A pipeline descaling device

A technology for pipes and pressing devices, which is applied in the directions of cleaning heat transfer devices, lighting and heating equipment, and deformation cleaning, etc., can solve problems such as laboriousness and damage to bench vices, and achieve the effect of simple structure, easy operation, and accelerated shedding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

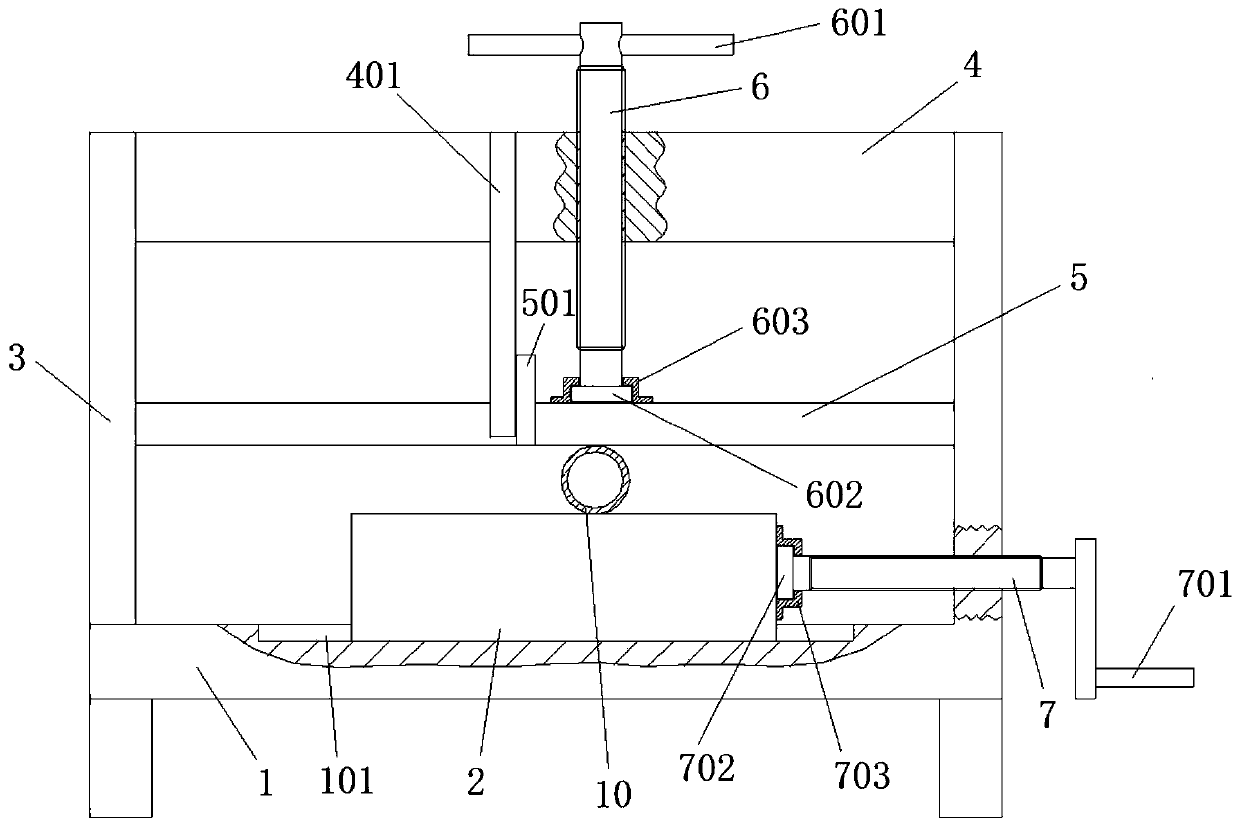

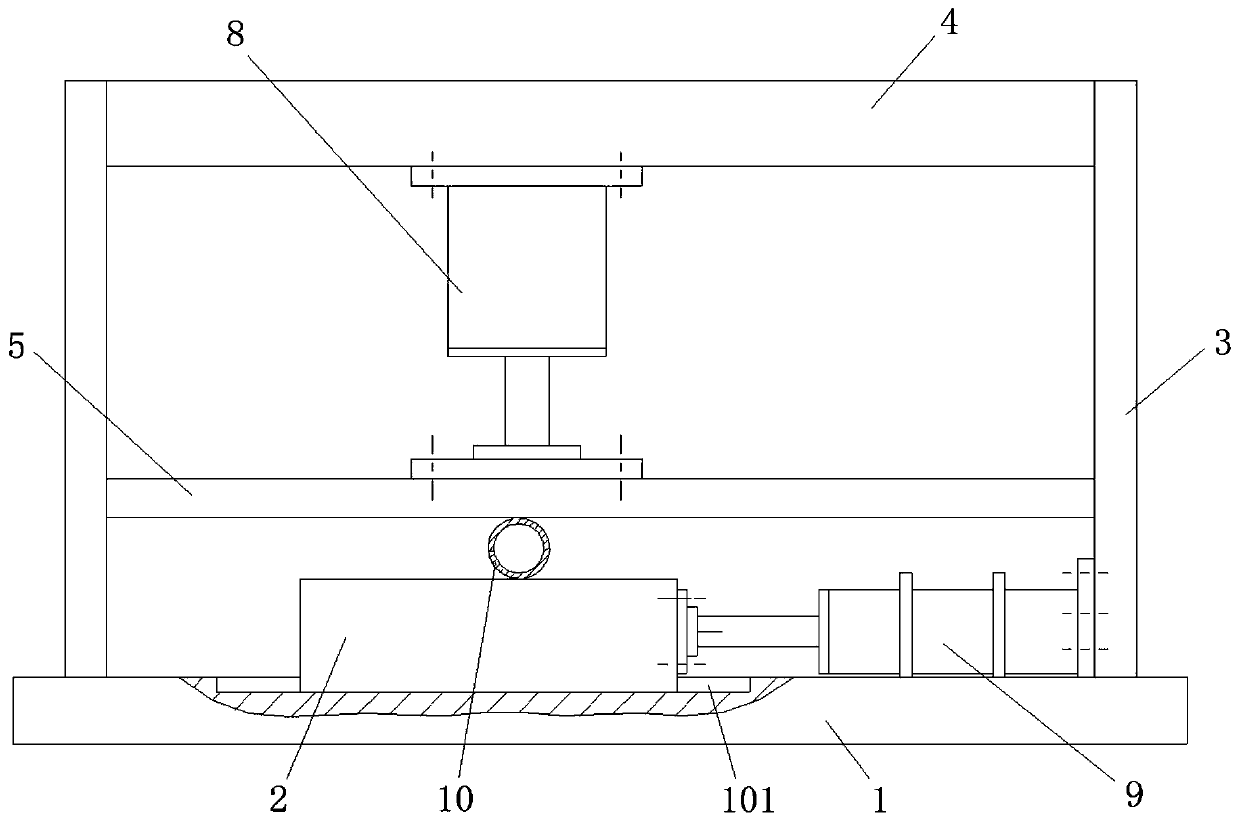

[0029] refer to figure 1 According to the proposed pipeline descaling device according to the embodiment of the content of the present invention, it includes: including: a base 1, a longitudinal pressing device and a transverse traction device; Both sides are provided with supporting side plates 3, and the upper ends of the two supporting side plates 3 are connected with top beams 4, and an upper pressing plate 5 is also arranged between the top beams 4 and the base 1; the longitudinal pressing device Assembled on the top beam 4, the lower end of the longitudinal compression device is connected to the upper platen 5; the lateral traction device is assembled on one of the supporting side plates 3, and the end of the lateral traction device Connected to one end of the lower platen 2.

[0030] In the above embodiments, the longitudinal compression device is assembled on the top beam 4, the lower end of the longitudinal compression device is pressed against the upper platen 5, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com