Absorption-type unit concentrated solution bypass defrosting device

A concentrated solution and absorption technology, which is applied in the field of absorption unit concentrated solution bypass defrosting device, can solve the problems of complex process, low efficiency, large power consumption, etc., and achieve the effect of reducing energy loss, low cost and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

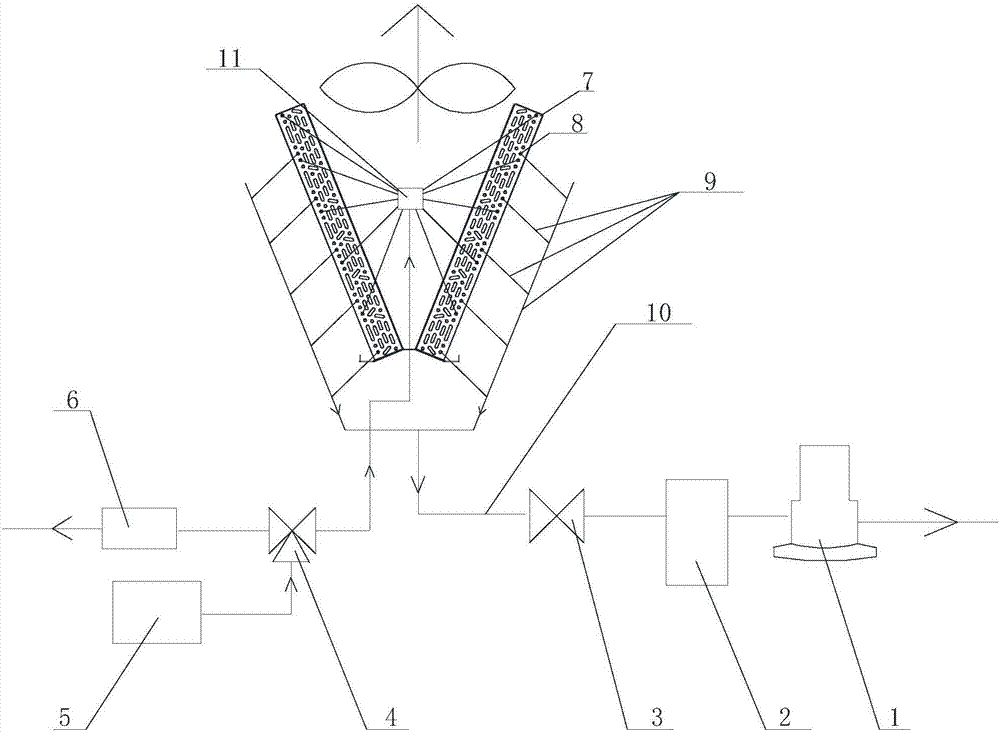

[0026] Example 1: See figure 1 , the present invention provides a concentrated solution bypass defrosting device for an absorption unit, comprising: a medium inflow pipeline and a medium outflow pipeline;

[0027] The medium inflow pipeline includes:

[0028] The absorber 5 is used to accommodate the concentrated solution medium;

[0029] The concentrated solution flow control device is an electromagnetic three-way valve 4, which is connected to the absorber 5, the casing 6 and the input end of the liquid separator 11 through pipelines;

[0030] Liquid separator 11, the output end of which is used to be connected to the evaporator of the heat pump unit; wherein, the evaporator includes an air-cooled finned heat exchanger 7, and the air-cooled finned heat exchanger 7 includes fins tube, the inner cavity of the finned tube is provided with a heat exchange coil and a defrosting coil 8, and the defrosting coil 8 is attached to the heat exchange coil; the output end of the liquid...

Embodiment 2

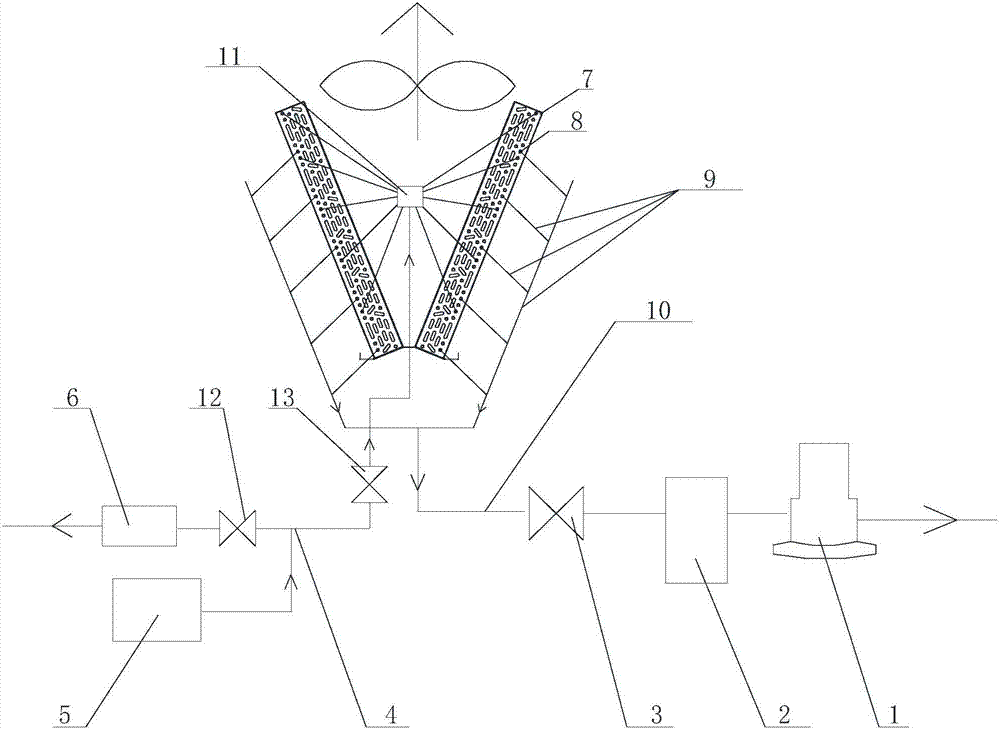

[0035] Example 2: See figure 1 The difference between embodiment 2 and embodiment 1 is that the concentrated solution flow control device includes a first control valve 12 and a second control valve 13, and the first control valve is arranged on the pipeline where the concentrated solution medium flows to the casing; The second control valve is arranged on the pipeline where the concentrated solution medium flows to the liquid separator.

[0036] When in use, when it is judged that the frosting condition is reached, close the electromagnetic three-way valve 4 (the first control valve 12 in embodiment 2) to enter the casing pipeline, and open the electromagnetic three-way valve 4 (the second control valve 12 in embodiment 2). Valve 13) into the valve of the liquid separation device 11, so that the high-temperature concentrated solution medium enters the outermost defrosting coil 8, and the defrosting coil 8 is close to the heat exchange coil of the air-cooled fin heat exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com