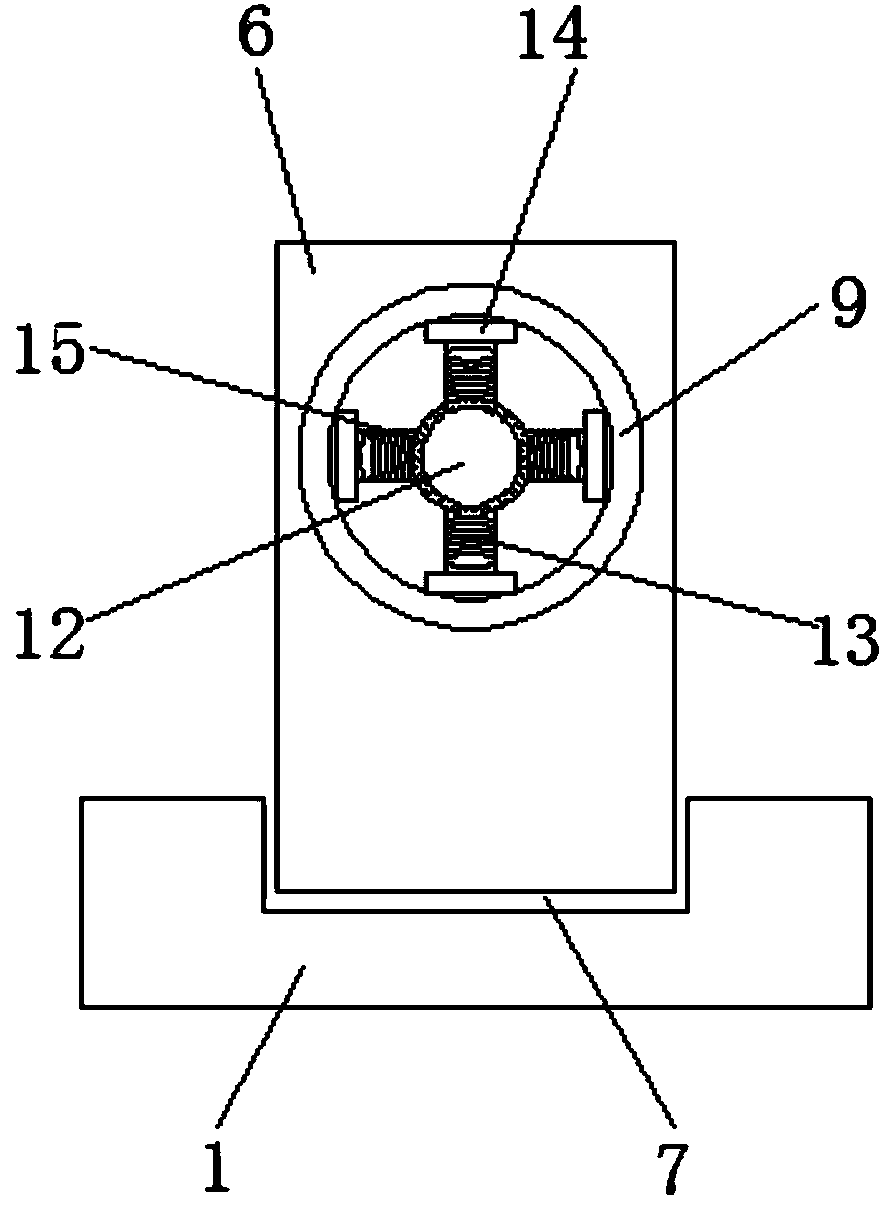

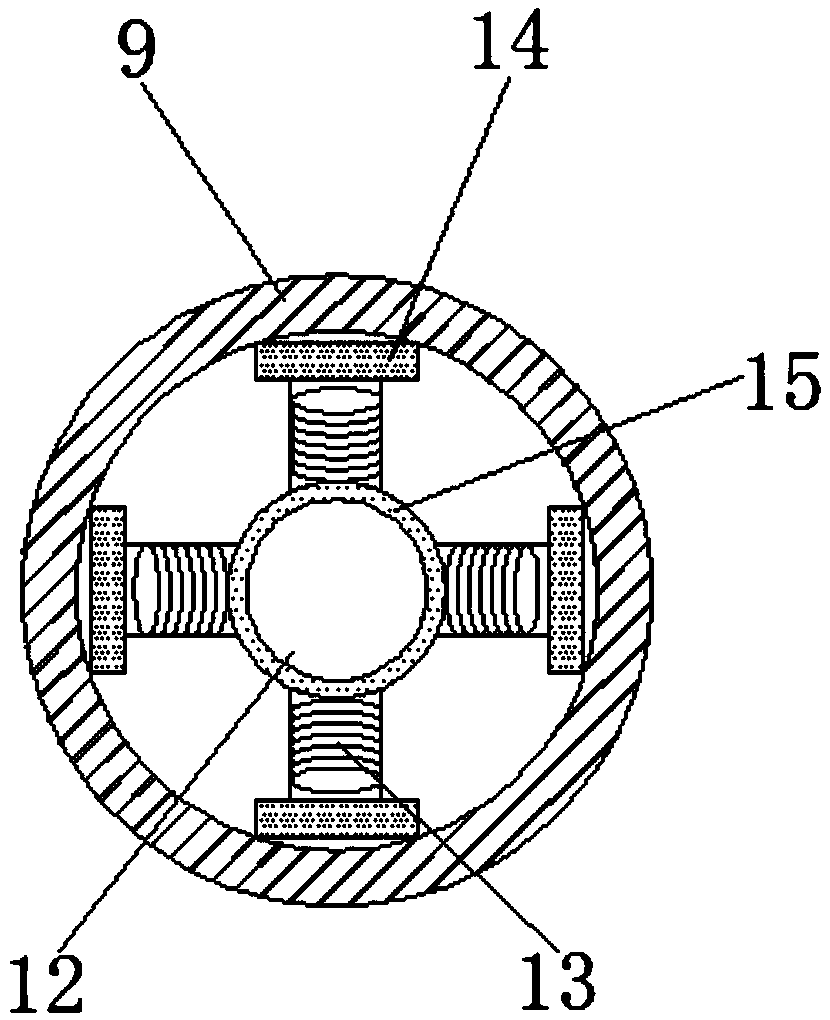

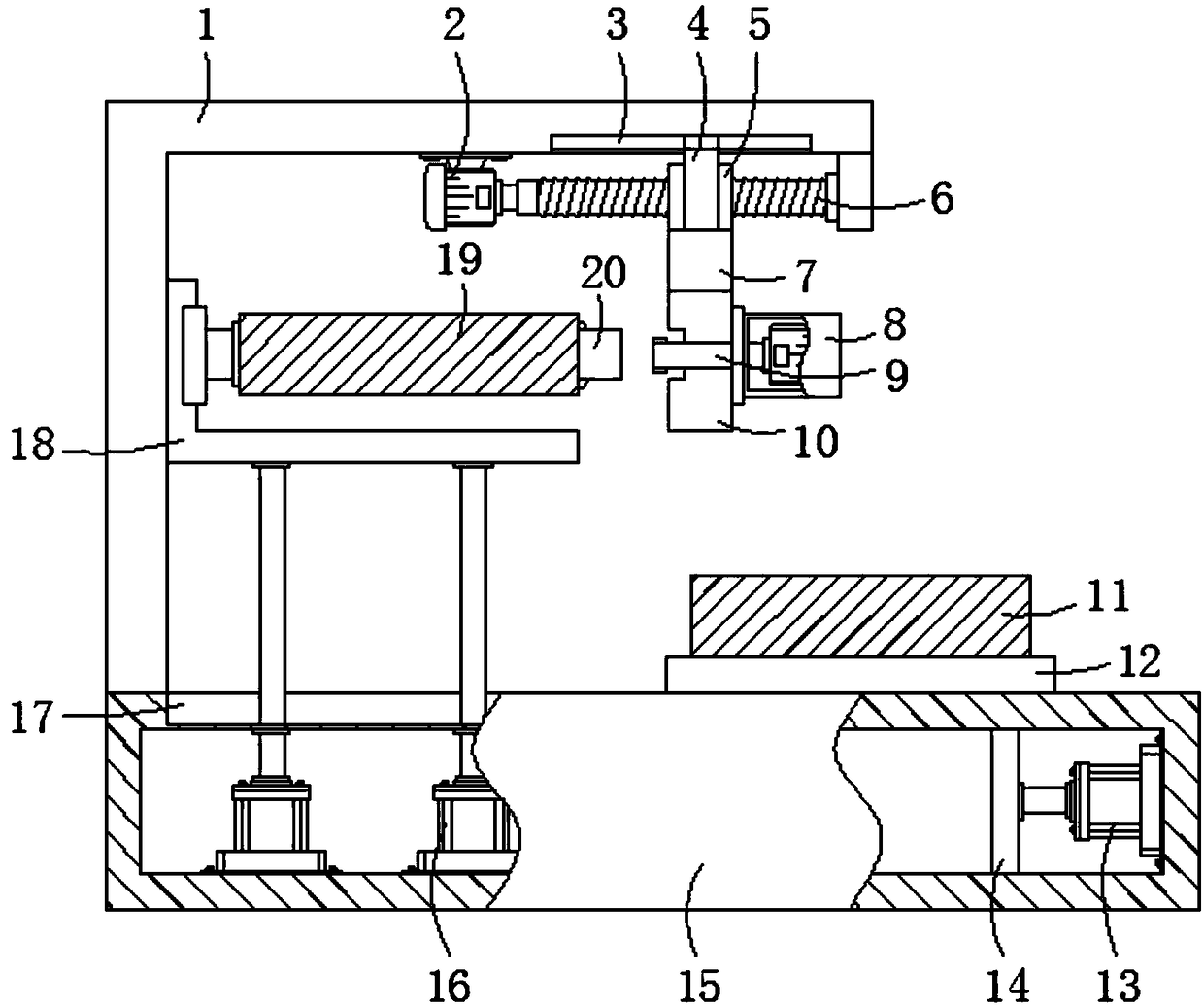

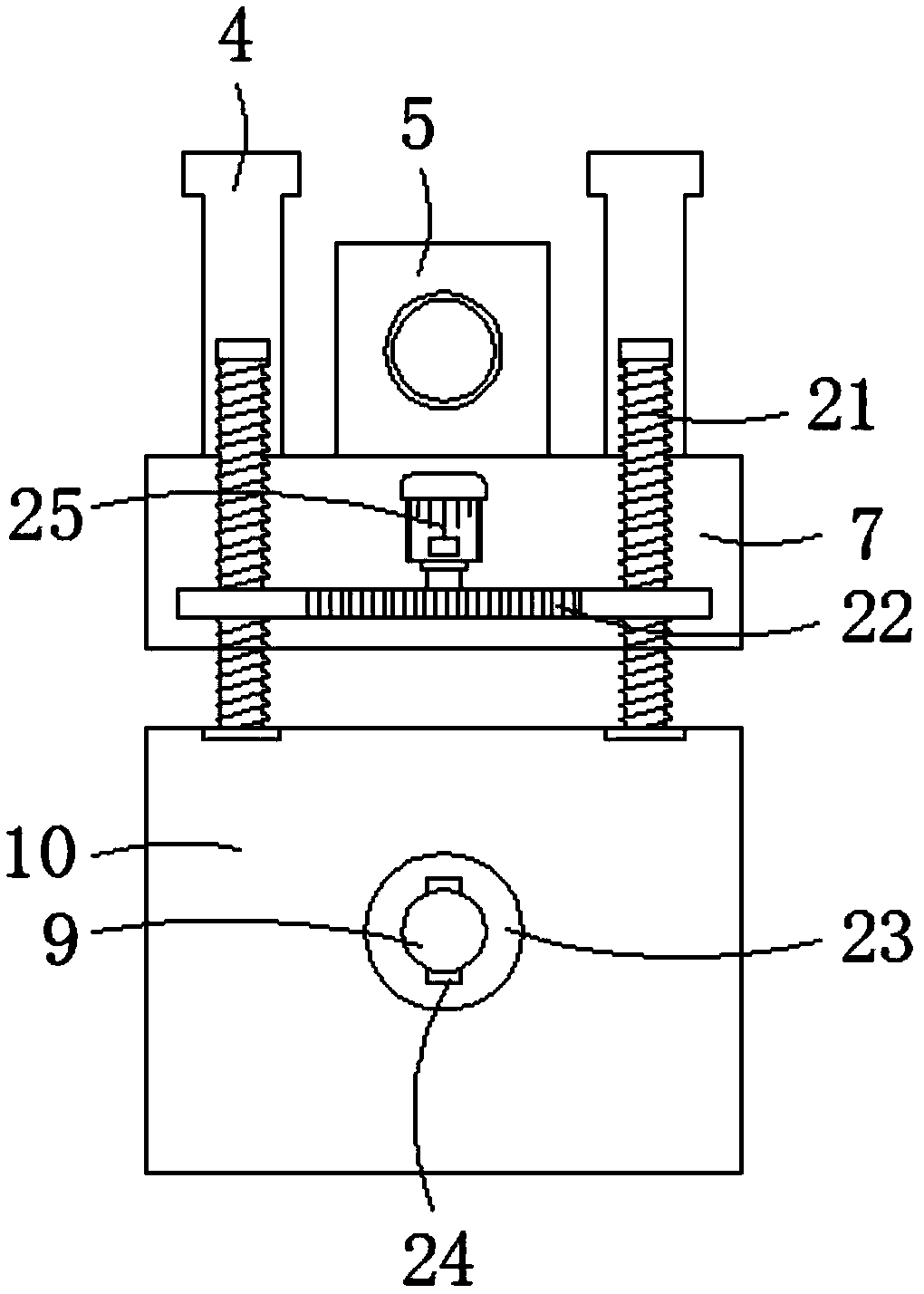

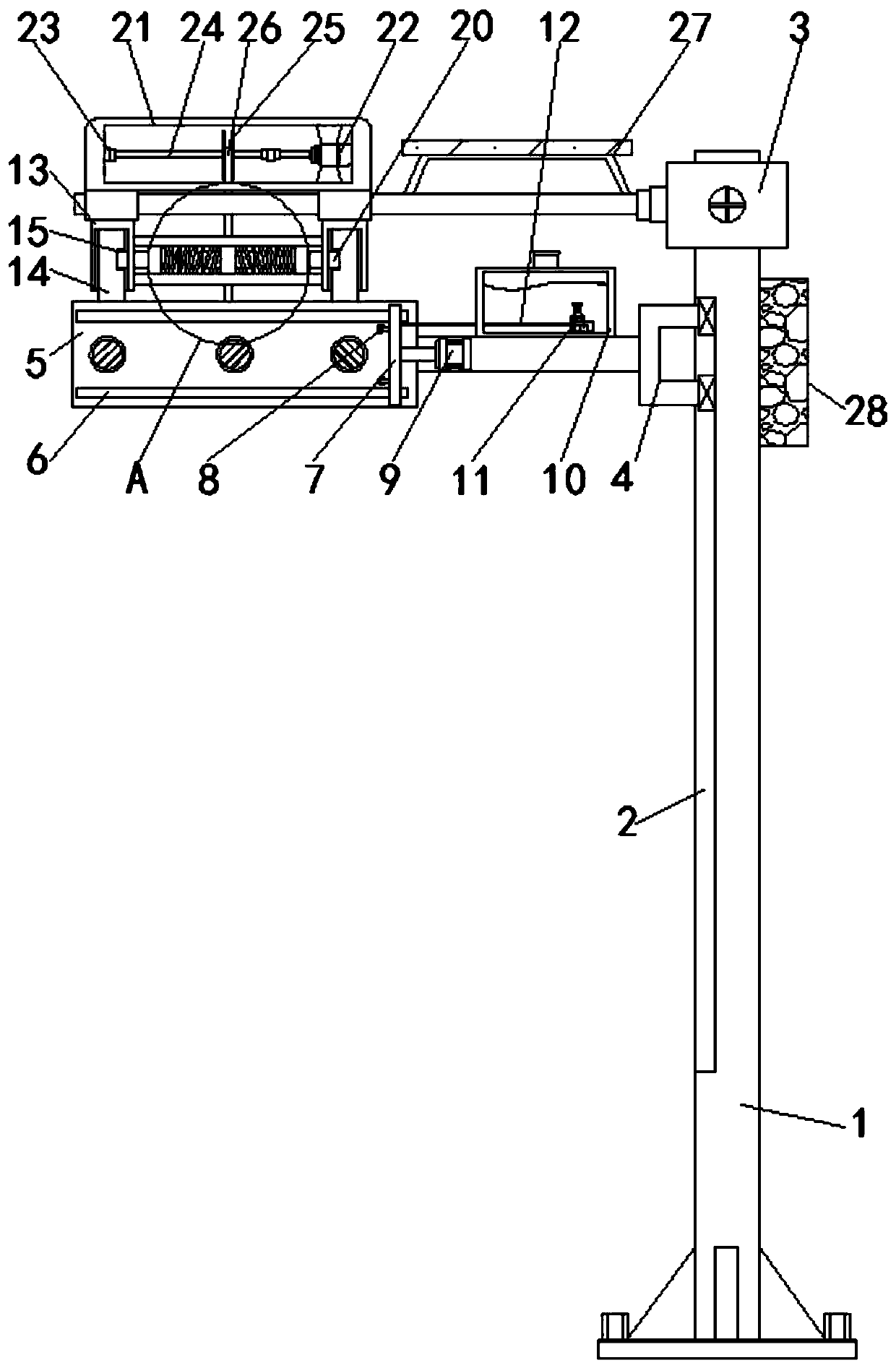

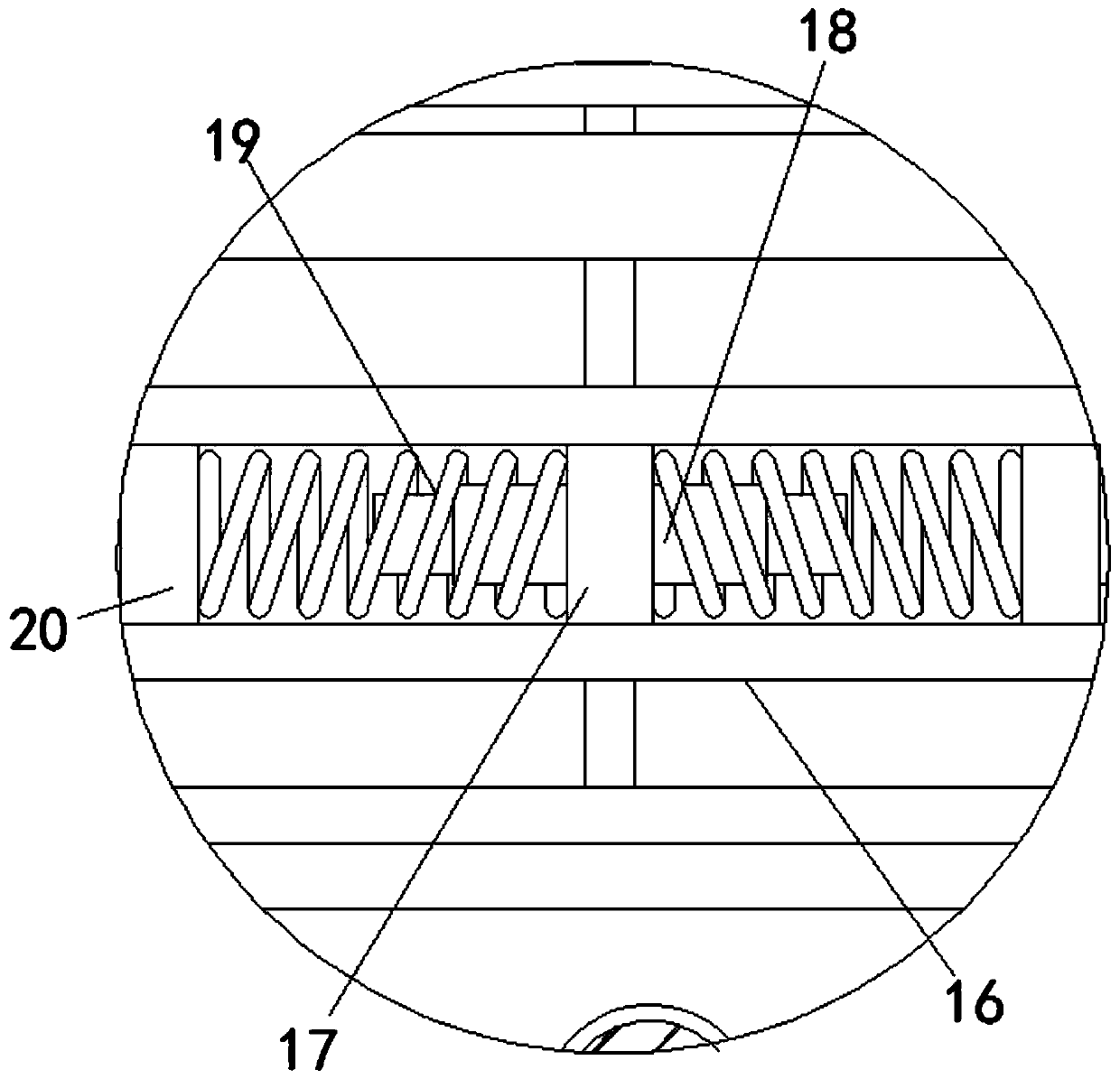

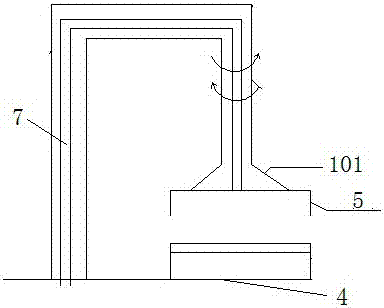

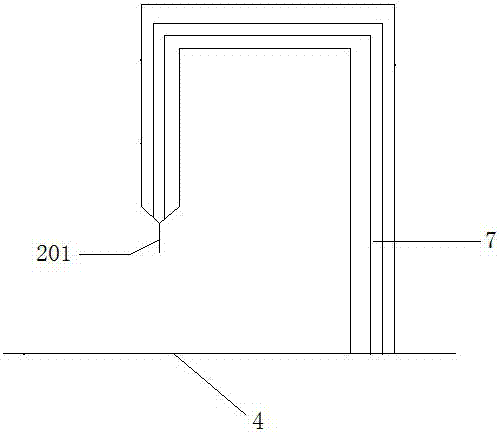

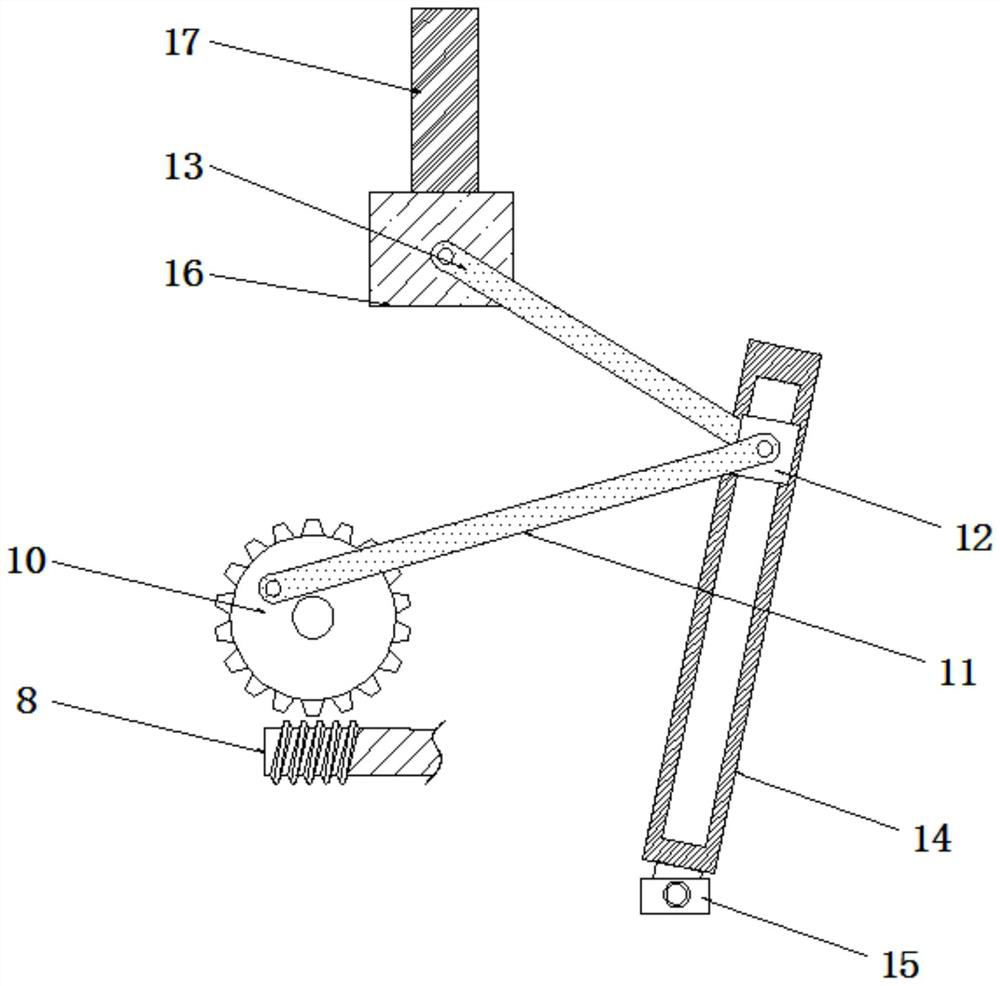

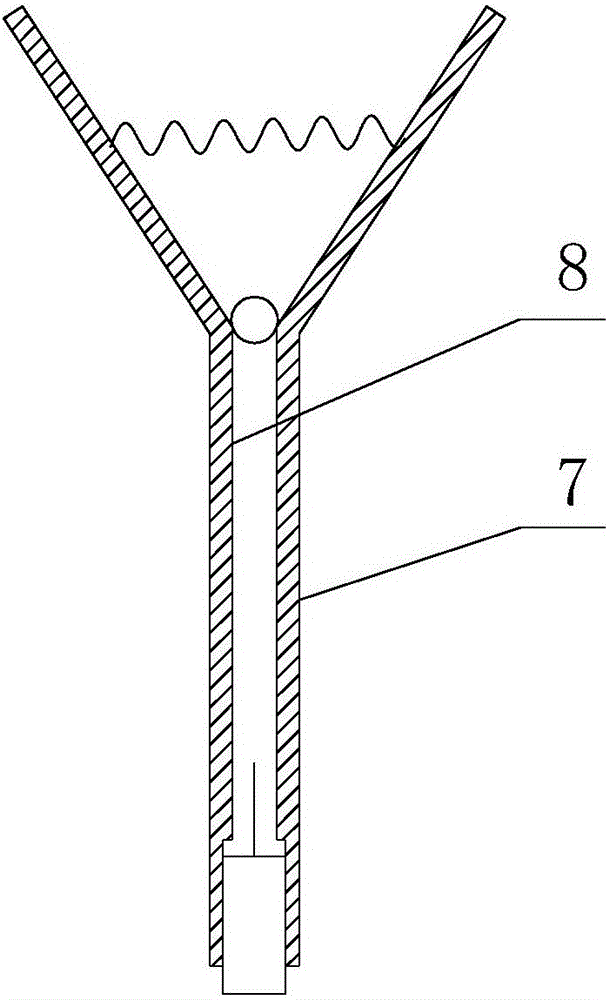

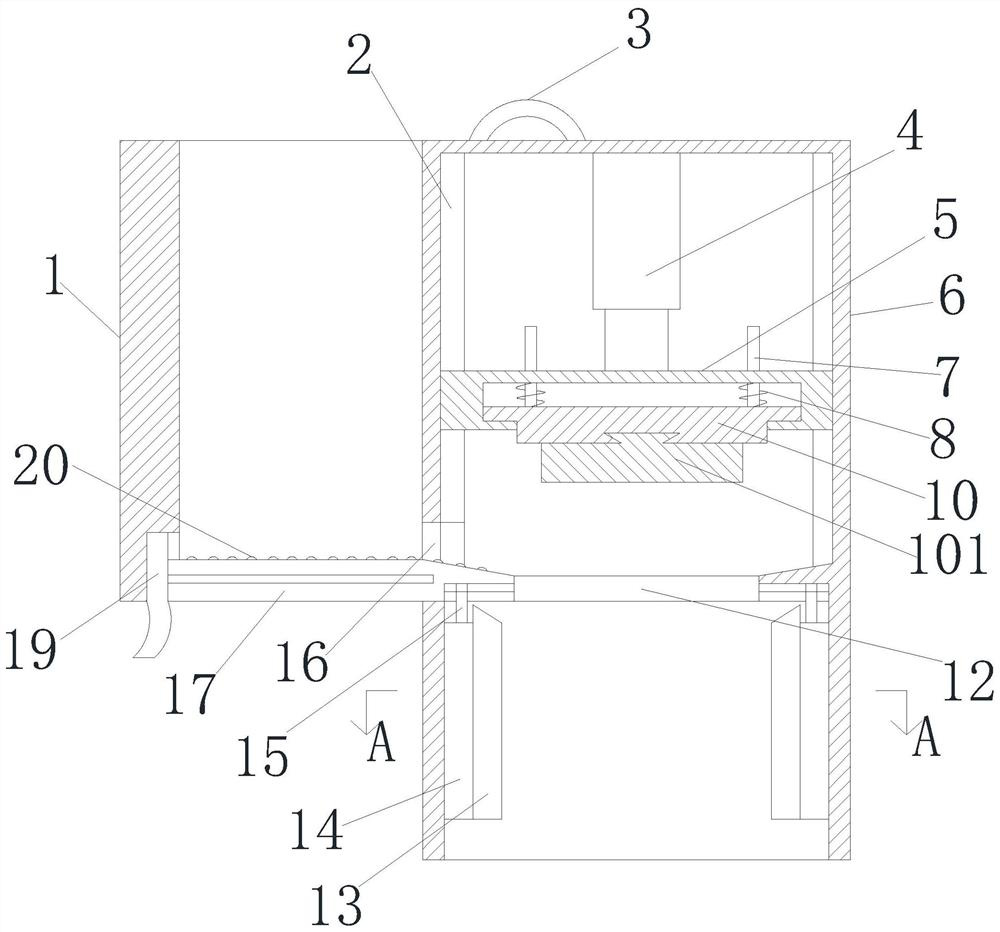

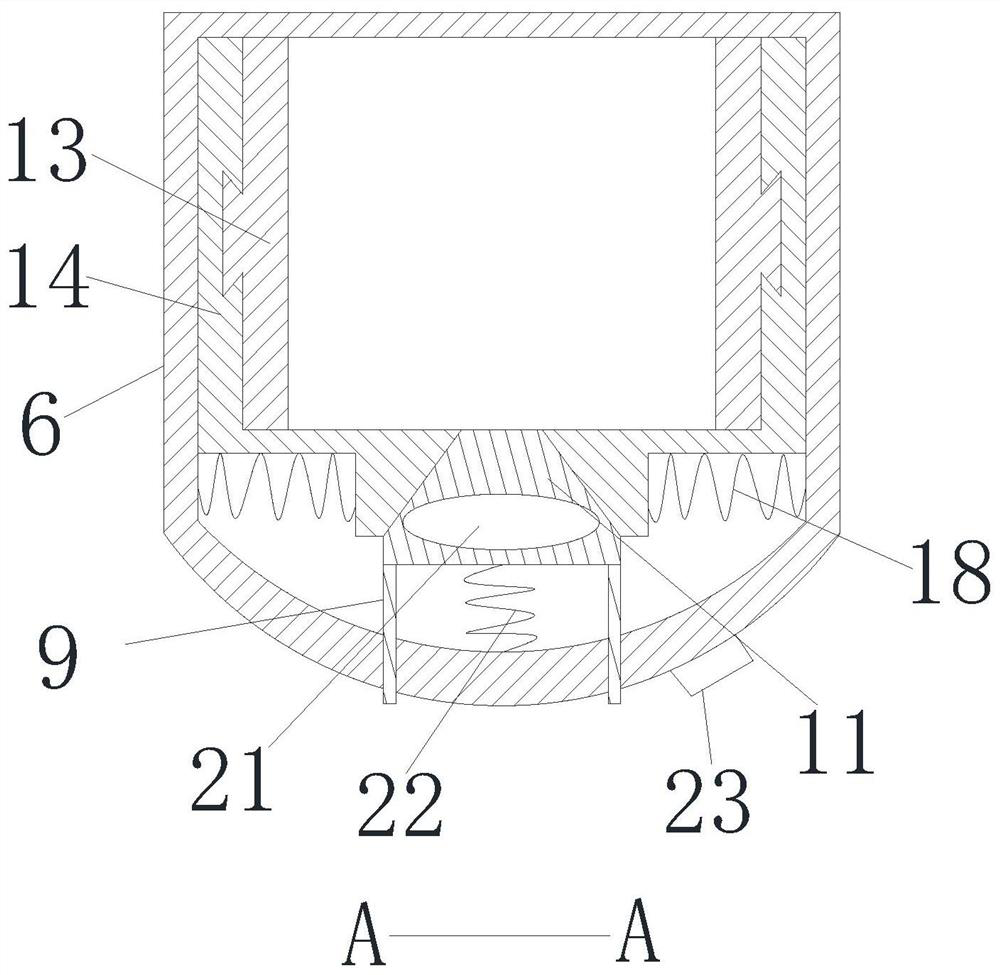

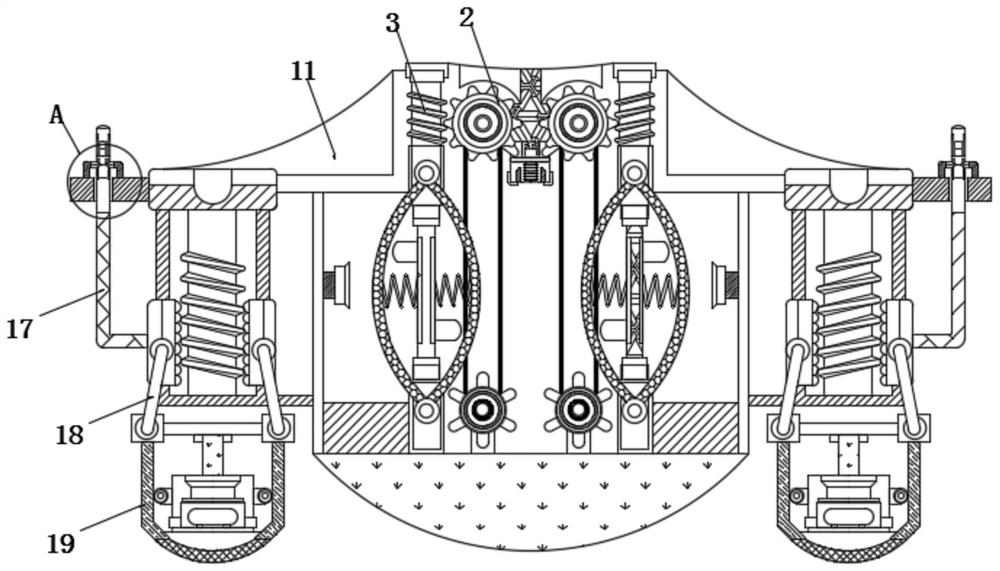

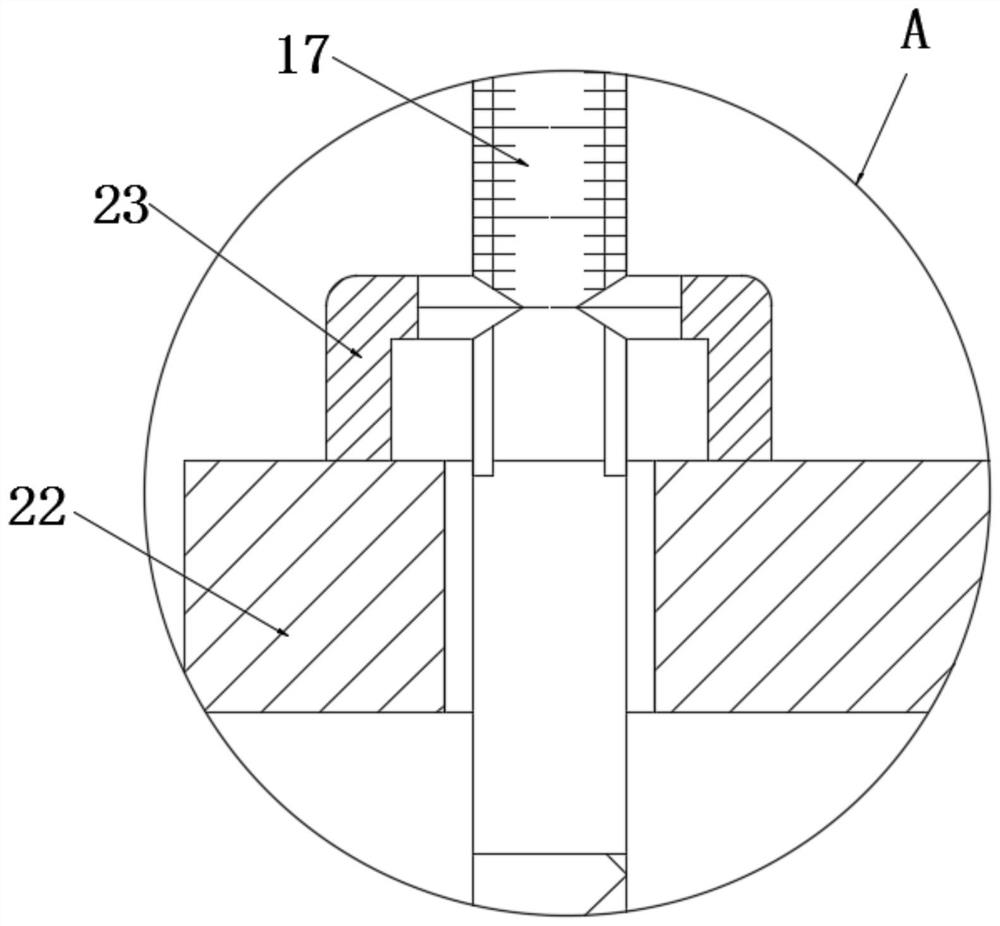

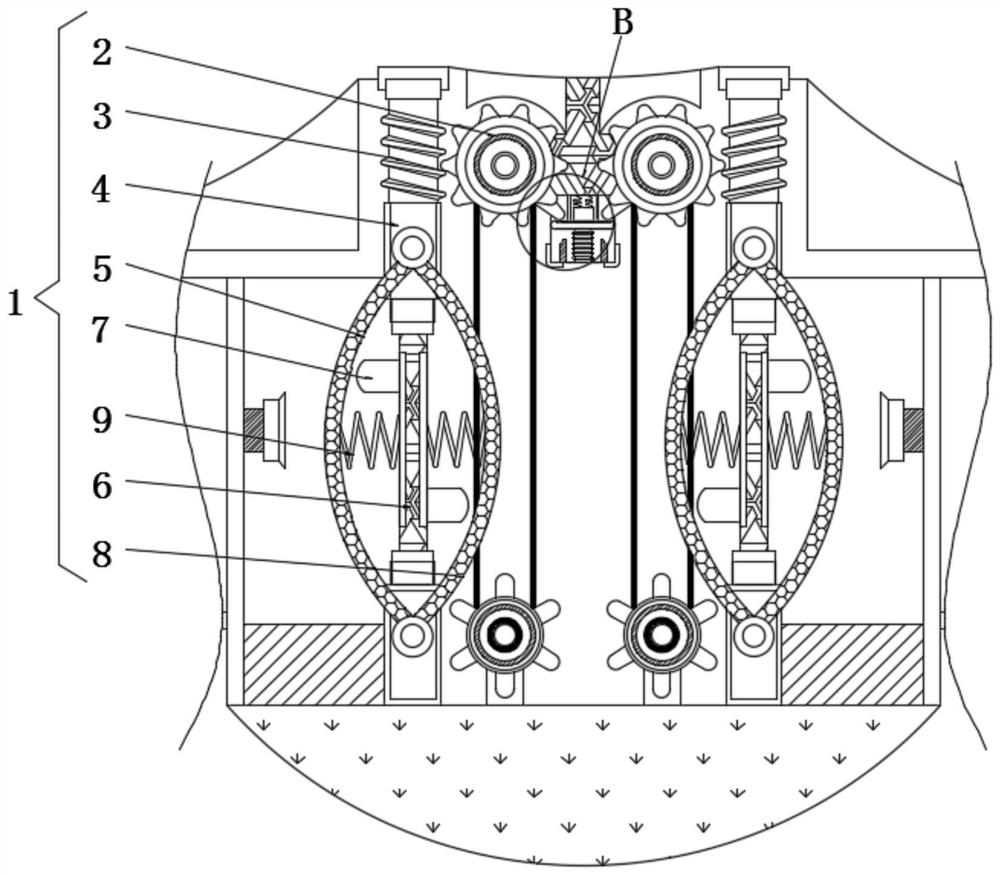

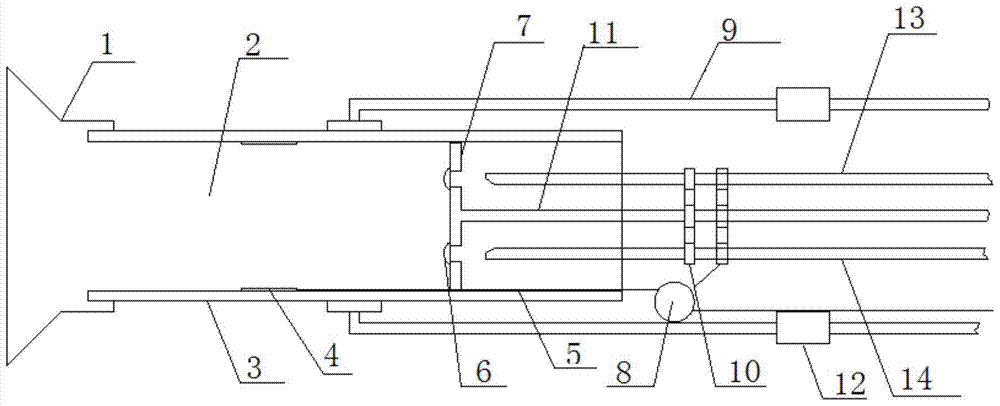

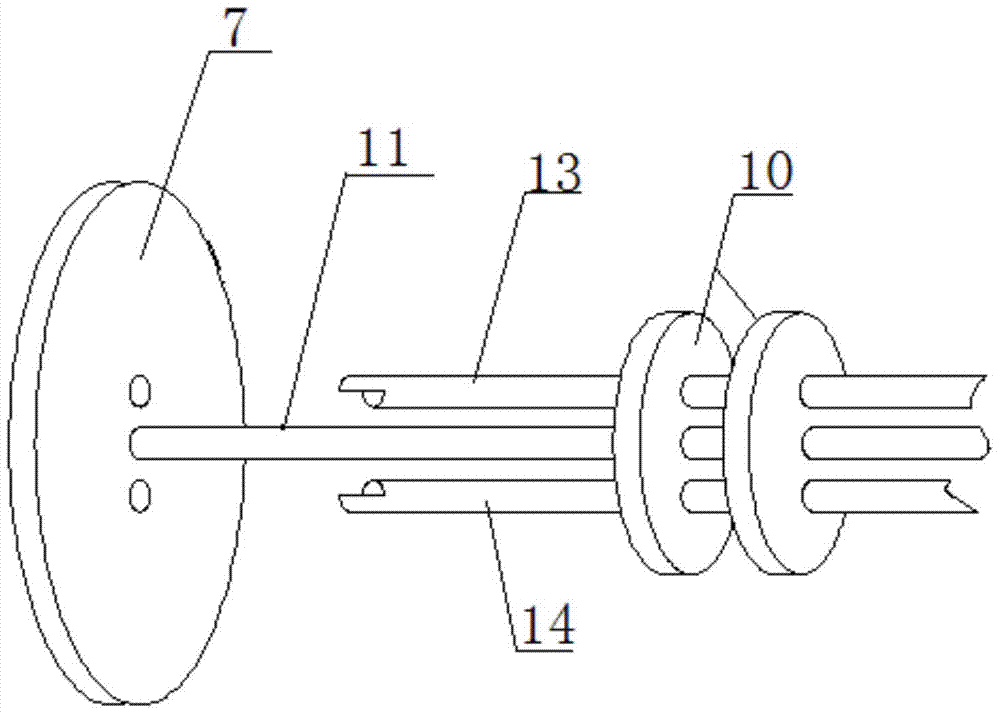

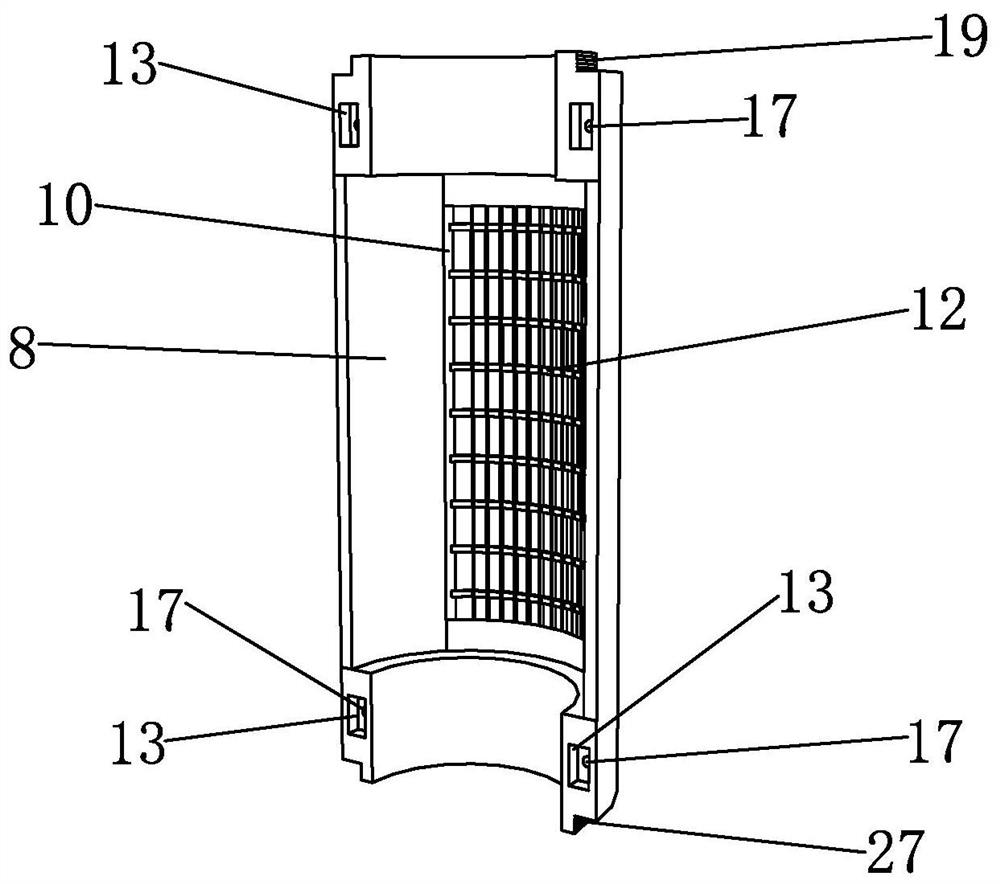

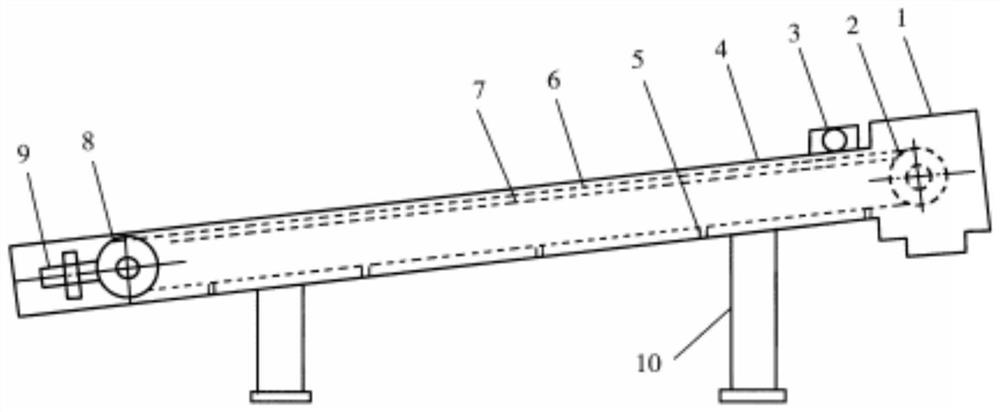

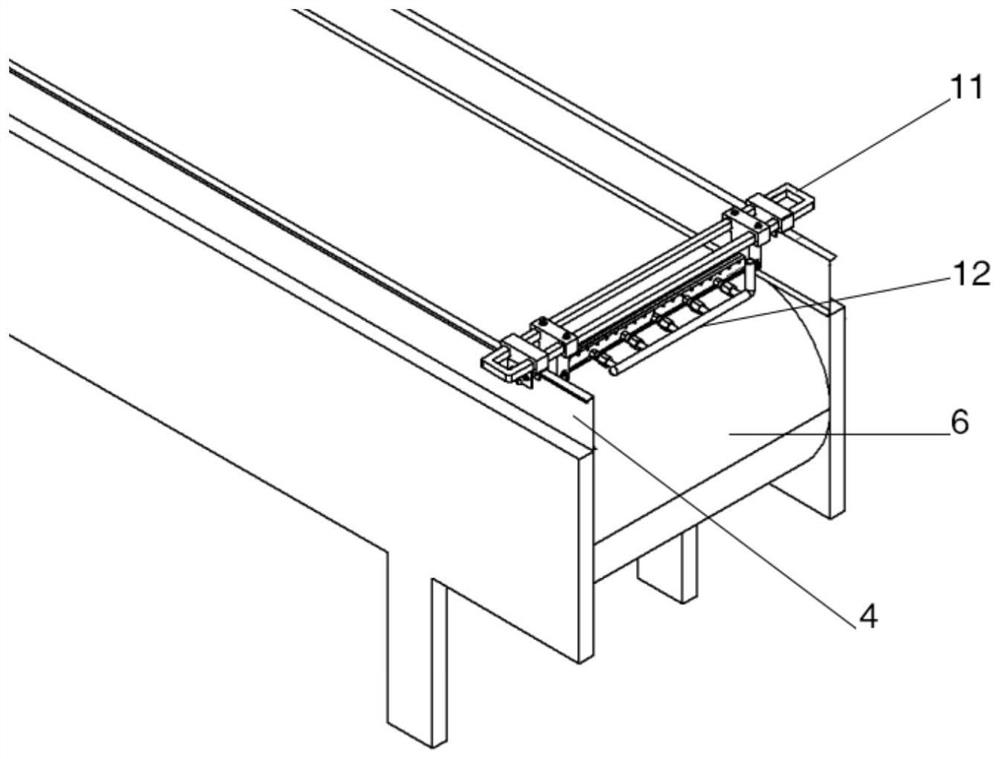

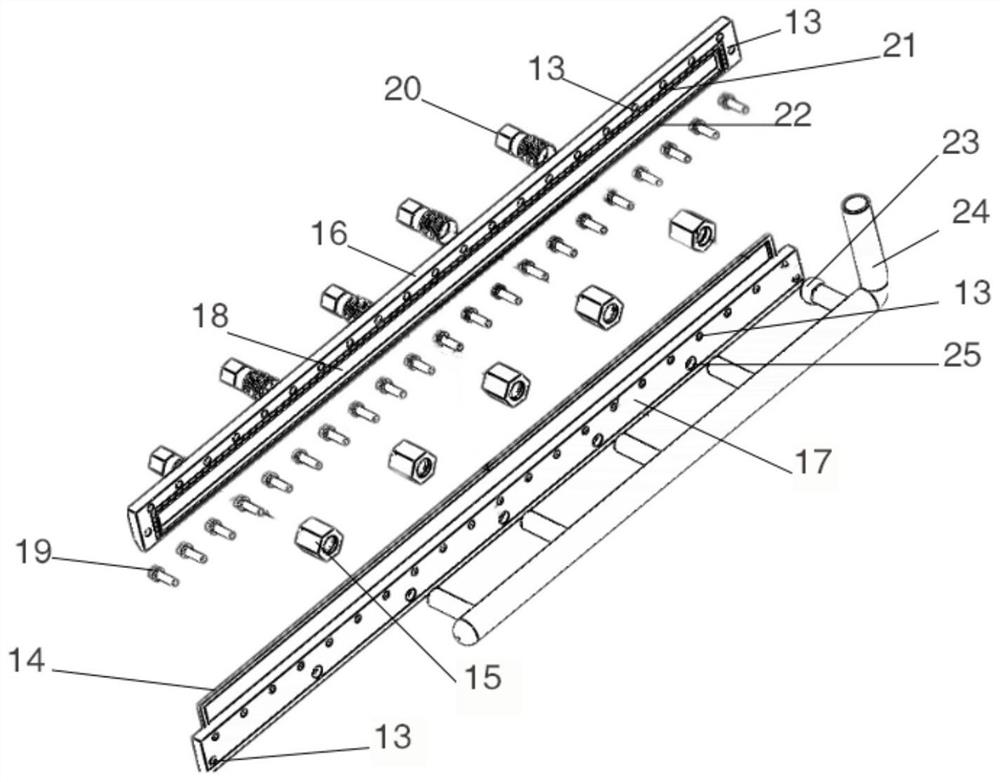

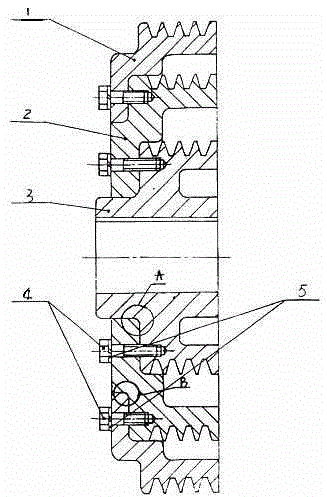

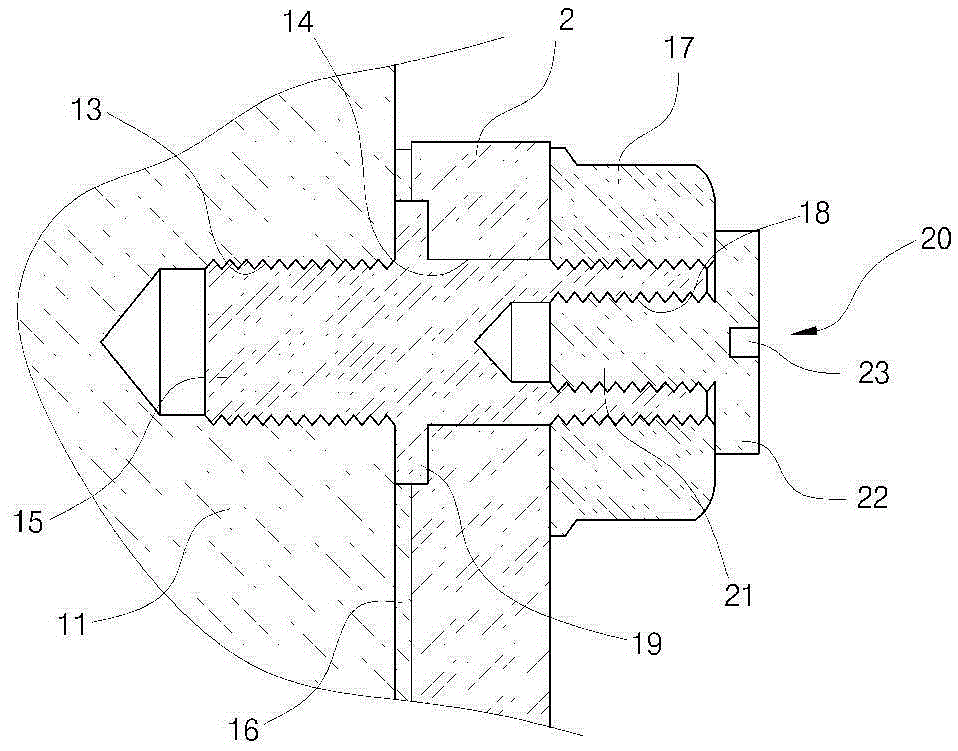

Multi-channel drilling, injecting and pre-tightening integrated anchor rod construction device and method

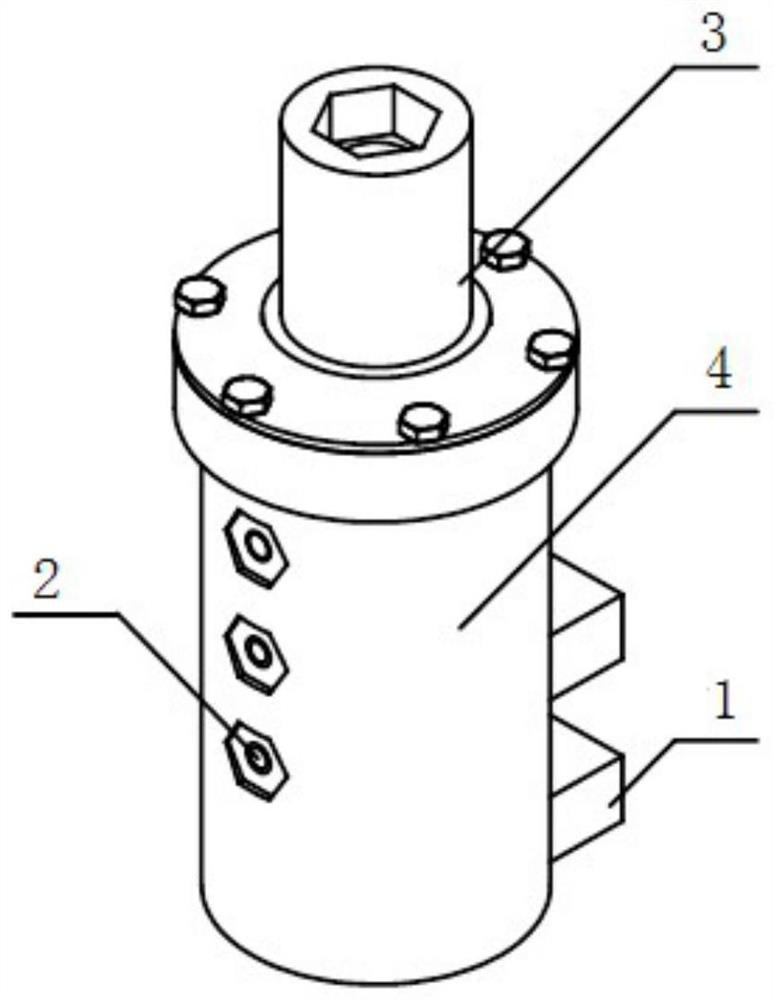

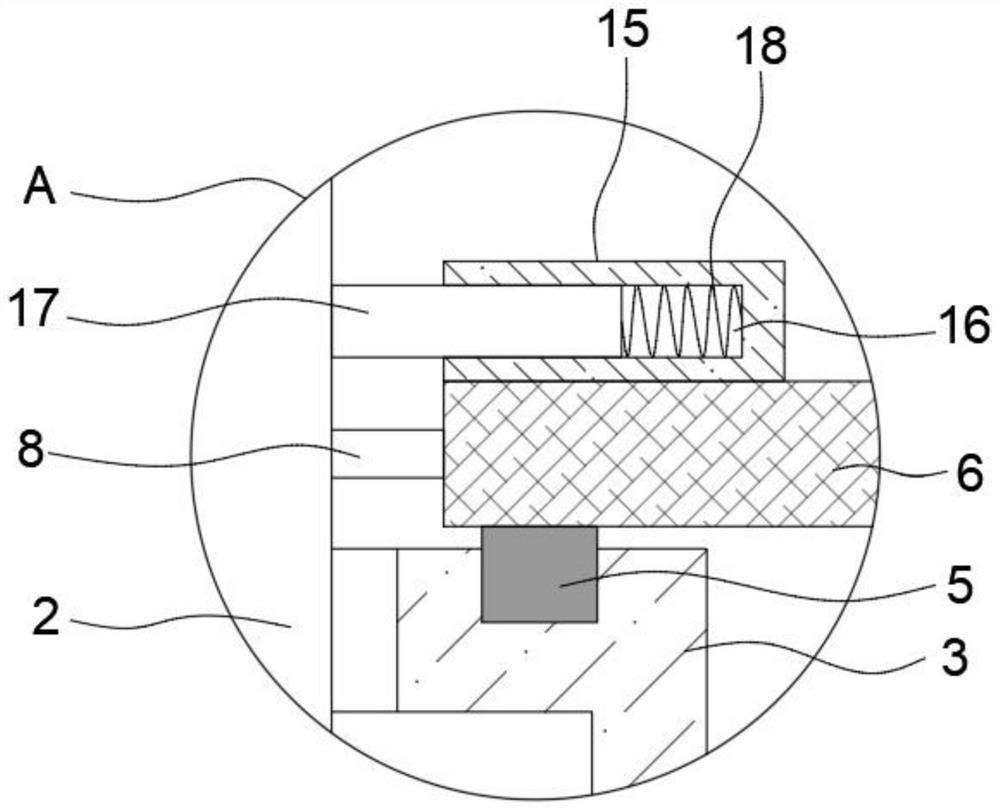

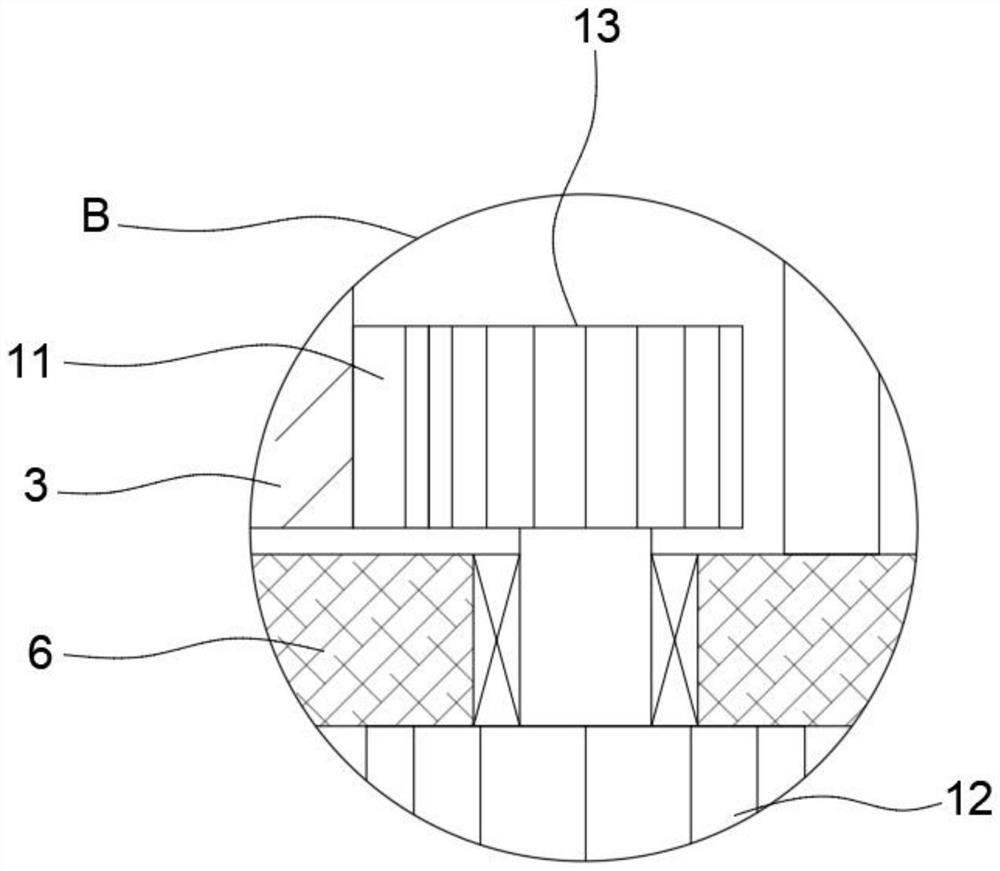

InactiveCN112360507AAvoid manual installationReduce labor intensityUnderground chambersTunnel liningRotational axisClassical mechanics

The embodiment of the invention provides a multi-channel drilling, injecting and pre-tightening integrated anchor rod construction device and method. The multi-channel drilling, injecting and pre-tightening integrated anchor rod construction device comprises a sleeve and a rotating shaft. The sleeve and the rotating shaft are coaxially arranged, the sleeve rotatably sleeve the rotating shaft, a plurality of medium inlets located in different horizontal planes are formed in the side wall of the sleeve, and the medium inlets communicate with the interior of the rotating shaft, so that media required in the drilling and anchoring process are