Cylinder assembly for rotating type air conditioner compressor

An air-conditioning compressor, rotary technology, applied in the direction of rotary piston machinery, rotary piston pump, rotary piston/swing piston pump components, etc., can solve the problems of heavy weight, high energy consumption, large volume, etc. Achieve the effect of weight reduction, small structure and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

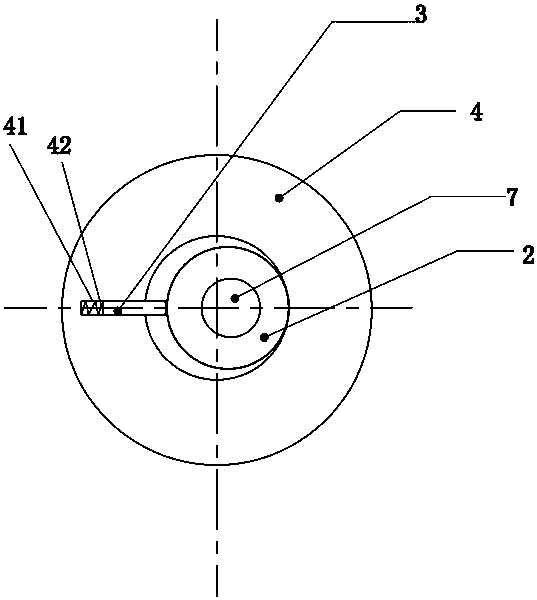

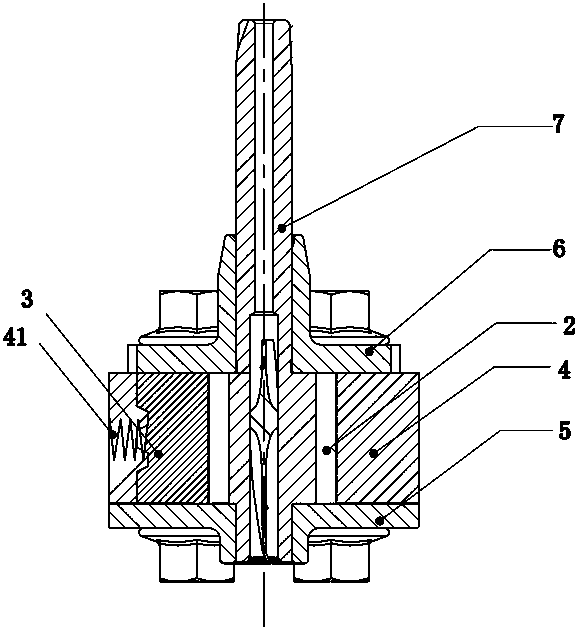

[0023] like figure 1 , figure 2 , Figure 5 As shown, a cylinder assembly for a rotary air conditioner compressor includes a cylinder block 4 , a crankshaft 7 , an upper bearing 6 , a lower bearing 5 , a hollow rolling piston 2 , and a sliding vane 3 .

[0024] The above-mentioned cylinder block 4 is fixed with the upper bearing 6 and the lower bearing 5 to form the cavity of the compressor, the hollow rolling piston 2 is eccentrically placed in the cavity of the above-mentioned cylinder block 4, and the sliding vane 3 is placed in the sliding vane groove 42 provided in the cylinder block 4. , one end of the sliding vane 3 is in close contact with the surface of the hollow rolling piston 2, and the other end is pressed by the spring 41 arranged in the sliding vane groove 41 to make it close to the surface of the hollow rolling piston 2, and the sliding vane 3 pushes the cavity one Divided into two.

[0025] The hollow rolling piston 2 is fixed inside the crankshaft 7 and i...

Embodiment 2

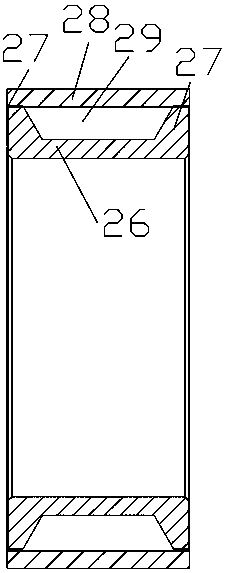

[0027] like image 3 The rolling piston of the cylinder assembly for the rotary air conditioner compressor shown.

[0028] Rolling pistons include:

[0029] The inner hollow inner cylinder 26 is provided with radial support members 27 at both ends of its outer surface, and the support members 27 are used to connect and fix the outer cylinder 28;

[0030] an inner hollow outer cylinder 28;

[0031] The joints of the inner cylinder 26 and the outer cylinder 28 are welded together to form a rolling piston.

[0032] Since the cavity 29 is formed between the inner cylinder 26 and the outer cylinder 28, the weight of the entire rolling piston is reduced.

[0033] The inner surface of the longitudinal section of the support parts 27 at the two ends is enlarged and inclined from the head to the bottom, so that the longitudinal section of the entire inner cylinder is generally C-shaped.

[0034] The other components of the cylinder assembly for a rotary air conditioner compressor a...

Embodiment 3

[0036] like Figure 4 The rolling piston of the cylinder assembly for the rotary air conditioner compressor shown.

[0037] The hollow rolling piston includes an outer ring 21 and an inner ring 22. The longitudinal section of the inner ring 22 is an inverted E shape, the left plane 23 and the right plane 25 of the inverted E shape are parallel end faces, and the middle plane is the support portion 24. The said The outer ring 21 is a cylindrical tube, the outer ring 21 is connected to the inner ring 22 through the inverted E shape of the three-sided inner ring 22, and the two end faces of the inner ring and the two end faces of the outer ring are on the same plane.

[0038] The other components of the cylinder assembly for a rotary air conditioner compressor are the same as those in Embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap