Passive radiant panel and preparation method thereof

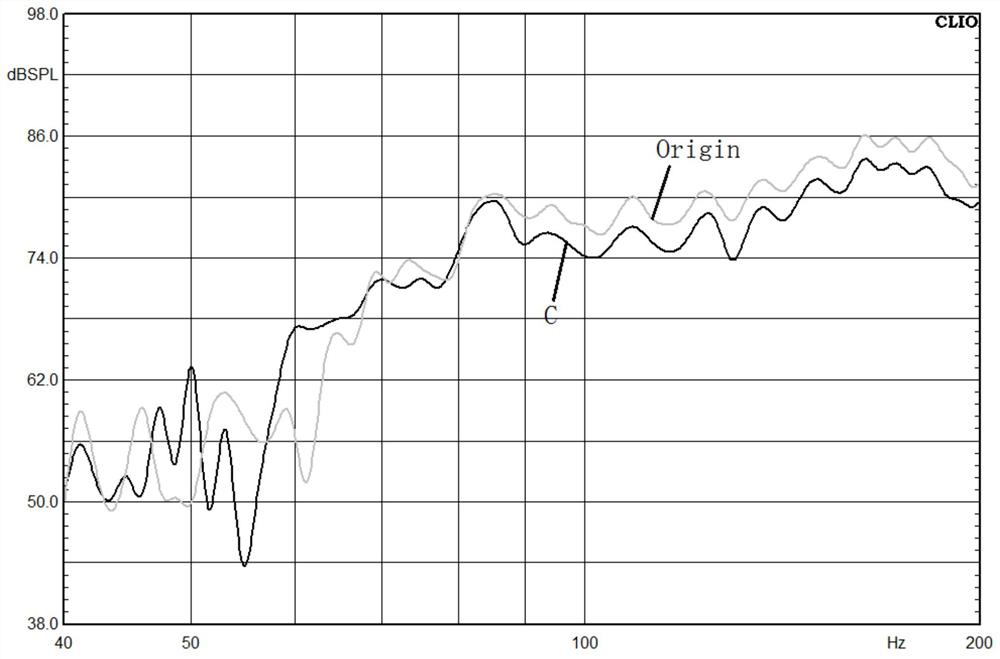

A radiating plate and polysiloxane technology, applied in the direction of sensors, electrical components, etc., can solve the problem of poor bass effect of the speaker, and achieve the effect of improving the bass performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In addition, the present invention also provides a method for preparing the above-mentioned passive radiation panel, which includes the following steps: uniformly mixing various materials; and molding the mixed materials by hot pressing or injection molding to form the above-mentioned passive radiation panel. plate.

[0032] In addition, the above preparation method also includes setting a weight plate on the passive radiation plate, and the passive radiation plate is installed on the sound box equipment. The role of the weight plate is to provide the inertial force for the vibrating structure in the speaker to vibrate back and forth.

Embodiment 1

[0035] 53%, 8%, 33%, and 6% by weight of vinyl-terminated dimethylmethylvinyl (siloxane and polysiloxane), dimethyldimethoxysilane, silicone Gum and hydroxyl-terminated dimethyl (siloxane and polysiloxane) are uniformly mixed; and

[0036] The above-mentioned mixed materials are molded by hot pressing or injection molding to form a passive radiation panel.

Embodiment 2

[0038] 45%, 2%, 45%, and 8% by weight of vinyl-terminated dimethylmethylvinyl (siloxane and polysiloxane), dimethyldimethoxysilane, silicone Gum and hydroxyl-terminated dimethyl (siloxane and polysiloxane) are uniformly mixed; and

[0039] The above-mentioned mixed materials are molded by hot pressing or injection molding to form a passive radiation panel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com