conveyed into an anchor rod for drill bit cooling, deslagging or anchoring; and an anchor rod connector used for being connected with the anchor rod is formed in the top of the rotating shaft, and a driver connector used for being connected with a driver is arranged at the bottom of the rotating shaft. According to the multi-channel drilling, injecting and pre-tightening integrated anchor rod construction device, multiple functions of drilling, anchoring agent pumping, anchoring, pre-tightening and the like in the anchor rod supporting process canbe integrally achieved, the supporting efficiency is improved, and rapid supporting of a roadway is achieved.

Owner:CCTEG COAL MINING RES INST +1

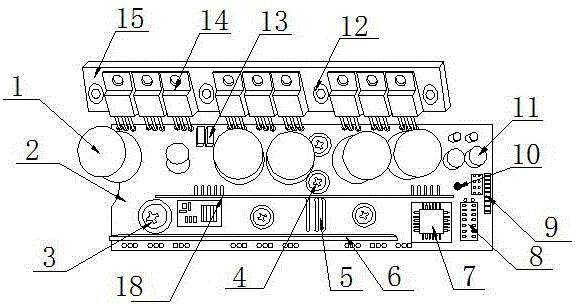

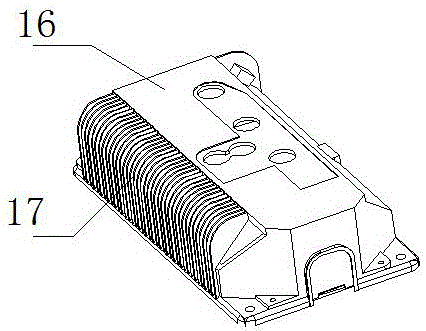

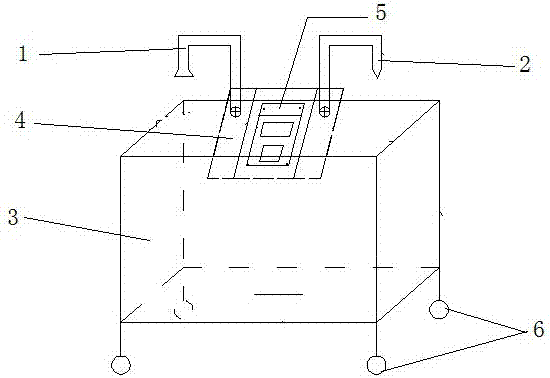

Power controller based on die-casting mould structure

InactiveCN106659038AImprove cooling effectImprove performanceCircuit arrangements on support structuresHermetically-sealed casingsPower controllerBridge type

The invention discloses a power controller based on a die-casting mould structure. The power controller comprises a large-current filtering element, a main PCB, a three-phase motor output terminal, a power input terminal, a current detection element, a bus bar, a master control MCU, a signal input filtering module, a wiring terminal, an indicating lamp, an auxiliary power supply discrete element, an elliptical positioning hole, an upper and lower bridge separation driver, a power switch tube, an aluminum substrate, an aluminum housing, heat dissipation teeth and a bridging type crossover auxiliary PCB. According to the technical scheme of the power controller in the invention, a double-row aluminum substrate and an aluminum shell are connected to improve heat dissipation effect, so that the thermal damage to the switch tube is reduced. Based on the bridging manner of PCBs, the current uniformity of power switch tubes connected in parallel