Voice diaphragm assembly processing method, voice diaphragm assembly and micro-loudspeaker

A processing method and sound film technology, applied in the direction of loudspeakers, sensors, electrical components, etc., can solve problems such as voice coil and sound film falling off, product failure, and reduced service life, so as to achieve uniform distribution and tight combination of sound film Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A processing method for a sound film component.

[0046] The sound membrane assembly includes a sound membrane and a voice coil 9 configured on the sound membrane, and the processing method includes:

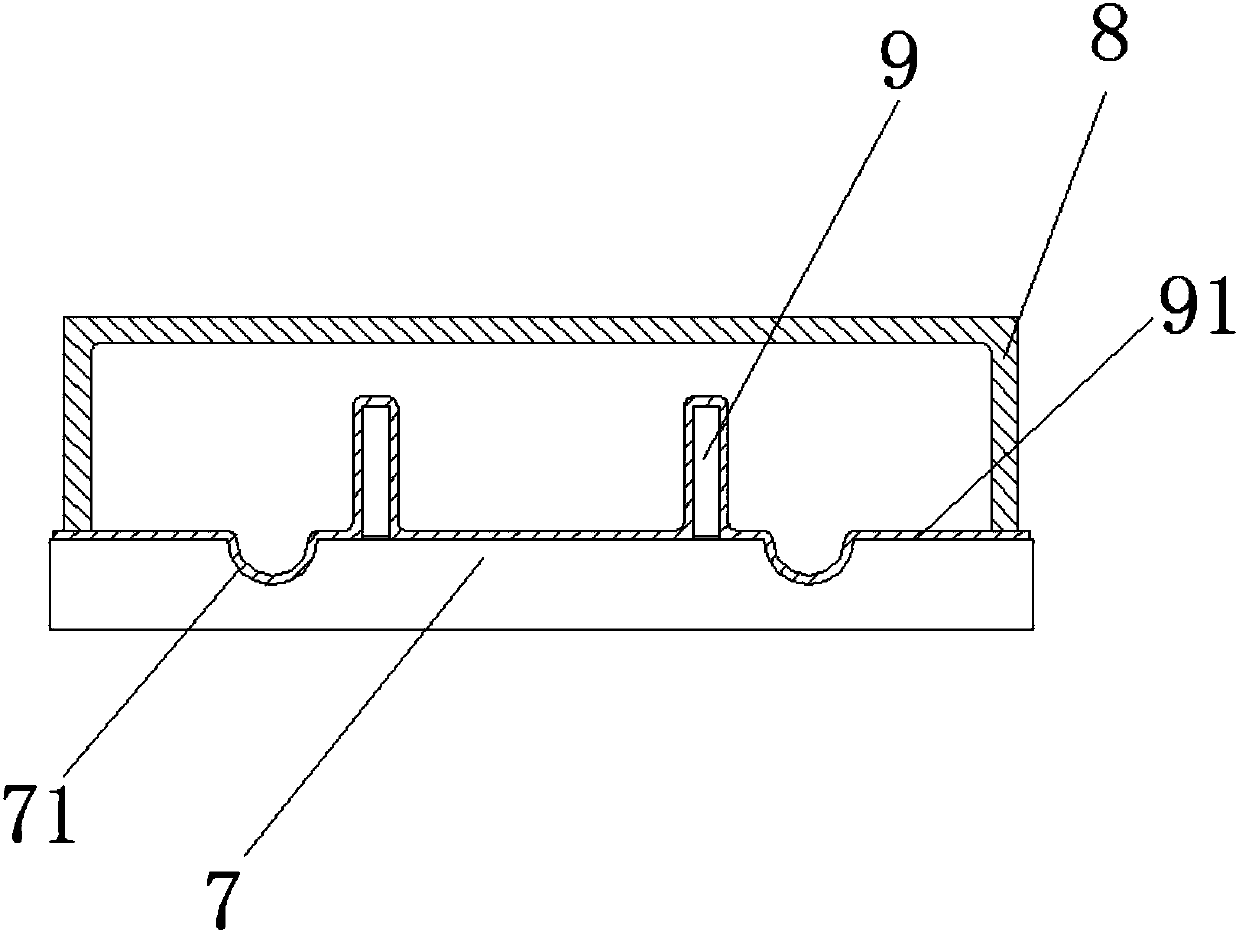

[0047] S1: Preheat the heat conduction mold to 80 degrees Celsius, and then arrange the voice coil 9 on the heat conduction mold to keep it fixed.

