A kind of porous brick palletizing claw

A perforated brick and stacking technology, applied in the field of object stacking, can solve problems such as quality damage of perforated brick stacking, and achieve the effects of quality assurance, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

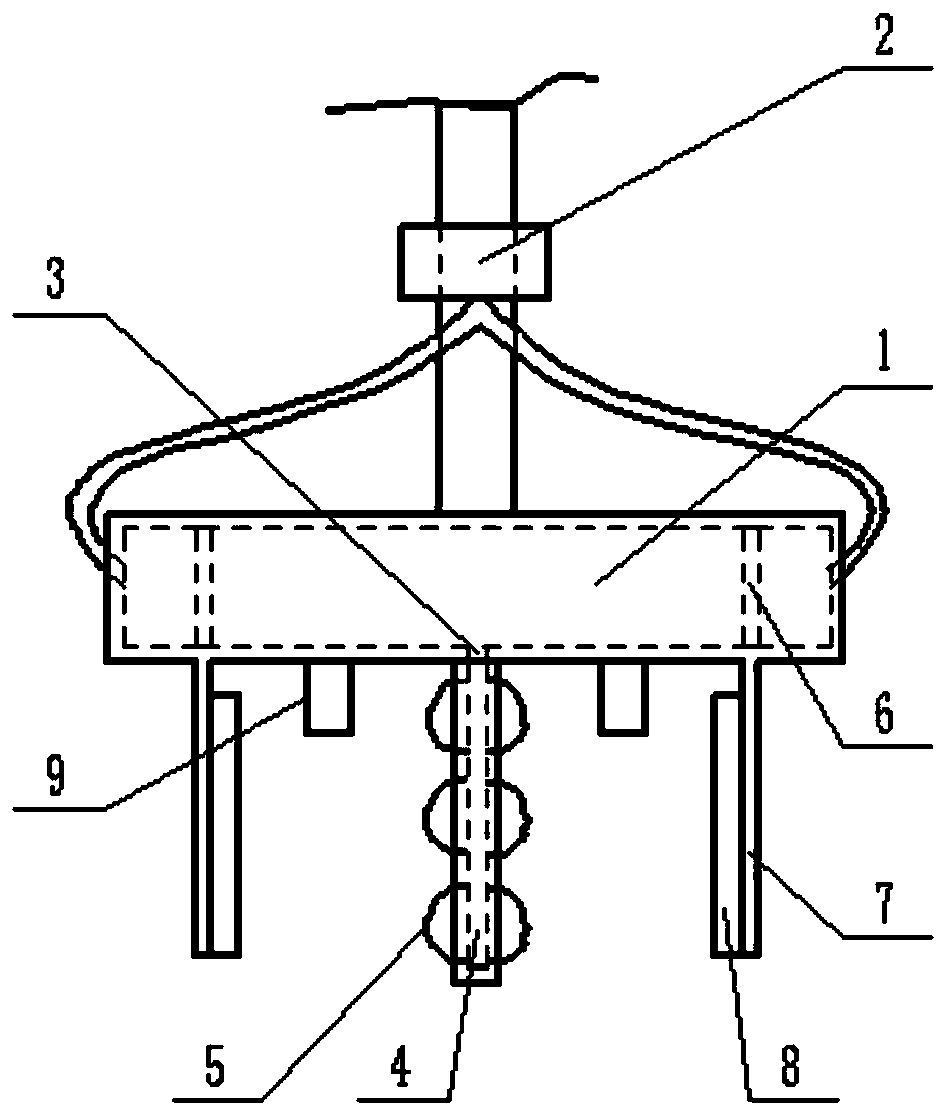

[0018] A kind of porous brick stacking claw of the present invention, as figure 1 As shown, it includes a cavity bottom plate 1, the two ends of the cavity bottom plate 1 are slidingly fitted with pistons 6, and the two ends of the cavity bottom plate 1 communicate with the output shaft of the air pump 2 through hoses.

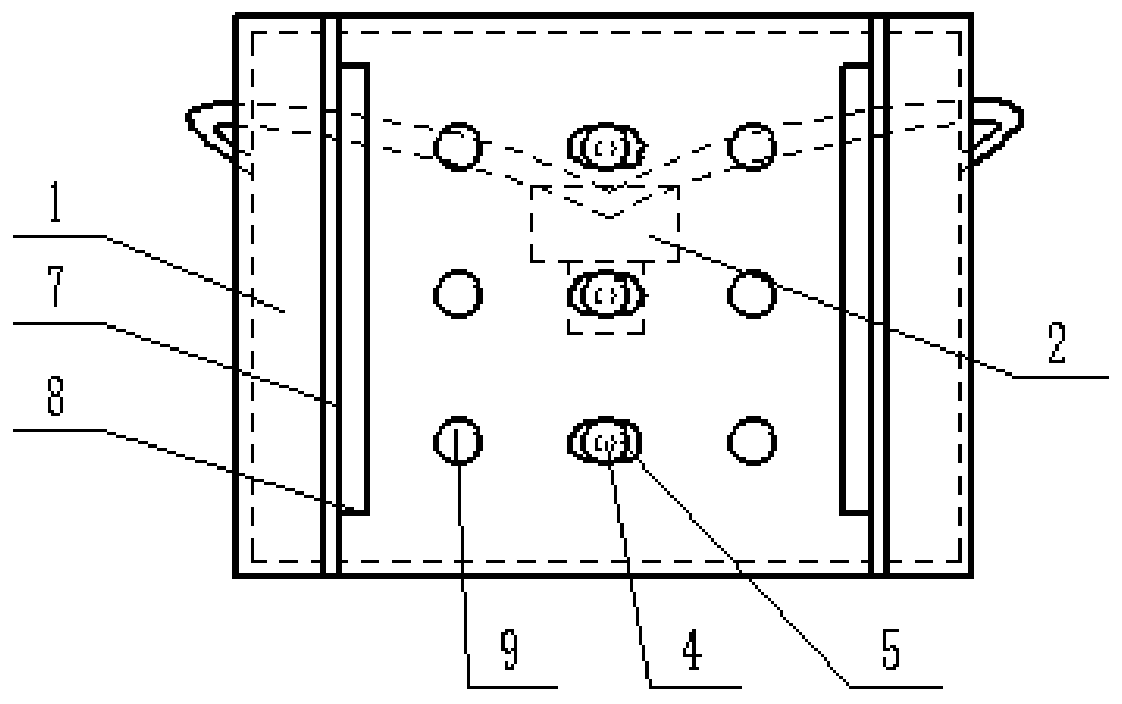

[0019] like figure 2 As shown, the lower end of the cavity bottom plate 1 is integrally formed with openings 3 distributed in a rectangular array, and the openings 3 can be screwed to the plug 9 or the working mechanism according to the specific number or structure of porous bricks, so that the palletizing claws of the porous bricks The scope of application is wider, reducing the cost of replacing different grippers for different working environments. The working mechanism includes a support tube 4 and two groups of airbags 5 that are uniformly communicated with the support tube 4 in the circumferential direction.

[0020] The pistons 6 at both ends of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap