Methods for producing and mounting heat-insulating decorative composite board comprising panel with through groove

A production method and technology of composite panels, applied in the direction of covering/lining, construction, building construction, etc., to achieve effective connection, prevent panel falling off, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The specific implementation manners according to the invention will be described below in conjunction with the accompanying drawings.

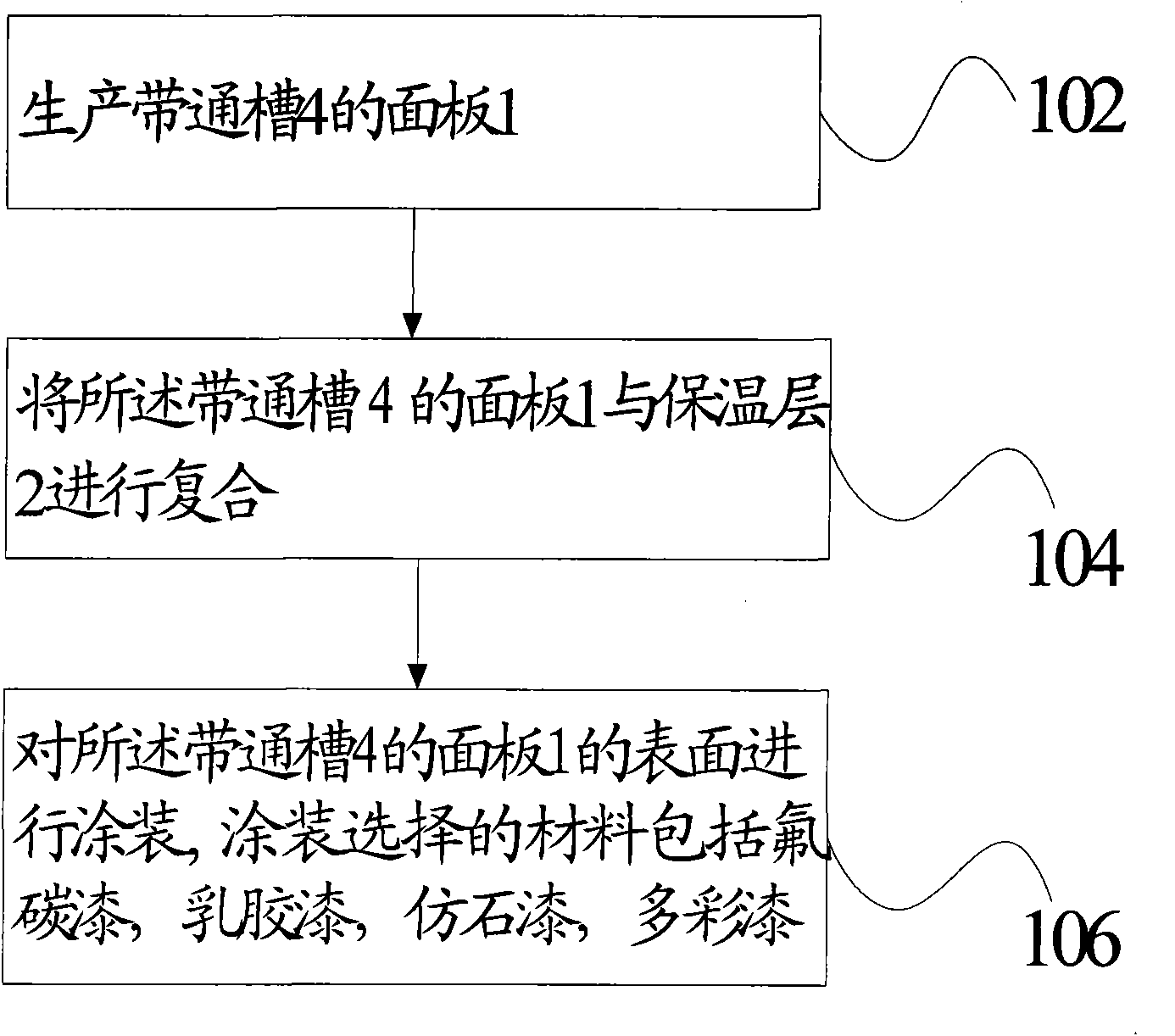

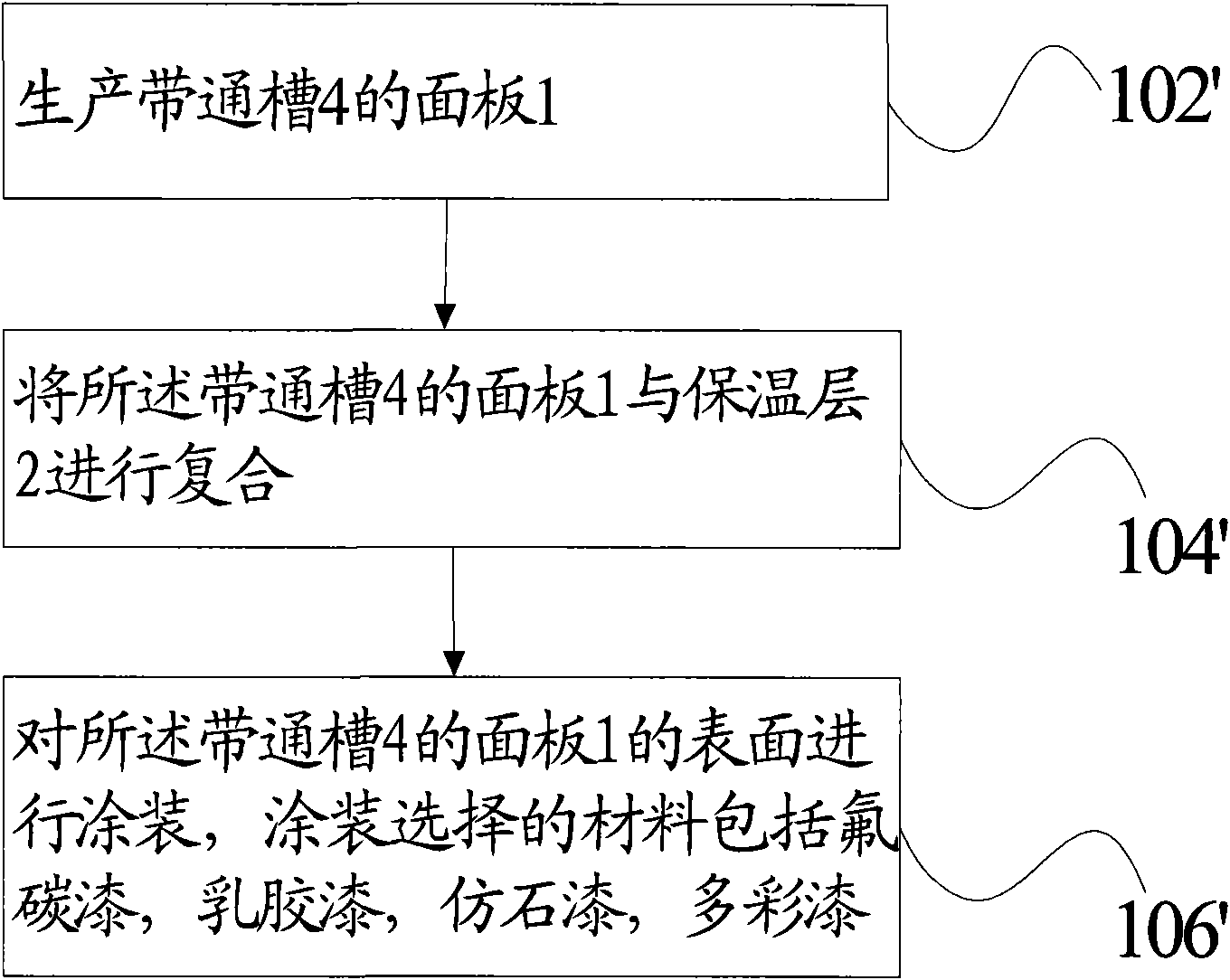

[0060] figure 1 It is a flow chart of an embodiment of the production method of the thermal insulation and decorative composite board with the through groove on the panel of the present invention.

