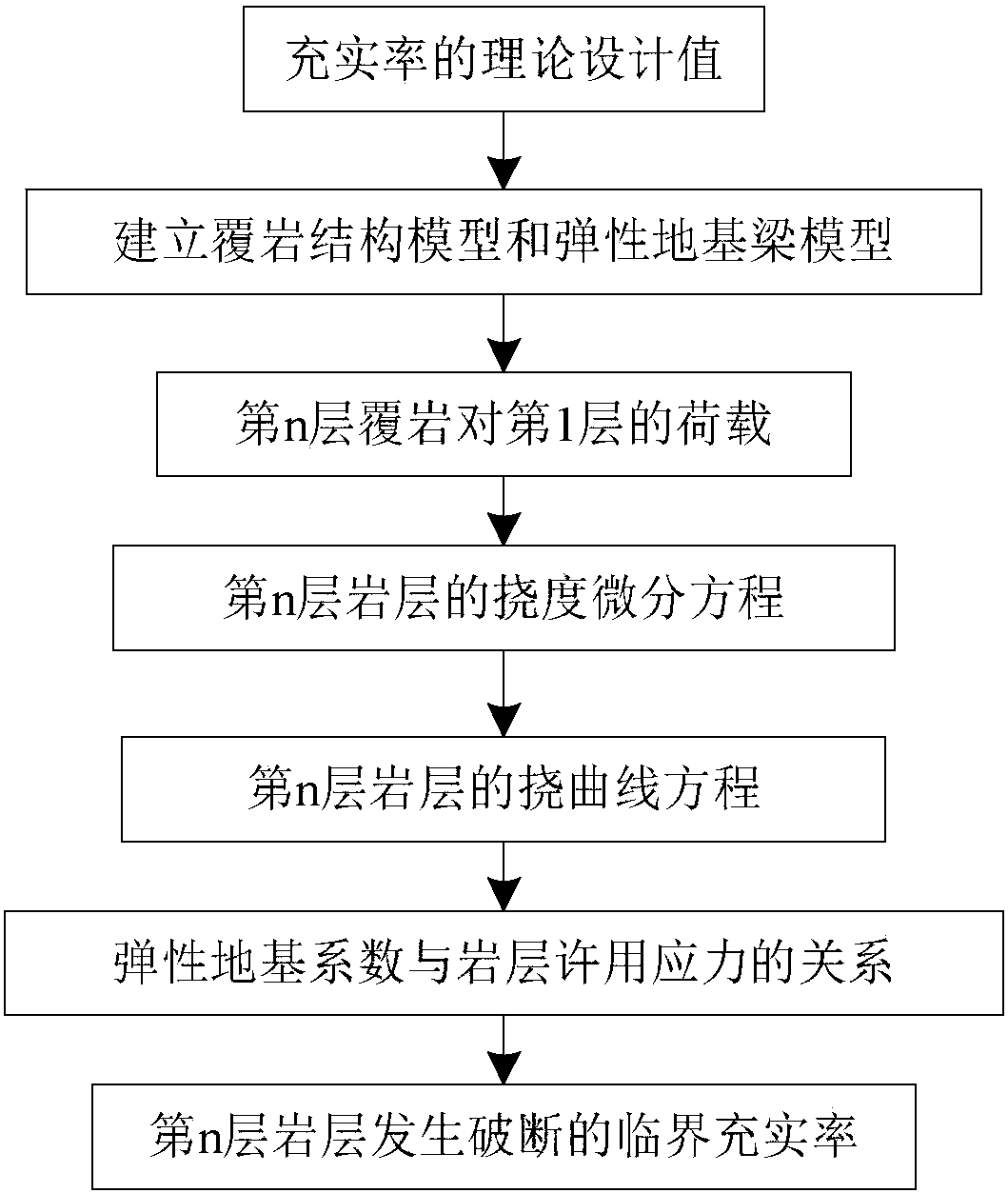

Filling mining critical-fullness-rate design method

A design method and filling rate technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as filling cost and equipment investment increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and specific embodiment the technical solution of the present invention is described in further detail:

