A drying detection mechanism for elevator car ceiling

A detection mechanism, elevator car technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low production efficiency, long gelation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

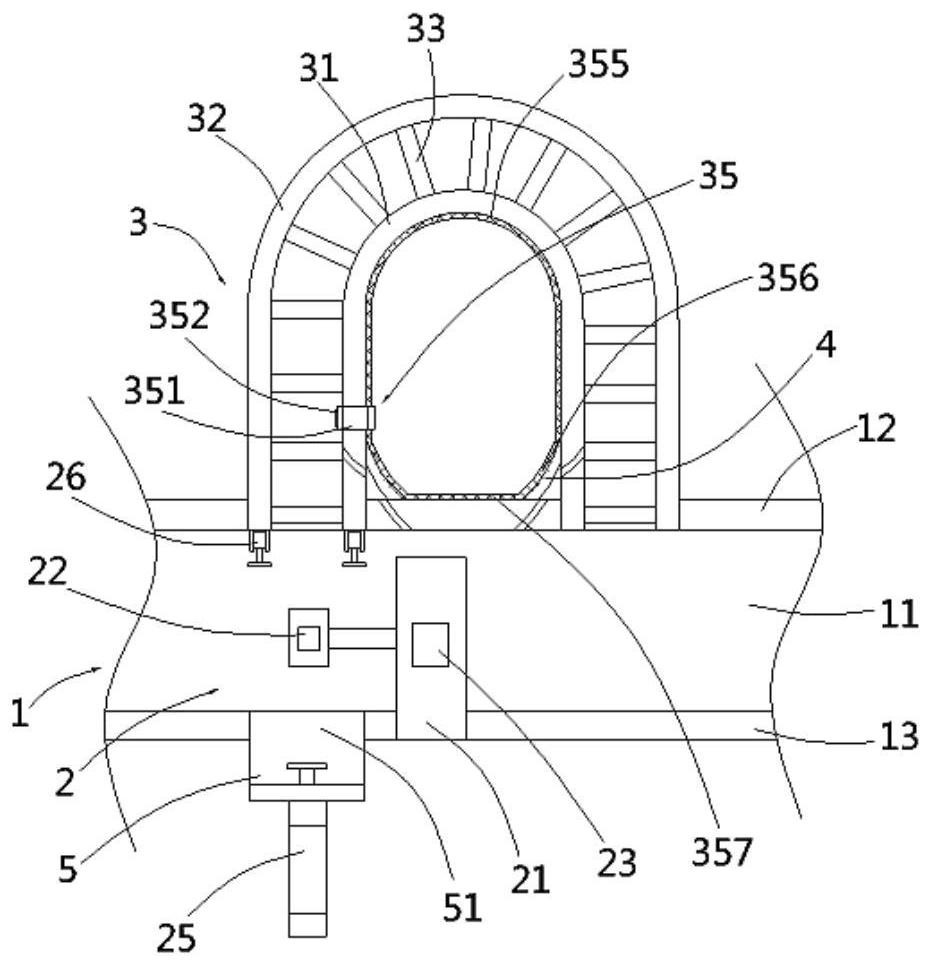

[0022] see figure 1 , a drying detection mechanism for the ceiling of an elevator car according to the present invention, including a main transmission belt 1, a detection unit 2 arranged on the main transmission belt 1 and a U set on one side of the main transmission belt 1 Type drying unit 3.

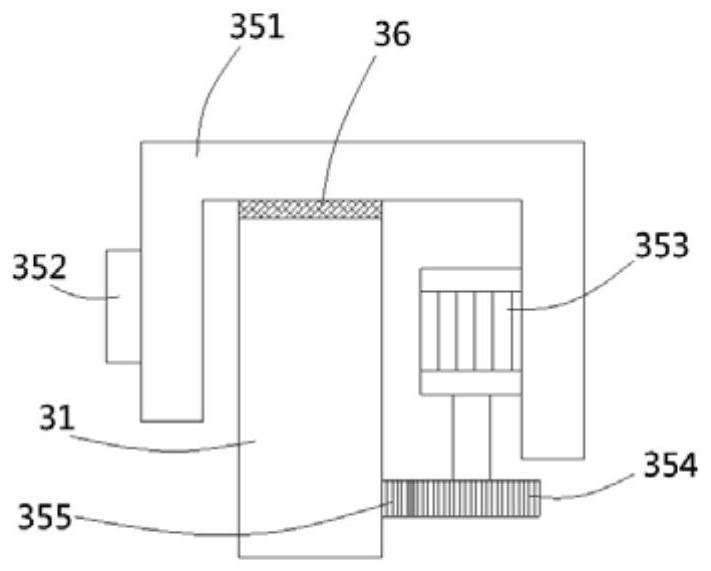

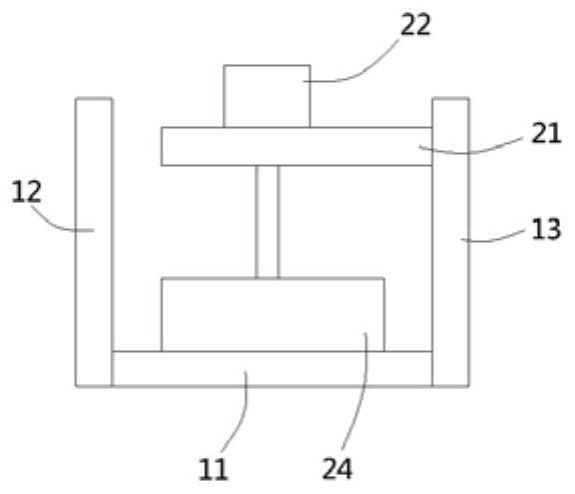

[0023] see figure 1 , image 3 , the main conveyor belt 1 includes a conveyor belt 11 and an inner plate 12 and an outer plate 13 arranged on both sides of the conveyor belt 11, and the detection unit 2 includes a support plate 21 fixed on the outer plate 13, fixed on The industrial camera 22 on the side wall of the support plate 21, the lift cylinder 23 fixed on the support p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap