Pressing equipment

A press-fitting and equipment technology, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low efficiency, time-consuming and labor-intensive manual pressing, and achieve a high degree of automation, manpower saving, and accurate pressing force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

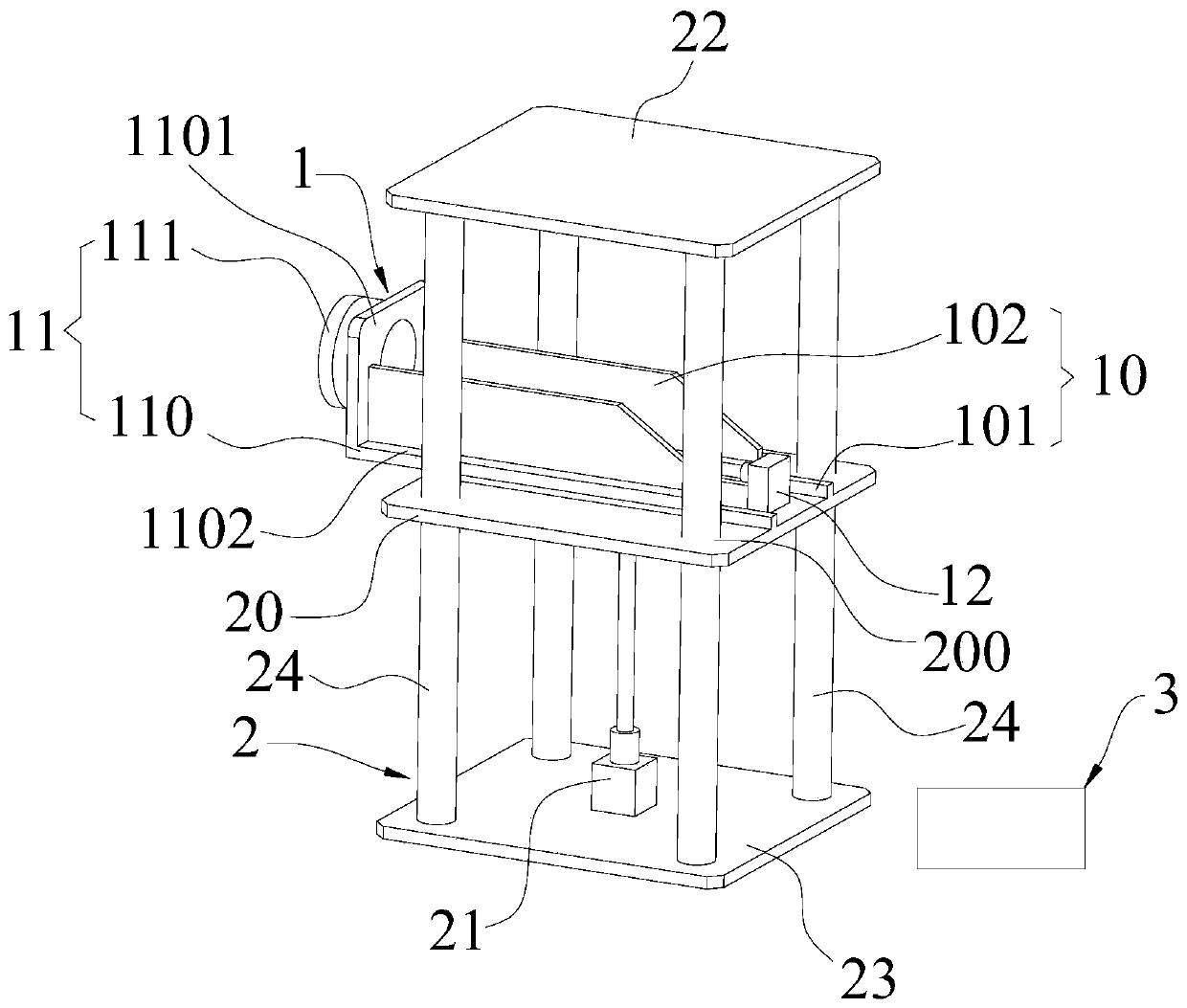

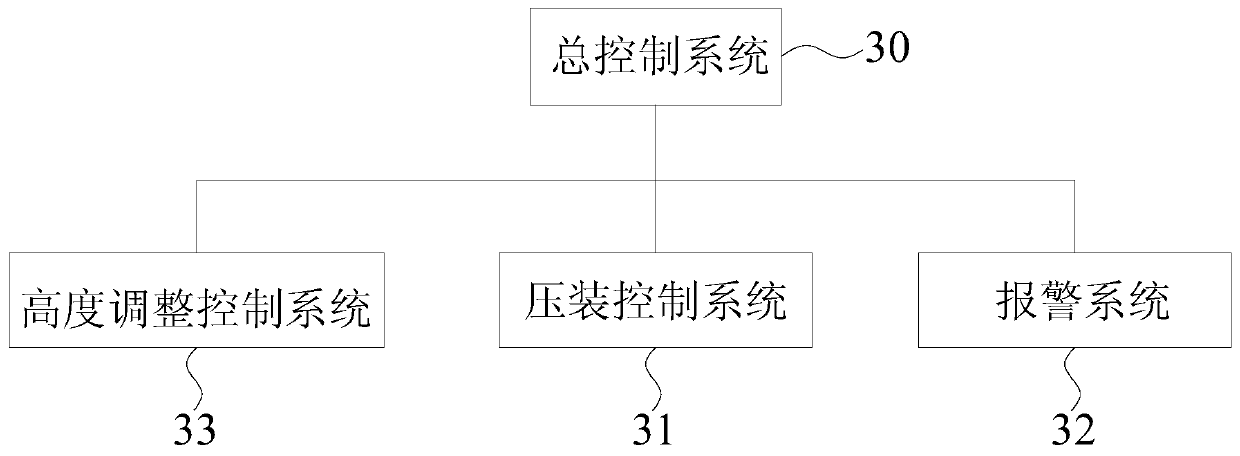

[0026] refer to figure 1 , a preferred embodiment of the present invention provides a press-fitting device for automatically press-fitting a fan onto the shaft of a motor rotor, including a press-fit mechanism 1 and a control system 3, wherein the press-fit mechanism 1 includes a fixedly installed guide rail Mechanism 10, the press-fitting head 11 that is slidably connected to the guide rail mechanism 10, and the drive mechanism 12 for driving the press-fitting head 11 to slide; the control system 3 includes a total control system 30 and a press-fit control system connected to the total control system 30 31. The general control system 30 is used to judge the model of the motor and send the exe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com