Force split hydraulic screw

A hydraulic nut and force-splitting technology, applied in the field of hydraulic nuts, can solve the problems of uneven distribution of thread force and crushing, etc., and achieve the effect of safe and reliable pressing and reducing force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

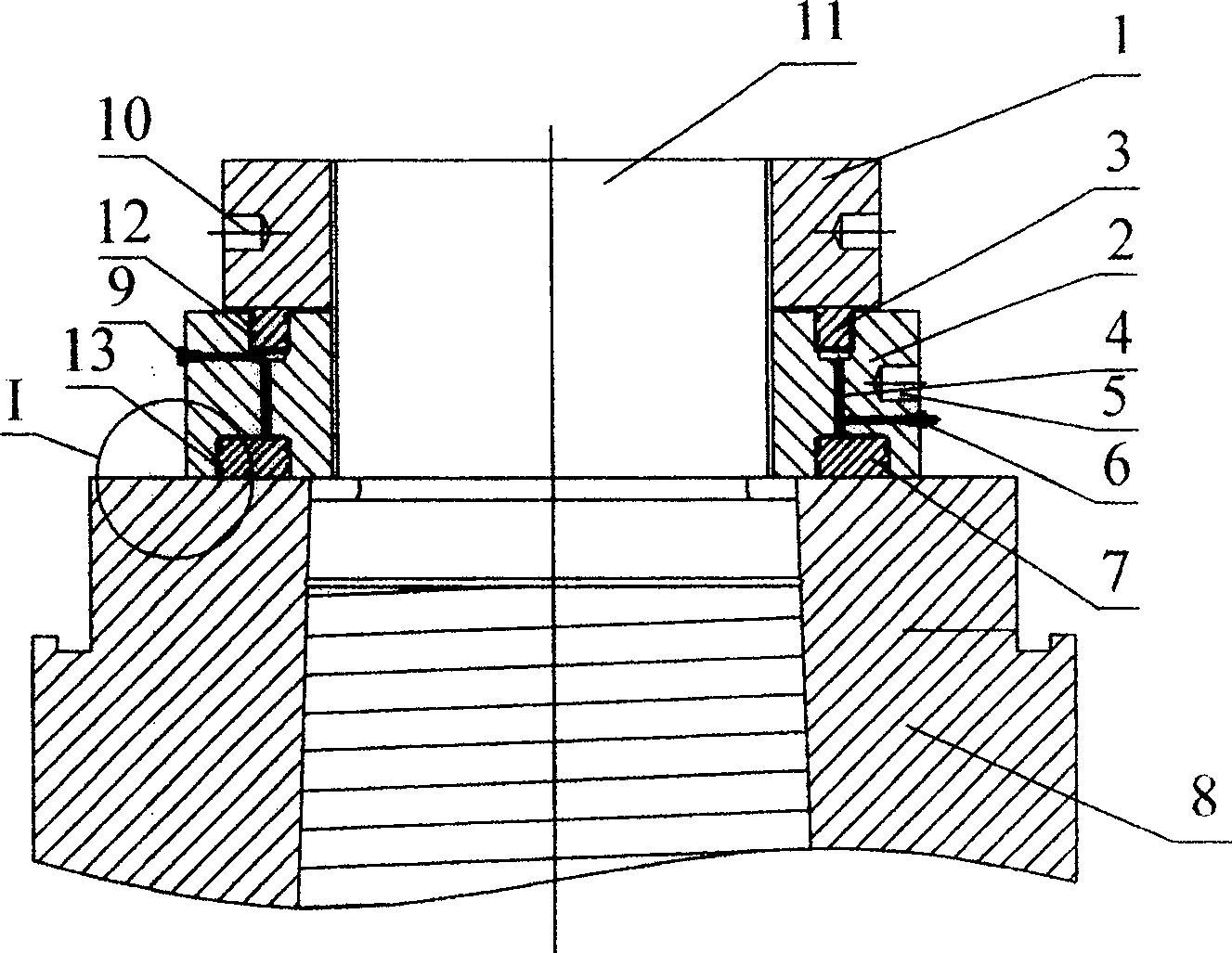

[0011] This example is the press-fitting of the rudder stock and the rudder handle, which is implemented by using two nuts as the force component hydraulic nuts, see figure 1 .

