Safety type electric fan with refrigeration function and manufacturing method thereof

A safe, electric fan technology, applied in manufacturing tools, heating methods, home appliances, etc., can solve problems such as excessive temperature rise, lower indoor temperature, and prolong the cooling time of refrigeration components, so as to increase stability and extend cooling time , to avoid the effect of excessive temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

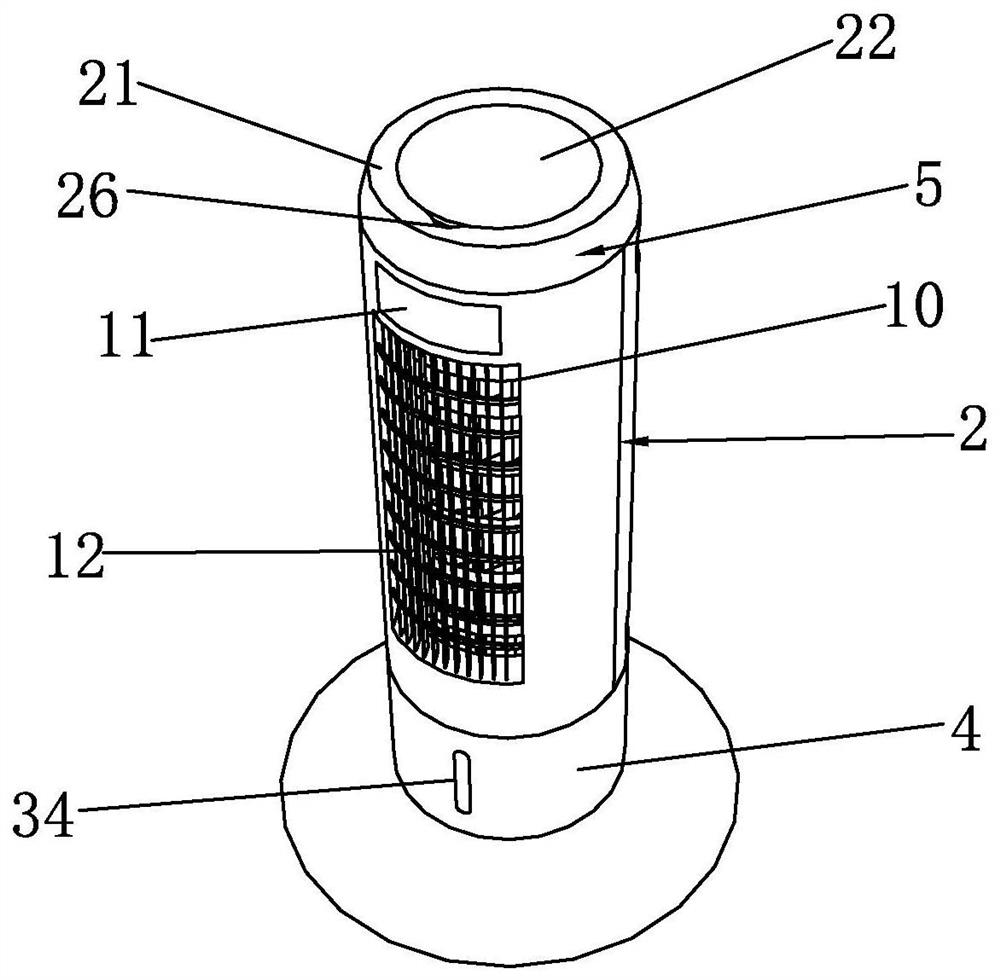

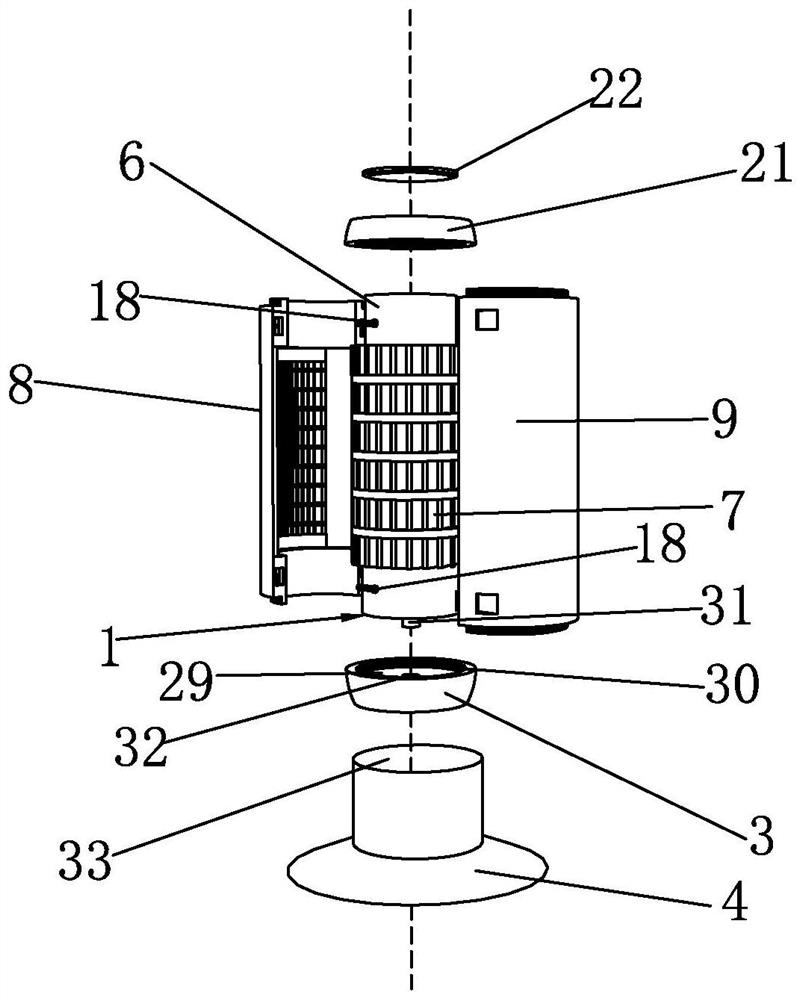

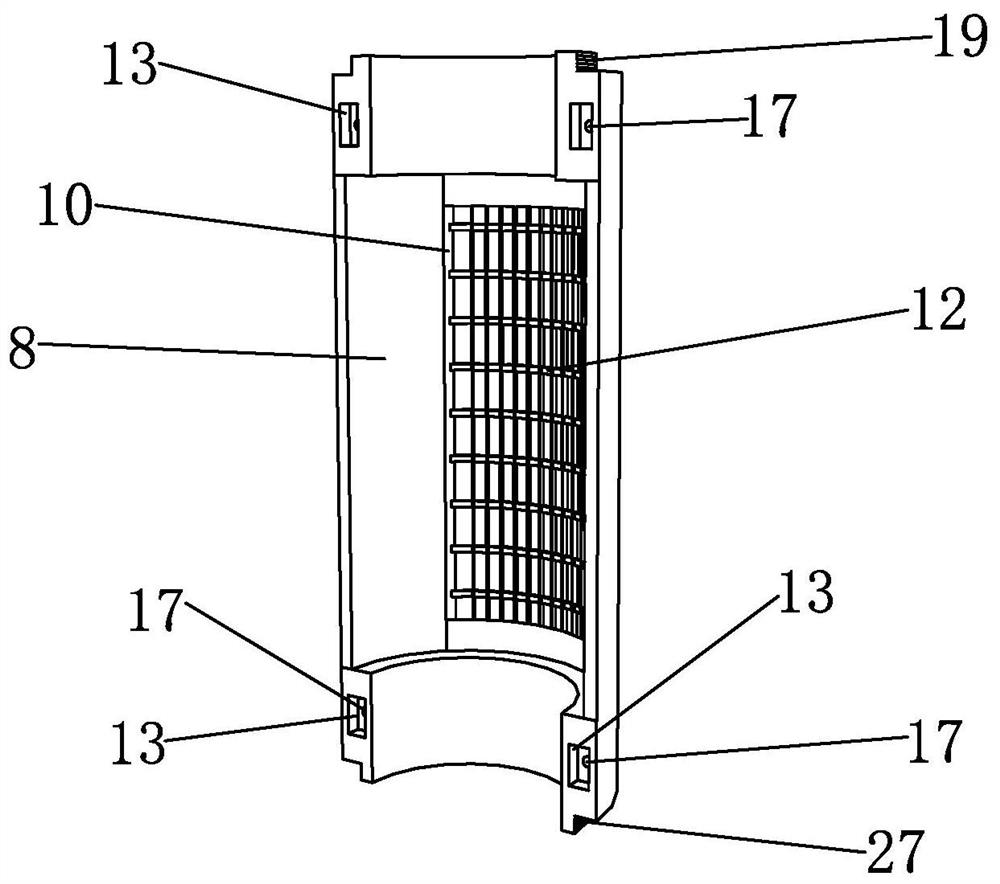

[0045]Such asFigure 1 to 5 As shown, a safety type electric fan having a refrigeration function of the present invention, including a base 4, a refrigeration assembly 1, and a housing 2 in the outer side of the refrigeration assembly 1, and the bottom of the housing 2 is provided with a cooling assembly 1 matching setting. The socherear portion 3, the plug portion 3 is fixedly connected to the bottom portion of the housing 2, and the bottom of the coupling portion 3 is inserted into the base 4, and the top of the casing 2 is provided with a closure assembly 5, the closure assembly 5 closed the housing 2. top.

[0046]The refrigeration assembly 1 includes a cylindrical body 6 and a tower fan 7, and the tower fan 7 is rotatably coupled to the outer side of the cylindrical body 6, and the cylindrical body 6 is used to flush the cooling water, the tower fan 7 blows out the cold air of the cylinder 6. The water is injected into the cylinder 6, and then the ice is placed in the water of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com