is guaranteed to the greatest extent. Meanwhile, the large-current impact resistance of the entire circuit is improved. The power input terminal and three output terminals (U, V and W) are led out in the casting mode by using a copper column and the aluminum shell of a die-casting mould. Therefore, the problem that water flows into the incoming and outgoing lines and the structure of a common controller in the prior art can be solved.

Owner:刘军

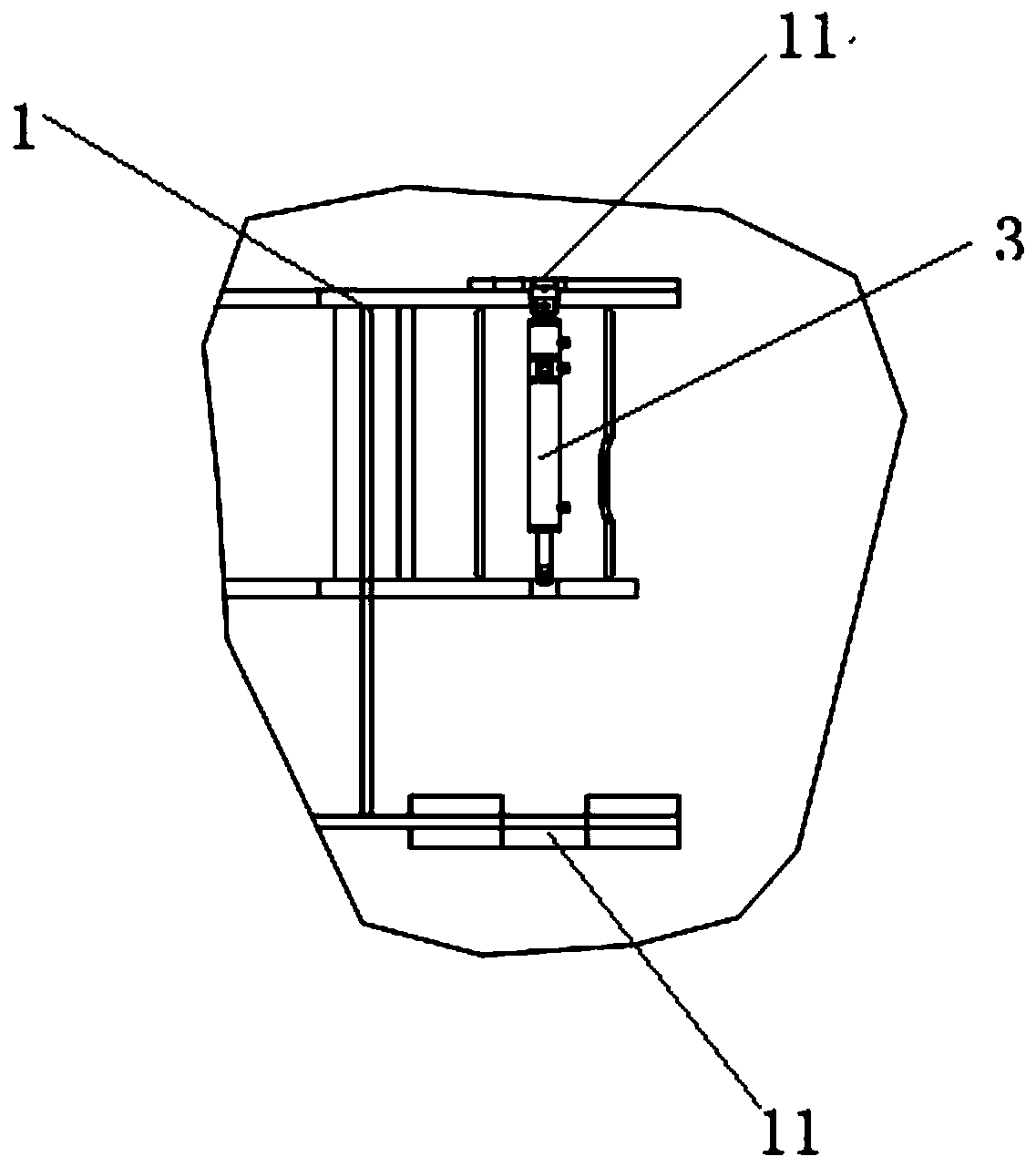

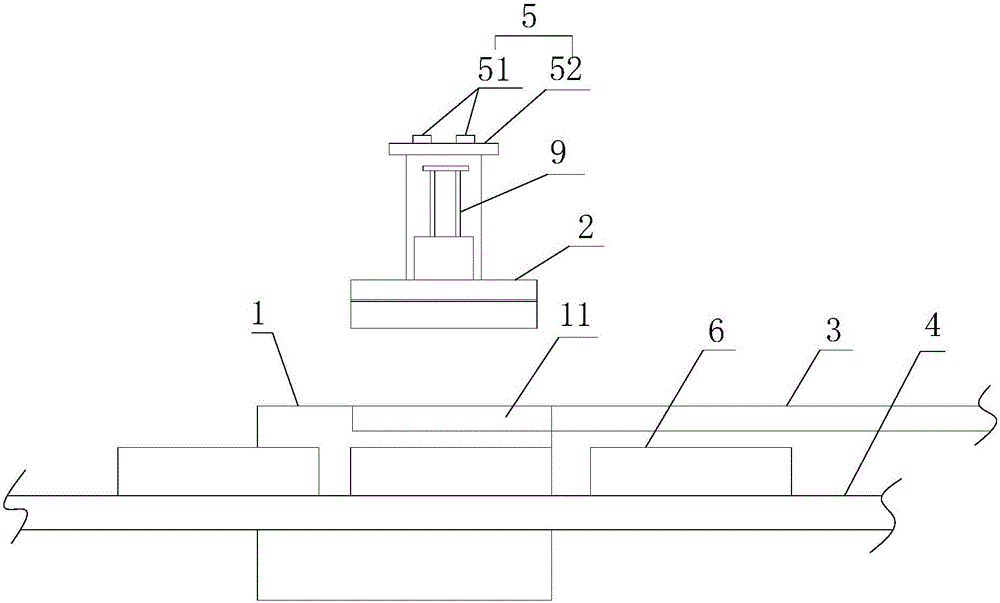

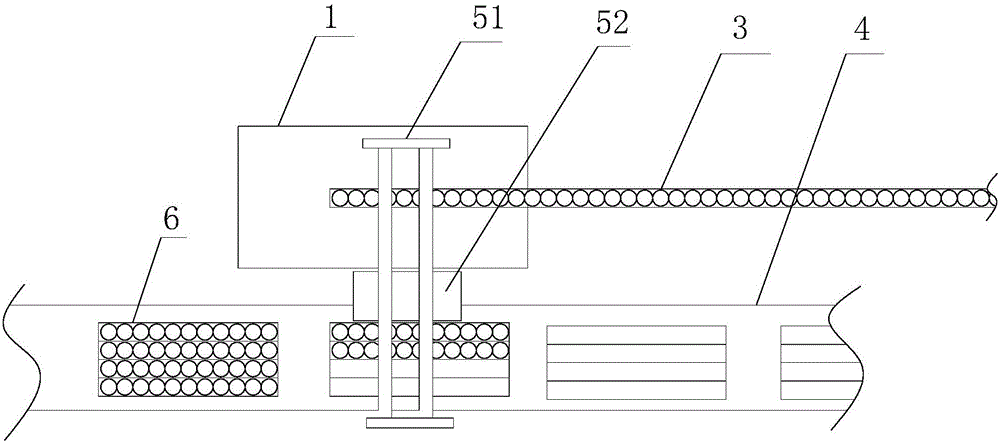

Mine exploding fixing installation device for facilitating palisade explosive installation

The invention discloses a mine exploding fixing installation device for facilitating palisade explosive installation. The fixing installation device comprises a base, a groove and an explosion barrel;a control panel is installed on the side of the base; a telescopic rod is connected to a first air cylinder; the groove is formed in the top of the base and internally provided with a moving frame; asecond air cylinder is fixed to the inner side of the top of the moving frame, and the side of the moving frame is provided with a positioning barrel; a fixed rod is connected to the second air cylinder and located in the positioning barrel; the explosion barrel is installed in the positioning barrel, and the outer side of the explosion barrel is provided with a lantern ring; and springs are installed on the lantern ring, and clamping blocks are fixed to one ends of the springs. According to the mine exploding fixing installation device for facilitating palisade explosive installation, the springs and the clamping blocks are arranged, the two clamping blocks are centrally symmetrical with respect to the explosion barrel, thus, the explosion barrel is placed more firmly, and through the first air cylinder and the second air cylinder, the explosion barrel is automatically pushed into an explosion hole.