[0061] Such as figure 1 As shown, the production process of the thermal insulation and decorative composite board with the panel band through groove provided by the present invention includes:

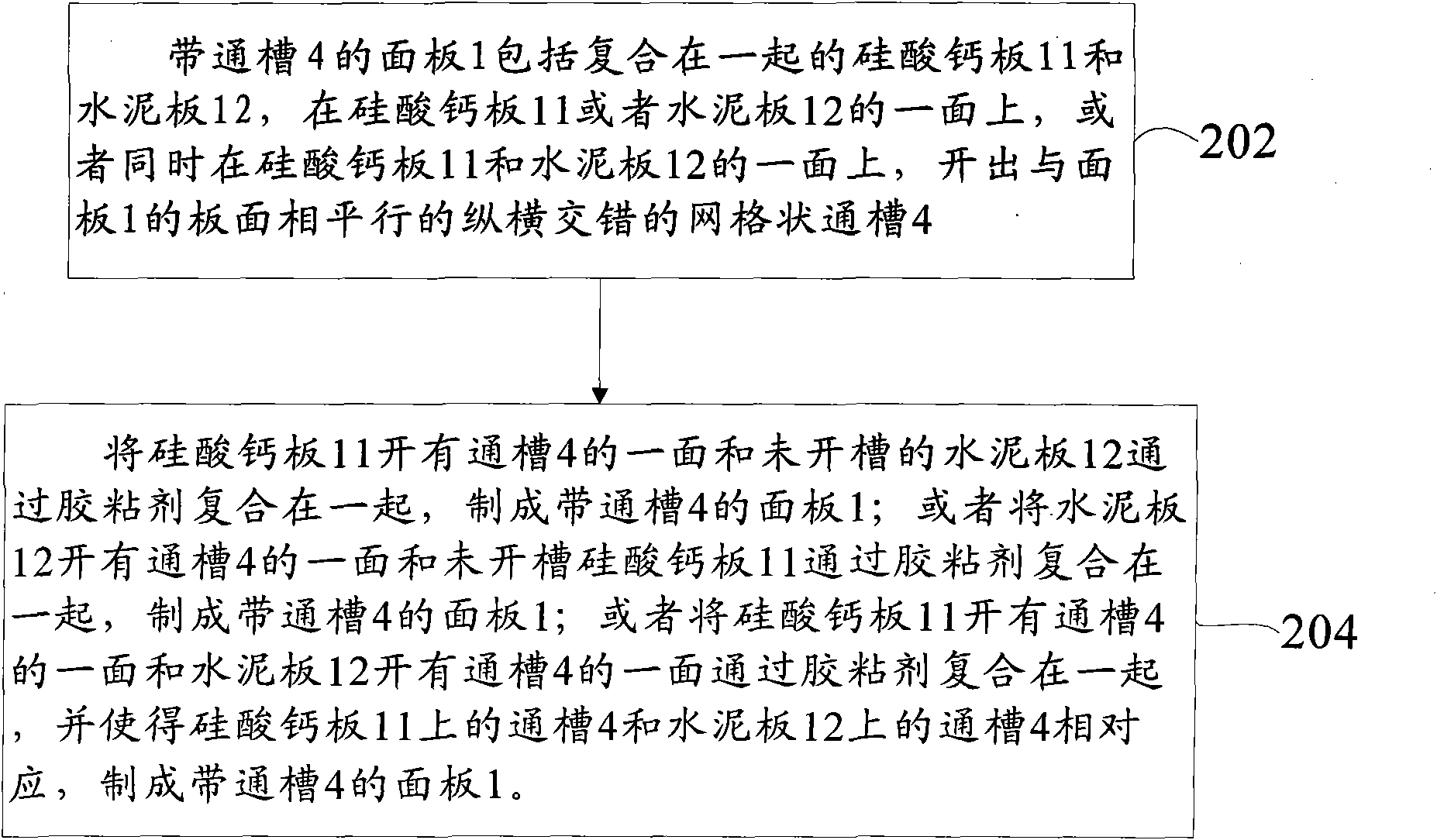

[0062] Step 102, producing the panel 1 with the slot 4;

[0063] Step 104, compounding the panel 1 with the pass-through groove 4 and the insulation layer 2;

[0064] Step 106, coating the surface of the panel 1 with the through groove 4, the materials selected for coating include fluorocarbon paint, latex paint, imitation stone paint, colorful paint, and make the thermal insulation decoration of the said panel with the through groove Composite b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com