Automatic valve assembling equipment

An assembly equipment and automation technology, applied in the direction of assembly machines, metal processing equipment, climate sustainability, etc., can solve problems such as low production efficiency and low degree of automation, and achieve the effects of improving efficiency, improving accuracy, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

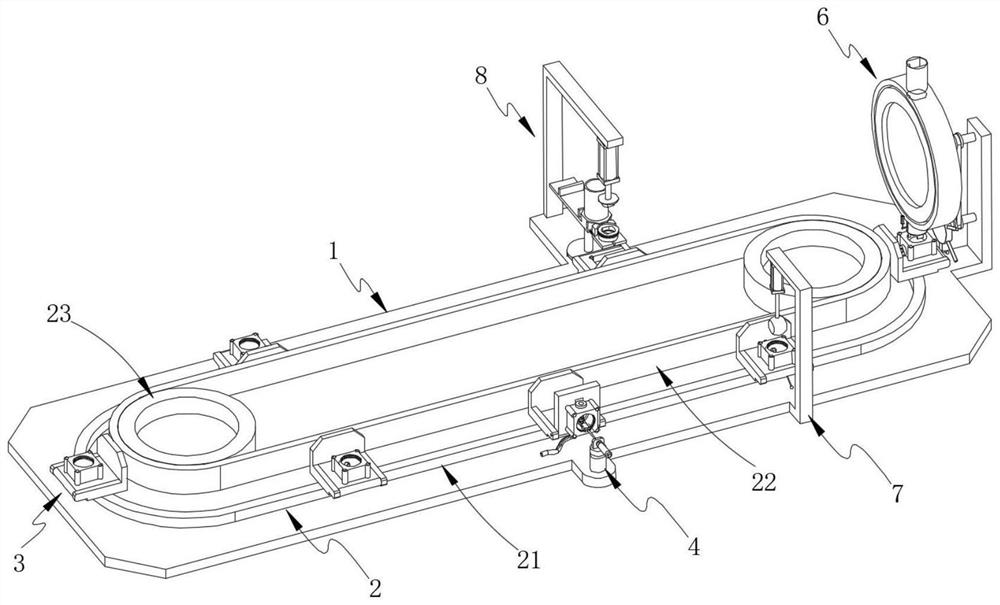

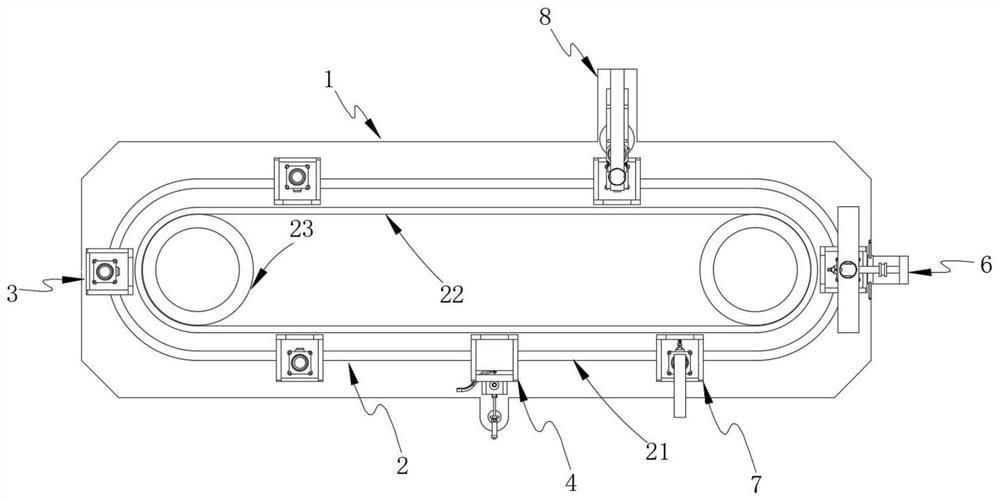

[0054] like figure 1 and image 3 As shown, the present invention provides an automatic valve assembly equipment, comprising: a workbench 1; an annular drive part 2, which is installed on the workbench 1; a material placement plate 3, which is arranged on the annular drive part 2 on the transfer valve body; also includes:

[0055] The first assembly part 4, the first assembly part 4 is set on the workbench 1 for installing the knob in the valve body; the transmission part 5, the transmission part 5 is set on one side of the workbench 1 for transmitting the knob; the second assembly part 6 , the second assembly part 6 is arranged on the workbench 1 for installing the valve core in the valve body;

[0056] The third assembly part 8 is provided on the workbench 1 for installing the valve cover in the valve body.

