A collection vessel capable of removing cyanobacterial sludge

A cyanobacterial oil and cabin technology, which is applied in special purpose ships, general water supply conservation, and open water surface cleaning, etc., can solve problems such as hole blockage, fishery and aquaculture hazards, and affect equipment work efficiency, avoiding manual installation and convenient. The depth of water entry and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

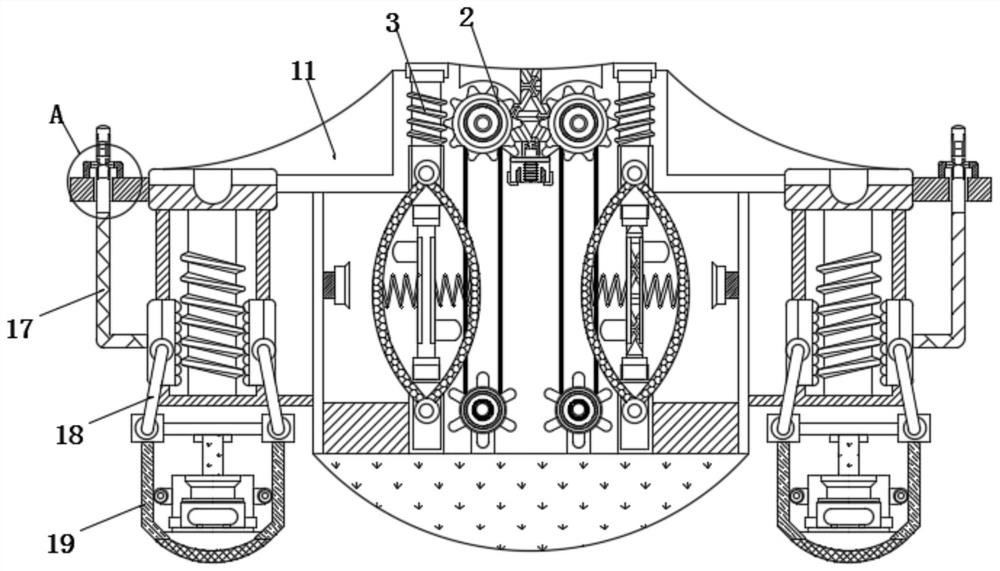

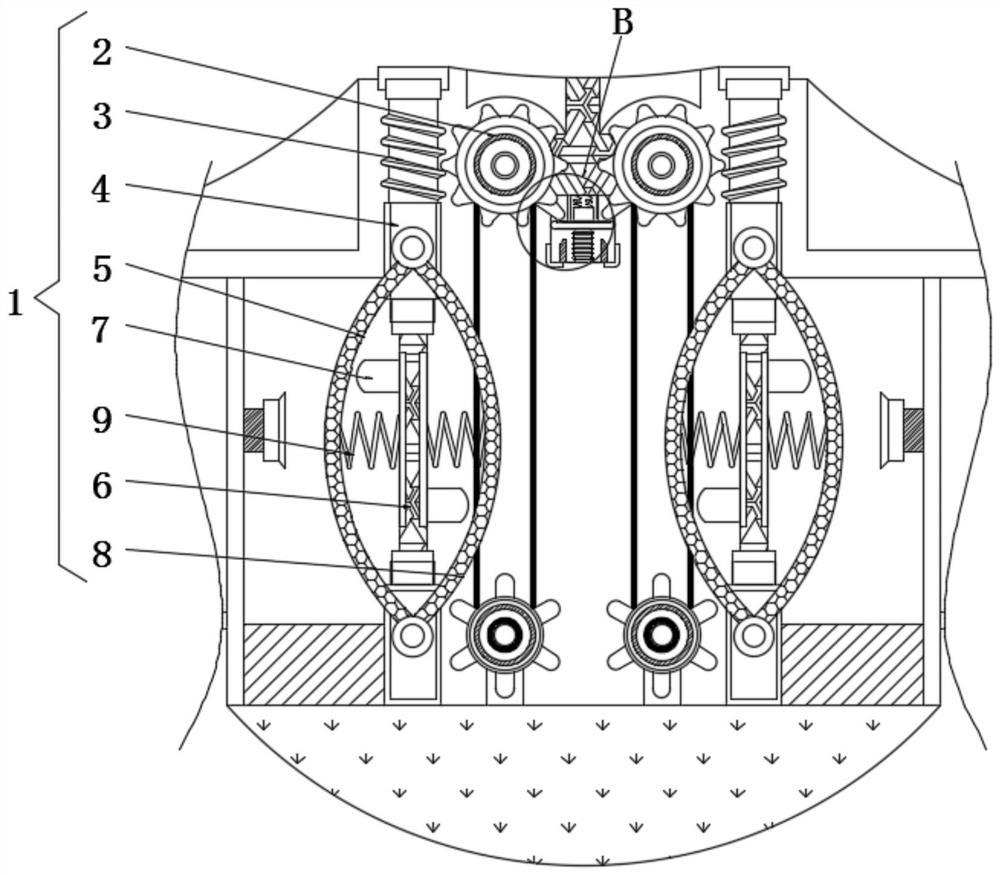

[0027] A collection ship capable of removing cyanobacteria sludge, comprising a drive assembly 1 and an adjustment mechanism 14, the drive assembly 1 includes a driven gear 2, the left side of the driven gear 2 is meshed with a drive shaft 3, and the outside of the drive shaft 3 is sleeved with Positioning pipe 4, the lower surface of driving shaft 3 is fixedly connected with vertical rod 6, the front surface of positioning pipe 4 is fixedly connected with first filter screen 5 and second filter screen 8 respectively from left to right, the left and right sides of vertical rod 6 The two side surfaces are fixedly connected with bump shifting plates 7 , and a tension spring 9 is fixedly connected between the first filter screen 5 and the second filter screen 8 .