Owner:GUIZHOU UNIV

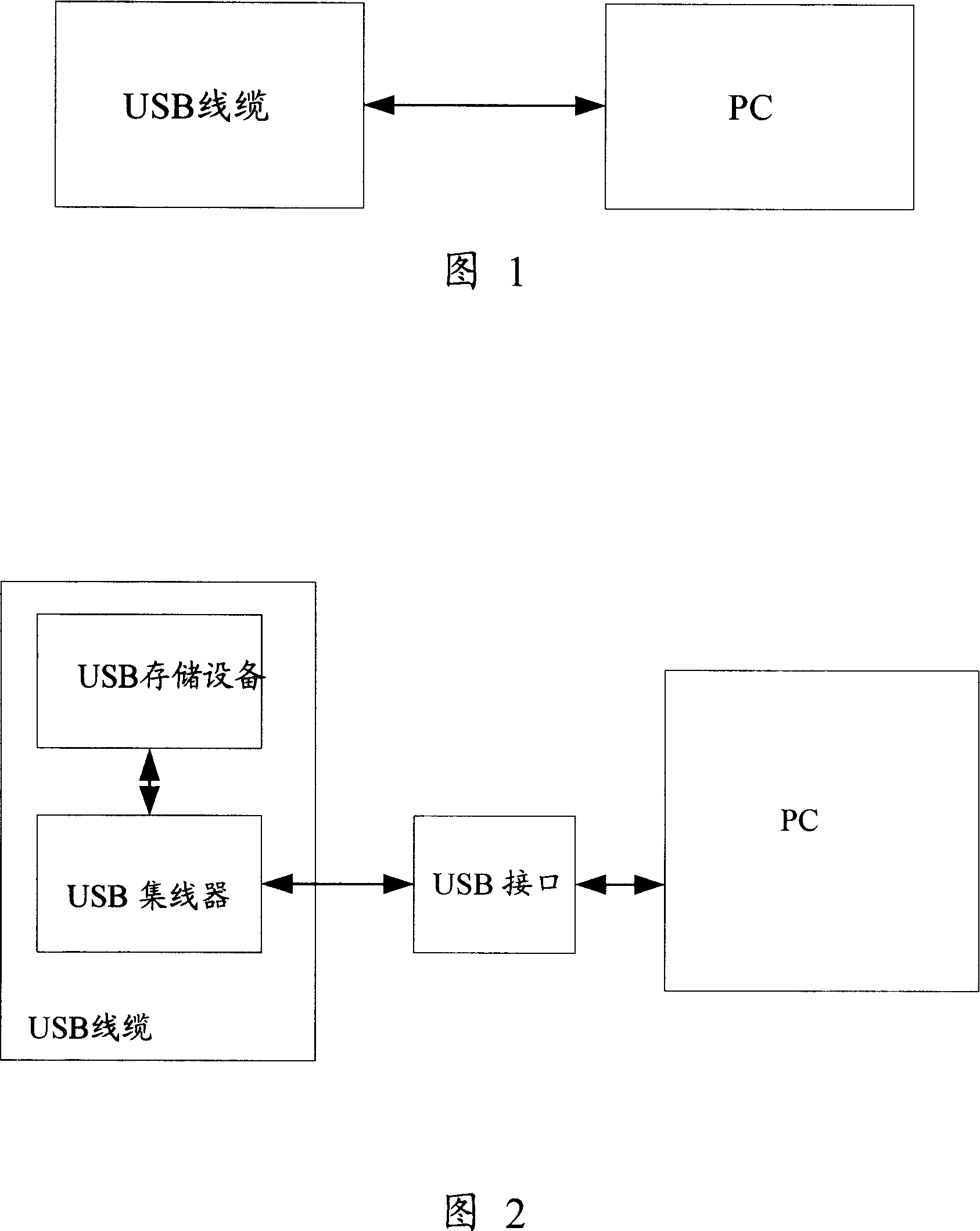

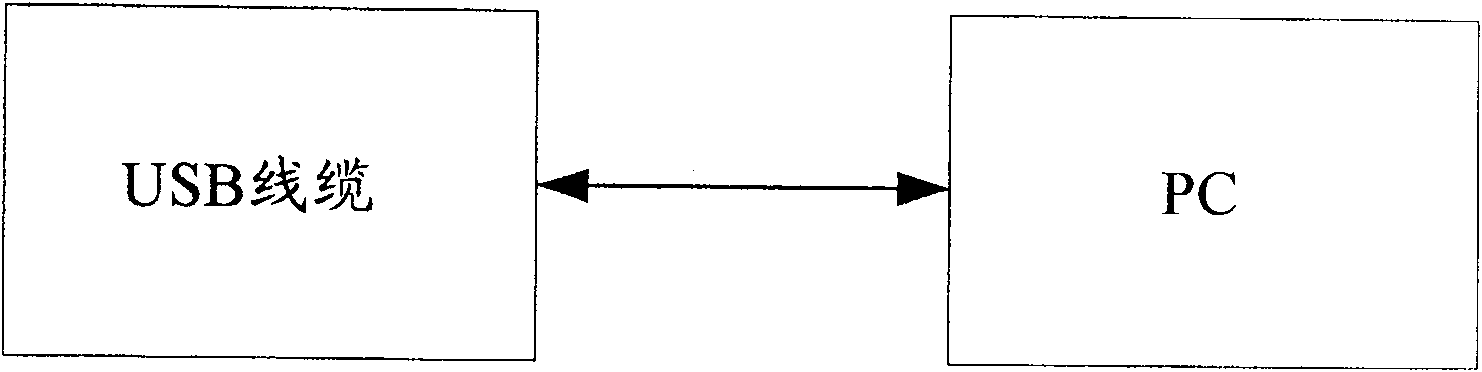

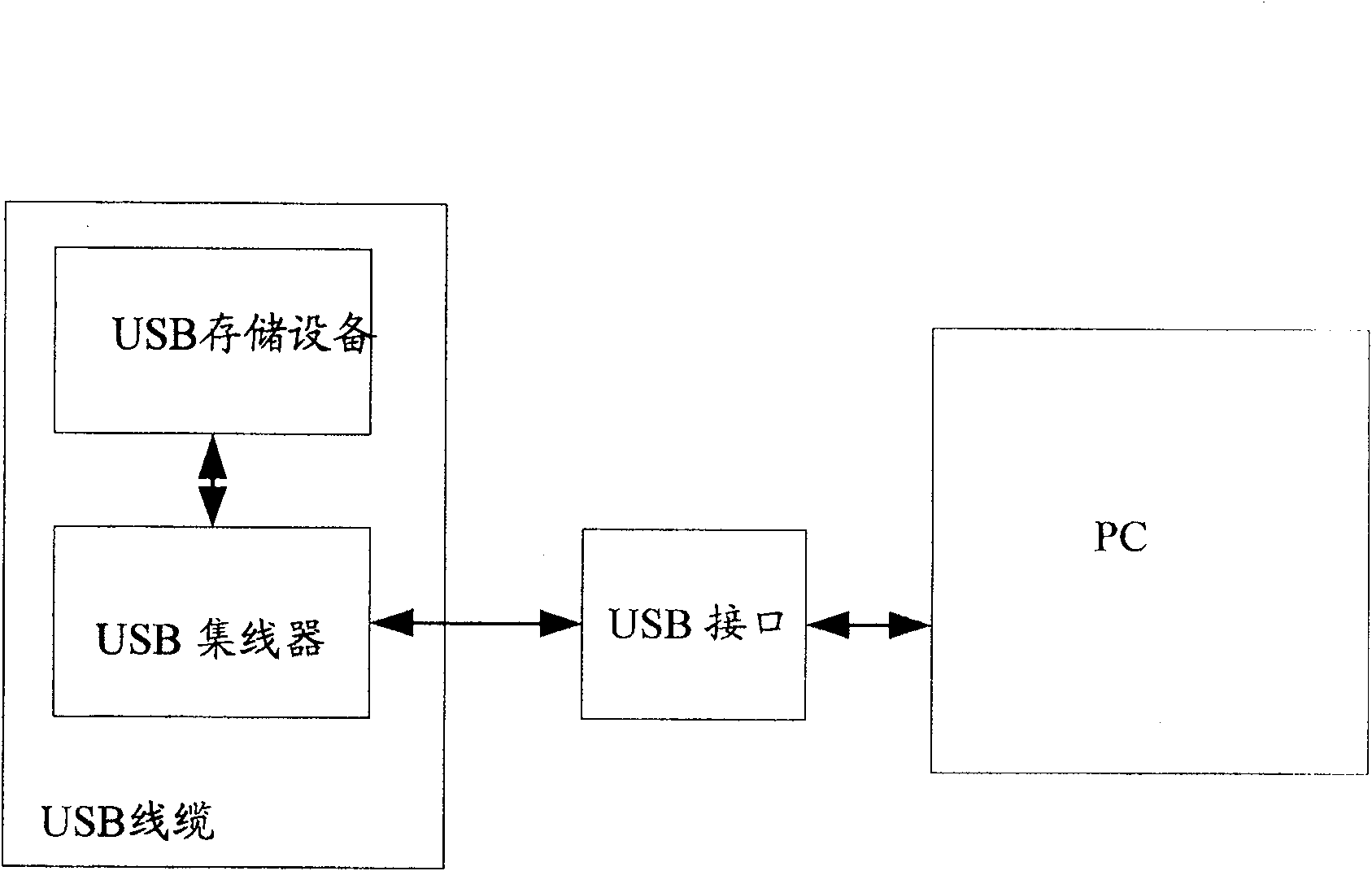

System and method for mounting peripheral device program and USB cable

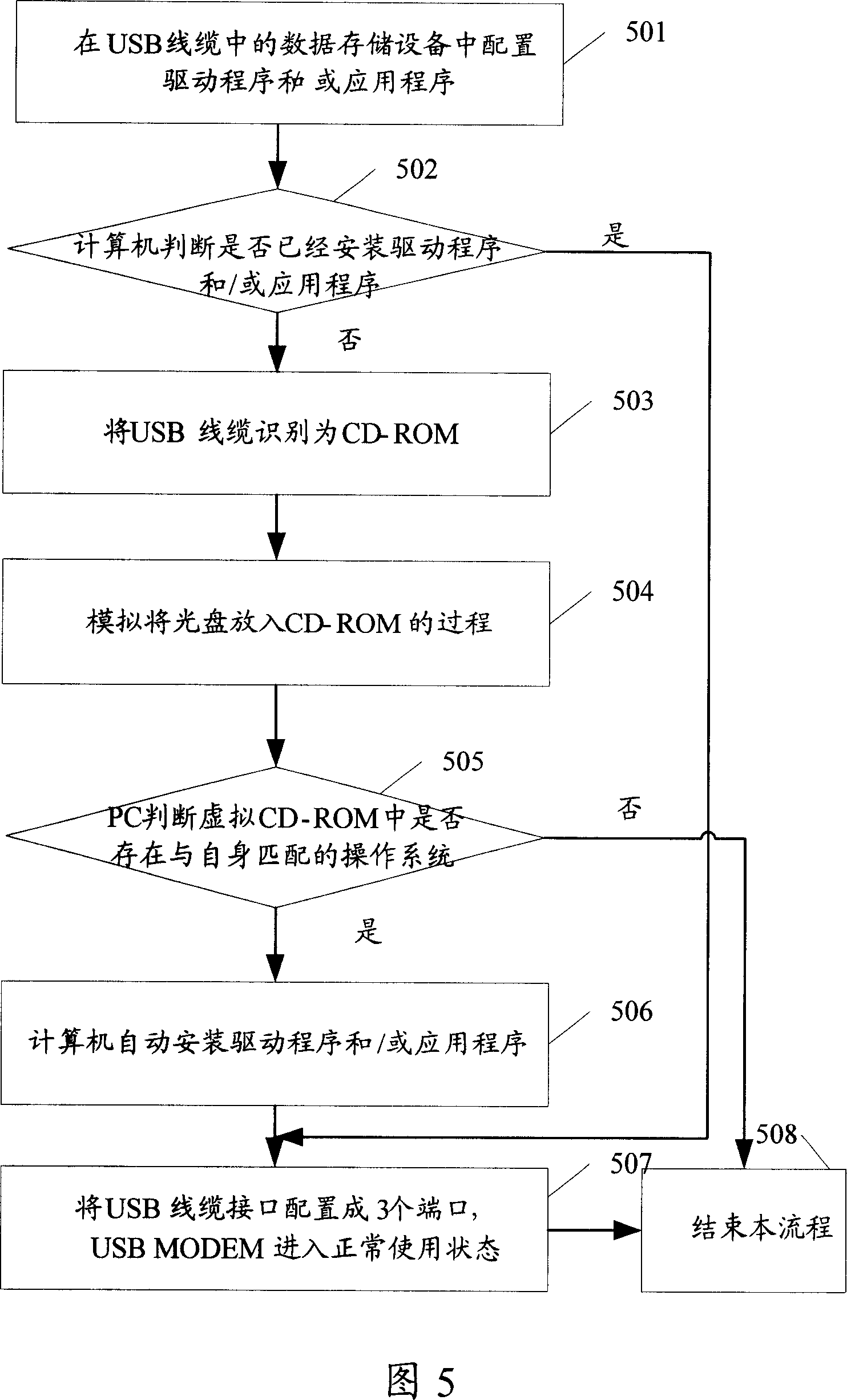

ActiveCN1996250AGood flexibilityEasy to useProgram loading/initiatingApplication softwareLarge capacity

A method for installing enclosure equipment comprises storing enclosure equipment drive program or application program of the USB cable, identifying the USB cable with large volume of storage equipment, installing drive or application program of the storage equipment. It also provides a system for installing enclosure equipment program and USB cable, storing the drive program and or application program on the USB cable to realize PC automatic installing of drive program or application program of the USB cable for the convenience of the user.

Owner:HUAWEI TECH CO LTD

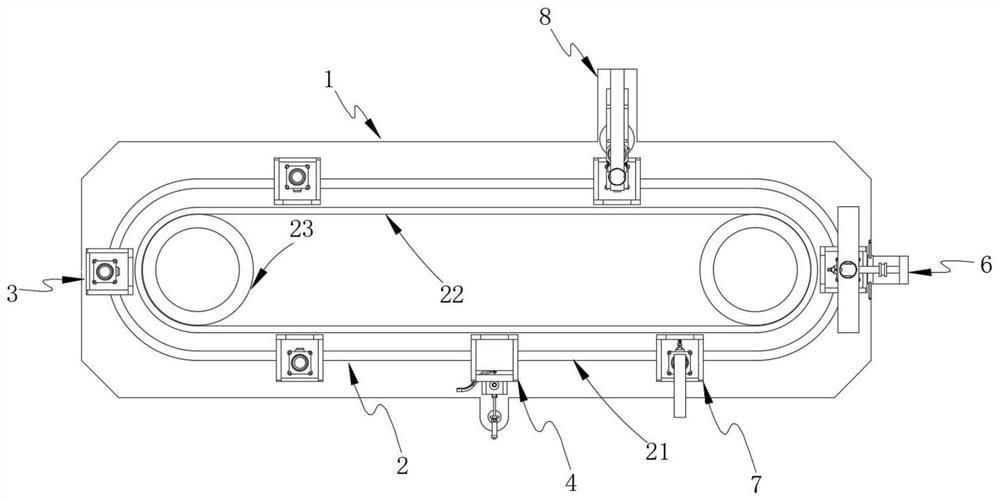

Automatic cloth feeding machine of clothing machinery

InactiveCN108423462AAvoid installing cloth rollsReduce manual labor intensityWebs handlingEngineeringMechanical engineering

The invention discloses an automatic cloth feeding machine of clothing machinery. The automatic cloth feeding machine comprises a machine base, a first hydraulic telescopic rod, a push plate and a second hydraulic telescopic rod are installed inside the machine base, and the push plate is located between the first hydraulic telescopic rod and the second hydraulic telescopic rod and is fixedly connected with the first hydraulic telescopic rod through bolts. According to the automatic cloth feeding machine, a first yardage roll, a conveying baseboard, the first hydraulic telescopic rod, the second hydraulic telescopic rod and a clamping groove are arranged, when a second yardage roll on a center shaft is used up, the second hydraulic telescopic rod conducts driving, so that an L-shaped fixedplate falls until the L-shaped fixed plate falls into the clamping groove, at this moment, the top face of a cross plate of the L-shaped fixed plate is flush with the top face of the machine base, the first hydraulic telescopic rod conducts driving, the conveying baseboard is pushed to move through the push plate, the first yardage roll on the conveying baseboard is pushed to the L-shaped fixed plate, the first yardage roll is in a hollow state and exactly sleeves the center shaft, and thus automatic feeding of the yardage rolls is achieved.

Owner:长兴瑞韬纺织科技有限公司

Signal traffic light convenient to adjust for urban traffic

InactiveCN110992720AEasy maintenanceEasy to installRoad vehicles traffic controlCleaning using toolsWater storageStructural engineering

The invention, which relates to the technical field of signal traffic lights, discloses a signal traffic light convenient to adjust for urban traffic. The signal traffic light comprises a light post;a guide groove is formed in the left side of the light post; a mounting rod is fixedly mounted at the top of the light post, and a moving rod is slidably connected into the guide groove. A light bodyis fixedly mounted on the left side of the moving rod, two sliding grooves are formed in the front surface of the light body, the interiors of the two sliding grooves are slidably connected with a cleaning brush, and the left side of the cleaning brush communicates with two spray heads. According to the signal traffic light, a miniature water pump in a water storage barrel pumps water in the waterstorage barrel into the cleaning brush communicating with the water pipe, the water is sprayed out through the spray heads to clean the surface of the light body; meanwhile, an electric push rod is matched to push the cleaning brush to move in the sliding grooves to clean the surface of the light body, so that manual cleaning and maintenance are avoided, and the daily maintenance cost is reduced.

Owner:扬州驿丰诚信息科技有限公司

Apparatus for automatically detaching cover from three-phase electric energy meter

PendingCN107543945ARemove the cover to avoidAvoid manual installationMetal working apparatusTime integral measurementControl engineeringManipulator

The invention belongs to the field of electric energy meter detection, and in particular relates to an apparatus for automatically detaching a cover from a three-phase electric energy meter. The apparatus includes a controller, a first manipulator, a second manipulator and a fixing apparatus. The controller is in separate connection to the first manipulator and the second manipulator. The first manipulator is provided with an absorbing disk thereon. The second manipulator is provided with a screw driver thereon. The first manipulator and the second manipulator are both disposed on the fixing apparatus. According to the invention, the apparatus herein can control the manipulators to automatically detach the cover through the controller, prevents workers from automatically attaching and detaching the cover of the electric energy meter, effectively saves man power and materials and also increases working efficiency.

Owner:JIEYANG POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

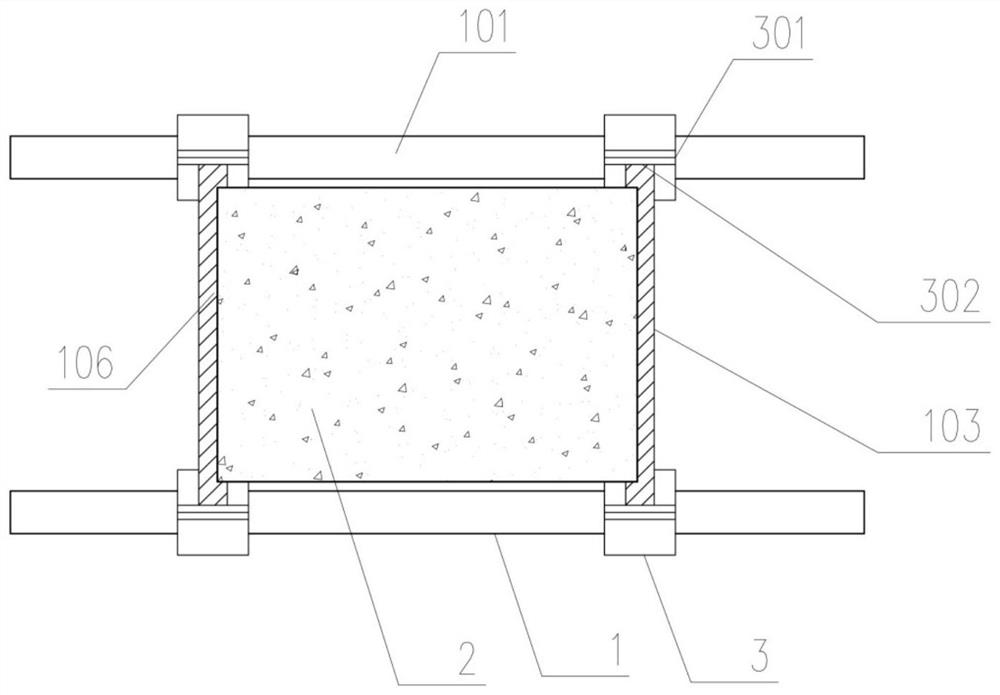

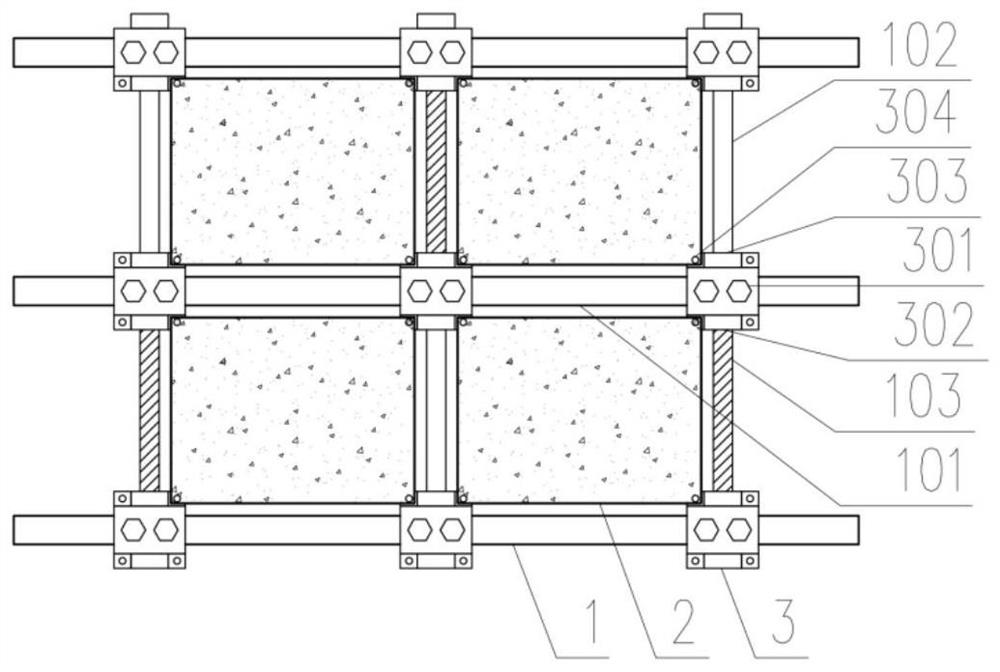

Multifunctional ecological restoration equipment and ecological restoration method

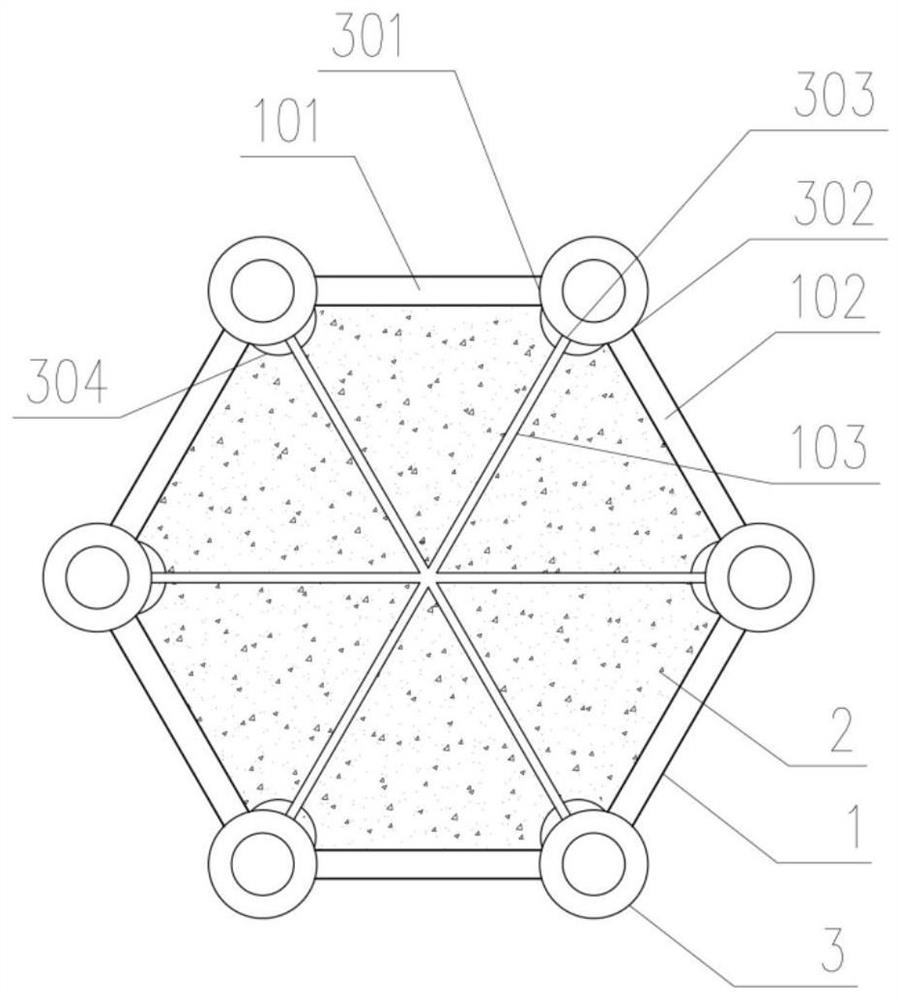

PendingCN112390366AEasy to installFlexible and convenient to buildWaste water treatment from animal husbandryAgriculture gas emission reductionEnvironmental resource managementEngineering

The invention provides multifunctional ecological restoration equipment, and belongs to the field of ecological restoration and treatment. The ecological restoration equipment comprises floating assemblies, functional modules and connecting assemblies, wherein the functional modules are detachably connected with the floating assemblies and / or the connecting assemblies; the floating assemblies comprise floating pieces, and the floating pieces are detachably connected through the connecting assemblies to form the floating assemblies. The functional modules can be selected from one or more of a planting assembly, a habitat assembly, a purification assembly, a landscape assembly and a power assembly. The functional assemblies can comprise planting units, buoyancy adjusting units and purifyingunits. The ecological restoration equipment is designed in a nature-imitated mode, installation and construction are convenient, manual intervention is reduced according to the concept of system treatment, and ecological restoration of the water body is achieved. The invention further relates to an ecological restoration method using the multifunctional ecological restoration equipment.

