Hoisting container monitoring system and tension fault monitoring method

A monitoring system and container technology, applied in lifts, lifting equipment in mines, transportation and packaging, etc., can solve problems such as difficult to determine responsibility for safety accidents, broken wire ropes, excessive tension differences, etc., to improve safety and informatization The effect of horizontal, rich state data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

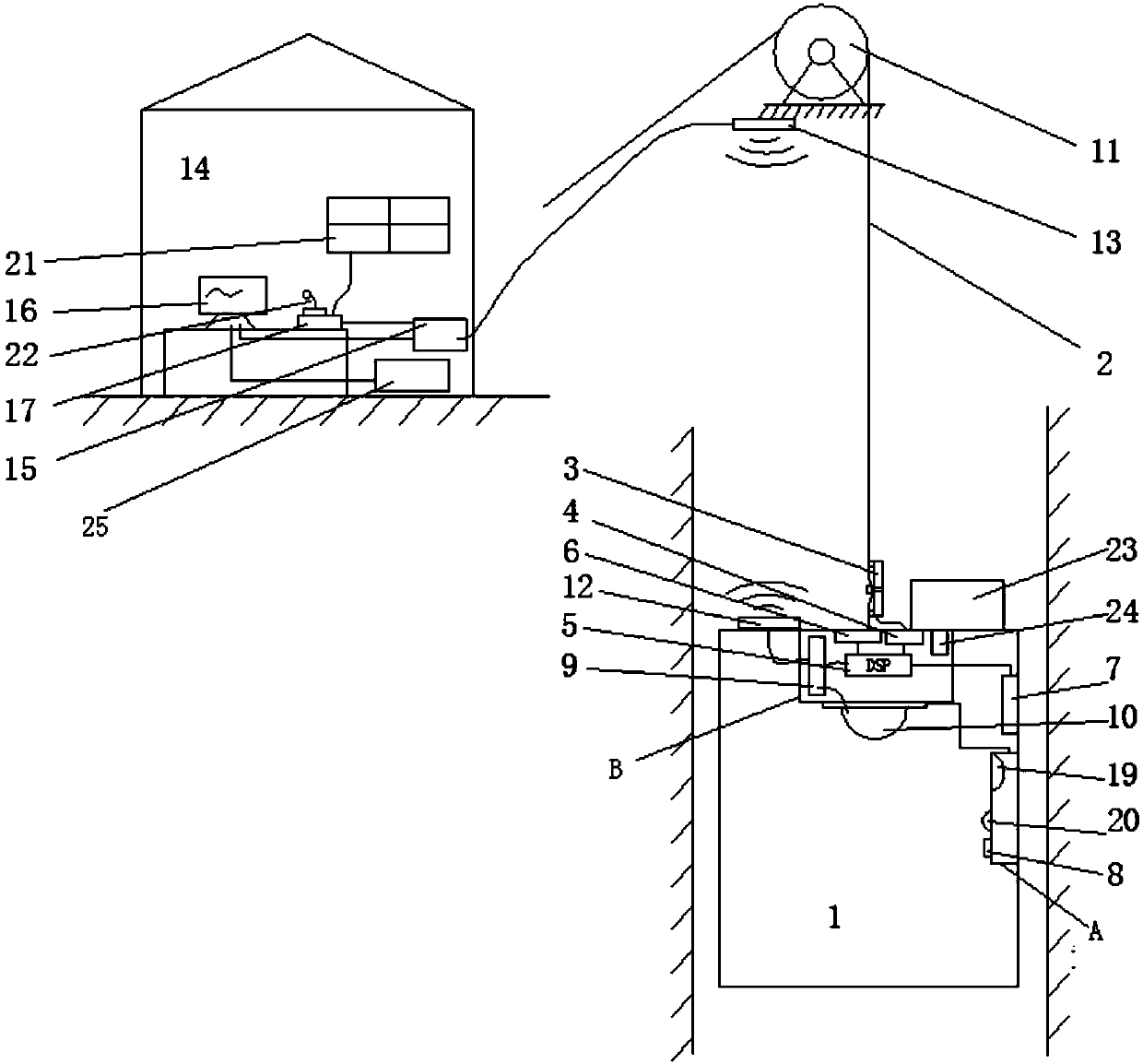

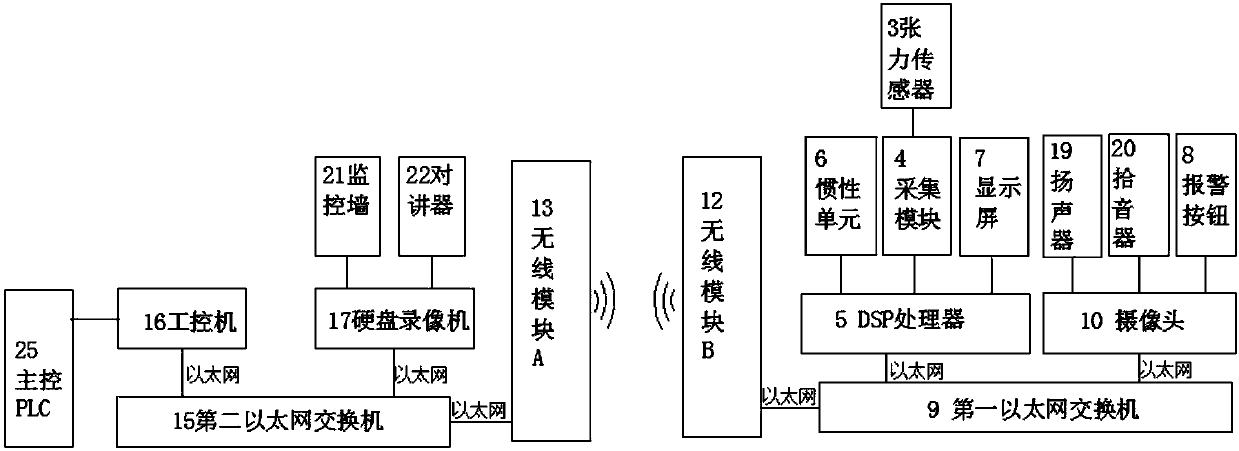

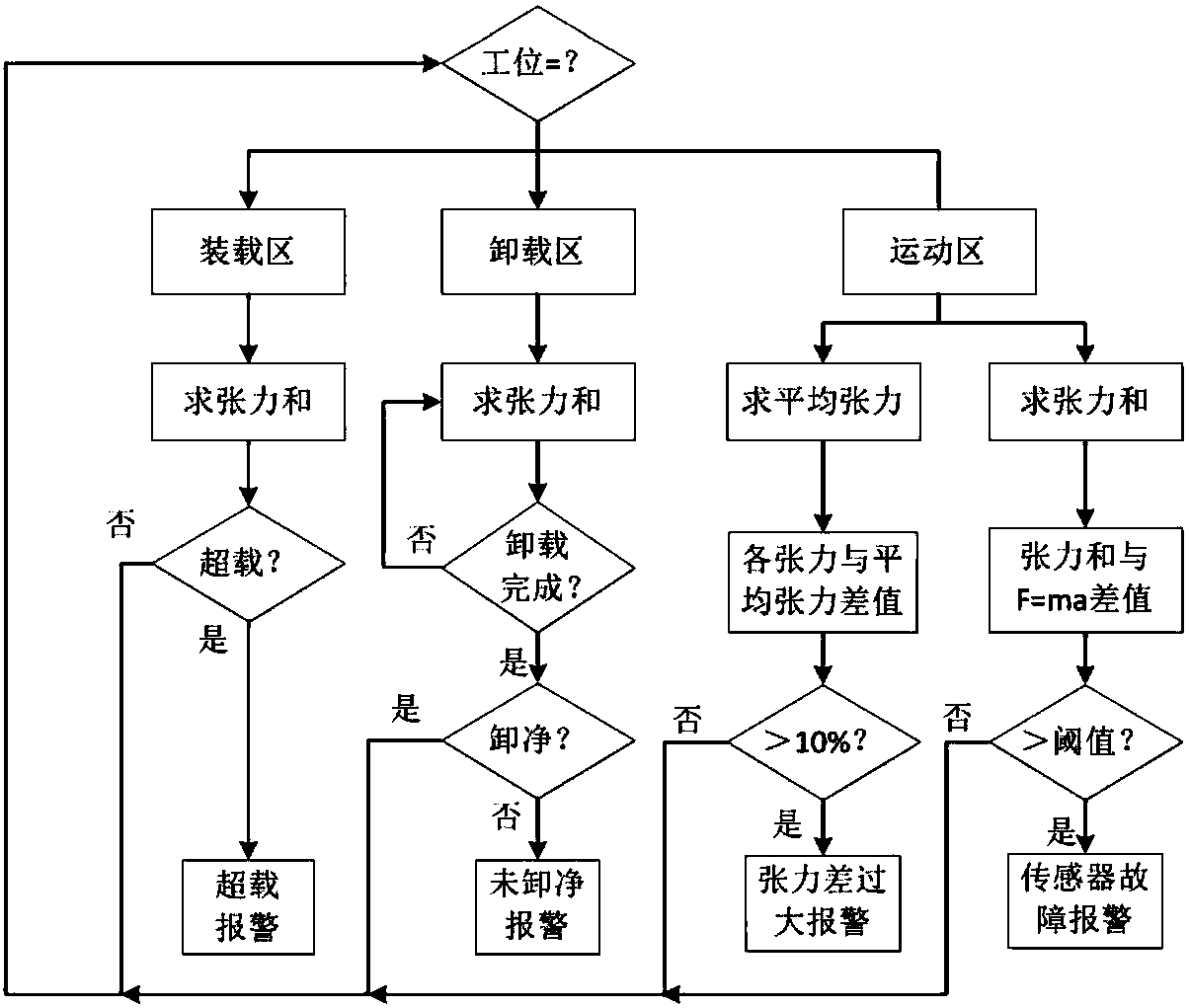

[0022] Such as figure 1 , figure 2 As shown, the embodiment of the present invention includes a tension sensor 3 installed at the lifting container 1 and the steel wire rope 2; the tension sensor 3 is connected to the acquisition module 4 installed in the lifting container; the acquisition module 4 is connected to the The processor 5 in the lifting container is connected; the processor 5 is connected with the inertial unit 6 installed on the top of the lifting container, the display screen 7 installed on the side of the lifting container, the alarm switch 8, the alarm switch 8 installed in the lifting container The first Ethernet switch 9 is connected; the Ethernet switch 9 is connected with the camera 10 installed at the bottom of the first Ethernet switch 9; the first Ethernet switch 9 is connected with the first installed at the top of the lifting container The wireless communication module 12 communicates; the first wireless communication module 12 communicates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com