[0028] Also comprise positioning assembly 10, positioning assembly 10 comprises cabin frame 11, the left and right sides of cabin frame 11 are positioned at the inside of guide rail bar 15 and are all rotatably connecte...

specific Embodiment 2

[0031] A collection ship capable of removing cyanobacteria sludge, comprising a drive assembly 1 and an adjustment mechanism 14, the drive assembly 1 includes a driven gear 2, the left side of the driven gear 2 is meshed with a drive shaft 3, and the outside of the drive shaft 3 is sleeved with Positioning pipe 4, the lower surface of driving shaft 3 is fixedly connected with vertical rod 6, the front surface of positioning pipe 4 is fixedly connected with first filter screen 5 and second filter screen 8 respectively from left to right, the left and right sides of vertical rod 6 The two side surfaces are fixedly connected with bump shifting plates 7 , and a tension spring 9 is fixedly connected between the first filter screen 5 and the second filter screen 8 .

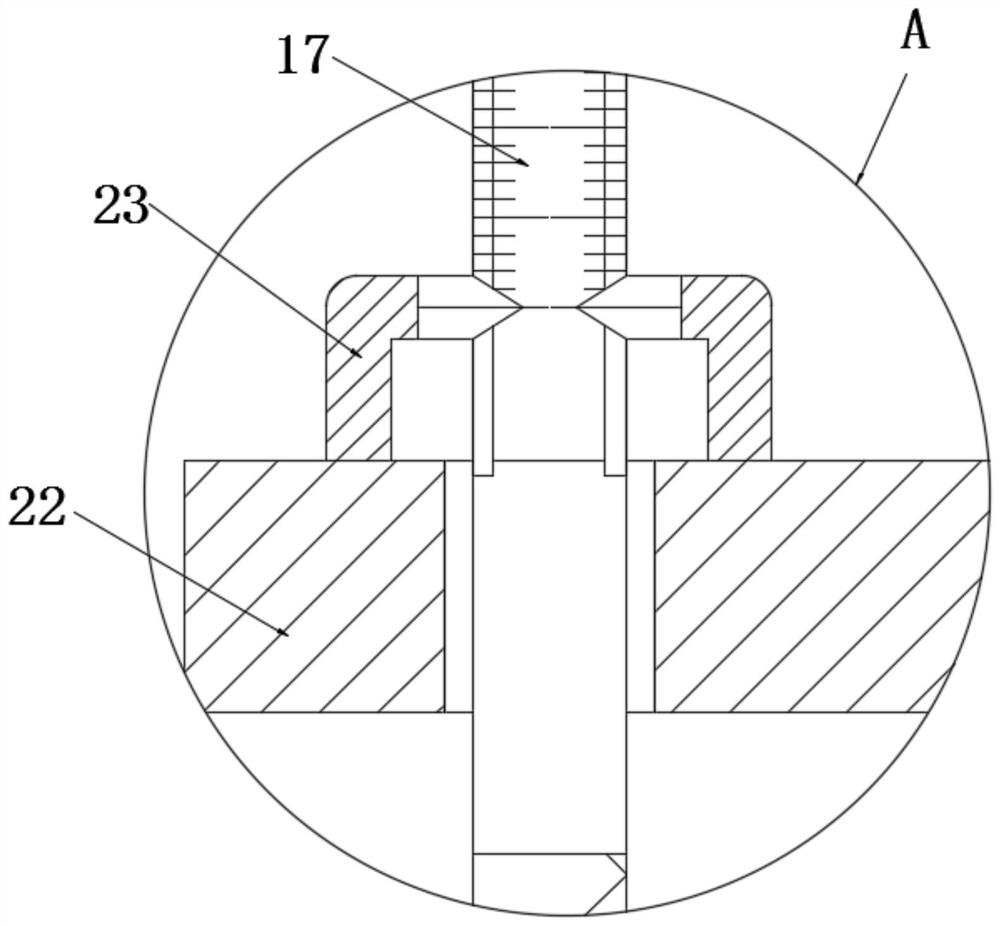

[0032] The adjustment mechanism 14 includes a guide rail rod 15, the outside of the guide rail rod 15 is sleeved with a sliding cover plate 16, the left side of the sliding cover plate 16 is fixedly connected with a sca...

specific Embodiment 3

[0035] A collection ship capable of removing cyanobacteria sludge, comprising a drive assembly 1 and an adjustment mechanism 14, the drive assembly 1 includes a driven gear 2, the left side of the driven gear 2 is meshed with a drive shaft 3, and the outside of the drive shaft 3 is sleeved with Positioning pipe 4, the lower surface of driving shaft 3 is fixedly connected with vertical rod 6, the front surface of positioning pipe 4 is fixedly connected with first filter screen 5 and second filter screen 8 respectively from left to right, the left and right sides of vertical rod 6 The two side surfaces are fixedly connected with bump shifting plates 7 , and a tension spring 9 is fixedly connected between the first filter screen 5 and the second filter screen 8 .

[0036]Also comprise positioning assembly 10, positioning assembly 10 comprises cabin frame 11, the left and right sides of cabin frame 11 are positioned at the inside of guide rail bar 15 and are all rotatably connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com