Melt liquid level control device

A liquid level control and melt technology, applied in the field of molten material transfer equipment, can solve problems such as high energy consumption, broken wires, overflow, etc., and achieve the effect of high liquid level, low speed and large speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

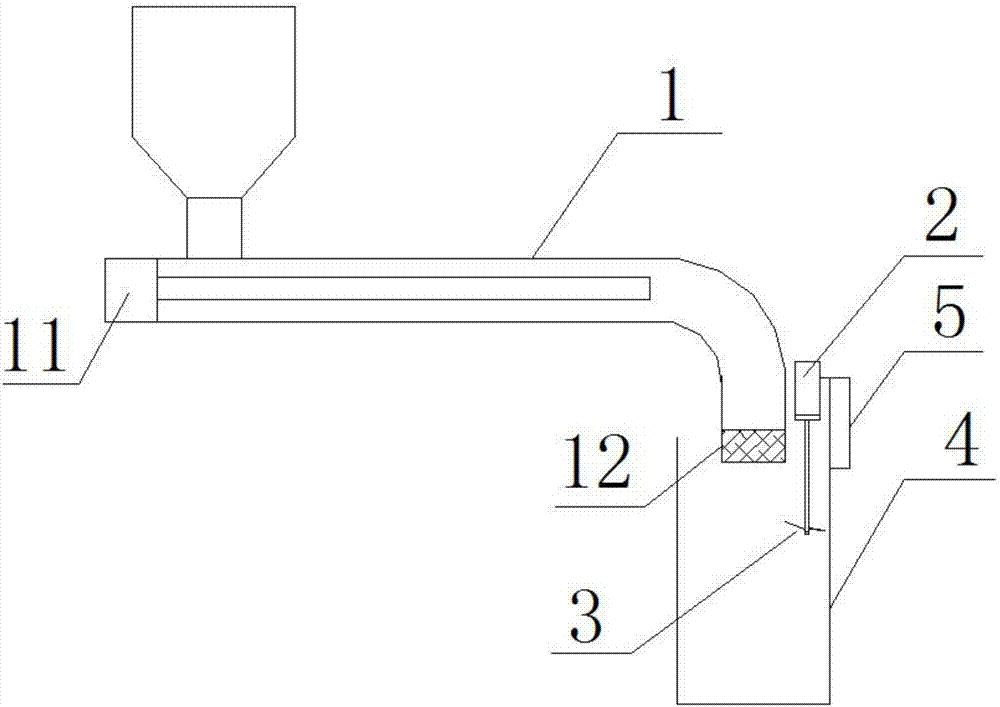

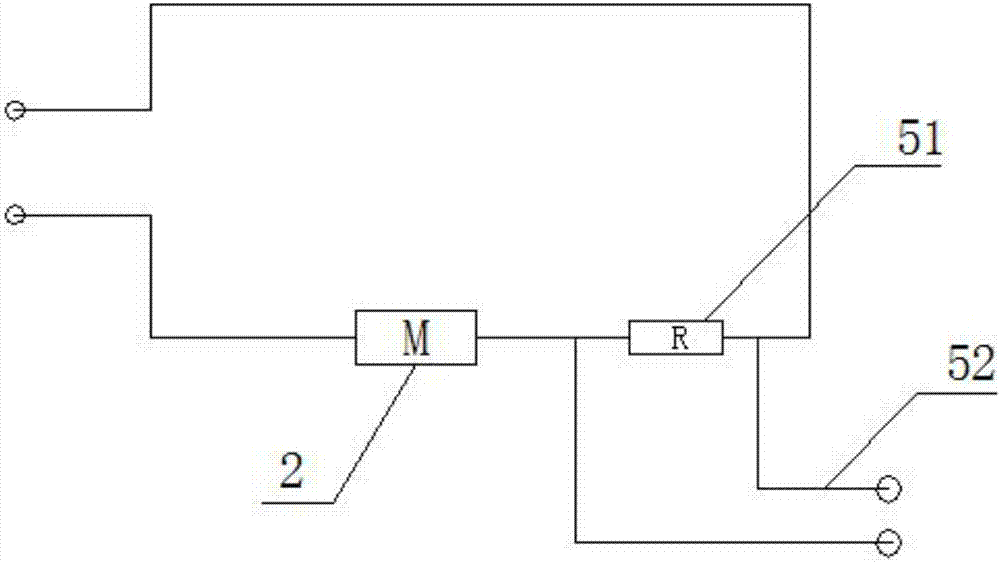

[0014] see figure 1 and figure 2 , a melt level control device, including a small DC motor 2, a barrel 4 and an electrical box 5, a stirring blade 3 is arranged below the small DC motor 2, the stirring blade 3 is located in the barrel 4, and the electrical box 5 is arranged There is an adjusting resistor 51 and a frequency converter control signal connector 52, the adjusting resistor 51 is electrically connected in series with the small DC motor 2, the frequency converter control signal connector 52, and the electrical box 5 is located on the side of the small DC motor 2. Feasibly, a screw extruder ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap