An all-round three-dimensional fracturing method for vertical wells in ultra-low permeability reservoirs

An omnidirectional, volumetric fracturing technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problem of large horizontal principal stress difference, high fracturing cost, and difficulty in forming three-dimensional network fractures, etc. problems, to achieve the effect of increasing the drainage area and avoiding drilling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

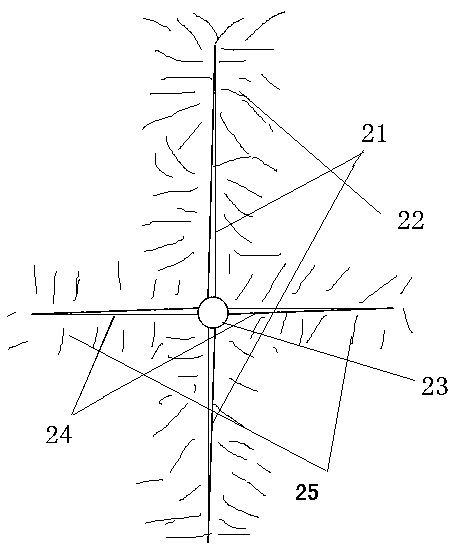

[0038] Example 1. An all-round three-dimensional fracturing method for vertical wells in ultra-low permeability reservoirs, comprising the following steps: figure 1 As shown, the first volume fracturing is carried out in the wellbore 23 of the vertical well of the target reservoir to form the main fractures 21 and the secondary network fractures 22 extending along the direction of the maximum principal stress, and temporarily plug the main fractures 21; The second volume fracturing was performed on the wellbore. Since the maximum principal stress field in a certain range around the wellbore turned nearly 90 degrees after the first volume fracturing, a fracture that is roughly perpendicular to the main fracture 21 can be constructed through the second volume fracturing. The intersecting secondary major cracks 24 form a network of cracks 25 around them. The network fractures 22 and 25 are not formed at the same time, the secondary network fractures 22 and the network fractures ...

Embodiment 2

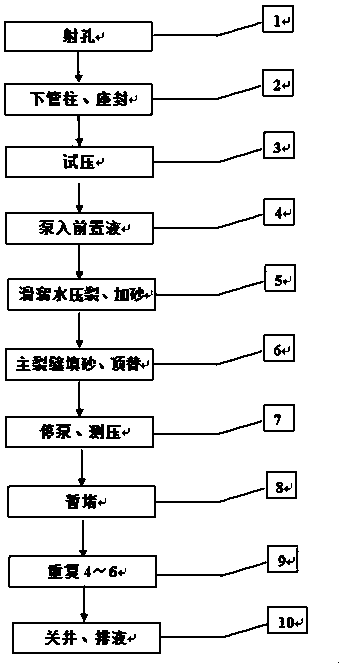

[0039] Example 2. An all-round three-dimensional fracturing method for vertical wells in ultra-low permeability reservoirs, comprising the following steps:

[0040] Step 1: Perforating the target reservoir; the azimuth of the perforation operation is 90 degrees, the hole layout is spiral, and the hole density is 13 holes / m.

[0041] Step 2: Lower the fracturing string and set the packer;

[0042] Step three: pressure test;

[0043] Step 4: Pump in the front hydraulic pressure to open the formation and create main fractures; the front fluid is glue, the viscosity of the glue is greater than 300mpa.s, and it is 170s at the reservoir temperature -1 The viscosity is greater than 50mpa.s under the shear rate for 2 hours.

[0044] Step 5: Pump in slick water for volume fracturing and add sand; the viscosity of slick water is 7mpa.s and the displacement is 6m 3 / min, the proppant particle size is 40 / 70 mesh, and the sand ratio is 3%-5%. The sand ratio changes during the fracturi...

Embodiment 3

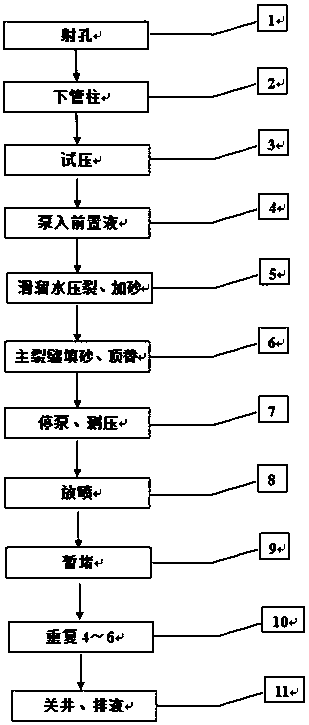

[0051] Example 3. A method for all-round three-dimensional fracturing of a vertical well in an ultra-low permeability reservoir includes the following steps: step 1: perforating the target reservoir; step 2: lowering the fracturing string and setting the packer; step 3: testing the pressure ;Step 4: Pump in glue to pre-hydraulicize the formation and create main fractures; Step 5: Pump in slick water for volume fracturing and add sand; Step 6: Pump in glue to add sand to main fractures; Step 7: Stop Pump pressure measurement and drain; Step 8: Pump in glue, add soluble temporary plugging agent to seal the fracture; Step 9: Repeat Step 4 to Step 6; Step 10: Shut in the well and drain. Through this method, two vertically intersecting main fractures can be formed around the wellbore, and on this basis, a fracture network with the main fractures as the main line can be formed, which greatly improves the degree of stimulation and realizes the economical production increase of oil we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com