Owner:奕江山环境科技(北京)有限公司

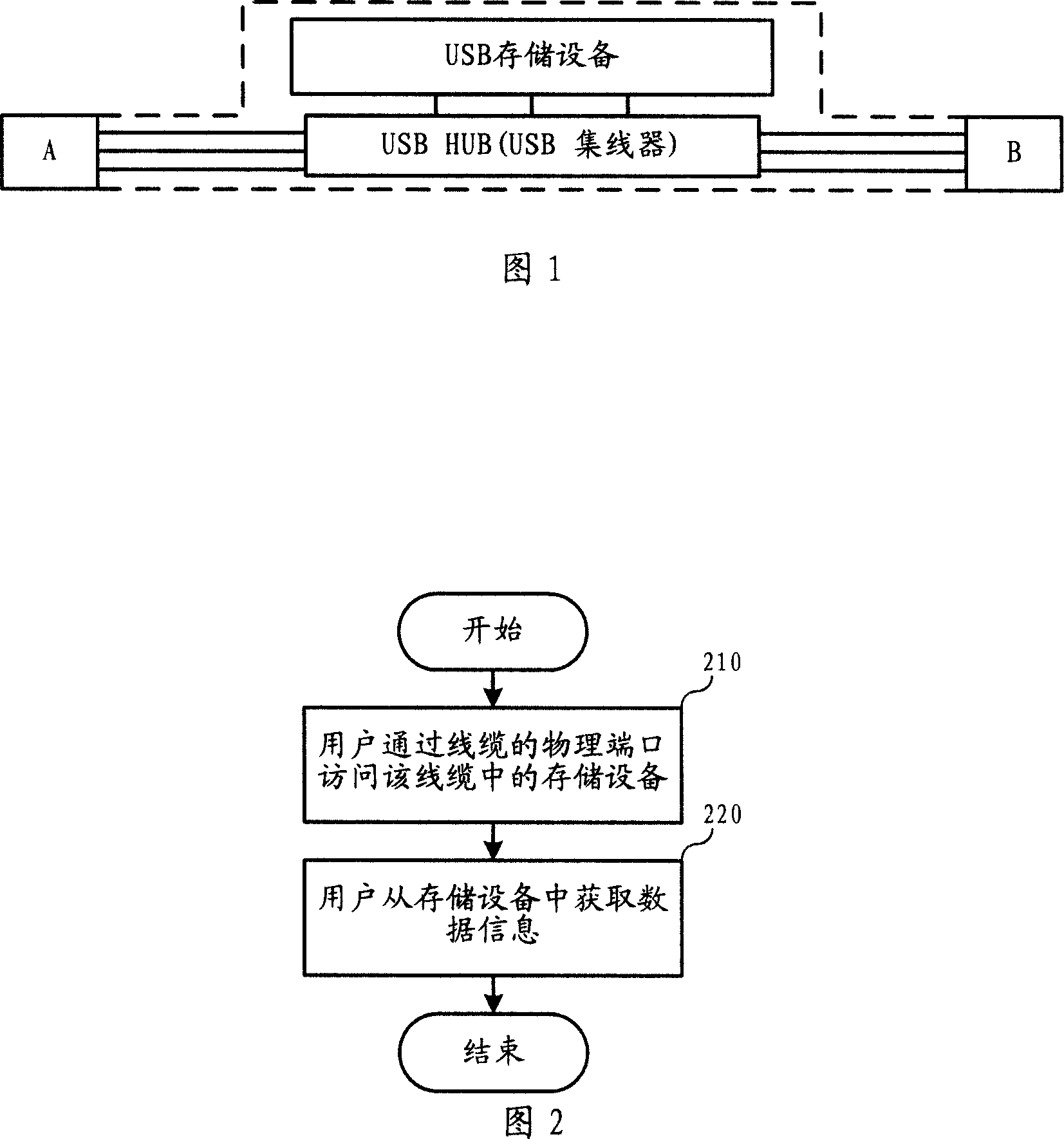

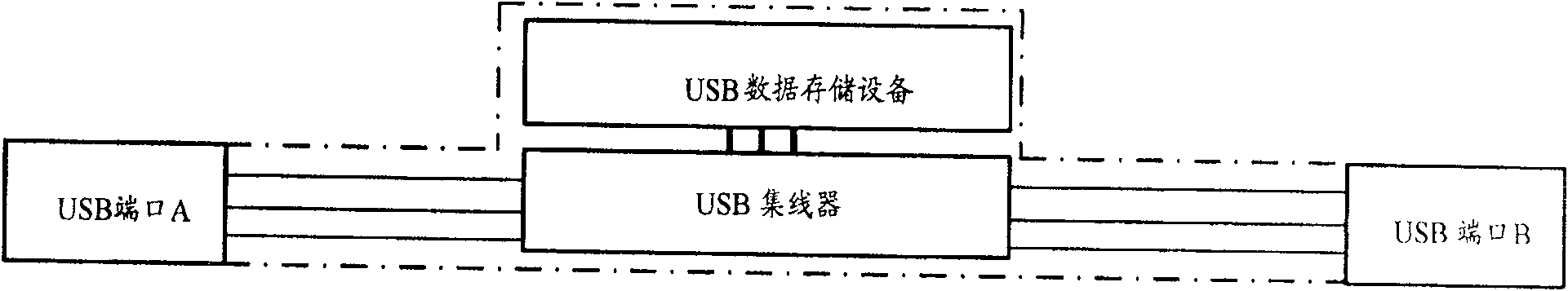

Cable and information getting method

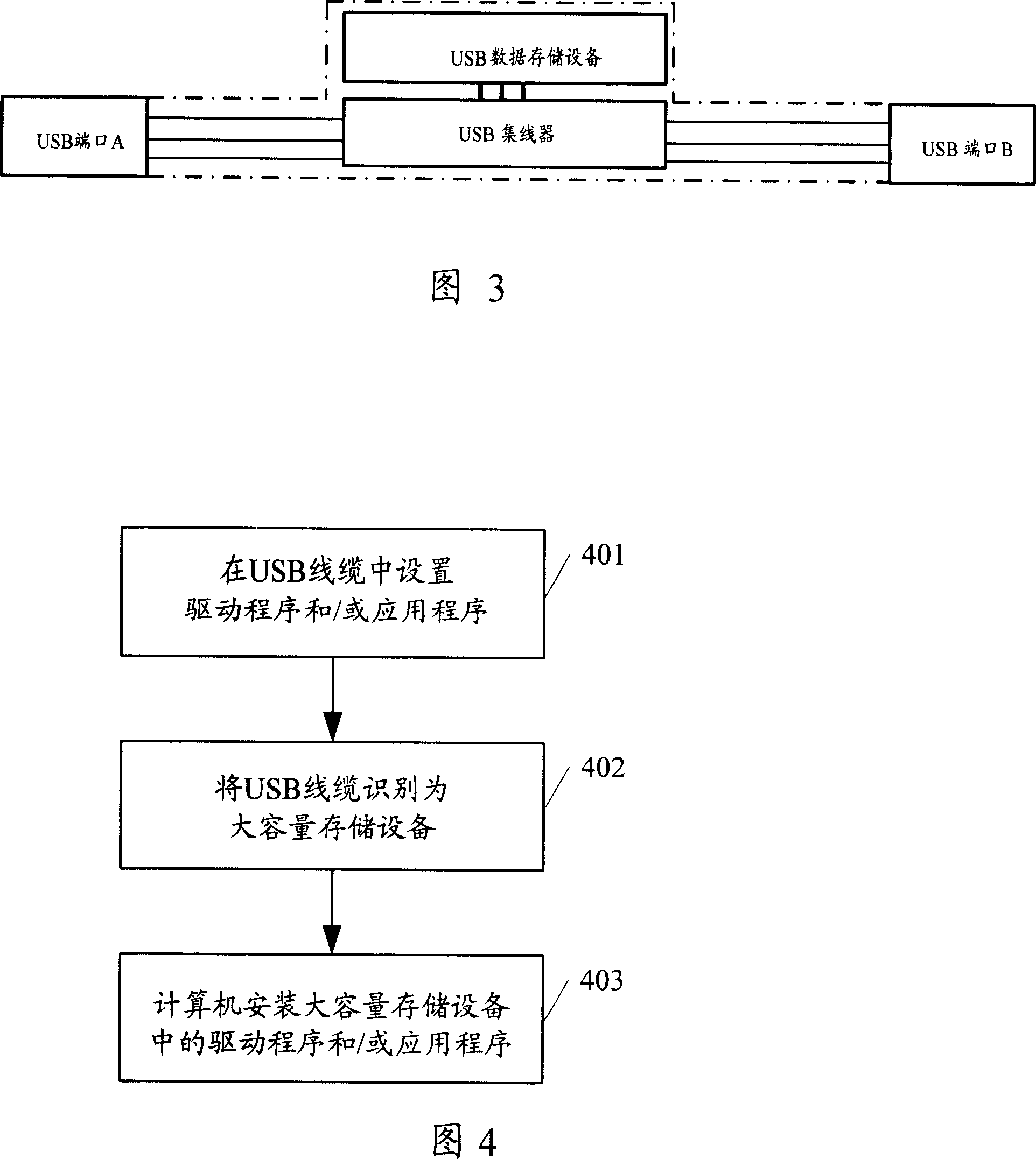

ActiveCN101000595AWith storage functionWith automatic operation featureProgram loading/initiatingEngineeringConcentrator

A method for obtaining information from cable includes arranging not only two physical ports at two ends of cable on cable but also arranging storage unit stored with personal data and / or external device software as well as concentrator connected to said storage unit on cable, and connecting concentrator separately to two physical ports through physical channels.

Owner:HUAWEI TECH CO LTD

High-efficiency bending device for aluminum alloy plate

The invention relates to the technical field of aluminum alloy plate bending equipment, in particular to a high-efficiency bending device for an aluminum alloy plate. The device comprises a workbench,a threaded rod is inserted into the lower surface of the workbench, a fixing plate, a first positioning sliding rail and a second positioning sliding rail are respectively and fixedly connected to the inner top surface of the workbench from left to right, a sliding rod is fixedly connected to the right side surface of the fixing plate, and a limiting plate is fixedly connected to the right end ofthe upper surface of the workbench. The inner bottom surface of the workbench is fixedly connected with a positioning block and a fixed sliding rod from left to right, the aluminum alloy plate is pushed to move to the right side through a sliding push plate, manual installation of a worker can be well avoided, potential safety hazards are solved, working safety is improved, the aluminum alloy plate is fixed through a clamping plate on the upper surface of a pull rod through the lever principle, deviation generated when the aluminum alloy plate is bent is avoided, therefore, the aluminum alloyplate can be well fixed, and meanwhile the bending efficiency of the equipment is improved.

Owner:卢婷婷

Automatic cleaning and pasting device of mobile-phone camera

InactiveCN106526774AReduce usageAvoid manual installationTelevision system detailsColor television detailsCamera lensBrush device

Owner:芜湖赋兴光电有限公司

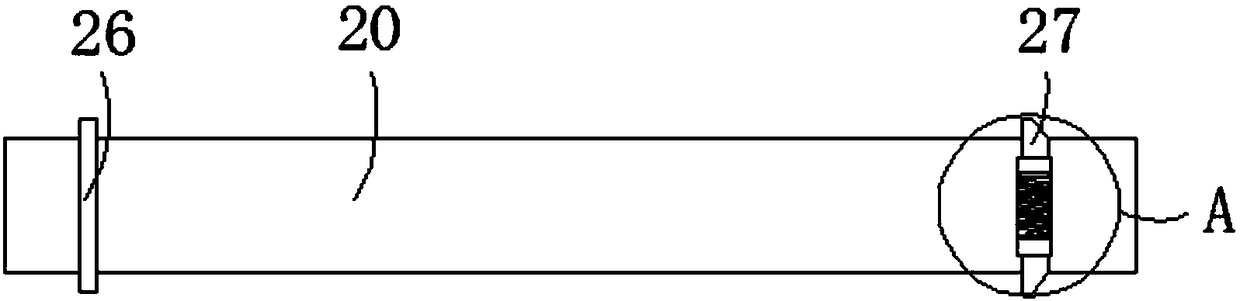

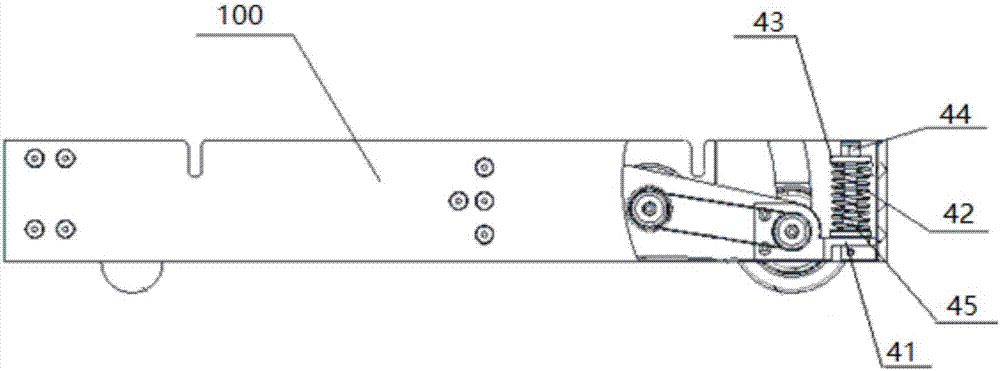

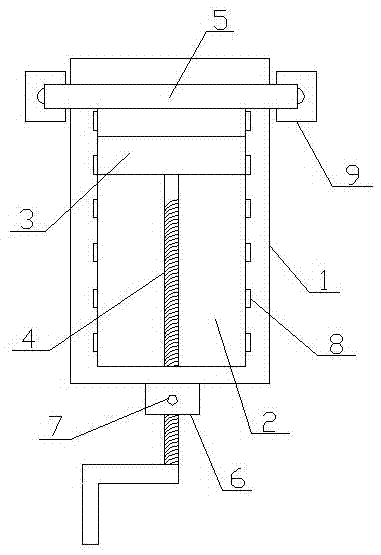

Tool and method for installing robot trolley suspension spring

PendingCN107877454AOvercome initial preloadAvoid manual installationMetal-working hand toolsMaterial PerforationMechanical engineering

The invention provides a tool for installing a robot trolley suspension spring. The tool comprises a cylindrical body, one end of the cylindrical body is open, and the other end of the cylindrical body is provided with a cylindrical bottom; and the cylindrical bottom is provided with a first penetrating hole. In the process of installing the suspension spring, the cylindrical body compresses a spring cover so as to compress the suspension spring, in the downward compressing process of the spring cover, the top of a sprig pulling rod gradually extends out from a hole in the spring cover, then afastening nut is tightened, and the tool is removed. According to the tool for installing the robot trolley suspension spring, operation is conducted through the tool, laborious manual installing isavoided, and high initial pre-tightening force of the suspension spring is overcome; through the special installing tool and with the help of a screwing-in mode of a screw and the nut, the suspensionspring is compressed to a certain size, then the suspension fastening nut is installed, operation can be completed by one person, and manpower is saved; and after the suspension fastening nut is installed, the installing tool is removed, and the installing tool can be used repeatedly.

Owner:浙江众导机器人科技有限公司

Automobile pedal spring installing tool

The invention provides an automobile pedal spring installing tool. The automobile pedal spring installing tool comprises an installing support. A sliding groove is formed in the installing support. A spring pressing head is arranged in the sliding groove. A threaded rod rotating handle is arranged at the lower end of the installing support. The upper end of the threaded rod rotating handle is connected to the lower end of the spring pressing head. A spring fixing pin is arranged at the upper end of the installing support. The threaded rod rotating handle drives the spring pressing head to compress a spring, the stroke of the spring is reduced, the space size is reduced, the tool and the spring are plugged in installing holes of a clutch arm and the support, and manual spring installing is avoided. The spring assembling function is achieved, the assembling operation difficulty is relieved, cost is low, and labor efficiency is improved.

Owner:WUHU POWER TECH

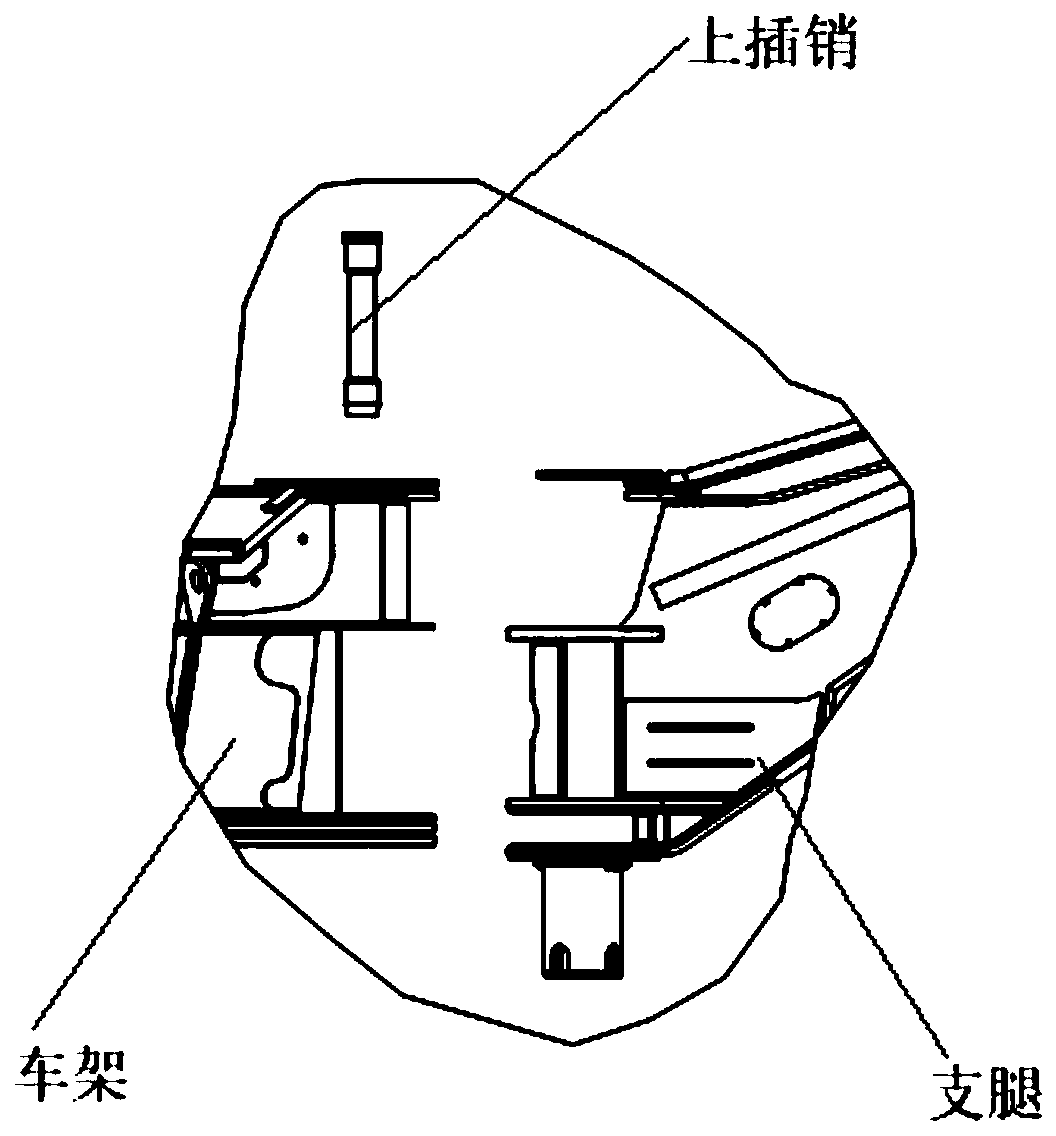

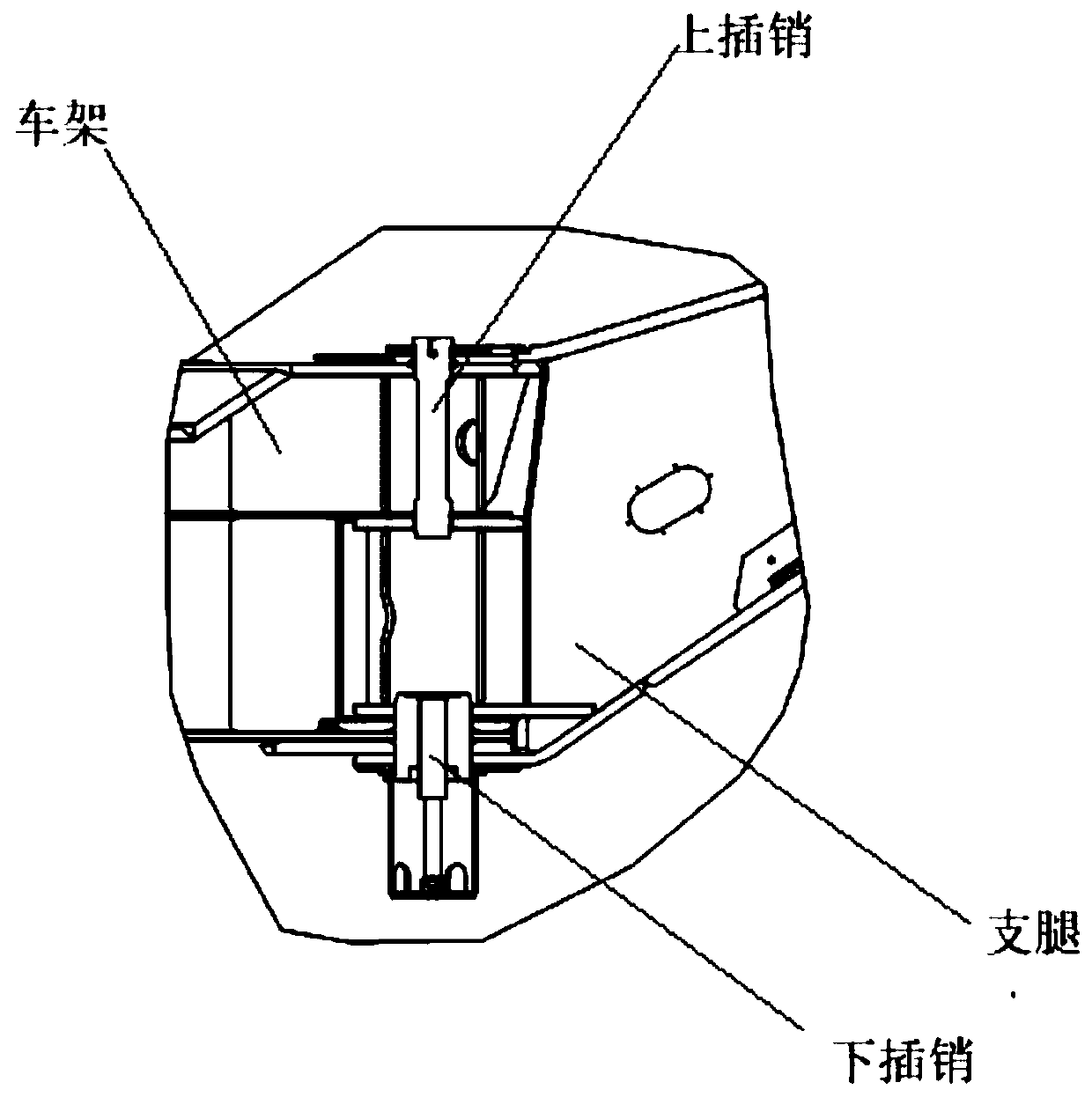

Insert and pull connection structure, supporting leg and frame connection assembly and crane