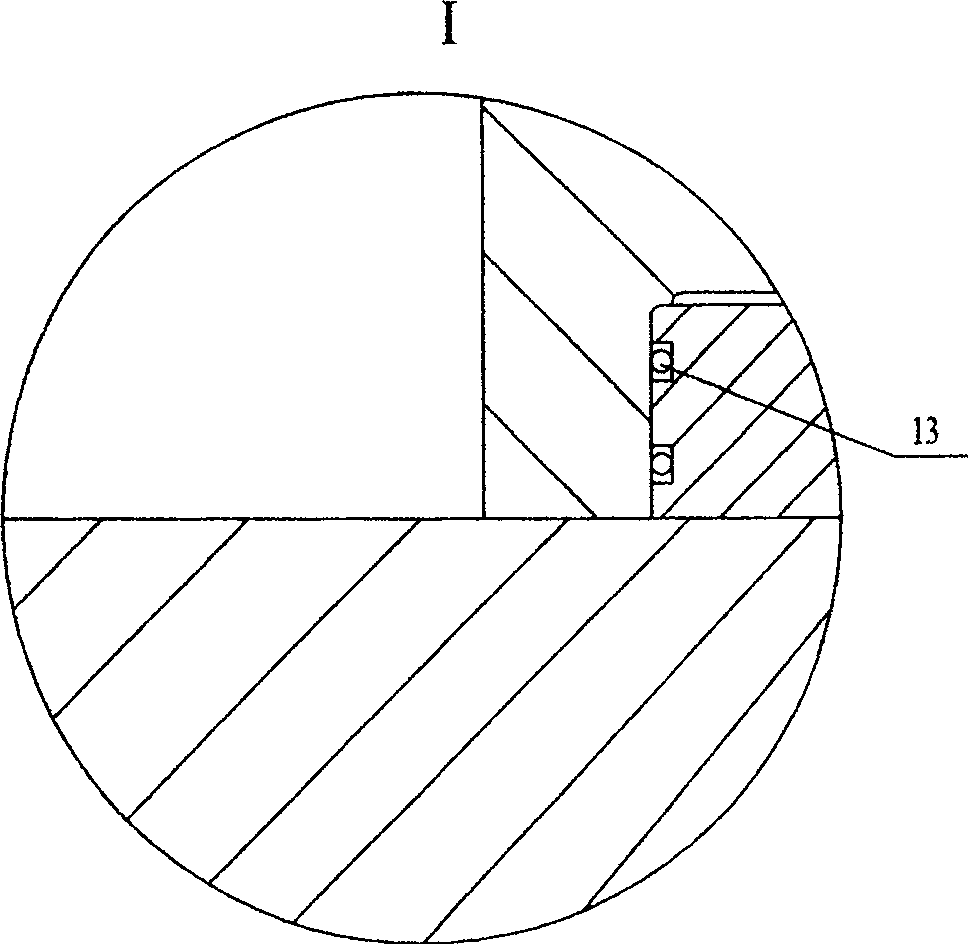

[0012] Component force hydraulic nut, including force component nut 1 and hydraulic nut 2. The force component nut 1 and the hydraulic nut 2 are installed on the threaded rod of the rudder stock 11. The force component nut 1 is an ordinary round nut, and eight blind holes 10 for installing a wrench are processed on the periphery, and the eight blind holes 10 are evenly distributed. 1 on the perimeter. The hydraulic nut 2 is composed of a hydraulic nut body and two piston rings 3 and 7. Piston ring grooves are processed at both ends of the hydraulic nut body, and eight connection holes are processed between the piston ring grooves at both ends. Connected, and communicated with the oil chamber and the oil inlet passage 6, the exhaust passage 9, there are six blind holes 5 for the wrench in the periphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com