Can be used for tbm dynamic self-adaptive solid non-polarized electrode and using method

A dynamic self-adaptive and polarized electrode technology, which is applied in the fields of re-radiation, electric/magnetic exploration, radio wave measurement system, etc., can solve the problems of high labor intensity, manual installation of electrodes, and low efficiency, so as to ensure the safety of personnel , Improve work efficiency and ensure construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

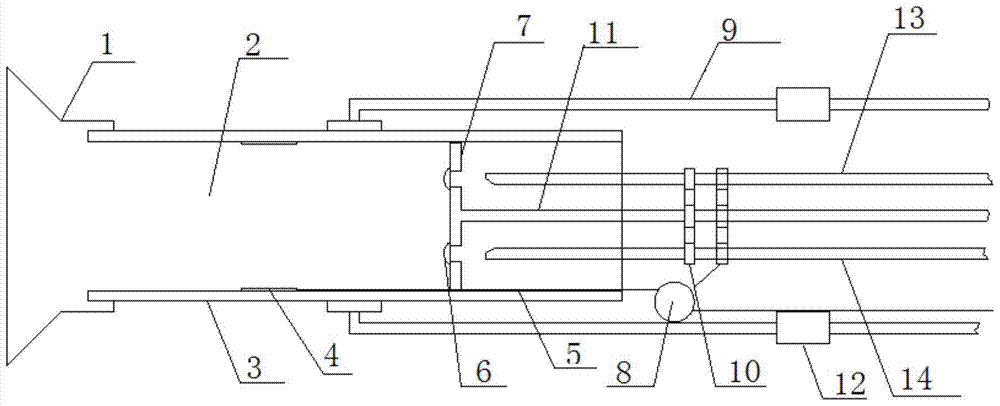

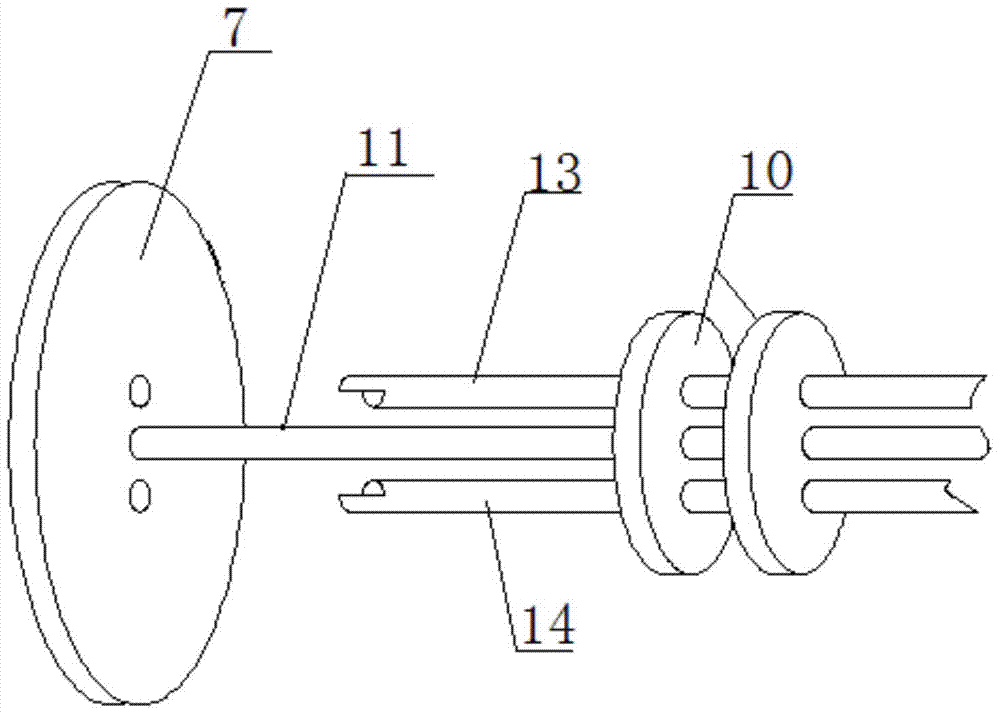

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] like Figure 1-2 As shown, it can be used for TBM dynamic adaptive solid non-polarized electrodes, including non-polarized electrodes; the outer wall of the non-polarized electrodes is fixedly connected with the telescopic linkage device, and the telescopic linkage device stretches to drive the movement of the non-polarized electrodes; the internal seal of the non-polarized electrodes The sleeve is equipped with a pushing device, which can move relative to the non-polarized electrode.

[0033] The non-polarized electrode includes a PVC pipe 3, the outer wall of the PVC pipe 3 is fixedly connected with the telescopic linkage device, the inner sealing sleeve is equipped with a pushing device, one end of the PVC pipe 3 is installed with a tapered pipe sleeve 1, and the PVC pipe 3 and the tapered pipe sleeve 1 form a The cavity is the electrolyte ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com