Capacitive touch electrode structure

An electrode structure and capacitive touch technology, applied in the direction of electrical digital data processing, data processing input/output process, instruments, etc., can solve the problems of rising raw material costs, high requirements for equipment manufacturing process, serious environmental pollution, etc., and achieve linearity Excellent, convenient and fast operation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the embodiments do not constitute any limitation to the present invention.

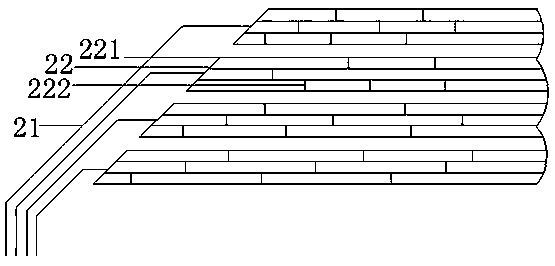

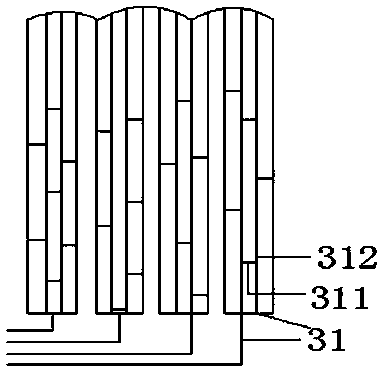

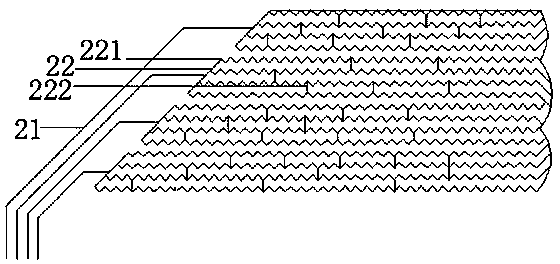

[0017] see figure 1 , figure 2 , image 3 , an electrode structure for capacitive touch control, which is composed of a base material and metal grid layers on both sides of the base material, and the metal grid layers on both sides respectively include several sensing layer regions 22 and several driving layer regions 31 . The sensing layer area 22 includes 10-50 sensing linear metal grids, and the driving layer area 31 includes 10-50 linear driving line metal grids.

[0018] The sensing layer area 22 has 10-50 sensing layer linear metal lines 221 , and the driving layer area 31 has 10-50 driving layer linear metal lines 312 , and the grids are slightly disconnected to realize electrical separation.

[0019] The distance between each sensing layer region 22 and driving la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com