Glass rod straightening device

A glass rod and straightening technology, used in measuring devices, glass forming, glass re-forming, etc., can solve the problems of high staff skill requirements, low efficiency, inability to guarantee the stability of bending and bending position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

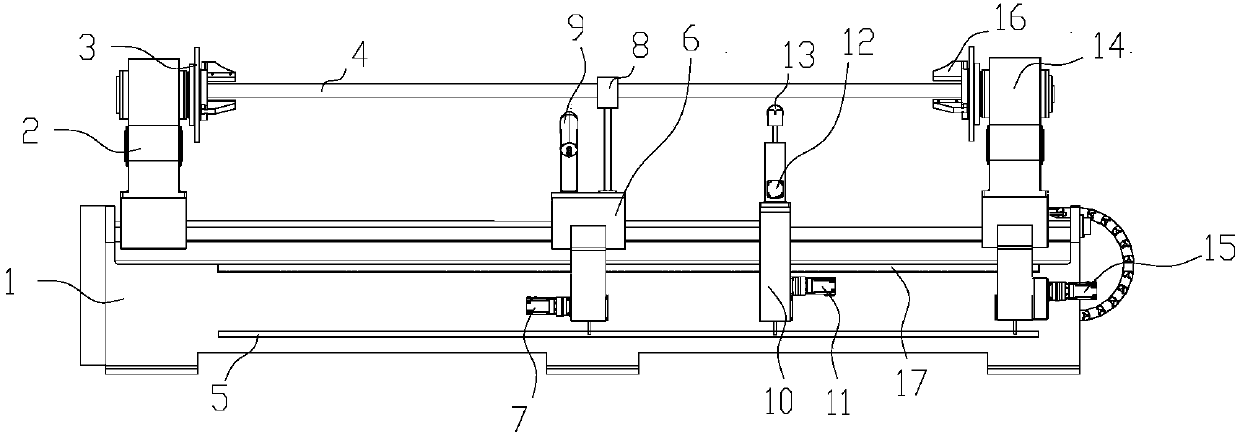

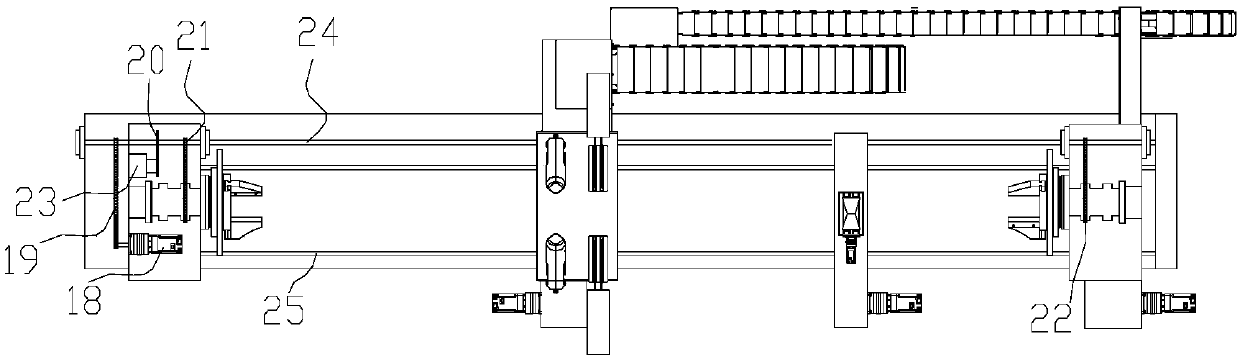

[0017] As shown in the figure, a glass rod straightening device includes a lathe body 1, a fixed slide table 2, a left chuck 3, a glass rod 4, a grating ruler 5, a torch stand 6, a torch moving motor 7, a deviation measuring instrument 8, Blowtorch 9, auxiliary sliding table 10, auxiliary sliding table moving motor 11, straightening motor 12, straightening piece 13, moving sliding table 14, moving sliding table moving motor 15, right chuck 16, rack 17, rotating motor 18, Rotary chain 19, left chuck chain 21, right chuck chain 22, transmission rod 24 and guide rail 25; Described lathe body 1 is provided with transmission rod 24 and guide rail 25, and described left chuck 3 is installed on fixed slide table 2 Above, the lathe body 1 is provided with a rack 17 and a grating ruler 5, the fixed sliding table 2, the torch table 6, the auxiliary sliding table 10 and the mobile sliding table 14 are slidably matched with the guide rail 25, and the torch table 6 is provided with There i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com