Process method for efficiently removing residue of plasticizer in extract

A process method and technology of plasticizer, applied in food science and other directions, can solve the problems of long production cycle, complex process flow, increase production cost, etc., and achieve the effect of high degree of automation, simple production process and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

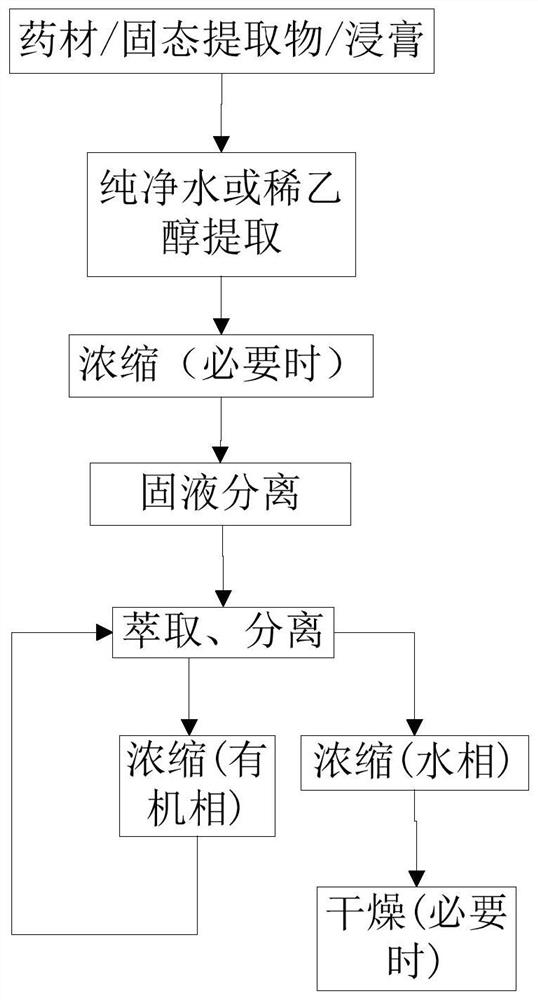

Method used

Image

Examples

Embodiment 1

[0048] (1) Extraction: put Epimedium (di-n-butyl phthalate (DBP) 1.14mg / kg into a 5400L multi-functional extraction tank, no other phthalate plasticizer components were detected, and the plasticizing The agent residue does not meet the requirements ((DBP should be ≤0.3mg / kg)) 200kg, add 4000L 50% ethanol to extract, the extraction temperature is 85 ℃, the extraction time is 1.5h, and the number of times of extraction is 3 times. The three extractions are combined, The extract is 11300L in total.

[0049] (2) Concentration: Concentrate the extract with a vacuum concentrator at a concentration temperature of 60° C. and a vacuum of 0.06 MPa to a Brix value of 1.9% to obtain 4 000 L of a concentrate.

[0050] (3) Separation: Disc centrifuge is used for centrifugation at a speed of (7000±500) r / min, 3900L of clear and transparent centrifuged liquid is collected, and the centrifuged residue is discharged into the sewage treatment system.

[0051] (4) Extraction: use a centrifugal e...

Embodiment 2

[0056] (1) Extraction: Add 3000L 20% ethanol (prepared with edible alcohol and purified water) in the 4000L alcohol sinking tank, drop into the Epimedium extract (icariin content is 10.7%; DBP 13.5mg / kg, no other phthalate plasticizer components were detected, and did not meet the requirements) 100kg, heated to 40-50°C and kept stirring to dissolve, stirring time 0.5h.

[0057] (2) Concentration: Concentrate the centrifuged supernatant with a vacuum concentrator at a concentration temperature of 70°C and a vacuum of 0.075MPa until the feed liquid has no obvious ethanol smell to obtain a concentrated liquid of about 2000L with a Brix value of 5.5%.

[0058] (3) Separation: A disc centrifuge is used for high-speed centrifugal separation at a rotational speed of (7000±500) r / min. A total of 1900L of clear and transparent centrifuged liquid is collected, and the centrifuged residue is discharged into the sewage treatment system.

[0059] (4) Extraction: Use a centrifugal extractor...

Embodiment 3

[0064] (1) Extraction: Put the deoiled peach kernel cake (di(2-ethyl)hexyl phthalate (DEHP) at 3.6mg / kg into a 5400L multifunctional extraction tank, and no other phthalates were detected. Diformic acid ester plasticizer component, does not meet the requirements) 400kg, add 4000L 50% ethanol for extraction, the extraction temperature is 81°C, the extraction time is 1.5h, and the extraction times is 3 times. The extracts were combined to obtain 11 500 L of extracts.

[0065] (2) Concentration: Use a double-effect concentrator to concentrate the centrifugal supernatant under reduced pressure. The concentration temperature is 55°C and the vacuum degree is 0.08MPa. In the later stage of concentration, add water to the concentrator until the feed liquid has no obvious ethanol smell, and peach kernels are obtained. The concentrate is about 4000L, and the Brix value is 3.1%.

[0066] (3) Separation: and use a disc centrifuge for high-speed centrifugation, with a speed of (5000±500) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com