ActiveCN110294426AImprove installation efficiencyAvoid manual installationCranesVehicle frameEngineering

The invention discloses an insert-pull connection structure, a supporting leg and a frame connection assembly and a crane. The insert-pull connection structure is used for enabling a frame to be connected with the supporting leg, the insert-pull connection structure comprises a bidirectional oil cylinder, an upper bolt and a lower bolt, wherein the first end of the bidirectional oil cylinder is used for driving the upper bolt, so that the upper part of the frame is connected with the upper part of the supporting leg through the upper bolt, the second end of the bidirectional oil cylinder is used for driving the lower bolt, so that the lower part of the frame is connected with the lower part of the supporting leg through the lower bolt. The supporting leg and the frame connection assembly and the crane comprises the above insert-pull connection structure, so that the problems that a traditional frame is connected with the supporting leg and the traditional frame is also connected with the supporting leg during the dismantle process and the disassemble of an oil channel are solved, so that the mounting and dismounting efficiencies of the frame and the supporting legs are improved, and the labor is saved.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

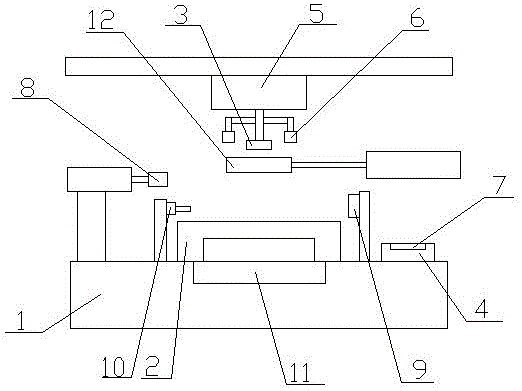

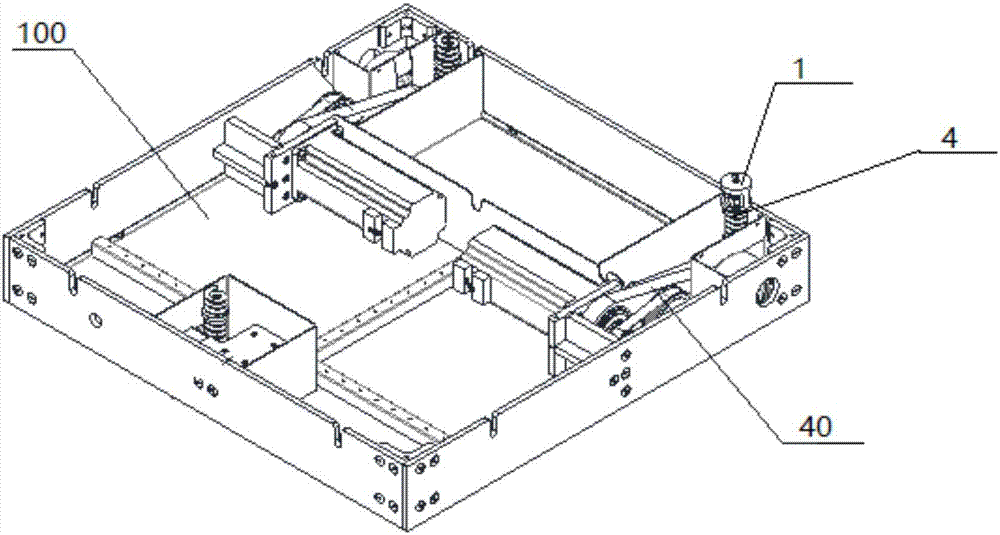

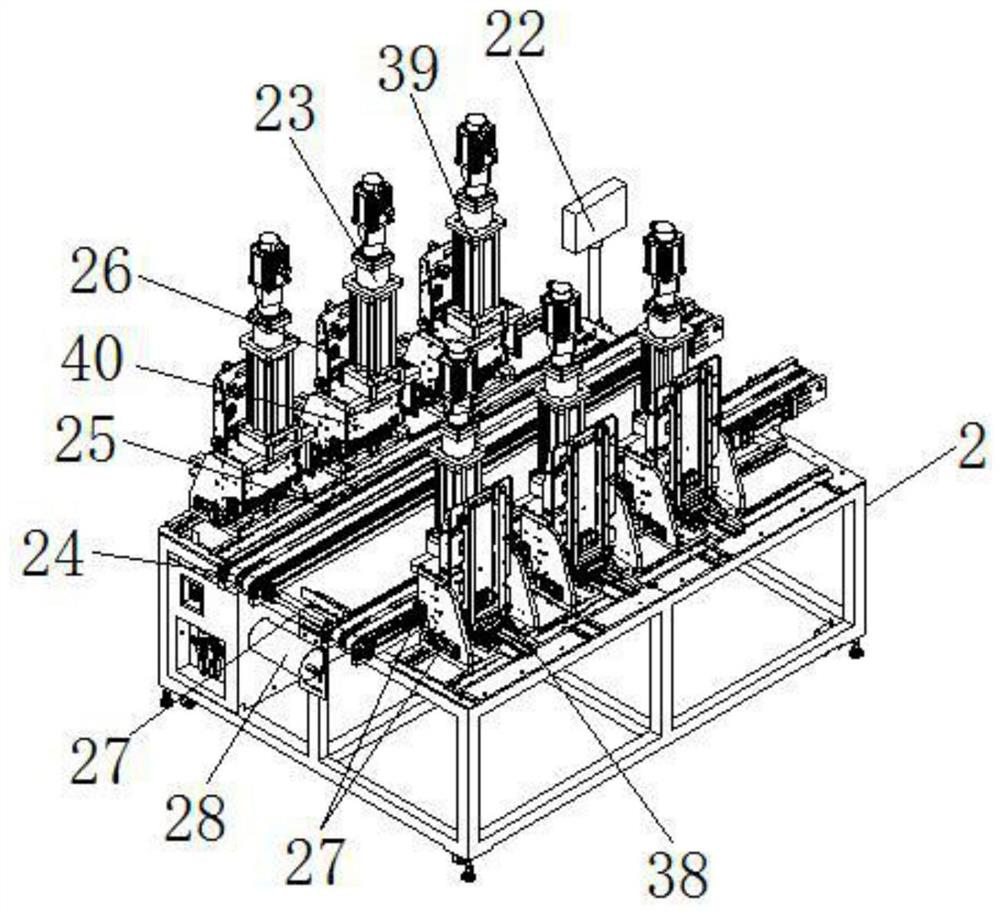

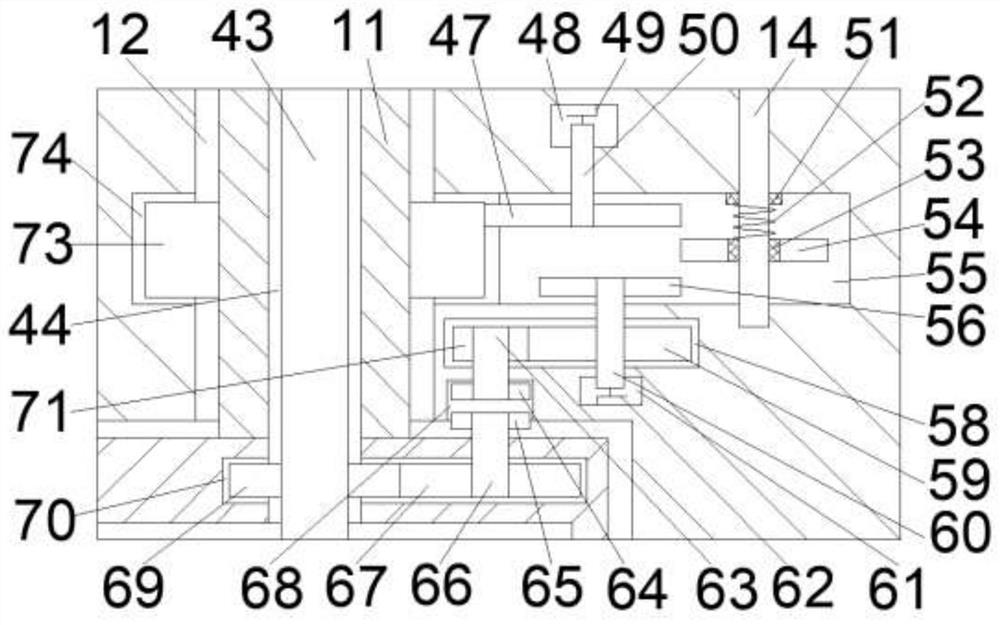

Automatic racking system for capacitors

InactiveCN105761953ARealize the purpose of automationAvoid manual installationCapacitor manufactureRackingPower unit

The invention discloses an automatic racking system for capacitors. The automatic racking system includes a workbench, a clamping mechanism, a first delivery mechanism, a second delivery mechanism, a steering mechanism an a driving mechanism, a strip-shaped groove is arranged on the workbench, and one end of the strip-shaped groove is provided with a feeding port; the first delivery mechanism is connected with the feeding port; the second delivery mechanism is parallel to the strip-shaped groove; the steering mechanism includes a guiding track, a sliding table and a first power unit, wherein the guiding track is horizontally arranged above the workbench and extends from the workbench towards the direction of the second delivery mechanism to above the second delivery mechanism; the sliding table is driven by the first power unit to move back and forth on the guiding track; the clamping mechanism is mounted on the sliding table and used for clamping capacitors in the strip-shaped groove; and the driving mechanism is used for driving the clamping mechanism to perform vertical lifting. The automatic racking system for capacitors realizes the purpose of automation of loading the capacitors on a charging rack, and avoids a process of manually installing a large number of capacitors on the charging rack, thereby saving a large amount of time, and improving production efficiency.

Owner:ANHUI PUHE ELECTRONICS

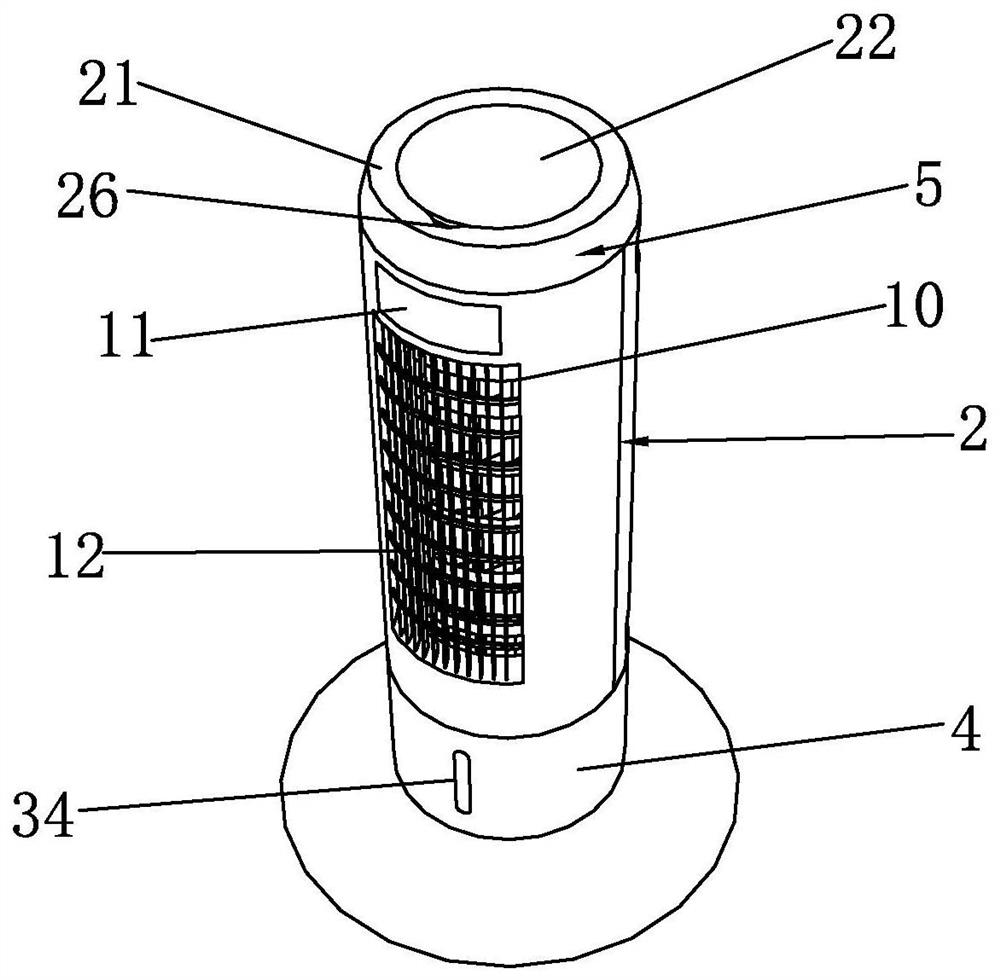

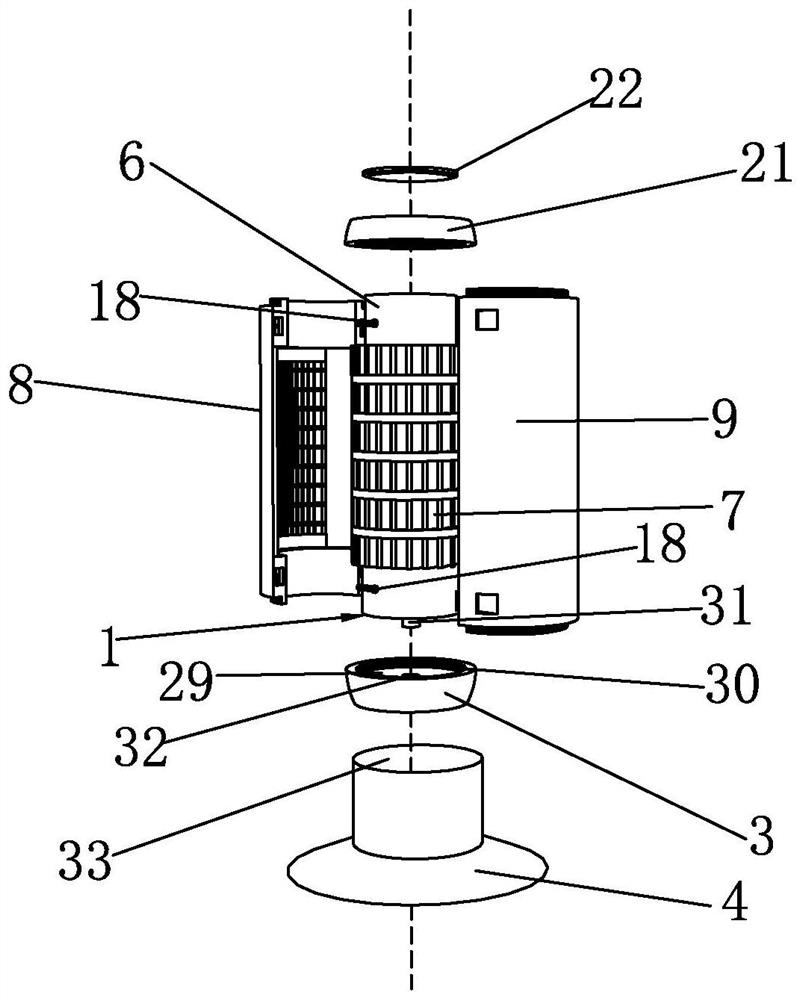

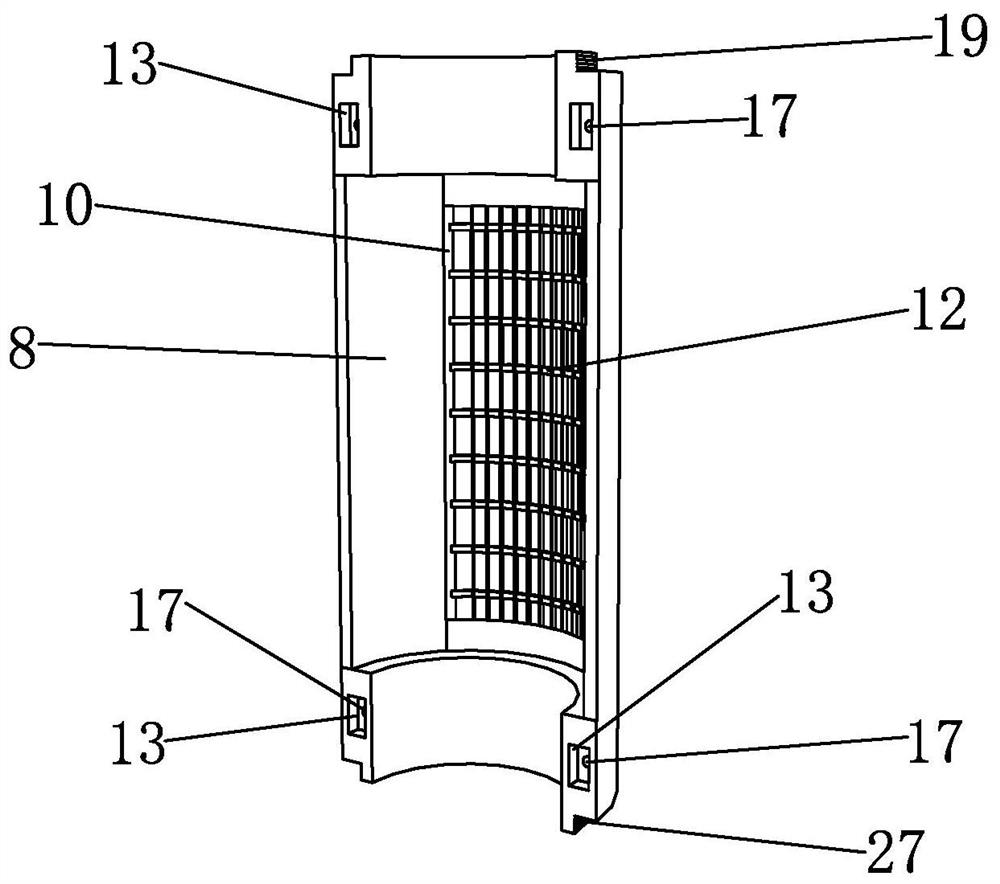

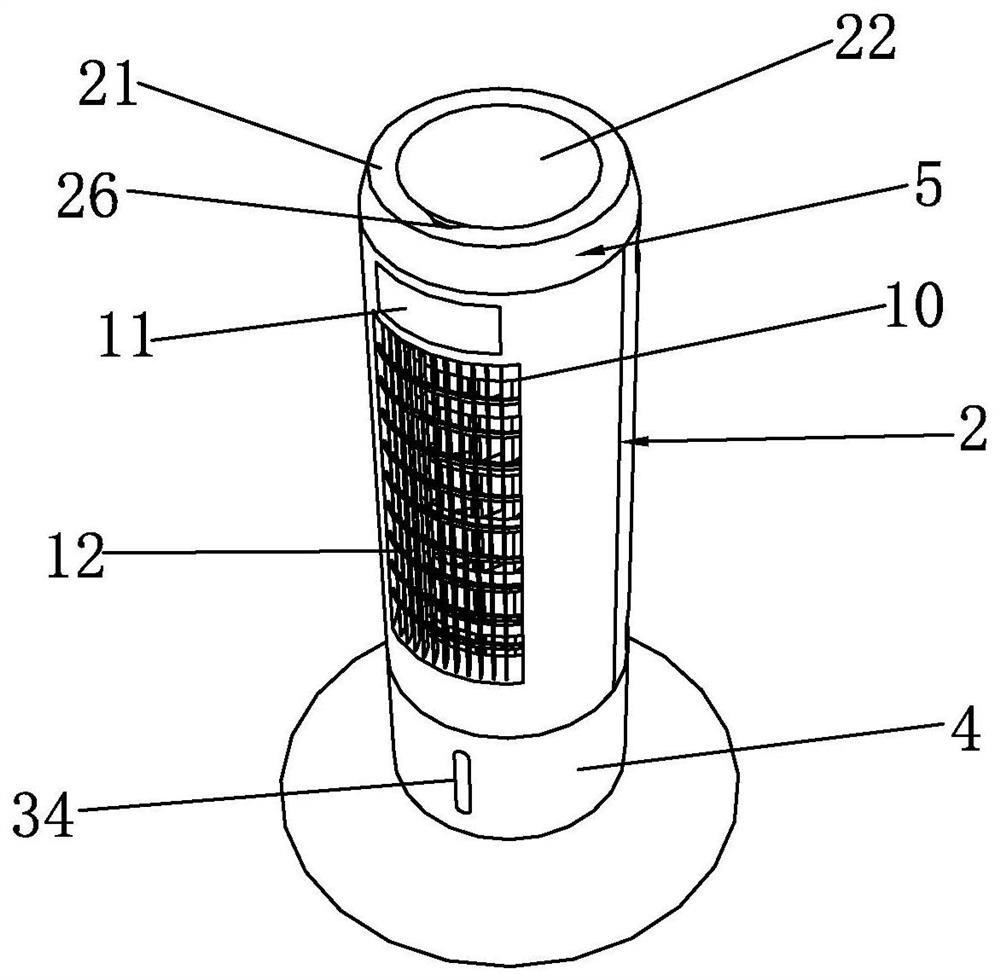

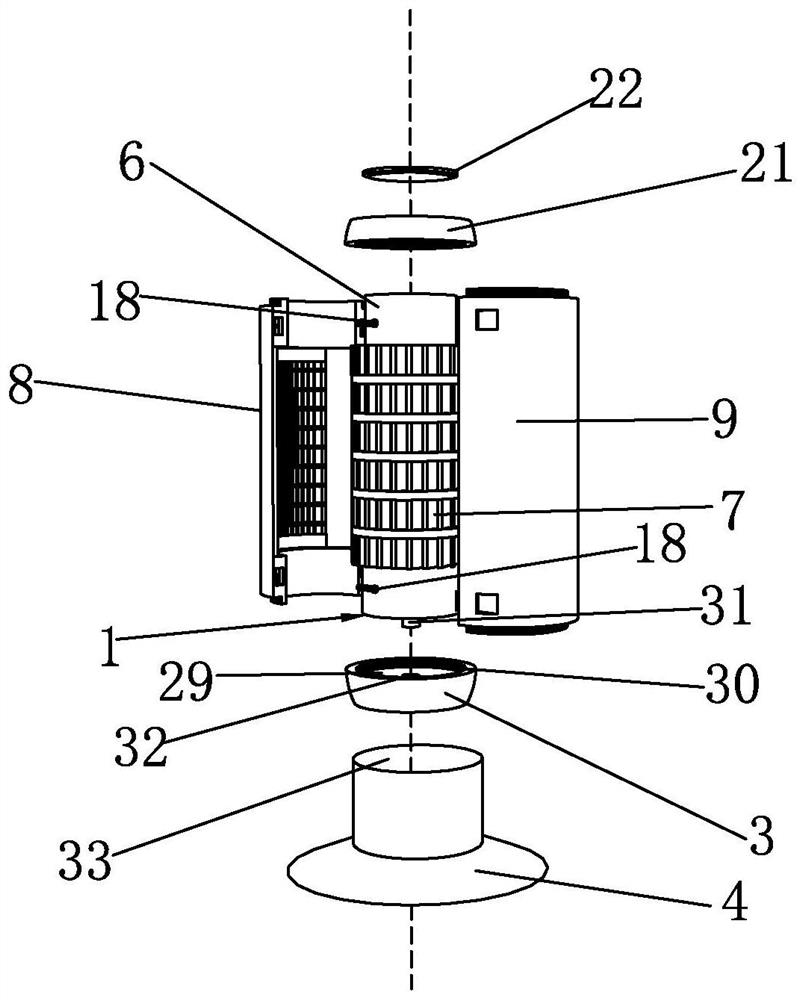

Safety type electric fan with refrigeration function and manufacturing method thereof

ActiveCN112539487APlay a thermal insulation effectExtend cooling timePump componentsLighting and heating apparatusCold airEngineering

The invention discloses a safety type electric fan with a refrigeration function and a manufacturing method thereof. The safety type electric fan comprises a base, a refrigeration assembly and a shellarranged on the outer side of the refrigeration assembly in a sleeving mode, wherein an inserting part matched with the refrigeration assembly is arranged at the bottom of the shell and fixedly connected to the bottom of the shell, and the bottom of the inserting part is inserted into the base; and a sealing assembly is arranged at the top of the shell and seals the top of the shell. The method comprises the following steps of: a, preparation before mounting; b, assembling of the shell; c, mounting of the inserting part; d, mounting completing. Cold air is blown out of the shell through the refrigeration assembly, so that the indoor temperature is reduced. The arrangement of the sealing assembly achieves a heat preservation effect on the refrigeration assembly, the situation that the temperature of the refrigeration assembly rises too fast is avoided, and the refrigeration time of the refrigeration assembly is effectively prolonged. The shell is fixed to the base through the arrangement of the inserting part, and thus the operation stability of the electric fan is improved.

