Organic light-emitting device structure and internal temperature monitoring method

A technology of organic light-emitting devices and organic devices, which is applied in the directions of measuring instrument components, instruments, measuring electricity, etc., and can solve the problems of difficult real-time monitoring, complex equipment, and low test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

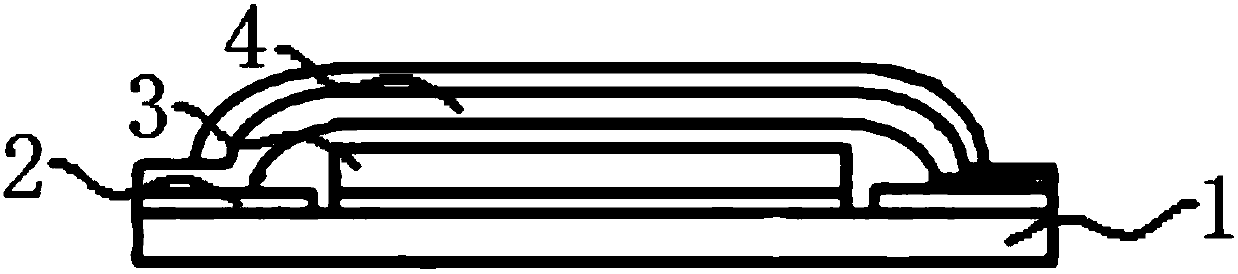

[0032] Please refer to figure 1 , this embodiment specifically discloses a specific structure of an organic light emitting device.

[0033] The structure of the organic light emitting device includes: a substrate 1 , electrodes 2 and organic devices 3 formed on the substrate 1 , and a packaging structure.

[0034] The substrate 1, the electrodes 2 formed on the substrate 1 and the organic device 3 are the basic components of the organic light-emitting device, which can realize that the organic material will emit light when a current passes through, that is, it has the characteristic of self-luminescence.

[0035] The encapsulation structure is the key component structure in this embodiment, which includes at least three layers and one of them is an inorganic semiconductor layer 4. Based on this design, when a certain area of the organic light-emitting device generates a higher temperature, the excessively high The temperature of the inorganic semiconductor layer will affect...

Embodiment 2

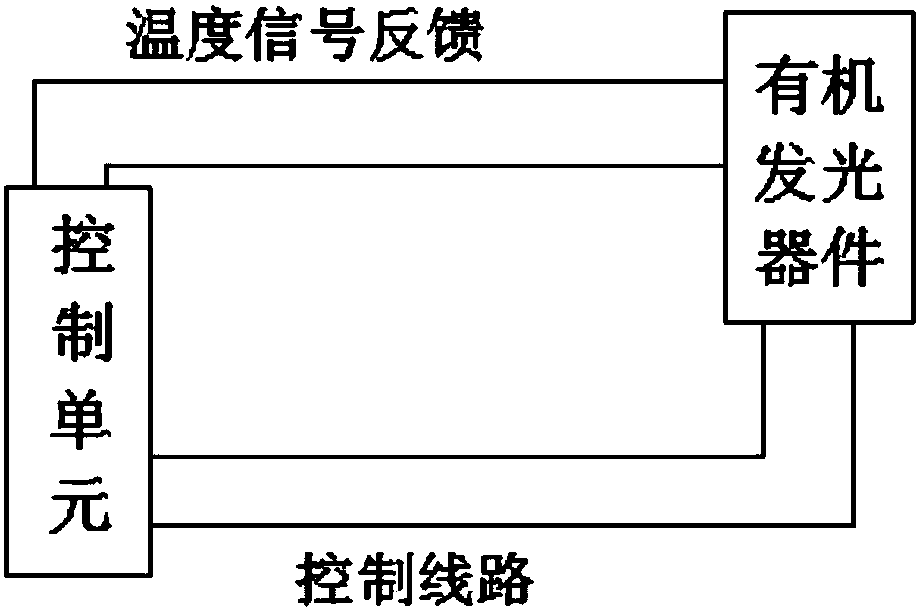

[0044] see figure 2 and image 3 , this embodiment specifically discloses a method for monitoring the internal temperature of an organic light emitting device.

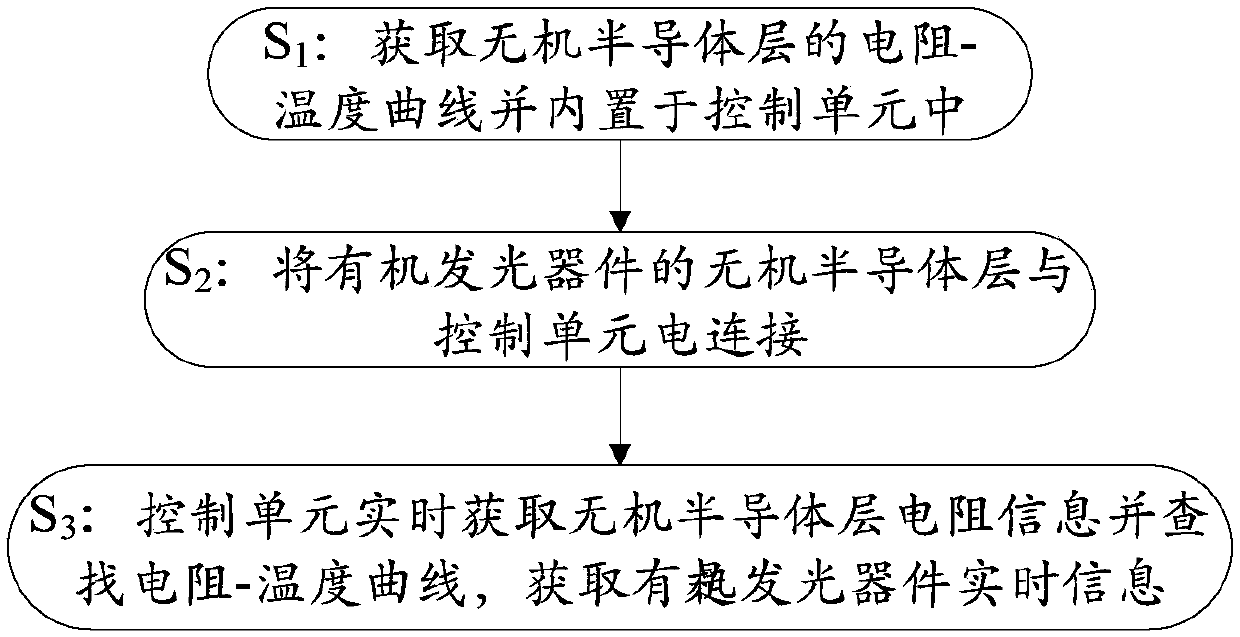

[0045] The method for monitoring the internal temperature of an organic light-emitting device specifically includes the following steps:

[0046] S1: Obtain the resistance-temperature curve of the inorganic semiconductor layer and build it into the control unit;

[0047] S2: electrically connecting the inorganic semiconductor layer of the organic light-emitting device described in Embodiment 1 to the control unit;

[0048] S3: the control unit obtains the resistance information of the inorganic semiconductor layer in real time and searches for the resistance-temperature curve, and obtains real-time information of the organic light-emitting device.

[0049] see Figure 5 A set of resistance-temperature curve example diagrams are given. This figure shows an example of the temperature curve when the inorganic penins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com