Equipment for storing optical lens

An optical lens and equipment technology, which is applied to the field of equipment for storing optical lenses, can solve the problems of complex structure of the stored device, cannot be carried around, and high cost, and achieves the effects of simple structure, simple storage method and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

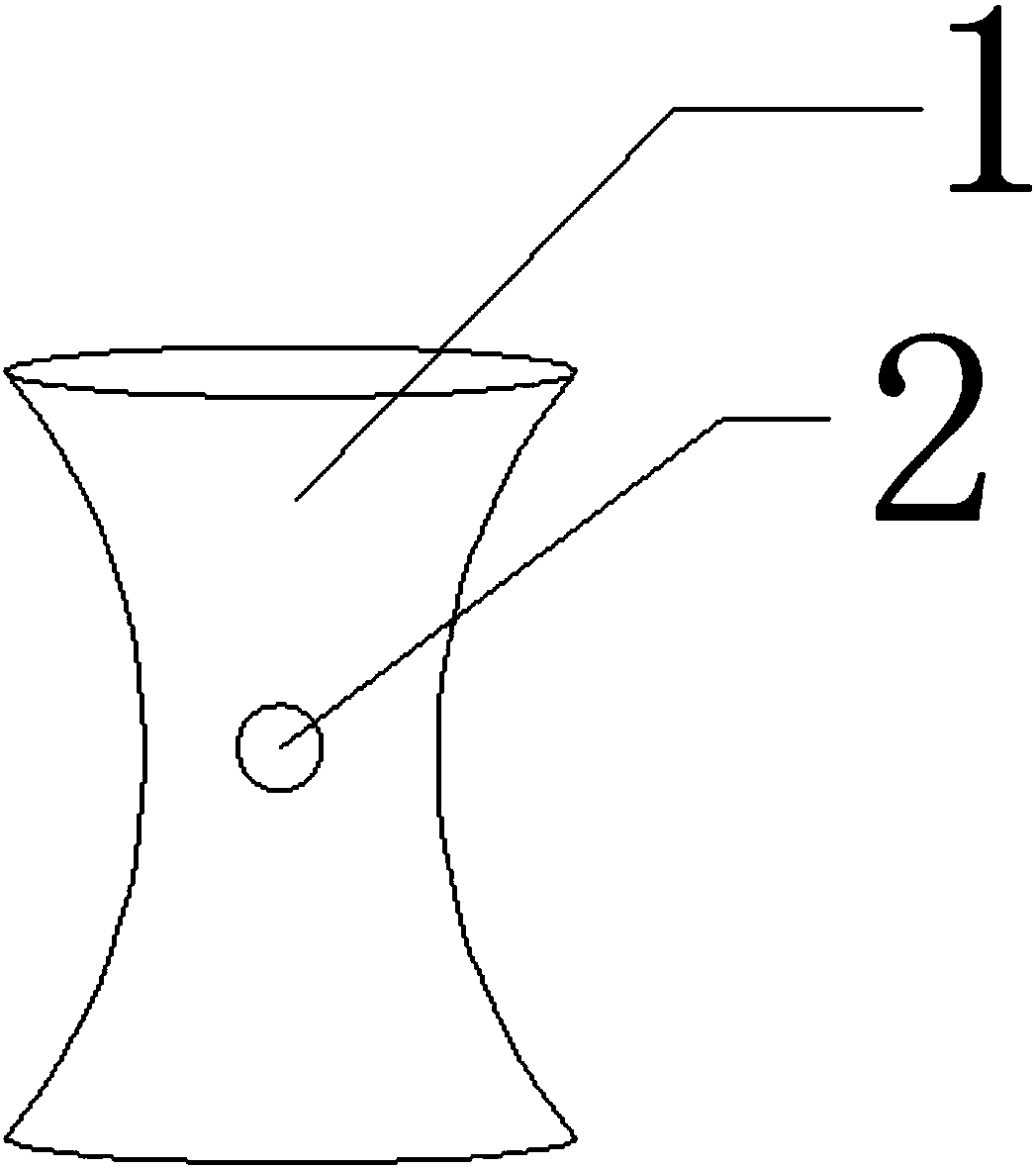

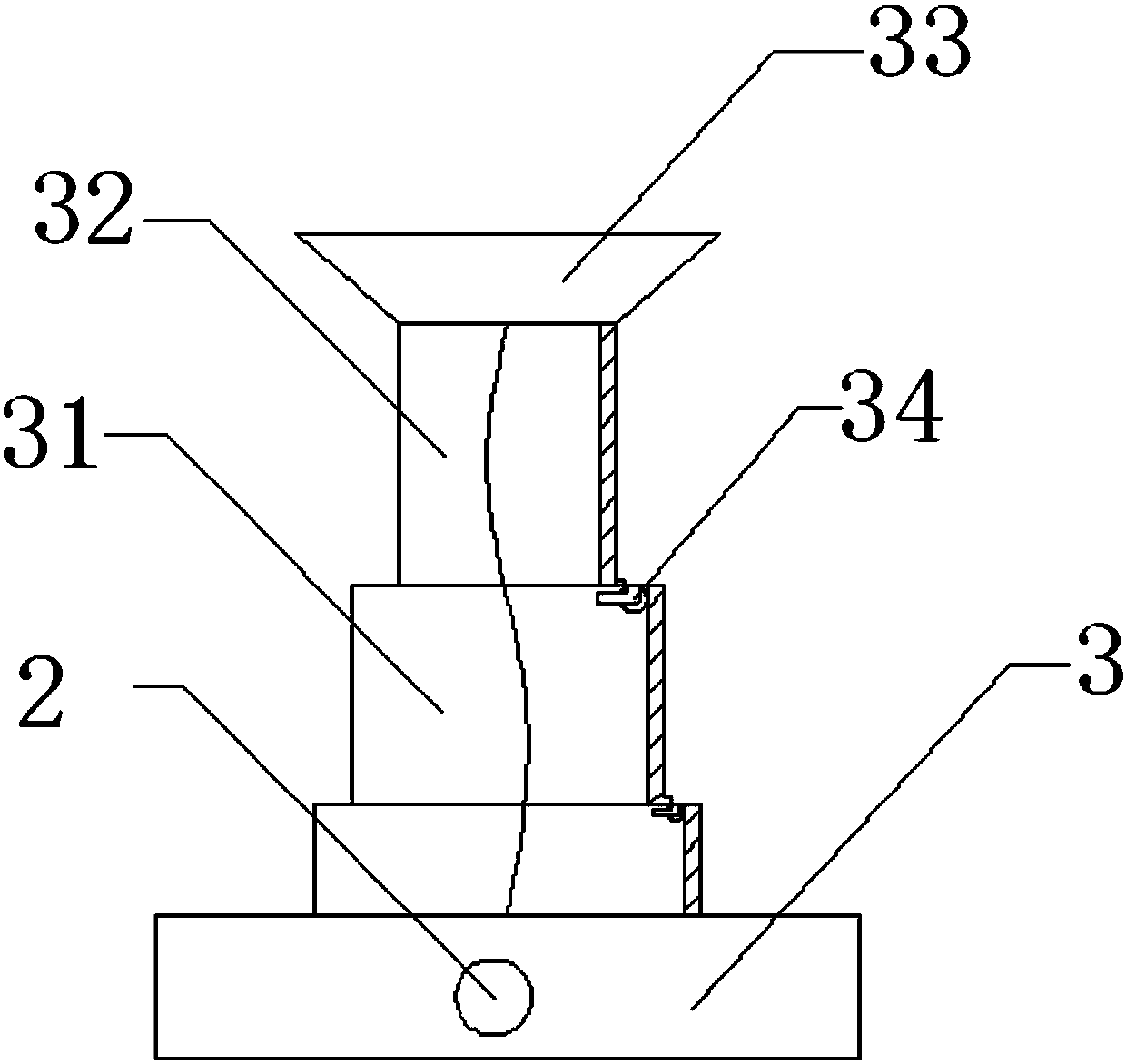

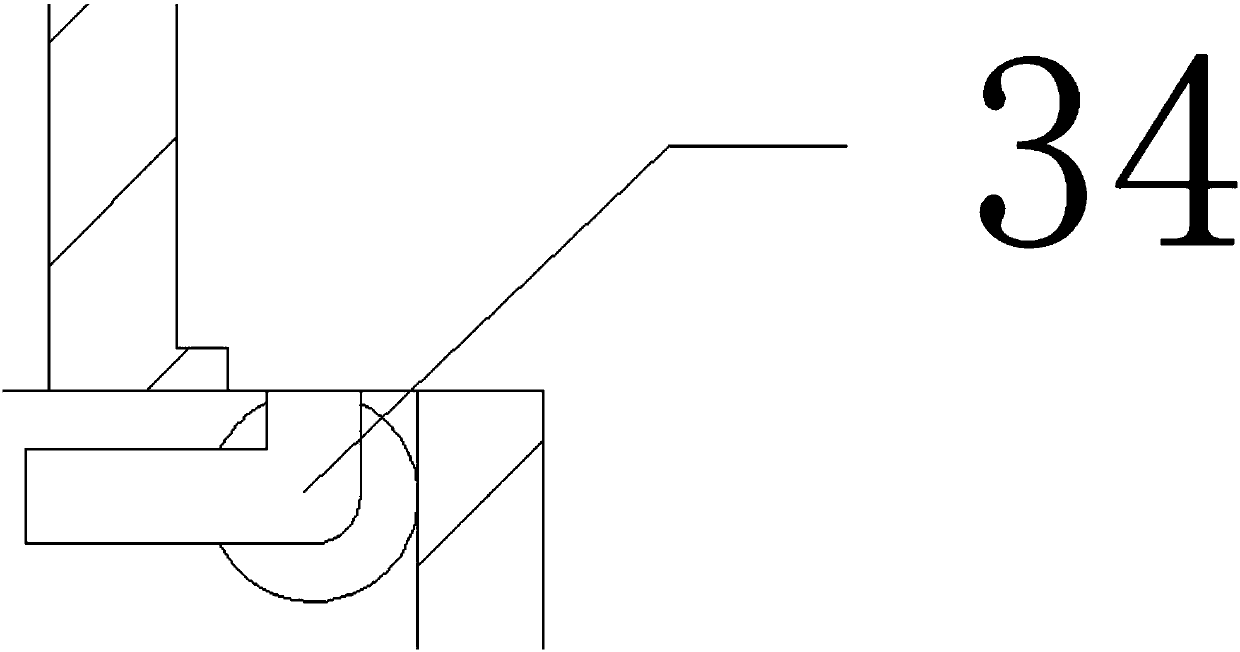

[0020] Such as Figure 1~3 As shown, the present invention is a device for storing optical lenses, which includes a fixed pin hole 2 provided in the middle of the storage frame 1, a through hole is provided in the middle of the storage frame 1, a single-leaf hyperboloid is used in the storage frame 1, and the middle part of the storage frame 1 is provided with There is a fixed frame 3, and the fixed frame 3 is fixed through the fixed pin hole 2, and the optical lens is placed in the through hole of the storage frame 1 through the fixed frame 3. The storage rack set on the single-leaf hyperboloid forms a cylindrical structure with large ends and a small middle, and a through hole is opened in the middle, and a fixed frame is installed in the middle of the through hole. When the optical lens is stored on the fixed frame, the optical lens The edge is in contact with the inner wall of the storage frame, and the position movement of the optical lens is restricted by the suction cup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com