Owner:浙江巴尔电器科技有限公司

A wine box top cover installation device

The invention discloses a device for installing the top cover of a wine box, which includes an installation box body, a top cover storage box is arranged on one side of the installation box body, and a toggle rod is slidably connected to the bottom of the top cover storage box. The top of the installation box is equipped with an automatic telescopic rod, the extension end of the automatic telescopic rod is connected with a pressing plate, the bottom of the pressing plate is provided with a gland plate, and the bottom of the gland plate is provided with a cover opening. A packaging fixing device is provided below the lid drop opening, the packaging fixing device includes a fixing plate, the fixing plate is arranged on both sides of the inner cavity of the installation box, and the side wall of the fixing plate close to the installation box is connected with Push plate, a tension spring is set between the push plate and the installation box, and a ladder-type stopper is set between the two push plates; the present invention can continuously install the top cover of the packing box, and the structure is simple and convenient Practical, avoid manual installation by workers, cheap cost, save production cost.

Owner:ANHUI YINGJIA TRIBUTE WINE

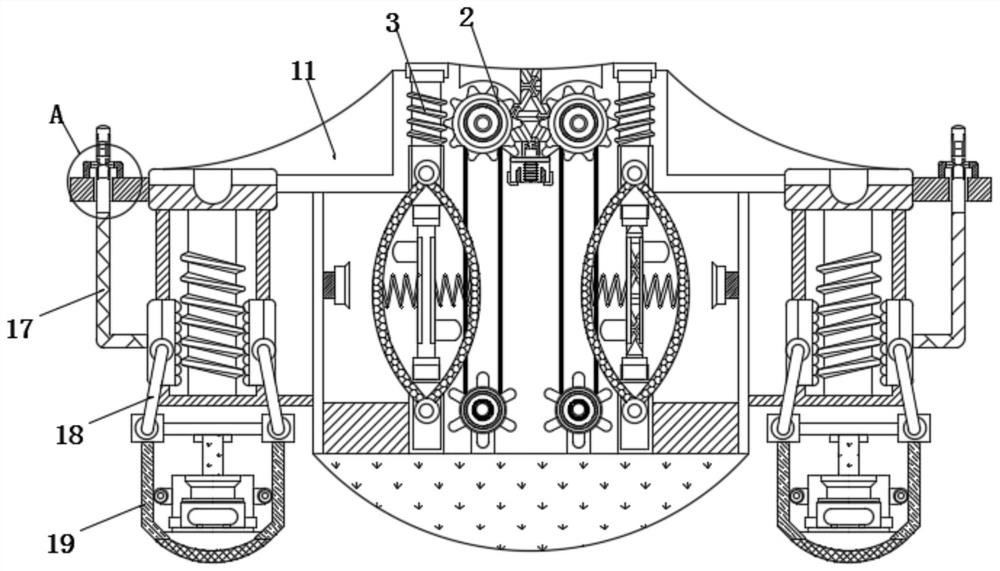

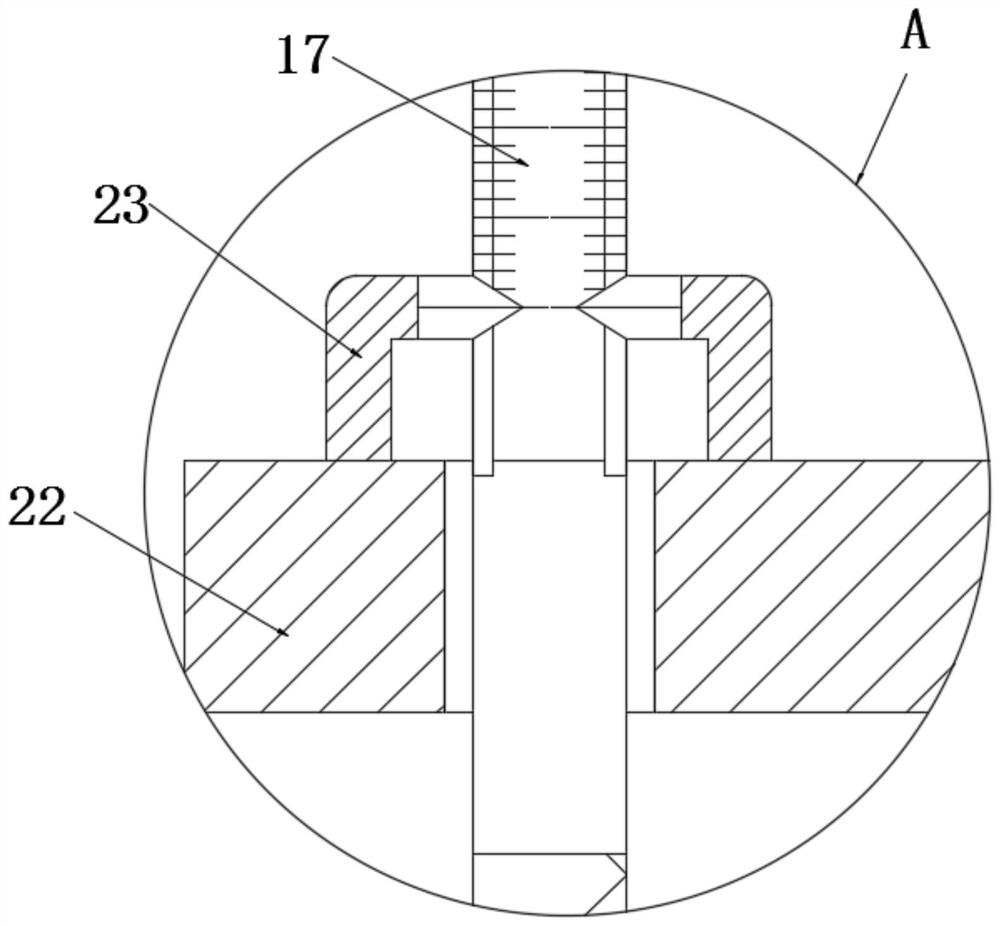

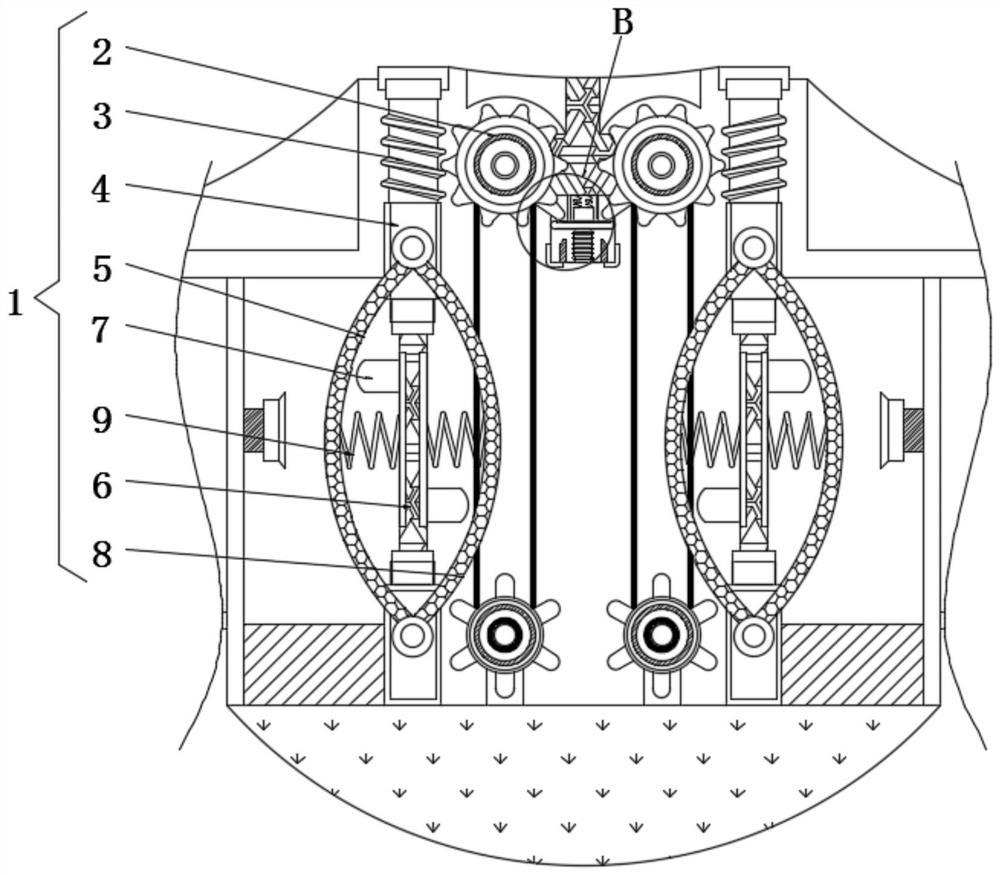

Collecting ship capable of efficiently removing cyanobacteria oil sludge

ActiveCN113386915AEasy to handleImprove protectionWater cleaningWaterborne vesselsGear wheelEnvironmental engineering

The invention relates to the technical field of cyanobacteria oil sludge collecting ships, in particular to a collecting ship capable of efficiently removing cyanobacteria oil sludge. The collecting ship comprises a driving assembly and an adjusting mechanism, the driving assembly comprises a driven gear, the left side surface of the driven gear is in meshed connection with a driving rotating shaft, the driving rotating shaft is externally sleeved with a positioning pipe, a vertical rod is fixedly connected to the lower surface of the driving rotating shaft, a first filter screen and a second filter screen are fixedly connected to the front surface of the positioning pipe from left to right, and the driving rotating shaft rotates in the positioning pipe. The vertical rod at the lower end of the driving rotating shaft drives a convex block shifting plate to rotate between the first filter screen and the second filter screen, convex block shifting plate pushes the first filter screen and the second filter screen back and forth, the first filter screen and the second filter screen are shifted back and forth, and the cyanobacteria oil sludge on the first filter screen and the second filter screen is shaken to fall off, so that the working efficiency of equipment is improved, and the equipment efficiently treats the cyanobacteria oil sludge.

Owner:江西强盛科技有限公司

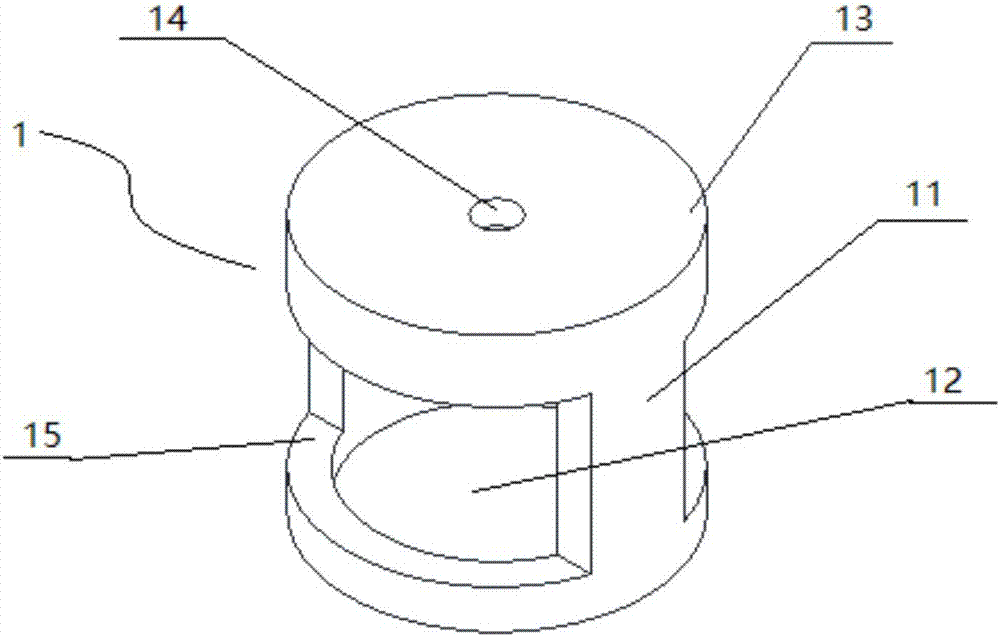

Can be used for tbm dynamic self-adaptive solid non-polarized electrode and using method

ActiveCN104391328BReduce manufacturing costEasy to carry and installElectric/magnetic detectionAcoustic wave reradiationEngineeringContact type

The invention discloses a dynamic self-adaptive solid non-polarized electrode for TBM and a usage method. The telescopic linkage device drives the non-polarized electrode to move, and the non-polarized electrode is sent to the face of the tunnel; then the material is fed by A feeding pipe and B The tube adds accelerator and electrolyte to the electrolyte tank, and the electrolyte and accelerator are compressed by the pushing device. After the pushing is completed, wait for 3-5 minutes to make the electrolyte solidify completely, and then start detection; after the measurement is completed, control the expansion and contraction The cylinder of the linkage device drives the telescopic rod to move backward, and at the same time drives the non-polarized electrode to leave the face, so as to realize the removal of the non-polarized electrode and complete the detection task. The invention realizes contact measurement, and has the characteristics of mechanical automation control installation and removal, and at the same time satisfies the small range of measurement electrodes and high measurement accuracy, adapts to the complex conditions of unevenness of the tunnel surface, and satisfies the automation and mechanization of TBM construction requirements.

Owner:SHANDONG UNIV

A safe electric fan with cooling function and its manufacturing method

ActiveCN112539487BPlay a thermal insulation effectExtend cooling timePump componentsLighting and heating apparatusCold airThermal insulation

Owner:浙江巴尔电器科技有限公司

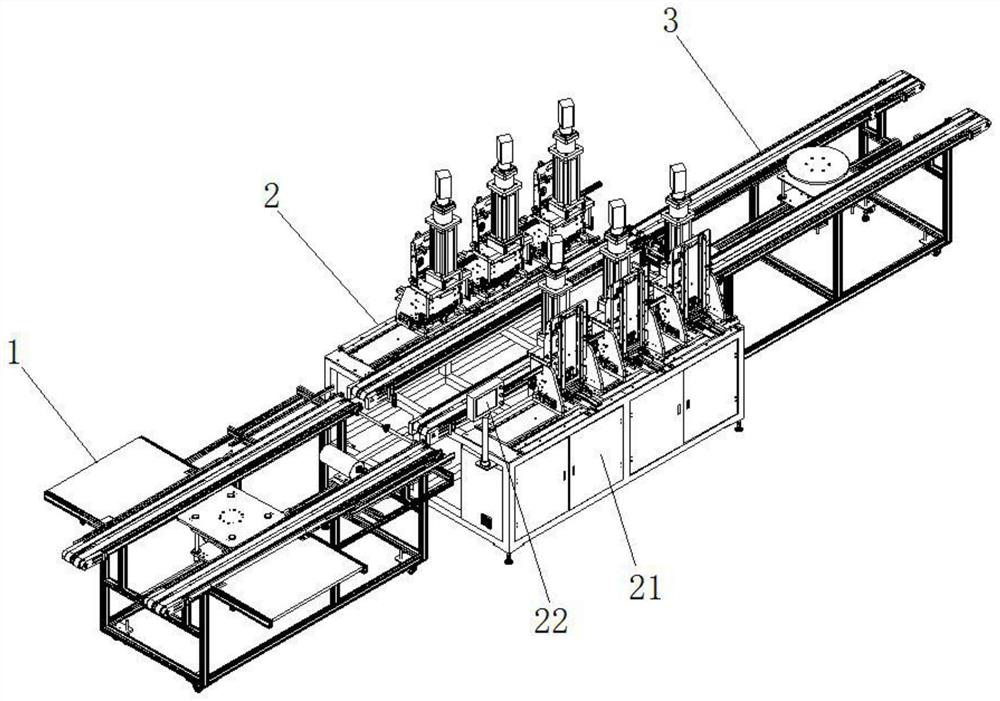

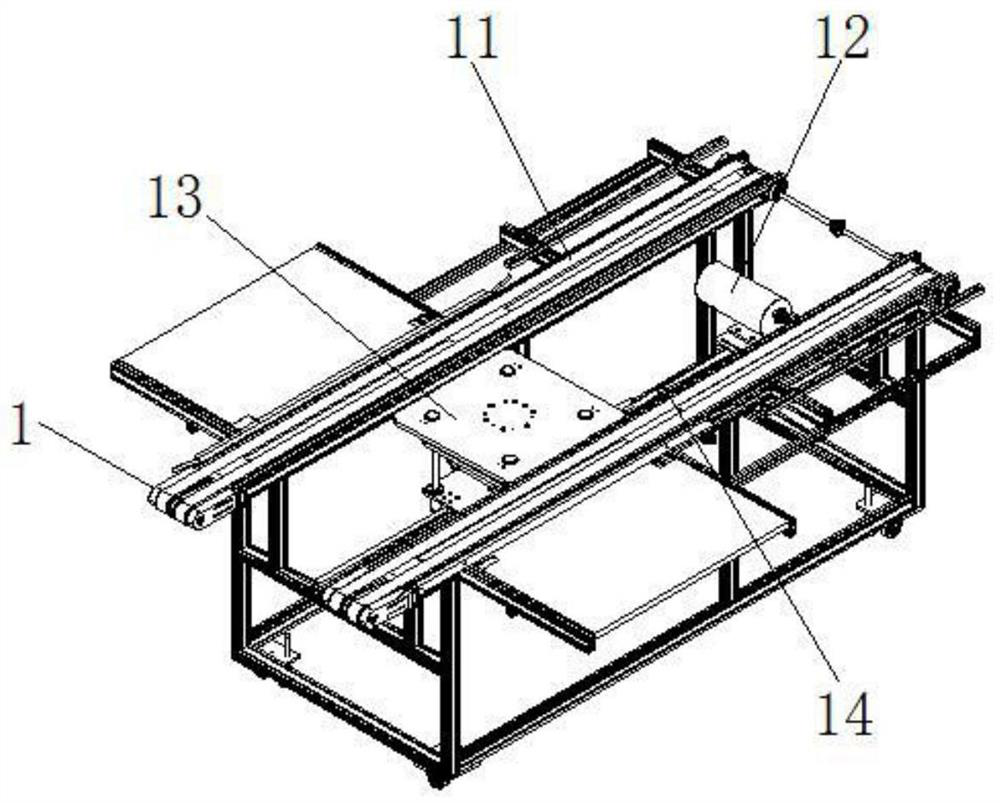

Solar panel corner protector automatic pressing and machining assembly line

PendingCN111843433AEfficient use ofIncrease productivityMetal working apparatusAssembly lineMachining

The invention discloses a solar panel corner protector automatic pressing and machining assembly line which comprises a first machining station. A second machining station is arranged on the outer side of the first machining station and is connected with the first machining station. A third machining station is arranged on the outer side of the second machining station and is connected with the first machining station through the second machining station. A rotating platform is arranged between two third conveying belts, and a jacking air cylinder is mounted below the rotating platform. A hardbarrier and a third sensor are arranged on the outer sides of the third conveying belts. According to the solar panel corner protector automatic pressing and machining assembly line, the solar panelcorner protector automatic pressing and machining assembly line is utilized conveniently, the production efficiency of solar panel corner protectors is improved, the situation that relevant workers need to mount and manufacture solar panel corner protectors manually is avoided, the labor intensity of workers is reduced, and meanwhile the use cost of workers is indirectly reduced; and the production cost is reduced, and meanwhile finished products meet use requirements better and conform to machining standards better.

Owner:昆山捷跃自动化科技有限公司

A collection vessel capable of removing cyanobacterial sludge

The invention relates to the technical field of cyanobacteria sludge collection ships, in particular to a collection ship capable of efficiently removing cyanobacteria sludge, including a drive assembly and an adjustment mechanism, the drive assembly includes a driven gear, and the left side of the driven gear is meshed with a The driving shaft is sleeved with a positioning tube outside, the lower surface of the driving shaft is fixedly connected with a vertical rod, and the front surface of the positioning tube is fixedly connected with the first filter screen and the second filter screen from left to right. The second filter screen, the drive shaft rotates inside the positioning tube, so that the vertical rod at the lower end of the drive shaft drives the bump dial to rotate between the first filter screen and the second filter screen, so that the bump dial pushes the second filter screen back and forth The first filter screen and the second filter screen make the first filter screen and the second filter screen move back and forth, so that the cyanobacteria sludge on the first filter screen and the second filter screen is shaken off, thereby improving the working efficiency of the equipment, so that The equipment efficiently treats cyanobacteria sludge.

Owner:江西强盛科技有限公司

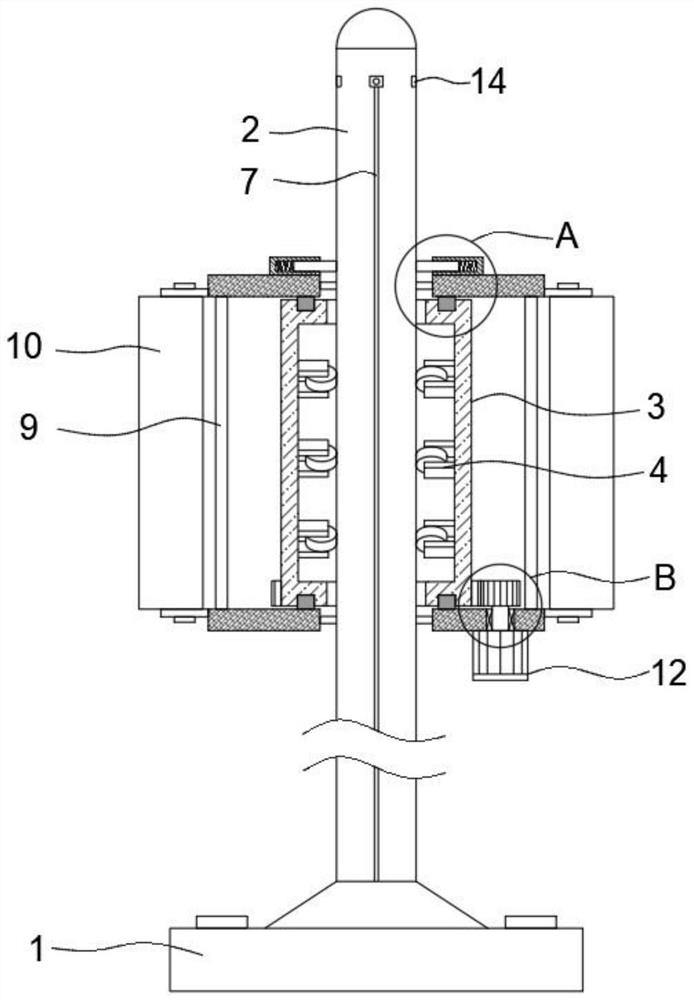

5G base station signal pole

InactiveCN114363725AAvoid manual installationEnsure human safetyTowersWireless communicationElectric machineryDrive motor

The invention discloses a 5G base station signal pole which comprises a fixed base, the upper end of the fixed base is fixedly connected with a signal pole, the signal pole is sleeved with a cylindrical lifting box, four sets of moving wheels which are evenly distributed in the circumferential direction are fixedly connected to the inner circumferential wall of the lifting box, and each set of moving wheels is composed of a plurality of moving wheels which are vertically arranged at equal intervals. And each moving wheel is attached to the outer circumferential surface of the signal rod and is obliquely arranged upwards in the clockwise direction, annular sliding grooves are formed in the upper end and the lower end of the lifting box correspondingly, and four evenly-distributed sliding blocks are slidably connected into the annular sliding grooves. The signal box has the advantages that the lifting box can be driven to move up and down through positive and negative rotation of the driving motor, so that the signal box can be installed at a high point without manual climbing, meanwhile, later maintenance work is facilitated, and the working safety is improved.