[0048]Among them, the preferred range of the preheating temperature of the heat conduction mold is 65 to 85 degrees Celsius, to avoid excessive heating temperature, the voice coil 9 is suddenly exposed to too high temperature and cause cracking, the preheating temperature is too low, increase the travel time, and additionally increase Time costs. In this embodiment, the preheating temperature is selected to be 80 degrees centigrade, which is moderate, and workers will not burn their hands because the temperature is too high in the next process, which is not conducive to the continuous work of workers.

[0049] S2: placing t...

Embodiment 2

[0072] The implementation principle and the technical effect of the device provided in Embodiment 2 of the present invention are the same as those of the sound membrane assembly produced by the method in Embodiment 1.

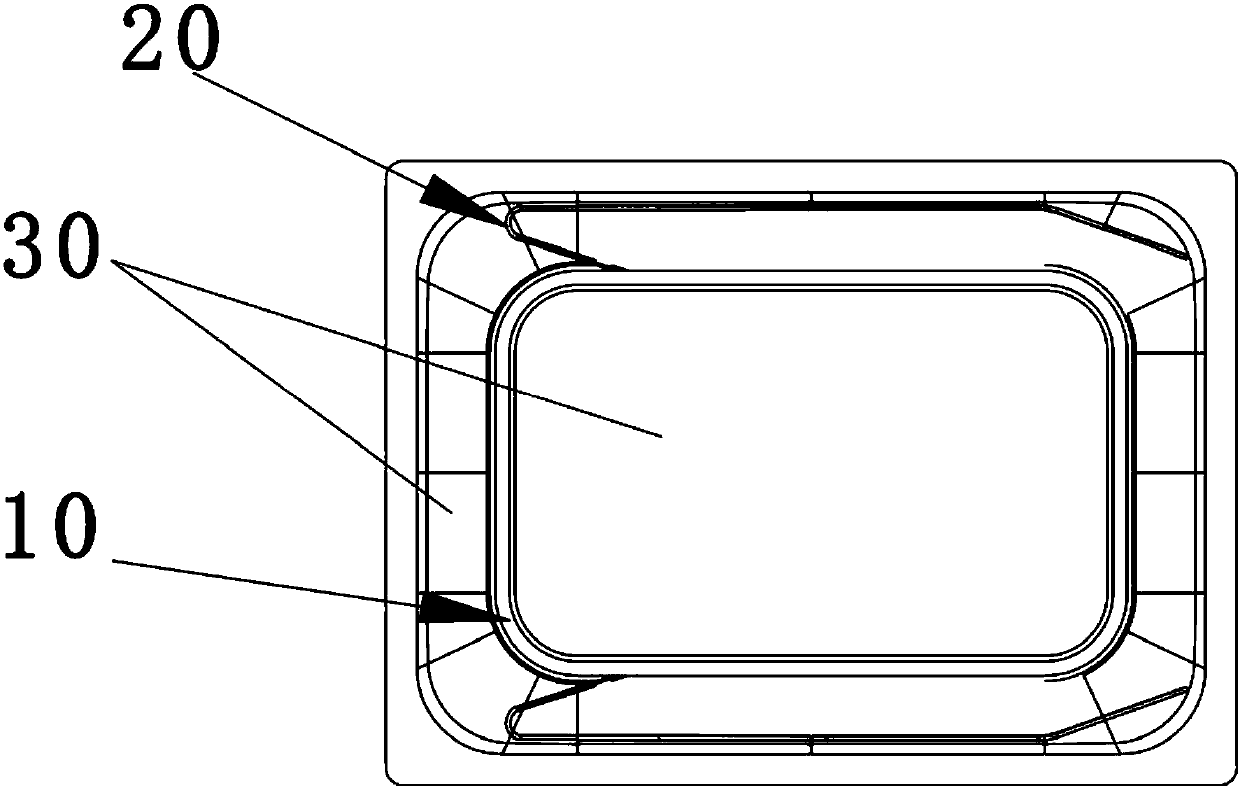

[0073] A sound membrane assembly includes a voice coil and a sound membrane 30 , the voice coil includes a coil 10 and a lead wire 20 , and the lead wire 20 is connected to the coil 10 .