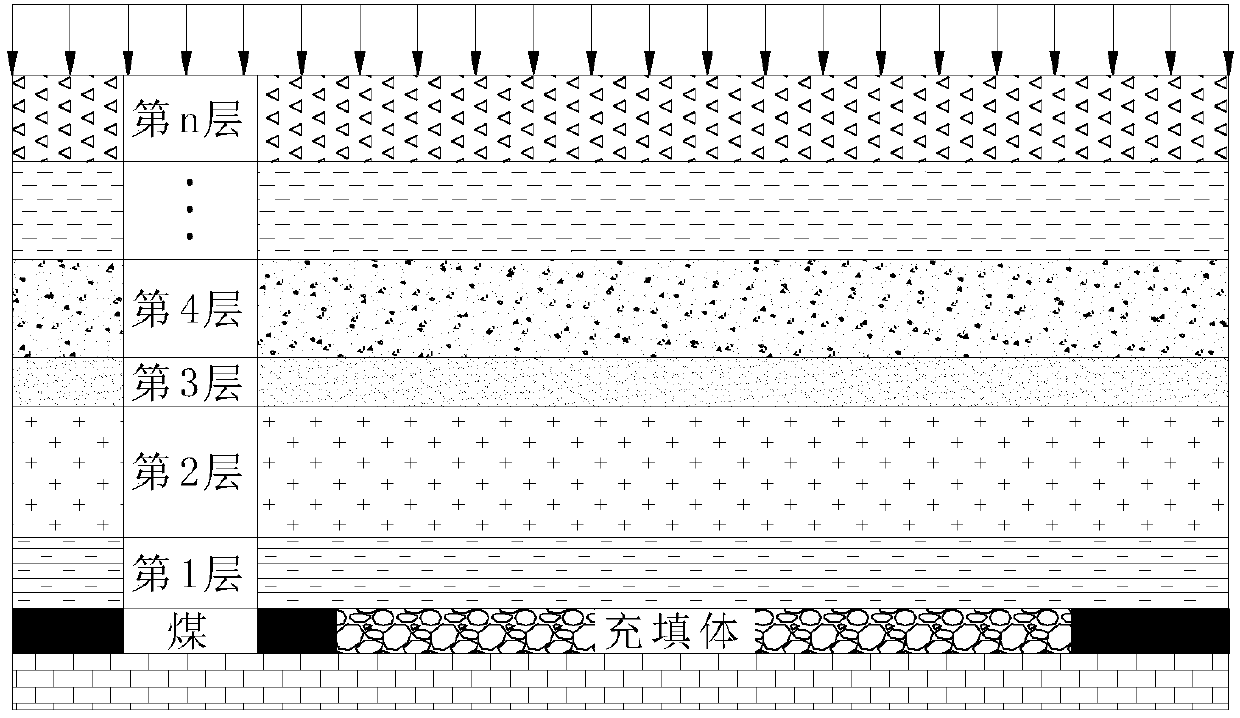

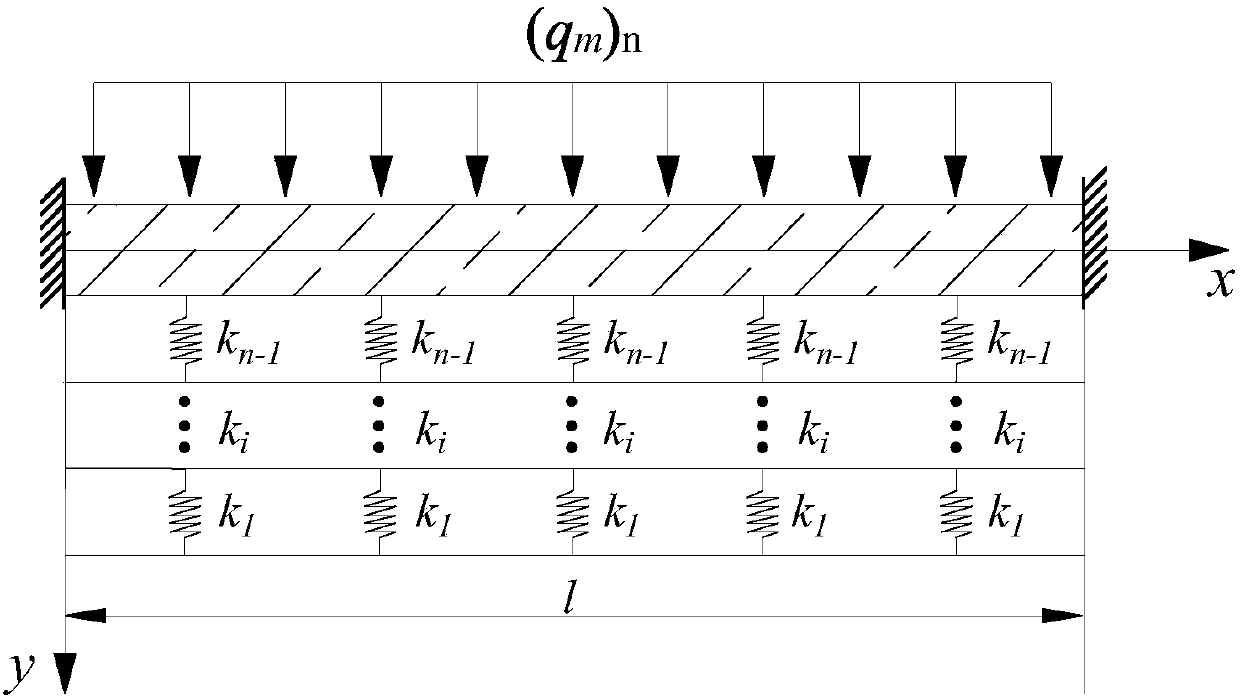

[0043] Since the filling body has different densities during compaction, different densities determine different elastic foundation coefficients (usually non-linear), which manifest as different anti-deformation capabilities under the action of the overlying strata, resulting in direct The movement degree of the overlying strata at different layers such as the top, basic top, and the key layer of the structure are respectively controlled at different stages with obvious characteristic differences. Defined as the critical filling rate. The obvious differences in motion state characteristics specifically include the failure of key structural layers, only bending subsidence of structural key layers, only bending subsidence of the basic roof, and only bending subsidence of the direct roof. It provides a reference for the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com