Owner:陈俊杰

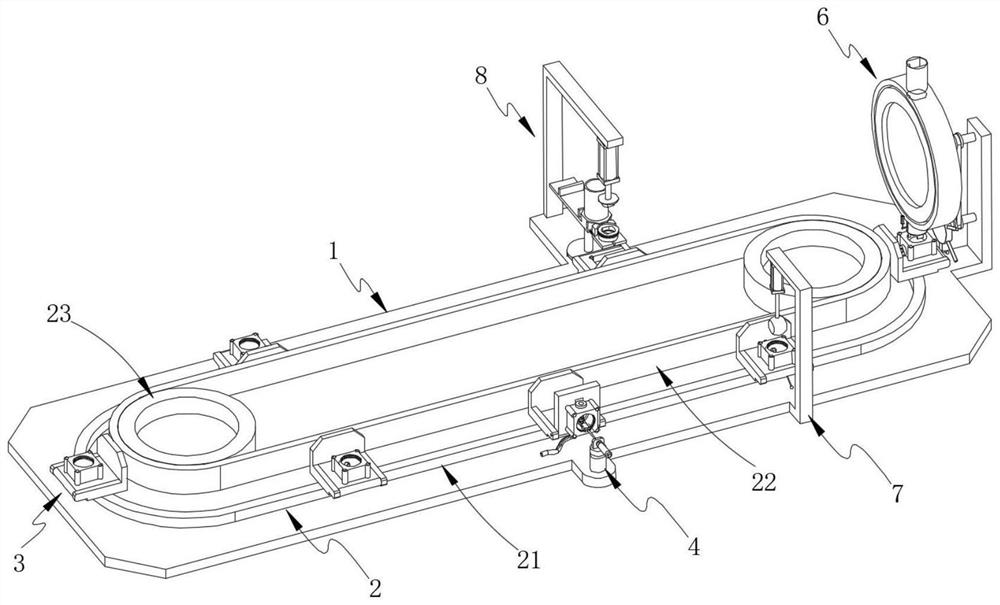

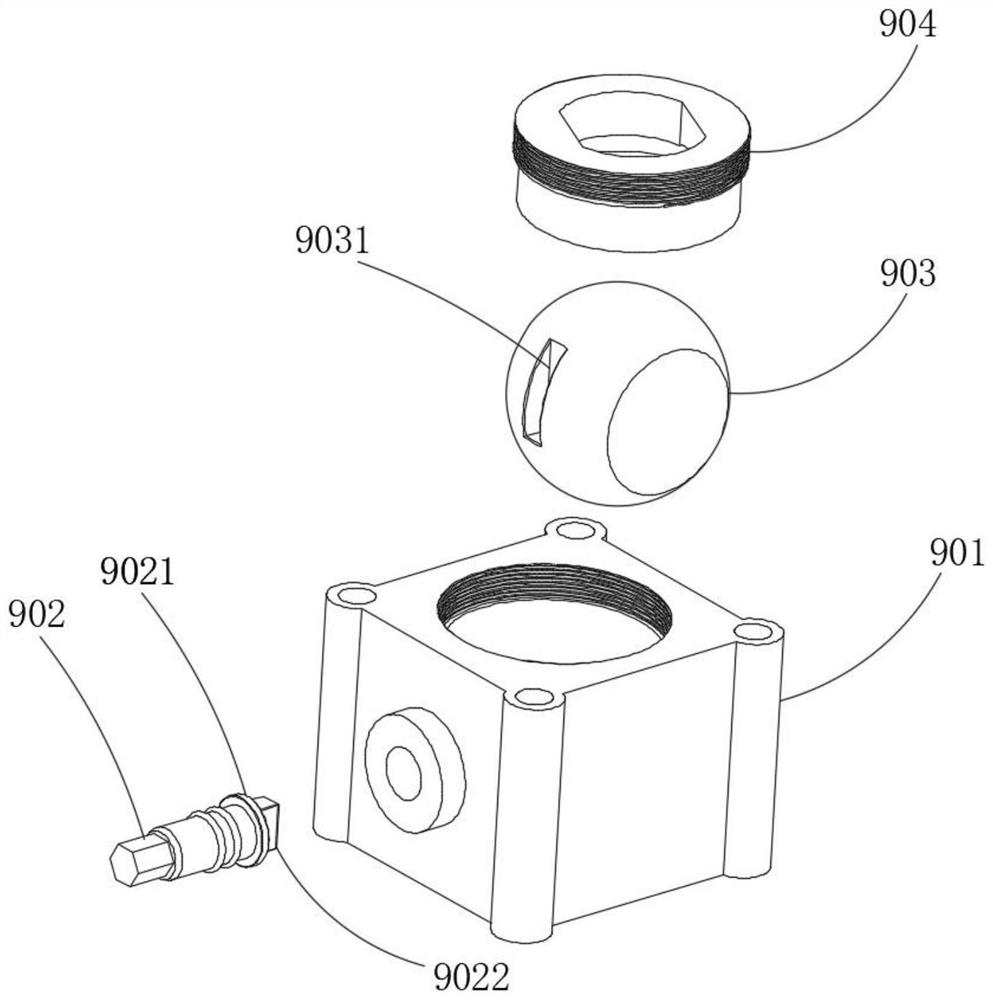

Automatic valve assembling equipment

ActiveCN114714083ARealize highly automated productionIncrease productivityFinal product manufactureAssembly machinesEngineeringWorkbench

The invention provides automatic valve assembling equipment. The automatic valve assembling equipment comprises a workbench; the annular driving part is mounted on the working table; the material placing plate is arranged on the annular driving part and is used for conveying the valve body; the first assembling part is arranged on the workbench and used for installing a knob in the valve body; the conveying part is arranged on one side of the workbench and used for conveying knobs; the second assembling part is arranged on the workbench and used for installing a valve element in the valve body. The valve body is conveyed through the material placing plate, the first assembling part is used for installing a rotary knob in the valve body, the conveying part is used for conveying the rotary knob, the second assembling part is used for installing a valve element in the valve body, the third assembling part is used for installing a valve deck in the valve body, high-automation production of the valve is achieved, and the production efficiency is greatly improved.

Owner:LIANKE VALVE CO LTD

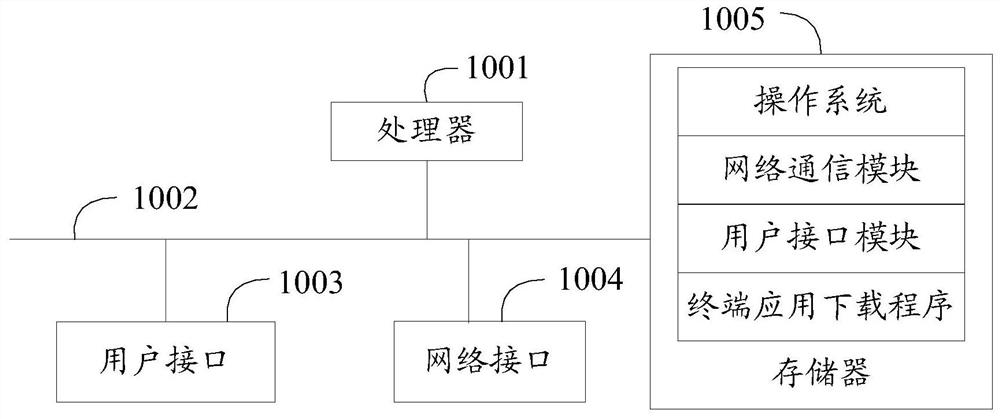

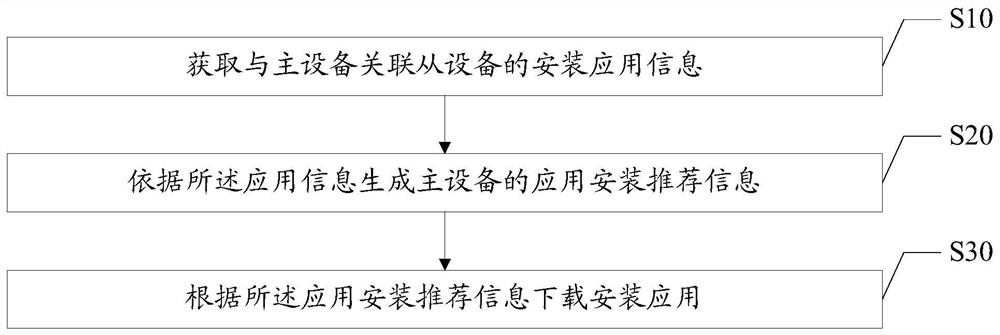

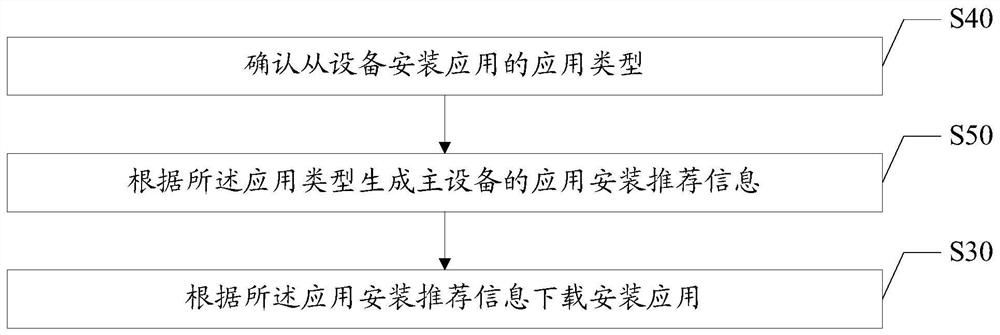

Terminal application downloading method, terminal equipment and computer readable storage medium

PendingCN112379894AImprove installation efficiencyMeet usage habitsSoftware deploymentSoftware engineeringTerminal equipment

The invention discloses a terminal application downloading method. The method comprises the following steps of acquiring the installation application information of slave equipment associated with master equipment; generating the application installation recommendation information of the main equipment according to the application information; and downloading and installing the application according to the application installation recommendation information. The invention further discloses terminal equipment and a computer readable storage medium. The method is advantaged in that the application recommendation information based on the installation application is provided from the application installed in the device in a big data analysis mode, the application download address based on theapplication recommendation information is automatically obtained from the server to achieve application installation of the terminal device, the use habit of a current user is met, the user is prevented from manually installing the terminal application, and the user experience is improved; and terminal application installation efficiency in the smart home application is improved.

Owner:SHENZHEN TCL NEW-TECH CO LTD

System and method for mounting peripheral device program and USB cable

ActiveCN100578450CEasy to useAvoid unnecessary troubleProgram loading/initiatingMass storageOperational system

A method for installing enclosure equipment comprises storing enclosure equipment drive program or application program of the USB cable, identifying the USB cable with large volume of storage equipment, installing drive or application program of the storage equipment. It also provides a system for installing enclosure equipment program and USB cable, storing the drive program and or application program on the USB cable to realize PC automatic installing of drive program or application program of the USB cable for the convenience of the user.

Owner:HUAWEI TECH CO LTD

Air-water cutter online device for cleaning belt conveyor, application and method for cleaning belt conveyor

The invention discloses an air-water cutter online device for cleaning a belt conveyor, application and a method for cleaning the belt conveyor. The air-water cutter online device comprises a support and an air-water cutter, the support is detachably installed on the belt conveyor, the air-water cutter is installed on the support, and a cutter edge of the air-water cutter right faces a conveying belt; the air-water cutter comprises an upper cavity plate, a lower cavity plate, a C-shaped sealing gasket and a water inlet pipe head, the upper cavity plate and the lower cavity plate are fixedly connected, a cavity is formed in the upper cavity plate and the lower cavity plate, the C-shaped sealing gasket is installed in a C-shaped sealing groove of the upper cavity plate, and a cutter edge is formed on the unsealed side of the C-shaped sealing groove; one end of the water inlet pipe head is connected to a chamber formed by the upper chamber plate and the lower chamber plate; the other end of the water inlet pipe head is respectively connected with a compressed air source and a tap water source through a connecting pipeline; an electromagnetic valve and a one-way valve are arranged on the connecting pipeline of the compressed air source; and an electromagnetic valve is arranged on a connecting pipeline of a tap water source. Cleaning and maintenance of the belt conveyor are automatically completed, the labor intensity of workers is reduced, and the maintenance efficiency is improved.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

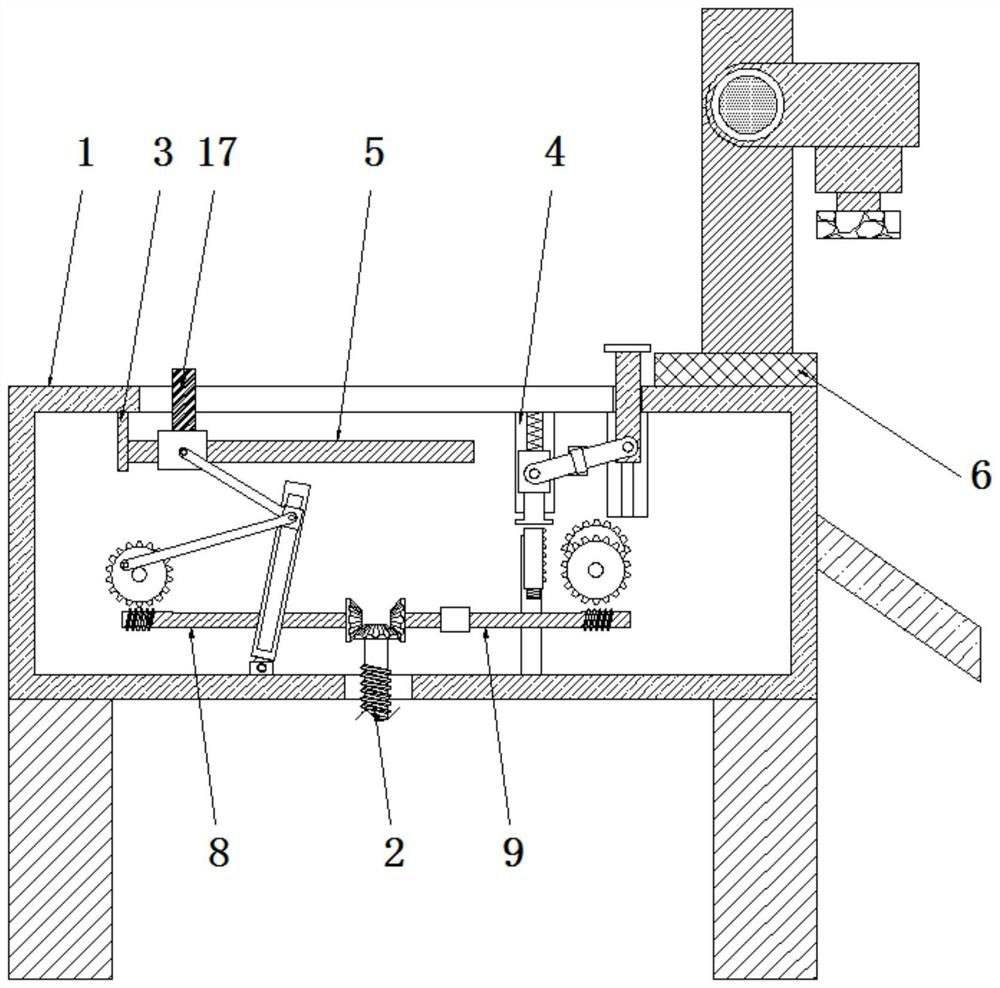

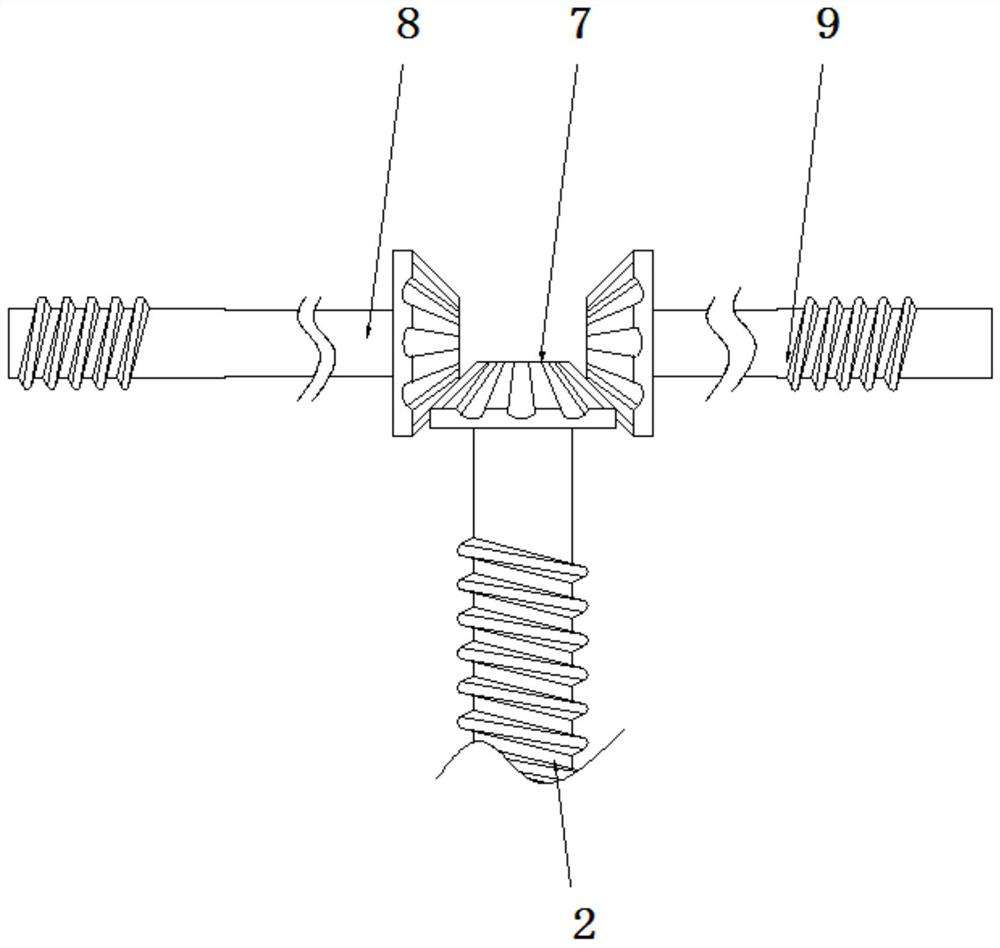

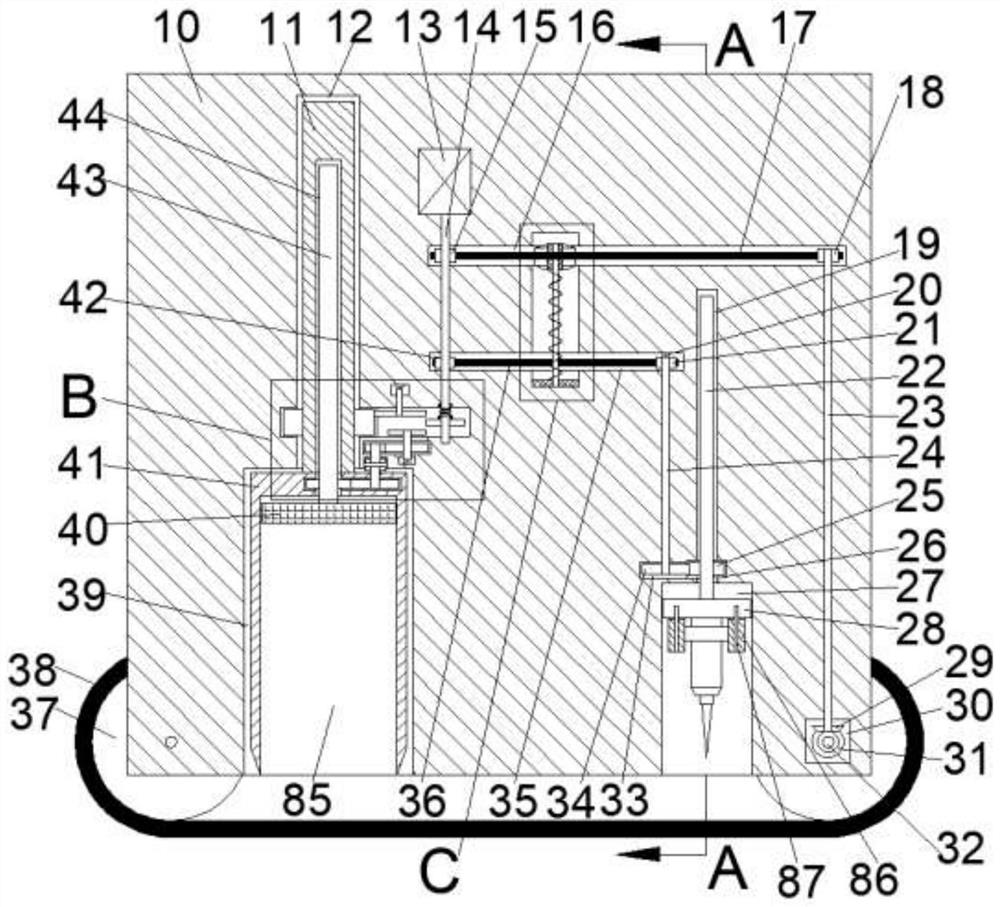

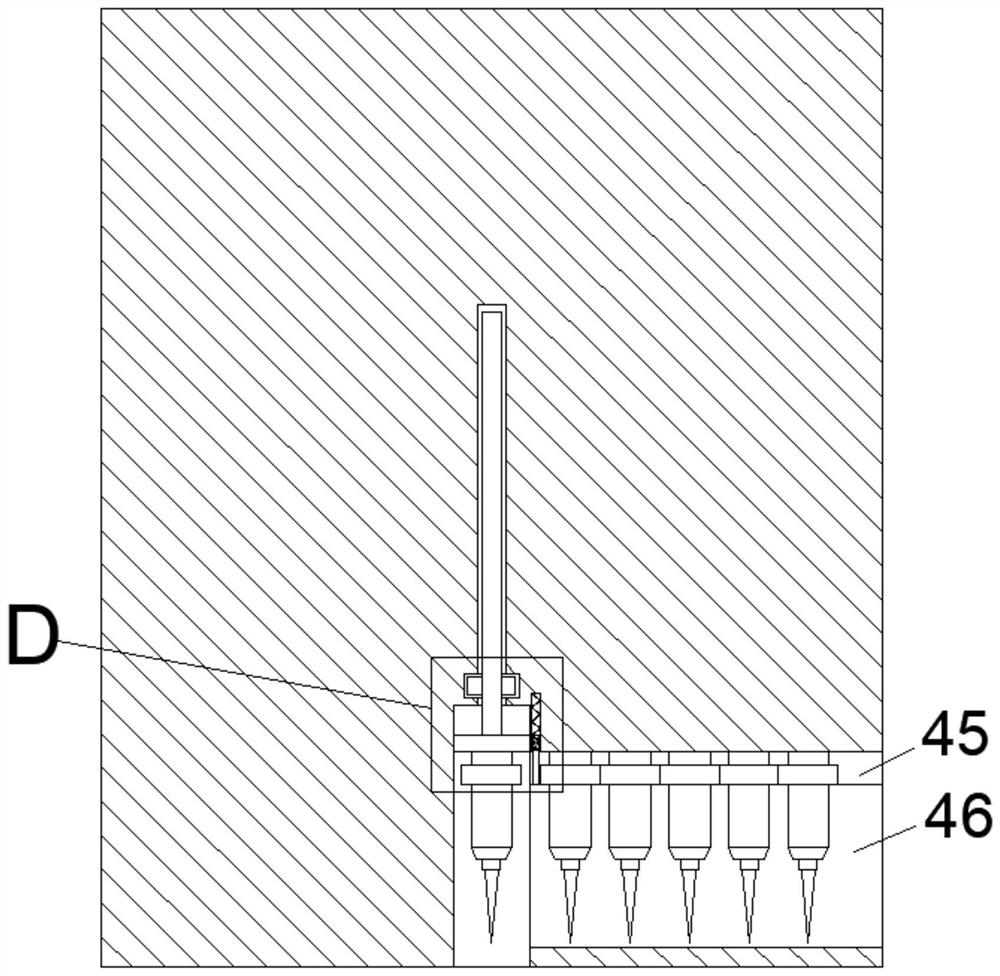

Buried electromechanical equipment mounting device

InactiveCN112195997AImprove installation efficiencyImprove drilling efficiencySoil-shifting machines/dredgersGear wheelElectric machinery

The invention relates to the electromechanical related field, and discloses a buried electromechanical equipment mounting device. The buried electromechanical equipment mounting device comprises a main box body, wherein a hole punching block cavity with a downward opening is formed in the main box body, a lifting nut cavity is formed in the upper side of the hole punching block cavity, and a lifting rod cavity extending downwards to penetrate through the lifting nut cavity into the hole punching block cavity is formed in the upper side of the lifting nut cavity; and a motor fixedly connected with the main box body is arranged at the right side of the lifting rod cavity, an advancing belt wheel cavity is formed in the lower side of the motor, an installing belt wheel cavity is formed in thelower side of the advancing belt wheel cavity, and an installing gear cavity is formed in the lower side of the installing belt wheel cavity. The buried electromechanical equipment mounting device isused for automatically punching a hole and replacing manual operation, so that the hole punching efficiency is greatly improved; a seismic wave receiver is inserted into the hole by using the mounting device, so that a large amount of manual labor is saved, and the installation efficiency of the receiver is greatly improved; and meanwhile, the problem that the receiver is difficult to install manually in a hard section is solved, the mounting device can adapt to different operation environments through a crawler-type advancing mechanism, advancing operation of operators is facilitated, and the applicability of the mounting device is greatly improved.

Owner:广州市鼎隆机电安装有限公司

Fixing device of belt wheel

InactiveCN105422804ATake advantage ofReduce the workload of disassembly and assemblyPinsNutsButt jointEngineering

The invention discloses a belt wheel, adjusted through a rod pumped well in an oil field, on a motor, and particularly relates to a fixing device of the belt wheel. The fixing device of the belt wheel comprises a belt wheel body. The belt wheel body is sleeved with a second wheel disc. The second wheel disc is provided with an inner hole allowing the outer edge of a first wheel disc to be sleeved. A locating groove allowing a belt to be located is formed in the outer edge of the second wheel disc. Bolt assemblies are arranged between the first wheel disc and the second wheel disc and comprise studs, nuts and screws. Mounting holes allowing the studs to penetrate are formed between the first wheel disc and the second wheel disc. One ends of the studs penetrate in the mounting holes and are provided with reverse-spiral internal threads connected with the screws, and the other ends of the studs are provided with external threads connected with the nuts. The nuts are clamped between the screws and the second wheel disc. The technical defect that belt wheels and motor shafts are in butt joint one to one in the prior art, and consequently the demounting workload is large after rusting is overcome, and the fixing device of the belt wheel can reduce damage to the belt wheel during demounting.

Owner:CHONGQING ZHIRUIDE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com