Steel wire rope for deep sea oil field lifting and production method thereof

A technology of steel wire rope and oil field, applied in the field of steel wire rope, can solve the problems of wire rope breakage, shortening the service life of steel wire rope, corrosion of steel wire rope, etc., to achieve the effect of buffering lateral force, increasing tensile capacity, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

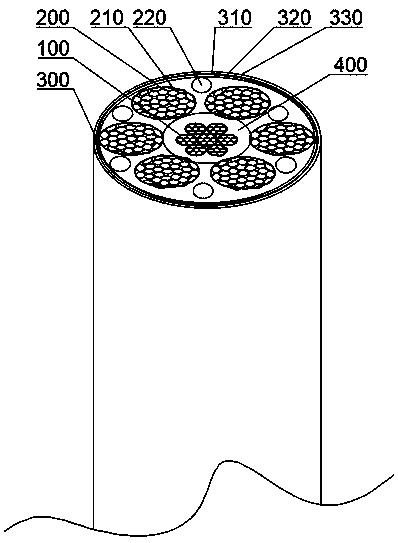

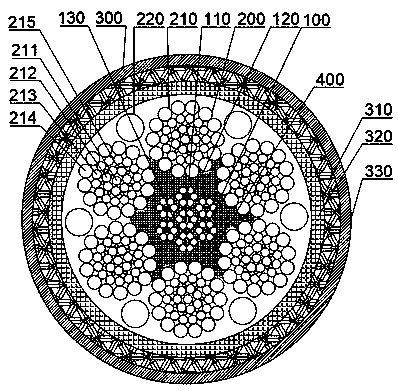

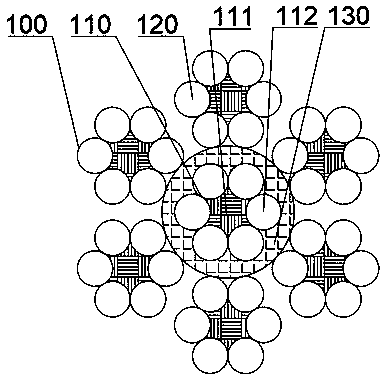

[0031] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments. Such as figure 1 and figure 2As shown, a steel wire rope for hoisting in a deep-sea oilfield includes a central strand 100, an outer strand 200 and a plastic-coated layer 300 surrounding the outer strand, the steel wire rope is centered on the central strand 100, and the outer The layer strand 200 is twisted around the periphery of the central strand 100, and there is a first filling layer 400 between the central strand 100 and the outer layer strand 200. The central strand 100 specifically includes the central strand 110 and the outer strand 200. Rope strands 120, the central strand 110 is located at the center of the central strand 100, the outer strands 120 are twisted around the periphery of the central strand 110, the outer strands 120 are arranged in a hexagonal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com