Detection and analysis system of buffer oil pressure of hydraulic operating mechanism

An analysis system and hydraulic operation technology, which are applied to measuring devices, measuring fluid pressure, and measuring fluid pressure through electromagnetic components, etc., can solve the problems of difficult detection and analysis of buffer oil pressure, and achieve the difficulty of detecting buffer oil pressure, The system is simple and the signal transmission distortion is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

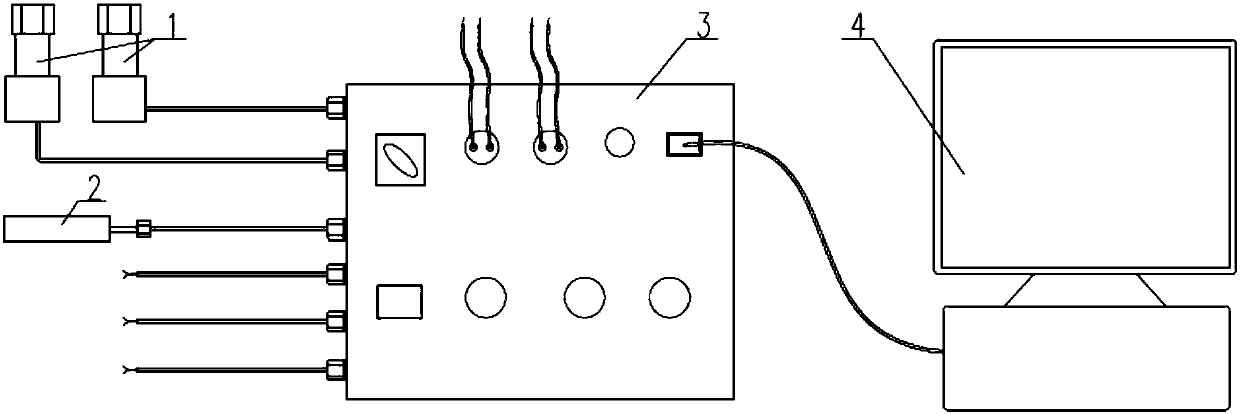

[0014] As shown in the drawings, the technical solution adopted by the present invention is: a hydraulic operating mechanism buffer oil pressure detection and analysis system, including a pressure sensor 1, a travel sensor 2, a control and data acquisition system 3, a data receiving and analysis system 4, etc. . Among them, the pressure sensor 1 is an ultra-high frequency and ultra-high pressure pressure sensor. A signal amplification circuit board is installed in the wiring seat of the pressure sensor 1, which can convert the transient oil pressure of the ultra-high oil pressure into a current signal. The travel sensor 2 adopts a linear or Rotary scribing rheostat sensor, each sensor signal is connected to the acquisition system through a shielded wire. The control and data acquisition system 3 includes the operation control part of the hydraulic mechanism and the analog signal acquisition conversion and storage part. The system is assembled in a box module, which can collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com