Electrochromic element with improved electrolyte layer

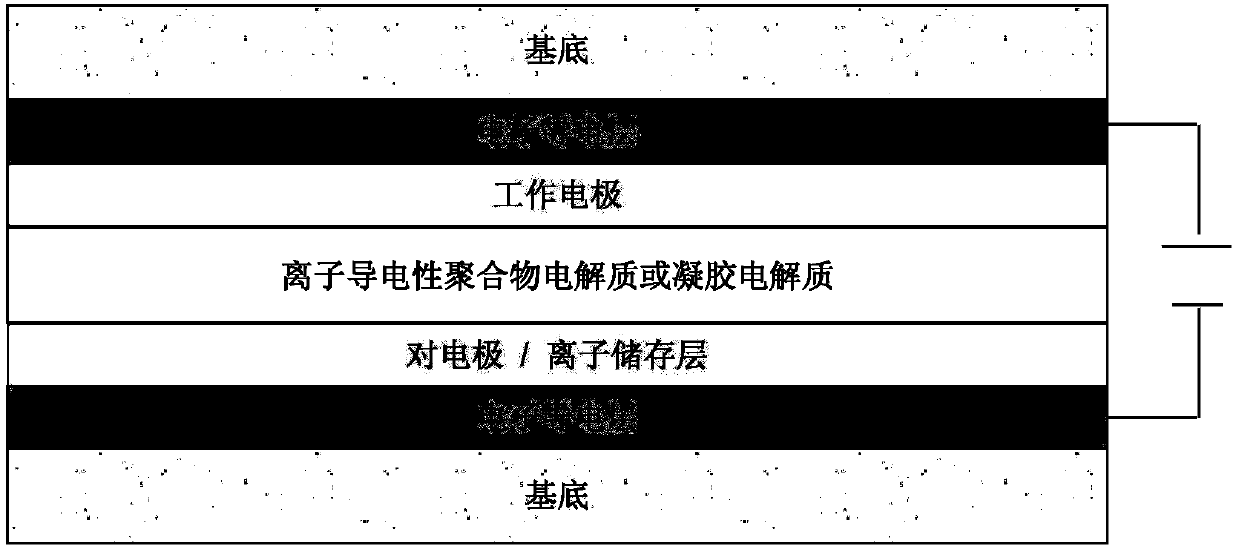

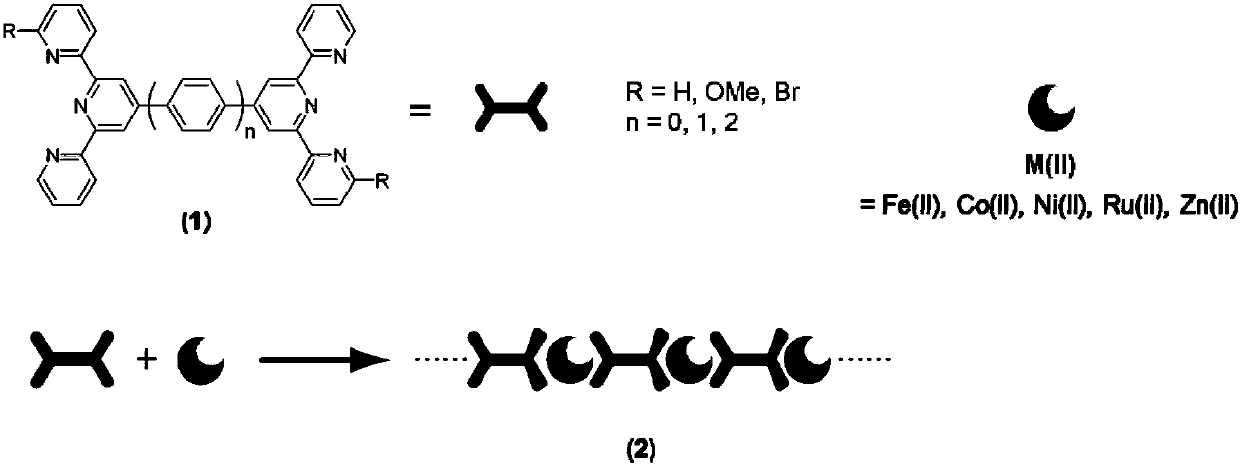

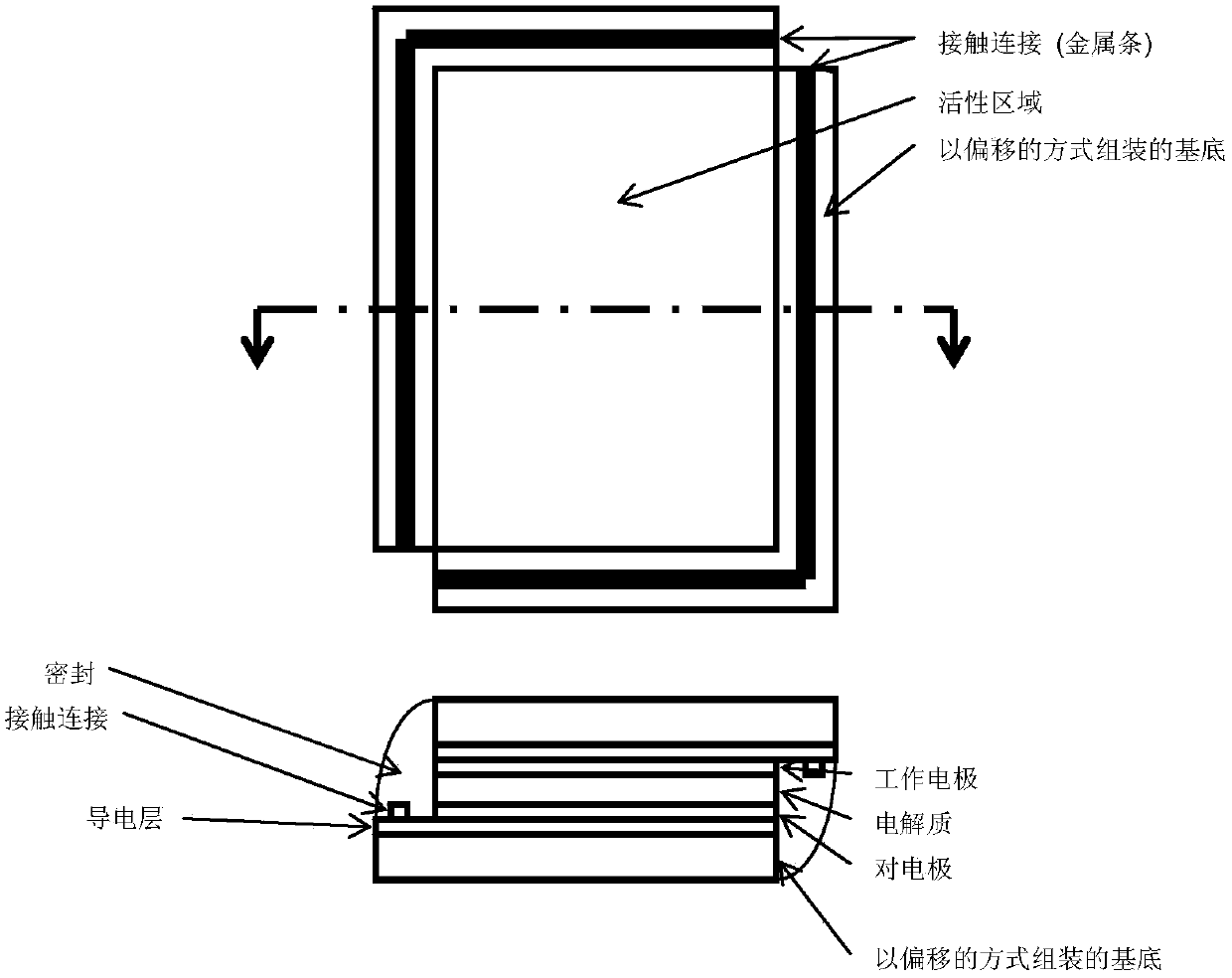

An electrochromic, electrolyte layer technology, applied in the direction of color-changing fluorescent materials, vehicle parts, instruments, etc., can solve the problem of inability to deposit materials directly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0193] Preparation Example 1: Synthesis of Hybrid Polymer Resin (ORMOCER@Resin 1)

[0194] To 248.35 g of 3-(trimethoxysilyl)propyl methacrylate (MEMO) was slowly added dropwise 27.03 g of 0.1 M HCl solution at a temperature 4 , and cooled to <5°C. 17.2 g of methacrylic acid (MAS) were added dropwise, and the mixture was stirred for 0.5 hours (=reaction solution B). Reaction solution A was then brought to <10°C and reaction solution B was added dropwise so that the reaction temperature was between 4 and 10°C. After the addition is complete, the reaction mixture can be slowly warmed to room temperature and stirred for 2d. The solvent was firstly removed on a rotary evaporator (Rotationsdampfer) and then by means of high vacuum. 298.72 g of a yellowish-orange transparent resin are obtained.

preparation Embodiment 2

[0195] Preparation Example 2: Synthesis of Acrylate Functional Hybrid Polymer Base Resin (HP) (BS-II)

[0196] stage 1