[0057] In the present invention, the valve body is transmitted through the material placing plate 3; the first assembly part 4 is used to install the knob in the va...

Embodiment 2

[0083] like Figure 18 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is:

[0084] This embodiment also includes a positioning adjustment part 7, which is arranged on one side of the worktable 1 to adjust the knob and the valve core for precise assembly;

[0085] preferably, as Figure 18 and Figure 19 As shown, the positioning adjustment component 7 includes: an adjustment component 71, which is arranged on the material placing plate 3 for adjusting the angle of the knob; a guide component 72, which is arranged in the discharge pipe 634 to discharge the valve core Provide guidance.

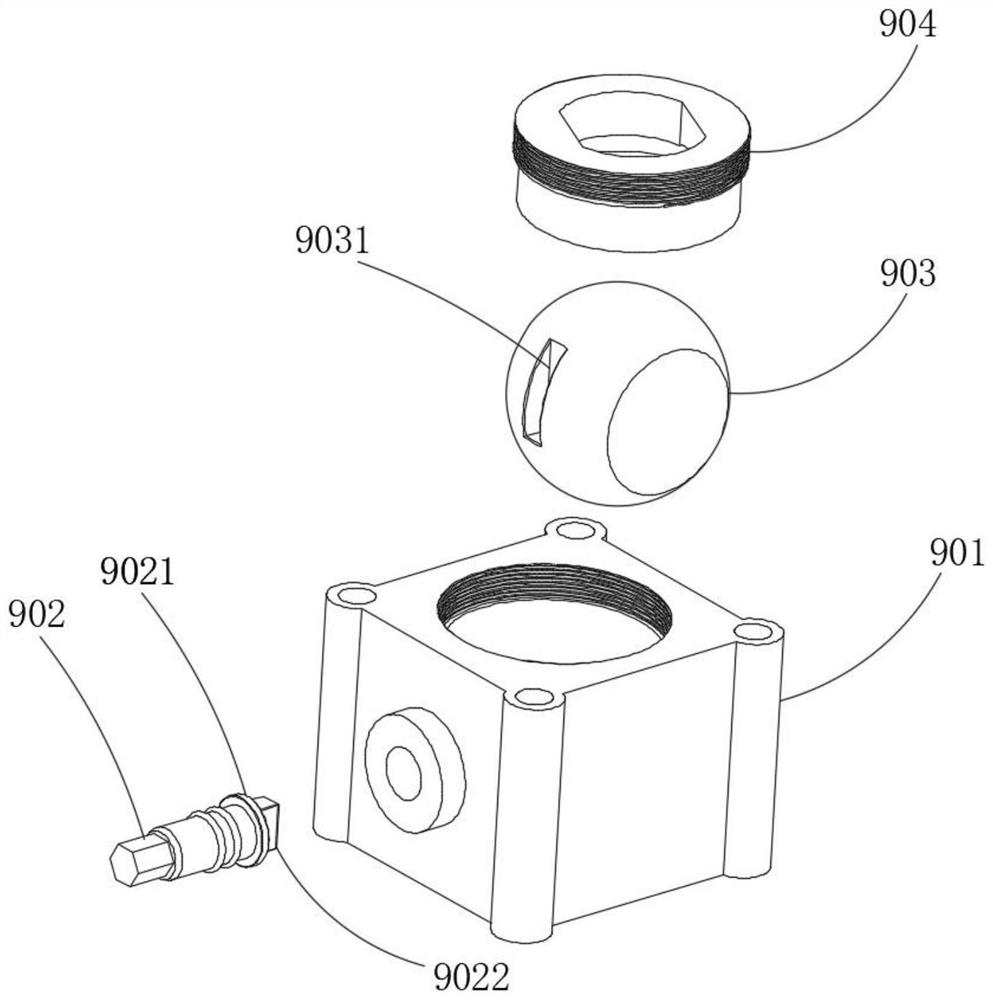

[0086] like figure 2 As shown, the end of the knob is provided with a word block 9022, which is used to match the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com