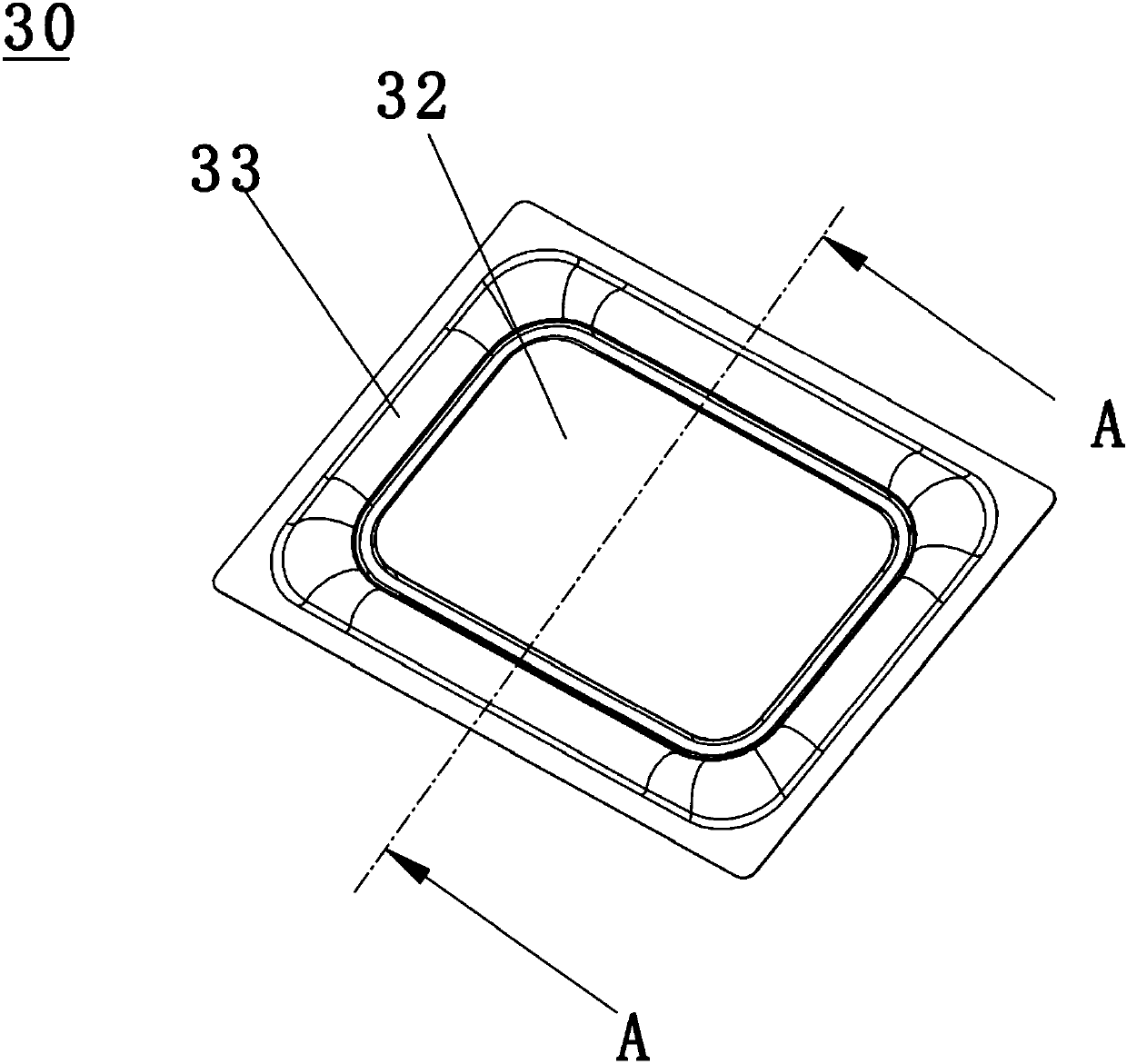

[0074] The sound membrane 30 includes an annular groove portion 31, a central portion 32 and a ring portion 33; The joint with the ring portion 33 is formed by being recessed downwards.

[0075] The coil 10 is embedded in the groove of the annular groove portion 31 and connected with the annular groove portion 31 by thermoplastic.

[0076] In the acoustic membrane 30 of the present invention, the annular groove portion 31 is formed by downwardly recessing the junction of the central portion 32 and the ring portion 33 . The coil 10 is embedded in the groove of the annular gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com