[0197] To a precharge of 40 g (0.08 mol) of 3-glycidoxypropylmethyldiethoxysilane was added dropwise 38 ml of 4N hydrochloric acid at room temperature with stirring, and stirring was continued for 3 days at room temperature. After work-up (washing with water, absorption in acetate, drying over sodium sulfate and removal of volatile constituents), a liquid resin with a high degree of condensation (>90%) and complete ring opening of the epoxy groups is obtained. The resin has a viscosity of 22 Pa·s at 25°C.

[0198] stage 2

[0199]

[0200] To the mixture of 20 g (0.104 mol) of the resin from stage 1, 24 mg of BHT and 61 mg of dibutyltin dodecanoate and optionally the non-aqueous solvent THF under stirring at 37°C in a dry atmosphere Charge dropwise x mol (see table below) isocyanatoethyl methacrylate and continue stirring at 37°C. The course of the re...

Embodiment 1a

[0202] Example 1a - Preparation of Polymer Electrolyte Formulation

[0203] 0.30 g of ethyl methacrylate-methyl acrylate-copolymer Paraloid B72 (dry) was dissolved in 3.00 g of dry propylene carbonate at about 40°C and mixed with 0.29 g of lithium perchlorate (battery grade). The solution was stirred overnight at room temperature (RT) under a dry atmosphere. Then add 0.35 g from the preparation example Resin 1, 0.65 grams of triethylene glycol dimethacrylate and 0.02 grams of Irgacure 651 (photoinitiator), and the mixture was packaged in a dark place. After about 1 hour a homogeneous high viscosity solution was produced which could be used directly for cell assembly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap